![]()

Bullett Preparation 2010

Cleared for Bonneville Long Course and 200 mph in 2010

Bryan Stock got all three licenses i.e 150/175/200 with passes at 145, 163 and 191 mph at the 2009 Bonneville World Finals. Mike Geokan had to sit out 2009 due to medical issues but will be with the bike in 2010 to support Bryan. Next stop is Speed Week in 2010. The Bullett has it's transmission torn down for a new replacement mainshaft and thorough inspection. The 139" Orca engine ran fine all through 2008/2009 and did not have a drop of blow-by. The engine has been completely torn down by Carl Pelletier to inspect all bearings, rods, bores and pistons as well as the cylinder heads. Power at this point is not the issue and the Bullett would spin the tire at will. She's just cruising at less than 10 lbs of boost. She has never been in 5th gear yet.

Every component front to rear is being inspected. In August 2010 we'll lean on her and find out what she'll do.

Teardown...Post World Finals

139" ORCA: Nine trips down the course in 2008/2009 to get bike sorted out and qualified for long course, then it was time to tear the engine and transmission down to ground zero in preparation for 2010. You don't let it stay buttoned up until next August/September/October. The engine was in fine shape we only had to check and refresh things. The Xtreme Performance ceramic coated piston tops showed we had no detonation, deformation or burned heat patterns under the dome. Piston pit fit was as installed. There were no marks on the bore or the skirts. A very slight brush of the bores was all that was required. Carl elected to put in a set of new pistons, pins and rings that were identical to the ones we ran so the old pistons could be inspected by Alan at Extreme Performance Coatings. Carl Pelletier of Competition Motorcycles in Boise handled the initial engine build and the post Bonneville teardown in his race engine shop.

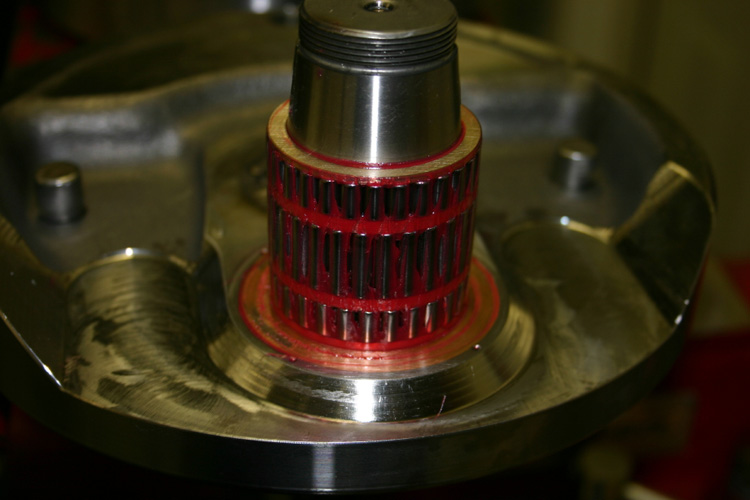

425 HP Lower End

Here Carl is assembling the Bullett's crankshaft with his unique full complement bearing structure and high pressure assembly lube. No issues were found after all the runs at Bonneville. We weren't going to return in 2010 without inspecting the engine.

139" ORCA Lower End..Carl Pelletier "Pro Rods"

