![]()

Bonneville SpeedWeek 2016/World of Speed...Cosworth Electronics Testing

Mike and the

Bullett

2016 and the Bullett heads for SpeedWeek: Mike Geokan and his creation 24 years after conception. Now it's 2016 and, one day after a serious operation, 100 pain pills in the trash, Mike's checking the Bullett, which is headed for Bonneville to test the revamped engine with new Cosworth Electronics, fly-by-wire throttle, 8800 parameters, and electronic phase anti-phase boost control...Headed for the real Dyno, the Great White Dyno, for testing. Mike stays home to spit nails at the wall.

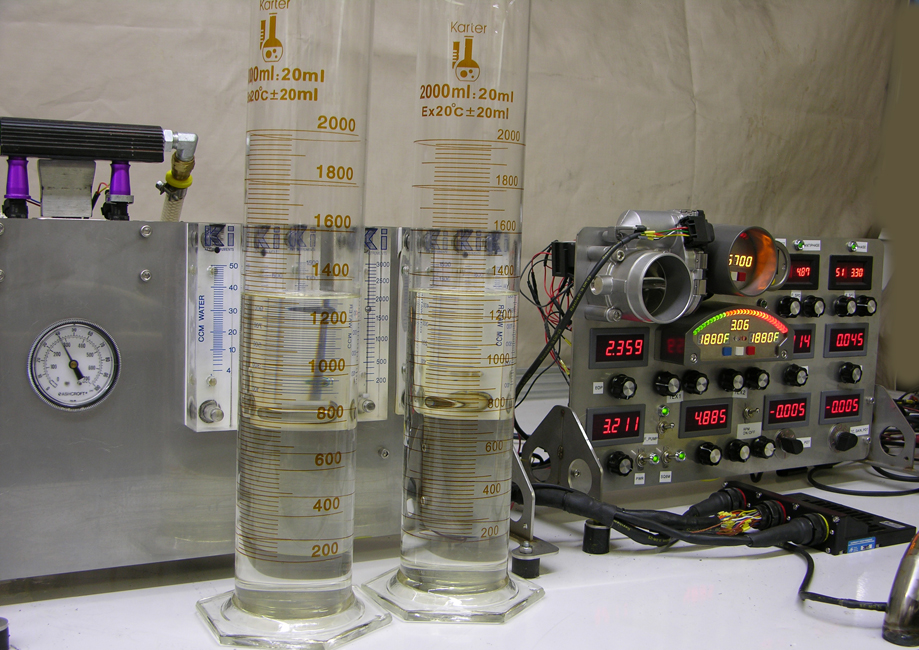

Cosworth Pectel SQ6M Injector Flow Calibration

Here we do an actual flow test of the Injector Dynamics ID2000 fuel injectors on the Cosworth Pectel SQ6M Simulator at 3 Bar and 6700 RPM to verify we have exactly 500HP worth of fuel. We do. We have no intention of melting the motor down. The ID2000's are perfectly matched. We'll dial in a rich fuel curve to start with, then lean it back after our first run. The loads at Bonneville are motor killers.

Why Complexity?

Cosworth Pectel SQ6M Engine Management Controller. Cosworth engineers were probably thinking of quad-cam V12's with 48 valves and dual Fly-By-Wire throttles when they designed this puppy, and not a pushrod V-Twin with two valve cylinder heads. It's perfectly at home however, and can control anything, including wheelies...Not that we are doing wheelies with the Bullett on the Bonneville Salt Flats.

Why? It's just the way

things go these days at Bonneville. If you do not have traction control

on the thin salt that is maybe 1/2" thick and is loose, wet,

bumpy etc. you are asking for disaster.

Many of the high horsepower motorcycles have crashed when the have overspun the rear wheel. If you don't like the thought of getting tangled up flipping down the salt with a 1000 lb object then traction control...the same control strategy as the Speed Demon and Ralph Hudson and others use, then traction control is a mandatory.

The other issue is electronic closed loop boost control by gear, by rpm, and speed so you can maintain control during the, what is essentially a drag race, trip down the salt. No more twisting a dial a boost pneumatic controller.

Between the wiring, the electronics, the sensors, the programmng and calibration figure on $20,000.00. For the Motec crowd hire experts like Shane Tecklenburg at $1,200.00 per days plus software calibration packages and all the hardware.

We just do it ourselves. The days of Rajay turbos and draw through carburetion are long long gone.

