![]()

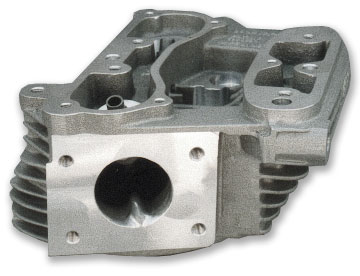

![]()

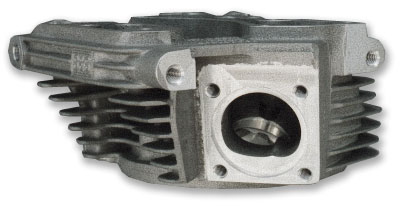

Big valves, raised inlet and exhaust ports, the latest small volume chamber design, long-life iron guides, triple valve springs, .600+"lift cams, automatic compression releases, flow bench optimized ports. These SA and B2 heads are serious parts meant for the race track where airflow equals horsepower. The inlet and exhaust ports require work to reach their full potential. Even without additional flowbench work they kick ass over any reworked stock Harley castings or billet pieces of crap that are at best poor copies of stock parts. Dedicated full race castings are the ticket to making power. Don't forget we are dealing with an air pump and all the power resides in that area defined by the piston crown, combustion chamber and port dimensions. If the design is essentially a copy of the oem Harley part you are already limited. Unless you straighten out and raise the ports and use advanced techniques like d-shaped exhaust ports and trench cut inlet valves, you will never reach the potential of your set-in-stone bore / stroke combination. Don't let the billet bandits suck you in with sweet talk and shiny baubles. S&S Cycle SA heads race, billet parts talk. Check out our RSR Inlet Valve Mach Index Calculator to understand how SA cylinder heads are so efficient.

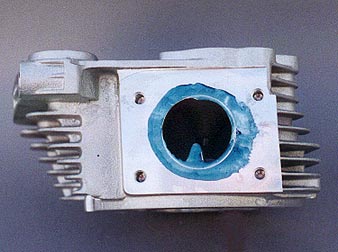

Both inlet and exhaust ports must be massaged to mate with the RSR Fuel Injection manifold as well as the special SA Turbo Venturis on the LSR exhaust systems. "Dykemed" and ready to be port-matched. The inlet ports are scribed to match the Special Application RSR Fuel Injection Inlet Manifold and the S&S directional vane is "knife-edged" and ported to direct the inlet flow past the inlet valve boss. If you remove this vane the cross-sectional area of the port increases and your flow numbers go up but velocity drops and in the real world power falls off where you need it...so we keep it, and shape it for your benefit. See the results in the pictures below.

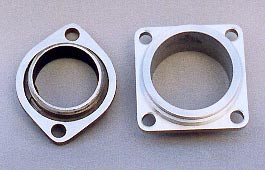

Compare the SA exhaust flange in the center right to the oem style flange used on factory Harley Davidson and inferior "billet" heads on the center left. These are serious pieces of work. No gaskets are used on our Special Application "SA" LSR Exhaust Systems...just a light coat of high temperature non-hardening black silicone that is O-Sensor compatible.

Orca "Active" Inlet Port

We call this ORCA inlet an "Active Port" because vanes on both the roof and floor of the port straighten the inlet flow around the valve guide boss and also because we leave a rough texture to prevent the wet flow from "sticking" to the walls of the port. Shiny, highly-polished, inlet ports are death on horsepower. The diameter of the SA inlet opening is 1.877" to exactly match the inlet casting with no steps or bumps.

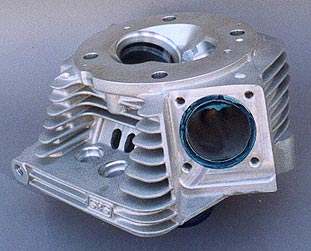

ORCA "Active" Exhaust Port

You can see the pronounced "D-Shape" of the SA exhaust port. Remember that we have a 1.800" exhaust valve that has almost a staight shot out of this raised port...but the vertical height of the port is only 1.675". The "D-Shape" flattens out the inside radius to increase flow on the exhaust cycle and provides a shelf to prevent reversion on the overlap phase of the camshaft timing. The RB Racing LSR Exhaust System's Turbo venturis also are machined to leave a small lip 360 degrees around the port as an anti-reversion measure. The exhaust port is lightly smoothed but is not enlarged, as velocity is what we are after. Highly efficient exhaust ports are well below the "accepted figure" of 80% of the inlet port flow.

SA/B2 heads

SA/B2 heads are standard on ORCAs. B2 heads feature larger inlet and exhaust valves: 2.220" Intake; 1.800" Exhaust.

Flow Data

If you want some figures that are essentially meaningless, but nonetheless suitable for dartboards....at 10" H20 these SA ports will flow 195 cfm with a light clean up. This does not reflect the dynamic situation with the inlet system and exhaust in place however.

Flow benches are interesting especially when they're pulling 65" H2O...with all components in place! Stay tuned.