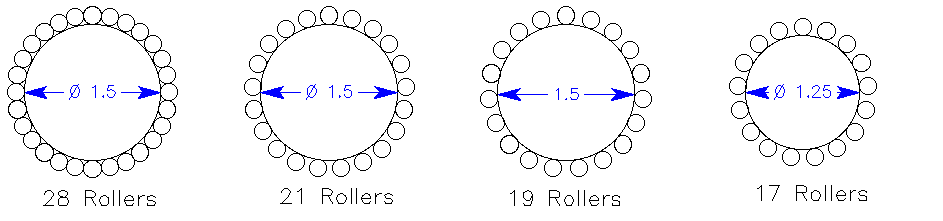

With all the boost pressure pushing on the CP Pistons though the heavy wall wrist pins and the 8.0" Shaker Nitro Rods, the antiquated roller bearing big end of the rods needed an upgrade. Stock Harley Evolution rods use 1.250" crankpins with 17 needle rollers (rightmost design above). S&S Racing 1.5" crankpins for both the Evo and Twin Cam Special Application race engines now use 19 needle rollers. They used to use 21 rollers! These designs from both S&S and Harley use rollers that are .1875" x .294" on the female rear rod and .1875" x .585" on the male front rod.

Carl Pelletier of Competition Motorcycles has three decades experience building Top Fuel, Pro Fuel and Pro Dragster engines that run 400 to 800 horsepower. Carl, frustrated at this "less bearing for more power scenario", worked with a major bearing manufacturer to come up with the solution involving custom races and rolling elements. The tolerances in this full compliment style bearing are unbelievably critical, as is the initial break in procedure. He calls the assembly his "Pro Rods". Tested for over two years without a failure on high output turbo and nitro motors. Lower end rebuilds used to be every couple of races. This design lower end went the whole season in a Nitro burning Pro Dragster. Now it is proven at Bonneville.

The 139" Turbo ORCA engine (far left design above) crankpin is pushing the limits of the 100 year old design so Carl uses 28 custom dimension rollers on the S&S 1.5" crankpin that are .1875" x .325" on the female rear rod and .1875" x .660" on the front male rod. You do the math. We gain a big advantage in load capacity. Those poor 28 rolling elements will have to endure run after run on the great white dyno. It also helps when we use a welded and trued crankshaft with under .0015" run out and side play. Timken Case bearings have been upgraded to take any side load. No Twin Cam pressed cranks!

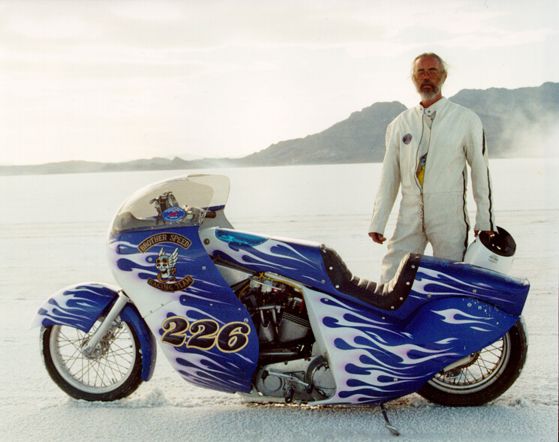

Carl has over 30 years of machining and engine building experience as well as Top Fuel, Pro Fuel and Pro Dragster wins. He also built the 104" Bonneville engine in Mike Geokan's original #226 Blue Bike that ran flawessly for years at Bonneville with 22 lbs of boost and 275 hp.

Whatever it takes. If you want a bulletproof lower end call Carl. Get your cases, lower end, and reciprocating assemblies set up for high horsepower reliability. We did.

Competition Motorcycles Timken Lower End

Bonneville is where you go to prove things and where you go to face things. Mike Geokan's famous #226 bike laid the groundwork for water cooling, fuel injection, water injection, and did a lot to find out how to hold a Big Twin lower end together with 275 hp on a six mile long course. Carl Pelletier and Mike had their fill of flywheels trying to drive apart and push themselves out the pinion side of the engine cases. Carl converted the 104" "Blue Bike" to a full Timken lower end and developed the tooling to do the accurate conversion. Precise clearances in both sideplay and runout plus expert heliarcing of the shafts kept the #226 together for years at Bonneville until the connecting rods finally snapped. The bike was rebuilt and still holds Bonneville records but it was retired to start work on the Bullett. It had accomplished it's mission. Carl went off to run Top Fuel bikes and Mike spent years getting the Bullett ready.