Two Bills

Last second change of plans. Brother Speed's "Two Bills" Bill volunteers to tow the Bullett Race Trailer with his Ford Diesel and head to most harsh, hot, eye-fying environment...the blindingly bright Bonneville Salt Flats, in spite of a serious eye infection in both eyes. Eyes swollen and beet red. Hey, whatever it takes. Ex Hard Hat Navy diver and a life of working in extreme environments...no big deal.

"Two Bills" Bill right. Mike Geokan center in his usual cheerful manner. Halt Hennig left. Walt hauls the Rhino on the tilting trailer we use to retrieve the Bullett after each run at the Salt Flats.

Ride to the Salt

Bryan and Nick Stock ride their chopped Dressers from Boise to Wendover with stops at Wendell, Jackpot, and Wells before the final push to Wendover and the Bonneville Salt Falts. Was it hot? Well, not in the air conditioned trucks, but on the Harleys it was searingly hot. Who rides out to race a bike at Bonneville . No one except Bryan, Nick, Mark and Brother Speed. Rolling Thunder.

Pits Bonneville Salt Flats

Before you can move in and set up your pit you have to go though the complete registration process with the SCTA-BNI which includes a vehicle technical inspection i.e. if you aren't legal then you don't set up a pit. Bring all sorts of money and medical forms. Actually it's the cheapest motorsport on a fee basis you will ever find.

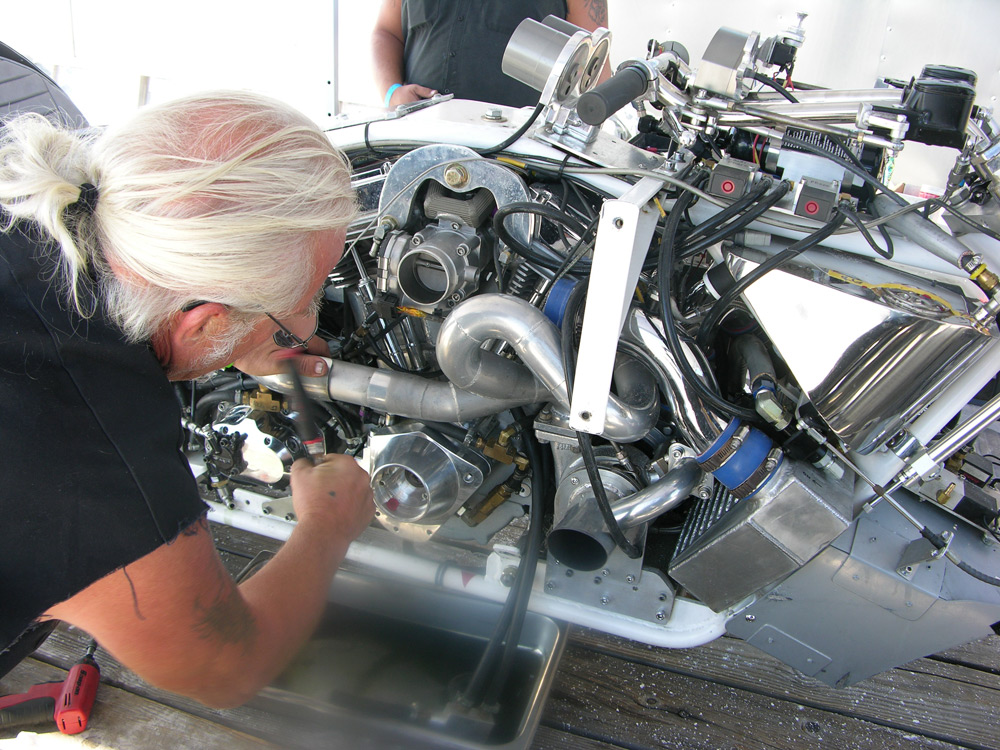

Maintenance after testing...new spark plugs, battery charging, cleaning salt off the intercooler, reprogramming the Pectel SQ6M engine controller and making safety checks before you put the bike back in the line.

The salt and track conditions were really bad with ruts in the soft salt...akin to high speed slaloming on snow with the occasional rut that took Bryan on an unplanned journey from the right side of the track to the left side of the track at 190 MPH. Hey, we came here to test the systems and the track wasn't going to be a 250 mph hard surface with good traction. The car guys came up and said you must have to have the biggest balls on the planet to go 190 to 200 MPH on two wheels on this track given the conditions. Many car guys went home after one run. Even the offical that dragged the track damaged his car on the rough course.

Brother Speed's Mark and Shane button up the Bullett for another run. The canopy must be removed for spark plug access. Bryan can sit in the air conditioned cab of Walt Hennig's diesel truck to avoid roasting in his leathers.

Mark secures the

"Alligator" pad that Bryan rests on at speed. Beneath it are 3/8" thick

aluminum plates. The whole Bullett weighs 1000 lbs.

Details

Casey cleans Bryan's face shield. Better in the pits than on the start line.

Red Bull at Bonneville

Way more than 30 years ago

we used to say when racing... "The only women you are going to see will

be tacked to the wall with the staples removed"...Bonneville is the new

exception to this rule.

Tailgate

Party...hold the Salt.

Crew food while we are waiting in the line.You wait a long time at the beginning of SpeedWeek and, as the days go by, and people leave or blow up, the lines get shorter. This day it was a long wait.

Mark and Walt...Sometimes

there is a spin on the course, a blown motor and debris on the track,

or even the wind comes up too strong and everything is put on hold.

Time to look at interesting iron.

When you get six to eight vehicles from running, we unload the bike and keep advancing it in the line. If you aren't ready when you are supposed to be it's back to the end of the line. Notice the exhaust burn on the fairing.

Showtime

You are the show at this point. The whole Bonneville world stops for you to do your thing...Isn't that a bit strange in todays world?..i.e. People politely waiting for you to have your moment without intruding.

George: Lawyer..Vintage Bike Club President, Racer, Bullett Starter

George, in the white uniform, absolutely loved the Bullet and we asked if he would like to be our engine starter. That involved actuating the solenoid when all electrical systems were armed and it was time to race. Bryan would give the nod and George would start the Bullet. Like all racers he did his job perfectly. Try that at Indianapolis or F1. Class act.

I was going 190 MPH

and the bike went sideways!

Course on hold and Bryan discussing Bonneville adventures with a Red Hat 200 MPH Club Member.

Off the Salt

Adjustments

We took the Bullett back to

our $3,500.00 worth of motel rooms in Wendover to get beer and make

adjustments to

the Cosworth Pectel SQ6M Fly-By-Wire system after our second run,

during which the throttle went into failure mode which was programmed

for a 14 degree fixed opening, a fast idle.

If you make assumptions you may turn out to be on the ass end of things. We assumed two Bosch 60mm FBW Throttle bodies would be the same. They weren't. In that the Pectel SQ6M FBW system has 167 programmable functions there are all sorts of safeguards built in. Small variances in the dual potentiometers caused the throttle to close.

Simple fix if you know how.

For Tomorrow We Die

Eat Drink and be merry

for.....Party Time. Ask the crew if they donate money each month to

Hillary Clinton's campaign...massive hissing...Fools. Politics and

racing are different. FOX News and Russian social media trolls take

their toll on this country.