Full circle....Carl took time away from his Top Fuel bike to attack the new issues with the 139 ORCA. Lessons learned on the Blue Bike were carried over to the new 139" ORCA motor. The new engine had potentially twice the hp of the 104" engine and had 40% more displacement and also benefitted from better cylinder head castings with the S&S SA B2 heads. John O'Keefe of Branch-O'Keefe worked over a month to bring the new heads up to turbo specifications and Carl handled the final details on the heads based on his Bonneville experience.

When it came time to assemble the 139's lower end Carl worked his magic and put in a full Timken lower end and upped the ante with heavy duty Pro Dragster 8.0" rods and the full complement bearing structure shown above. Very, very, expensive...all custom, but Carl only does things his way.

Timken bearing race takes side forces. Race installed in case with radial bearing on Pinion side.

Timken bearing installed.

Setting and checking end play. The reason why the Twin Cam engines skipped the Timkens....economics.

Four point welding.

Locking the nut with a heliarc weld. In case you are wondering, Carl ground the original one off to inspect the crank when he disassembled it for inspection. All new parts were installed. No problems were found after the 2008 and 2009 Bonneville runs. This is what it takes to keep the lower end together. It's expensive to install Timken on both sides of the lower end but it's the only way to hold 425 hp. If your budget isn't open-ended don't consider it as it is not for the budget conscious.

Engine Completed

Carl Pelletier completed the engine inspection, refreshing, and assembly and sealed all the open ports. Ready to be put back into the Bullett. In person it is rather intimidating as it is physically large. Bryan and Nick of Bryan's Customs in Boise will work with Mike Geokan to reassemble the Bullett with Walt Henning doing the heavy lifting.. All aluminum bodywork has been disassembled for polishing. It's a complex project.

Time to try to remember where all the hoses, bolts, wires and connectors go. A new engine sprocket was ordered as we sort of chewed up the last one when the crank nut got loose at the 2009 World Finals on Bryan's last 191 mph long course qualifying pass. We weren't up to making a new one out of two sprockets again....that was a bitch. The first sprocket we ordered was junk so we got another good 4350 Chrome Moly "Made In USA" one. The sprocket has to be offset about half an inch for the specialized sintered iron clutch.

139" Orca back in the Bullett's frame. Next up is the Jim's Fat5 transmission assembly and then an ocean of parts will migrate back into place. Everything has been torn down to ground zero for inspection. No one said it was going to be either easy or cheap. There is no rest even though Bonneville is six months away. The Bullet wears high heels and has expensive tastes.

New Clutch "hubcap" Machined

The old clutch "hubcap" that held the outer support bearing and sealed the top fuel sintered iron plates away from the primary oil needed to be upgraded. We added an outer retaining lip and increased the wall thickness a bit as we are going to up the power in 2010. You start out with a 30lb chunk of aluminum and make chips.

Original hat to the left and the newer one placed on the clutch basket. Even when the Bullett is not running it's a high maintenance item...You learn as you go and improve things.

The final part after hard anodizing. The anodizing is about .0002" thick so that has to be taken into account in dimensioning the part. Clutch will be assembled with nine new .120" steels and eight .140" sintered iron plates from Energy One Racing Clutches. While the basket and drive runs in an oil bath the clutch plates remain dry inside the anodized "hubcap". The outboard support bearing sockets into the access cover on the Barnett Tool & Engineering Billet FXR Primary cover.

History in Silver...Bernd Rosemeyer

More than 70 years ago, in the 1930's, Bernd Rosemeyer was the first person to go faster than 250 mph on a public road. That is not a misprint. In the 1936 to 1937 period Mercedes and Auto Union engaged in a fierce competition for the top speed crown. Mercedes' Rudolph Caracciola was the first to exceed 200 mph with a 600hp full bodied streamliner. Bernd countered in the Auto Union with a 252 mph flying mile on a road only 30 feet wide. Caracciola upped the record to 269 mph.