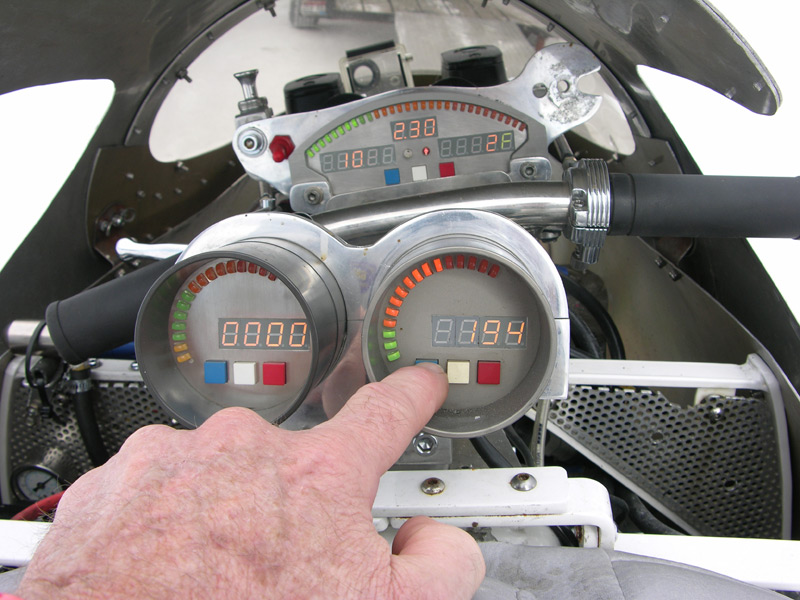

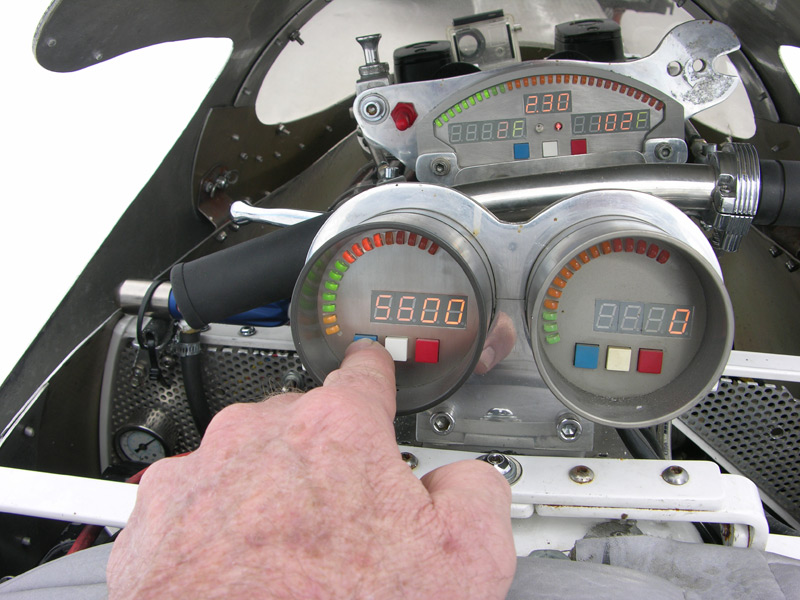

Back on the track...Fly-By-Wire reprogrammed..194 MPH

At 5600 RPM the rear wheel

was going 260 MPH and the bike was 194MPH on the GPS Speedometer. Bryan

was all over the track in and out of the throttle, throwing

roostertails

of salt. We were running the Pectel SQ6M programmed boost control which

targets

specific boost values by speed, gear, and throttle opening. Here the bike hit

or programmed 2.3 Bar or about 19 PSI of boost.

We made two runs where Bryan hit over

190 MPH but the course was rutted and there wasn't much in the way of

traction with Bryan plowing through soft salt and bouncing through the

ruts at these high

speeds. The ruts would take him all over the track. We learned a lot

and have ample power, in this case, about 380 HP @19 psi and 5600 RPM.

Nothing was hurt and we wait to see if the next events will offer a better track.

Back in Boise...Clean Up

Back In Boise at the Brother Speed clubhouse. Hoses and pressure washers with various openings like the turbo masked off. Shane and Bryan washing the Bullett.

Shane...working his ass off

at Bonneville and also back at the Brother Speed clubhouse. The Salt

eats everything. It's slowly been eating the trailer but we're still

good to go.

Bryan blow drying the Bullett with it resting on the Mike Geokan designed winches that elevate the bike and keep the tires off the ground.

Ready to roll at the next event with the Pectel SQ6M Seven Position Traction Control fully implemented.

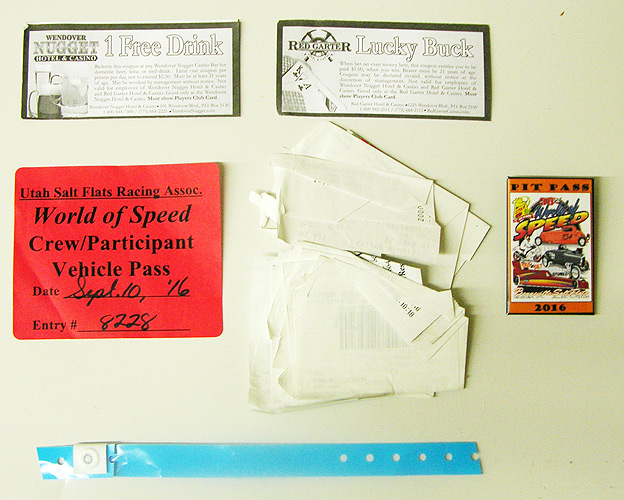

Memories

Red Vehicle Pass for Pits. Red Arm Band for Crew. Only one yellow arm band. Button for Crew. And a stack of credit card receipts.

Poster Seen at Wendover Post Office

Nick Arias III (Arias

Pistons) was an official on the starting line. He said we seemed to be

having a lot of fun even getting ready to run. We did. Brian has the

yellow arm band and that got him the best seat in the house at 194 MPH.

It's all Rock N Roll.

Big Dogs, Factory Dogs...Big Money Nonetheless

Tiny 3 cylinder motor. Honda Factory effort. The rising sun near where the Enola Gay trained. Time Time Time...Honda is a racing company.

2016 USFRA World of Speed 10-13 September

Headed for USFRA tech inspection.

USFRA Photographer stopped

by while were waiting in line to tell us how much he loved the Bullett.

Hand made craftmanship in the Bonneville tradition of Sir Malcolm

Campbell and others. We also had a couple from Geneva Switzerland stop

by...Heard the wife speaking French so we asked in French if they were

French..."Non, nous sommes Suisse....de Geneve"...Heuresement nous

parlons Francais. Small world. Genevois a Bonneville.

As you near the start..Here we are about 8 vehicles from our turn..We unload the Bullett. The trailer tilts and Nick Stock sits on the Bullett while Matt Torres guides him down the bike ramp.

Sunglasses

and sun block. Bullett headed for the Long Course which is timed

between the 4 and 4 1/4 mile. By the 5 mile marker you were supposed to

be shutting down and there was only a drag as far as the 6 mile. The

salt was thin, but hard, and there were some muddy spots where the salt

had broken through. Bryan and Nick Stock drove down the course to take

a look at it.

Monte, the USFRA starter, asked all competitors to drive

their passenger vehicles and trucks down the course before the actual

meet started. The idea was to let people decide if they were going to

run at all and, most likely, what plan of attack they would have on the

course.

Nearing showtime. Umbrella to keep the sun off the Bullett's seat.

Time to roll. Nick Stock

sinches up the D-rings on his dad's helmet. Blue arm bands are for crew

members. Shane and Matt keep Bryan and the Bullett in the shade, and

Mark secures Bryan's leathers. Mark starts the bike when were are given

the go.

On hold at the start as the three mile timing light malfunctions. There was a long wait in the hot sun in black leathers and a helmet. Way, way, long.

Crew members like Mark,

Shane, Bill, Matt, Wino, Casey, Nick, Diana and of course Bryan, the

Bullett's driver...all leave things on the plate to go to

Bonneville...bills, obligations, relationships, shutting down

businesses, skipping medical appointments and so on. Alternate reality

in a strange land. Brother Speed.

Bryan was about medium rare in the long wait, so we had him remove his helmet, and a cold towel to his neck to cool him down.