Auto Union and Bernd returned to beat the Mercedes record and made the first pass at 267 mph and on the return at 279 mph the streamliner was blown off the narrow road by a gust of wind and Bernd was killed. No roll cages, no seat belts and only a cloth helmet. All of this on public roads that were shut down for the attempt, not the great expanse of the Bonneville Salt Flats. Above is Audi's faithful recreation of Bernd's record setting streamliner. If it's in your DNA you honor the past.

Mike Geokan's Bonneville Bullet continues the long tradition of specialized silver, hand-formed, polished aluminum, purpose built land speed racers. The only logical thing to do with the Bullet's hand formed aluminum skin was to polish it. You have to remember that you only follow in others footsteps. Think about it...250 mph on a road 30 feet wide over 70 years ago.

There is no rollbar on the Bullett. Somethings never change.

Air Cooled 139" Turbo Orcas

139 EVO ORCAS are engines with 4.375" bores and 4.625" stroke using 8.000" Carrillo Shaker Rods c-c (.927 Piston Pins). 1.500" Race Crank Pin. Full Complement bearing structure. SA/B2 big valve, raised port heads. 9.0:1 (Turbo). Valve sizes 2.220" Inlet and 1.800" Exhaust. Dual spark plugs. External oil lines and internal piston oilers. Special 1/2" cylinder studs and custom case stud patterns are used. Custom Turbo Camshafts. Gas-filled Inconel cylinder head seal rings. Don't ask for our watercooled Bonneville version as that gets way, way, complicated with radiators, water pumps etc. There is no amount of money that will coerce us into doing that.

Carl will be assembling 139" Air Cooled ORCA Turbo Motors on a limited basis for those who have the necessary funds for so complex a product. This requires long lead times as these are completely custom and involves a lot of custom machine and assembly work by S&S, RB Racing and Competition Motorcycles. For planning purposes they are 1" taller than stock. All systems are RSR Fuel Injected with 600hp rated turbochargers featuring intercooling and water injection. About $22,500.00. These do not fit OEM chassis.

Product of a long development from our Bonneville Bullett program. We don't sell products unless we race and prove things.

Book

To bring a nearly 20 year odyssey into focus, a 20 page hard cover book was produced to chronicle Mike's journey in search of speed. Copies were produced for and distributed by Mike to those who had been an important part of his journey.

Ground Zero

No leaks in either oil or the water system were found. Upper end oil scavenging had been directed to the flywheel area. This was rerouted to the cam cavity. New parts for the Jim's Fat5 Transmission were ordered and installed to replace parts that had grinding marks as result of the Bub Meet repairs.

Complete disassembly and rustproofing and refinishing is required of any machine that goes to Bonneville. If you don't, you will drive two thousand miles to find out that you should have. We have taken the time in early 2010 to ceramic coat steel components, the stainless turbo manifold, and anodize aluminum components to make things more durable and corrosion free.

Dyan

Original Mike

Motorcycles are inanimate objects that only come to life when a real beating heart climbs on board. Some hearts are bigger than others. Warm bodies trump hot exhausts.

Eighteen years after Mike started work on his Bullett, the bike is back together and ready for long course at Bonneville in 2010. Here at the four day Boise Roadster show the Bullett sits next to $500,000.00 show cars. After nearly 40 years as an outlaw biker and more than 20 years as a Bonneville racer and record holder, the heart beats on. It's not the bike. It's who you are. Dyan and Mike...Eat your heart out car dudes.

The Bullet won "Best Engineered in Show" beating out all the cars and "Best in Class..Competition". Two for Two. Nick of Bryan's Customs stayed with the bike for the four day show and answered hundreds of questions about the bike and Bonneville. Nick first went to Bonneville in the early 90's with Mike and Bryan and the #226 Blue Bike and now has been with the Bullett for all its Bonneville runs. Here's Nick at the 2009 Bub meet on the Salt Flats....17 years later.