161 MPH, Third Gear, Salt Good, Watching the GPS and Tach, accelerating..Then

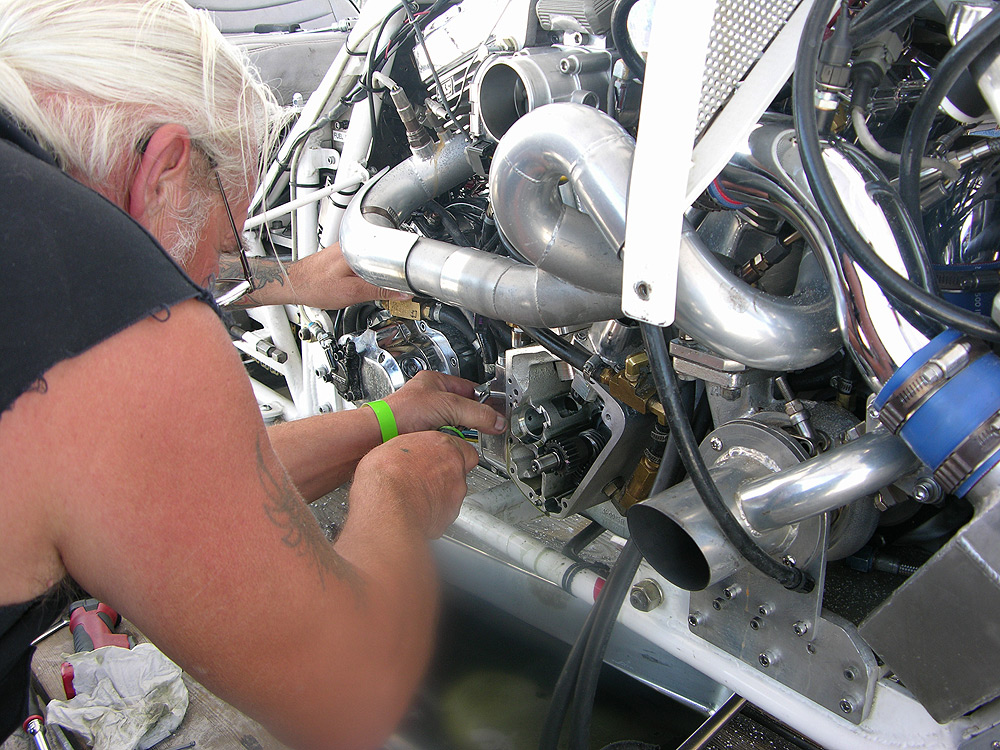

Bryan was accelerating in third gear at 161 mph, settling in to attack the 4 to the 4 1/4 timing lights, and he heard a loud noise and felt a loss of power so he vectored off the course slowing to 80 mph with the engine still running. He stopped and the engine was idling at our programmed 1300 rpm and a USFRA Course Official pulled up and saw oil coming out of our rear breather vent and told Bryan to cut the motor.

Back in the pits Bryan started to pull things apart to see what was what. We pulled the spark plugs and they were OK. We

then checked compression in front and rear cylinders and it was 175 psi

in both. Next we checked our four top end breather lines and they

were

dry. We then checked the dry sump oil bag and it was nearly empty.

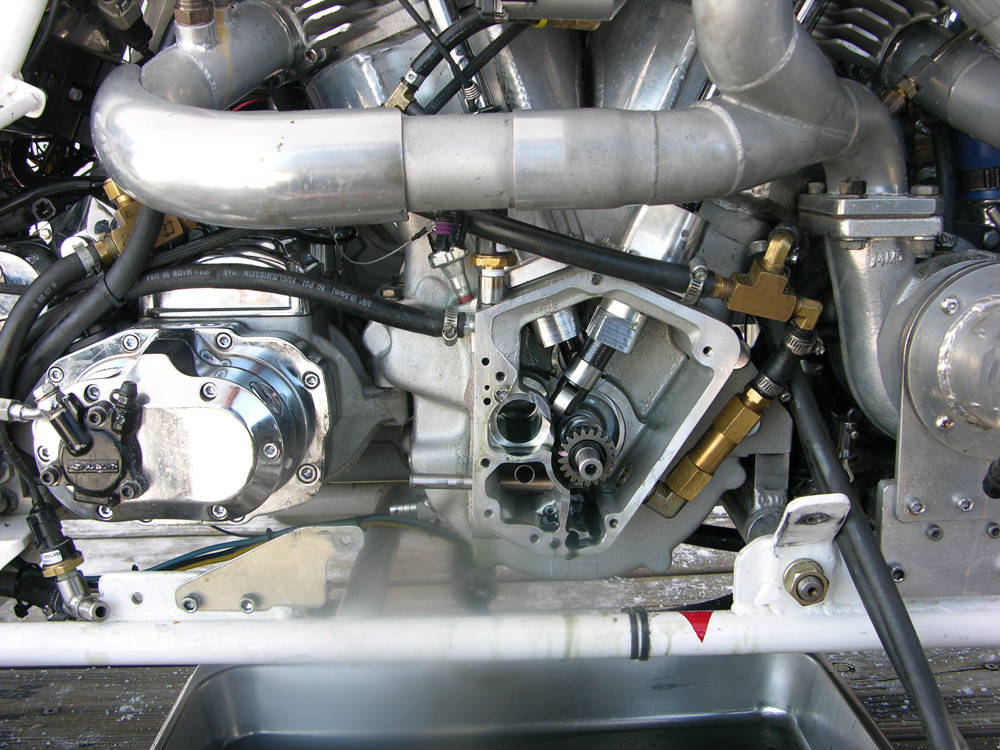

Bryan started dissecting the oil pump as there was no scavenging and

our jackshaft driven vacuum pump pumped the oil out of the lower end.

Oil pump removed with damage to the gears and shaft. One scavenge gear cracked when it injested something. Brass valves and fittings are part of the jackshaft vacuum pump setup. Visible are the watercooled cylinders. Stainless steel merge collector to the turbo with ceramic coating. Jim's Fat5 transmission.

Guilty Party

This circlip on a seal from the second bearing on the Pinion Shaft facing the cam case came off and took out the oil pump, shearing the key in the drive gears. The lower end filled with oil and slowed the motor and our vacuum pump, driven by the jackshaft, pumped the lower end out the back. Stupid fkking bearing that was put in won't be going back in. No way to fix this. Motor has to come apart and a more logical bearing be installed. Shame because we had a workable race surface due to all the work by Monty and the volunteers of the USFRA.

This is the Bullett's jackshaft-driven vacuum pump

which is connected to the upper and lower ends of the 139" motor. It kept

pumping when the the S&S Oil Pump drive keyway was sheared. Hard

anodized to keep the salt from eating it. No debris got to it.

Nothing to fix so we headed for the Hotel rooms

for beer, Vodka shots, controlled substances, and a Buffet Dinner.

Planning for 2017 begins. It was a good time nonetheless. Great people

and friendship. Another adventure and no one went to jail in Elko this time.

Bryan came home safe which is the most important thing of all. People have

died there recently.

Errata...147mph bicycle

Errata...Old School

![]()

Artifacts Circa 2016

Lucky Buck, 1 Free Drink,

Vehicle pit pass, personal pit badge, crew wristband, pile of credit

card receipts....stuff for the archaeologists to figure out the

religious or ritual significance of in the future. What motivated these

people to travel to this desolate location and give offerings to some

strange deity? What secret rituals did they perform and where did they

come from to begin with? No bones were uncovered. Where were their dead

buried?...All questions which are unanswered. They seem to have come

from many directions. How did they communicate to arrive at the same

time each year? Were sacrifices performed ?....They left straight blue

lines leading to a floating mountain.

Post 2016 Bonneville: Time for New Tires

One

set of these Goodyear LSR 300 MPH tires was used for the construction

of the Bullett. They became weathered during the long build process and

were cut in half for close inspection of the thickess of the rubber at

the request of Nate Jones Cowboy Tire. Shaving excess rubber was done by Nate

Jones to balance and prep the new tires and to round the front tire for

better handling. This second set was used for the initial running,

gaining licenses for the Long Course, and setting a 200 MPH Record that

stood for 5 years. After spinning the rear tire at over 260 MPH,

bouncing through some deep ruts at 194 MPH, and plus the effects of

weathering, we decided to put on new rubber for safety reasons. You are

looking at $1650.00 worth of new rubber. Our third set. Does get

expensive.

The

Bullett is about the only long course (>175 MPH) motorcycle that

actually has legal tires in the eyes if the SCTA-BNI Bonneville

Inspectors. There have been crashes at Bonneville due to tire failures,

and numerous instances of tires chunking with Z-Rated tires running

well over 200 MPH. Motorcycles have crashed and people have died in

other Speed Events...Perhaps with tire failure as one of the factors.

Mike Geokan, some 24 years ago, made the decision to design his Bullett around tires that would be safe. He had no guidance and he was on his own. He was proved to be correct. 45 degrees of rake, a stiff chassis, a long wheelbase, and safe tires to bring the rider home alive.

Bullett Pistons

When you stick a 560 Hp turbo on the 139 CID Bullett Orca Motor the pistons, piston pins, and rings get subjected to a lot of heat and pressure. A lot of people ask what we run and here are the specifications: CP Pistons 4.367" for a 4.375" Bore; Top Groove 0.064"; 2nd Groove 0.064"; Third Groove 0.149". Flat Top with relief for the 2.200" Inlets and 1.800" exhaust valves; 0.927" heavy wall pins with 0.073" wire locks.

We

cut the skirts for clearance and ceramic coat the piston tops and

graphite coat the skirts. Ring gaps are 0.026" for the Top Ring and

0.028" for the Second Ring; Std 3 piece oil ring. No cylinder head

gaskets or base gaskets with Silver-plated Inconel 600 psi Nitrogen

seal rings on the cylinder heads. We have even run PEEK Buttons on the

skirts. Drop $2,500.00 on the pistons...and more on the machining and

coating. We have had zero issues running high zinc content Brad-Penn

Oil.

The

139" Orca motor has been used as a test bed to experiment with new

technologies...electronics, closed loop boost control, traction

control, bearing designs, piston sealing, vacuum pumps, ceramic

coatings, high temperature valves, cylinder head porting, camshaft

design and more.. Somethings have worked and somethings have failed. It

is definitely not short on power as Bryan Stock can attest...His first

words after a 214 mph run...."I want one of those in my Dresser!".