![]()

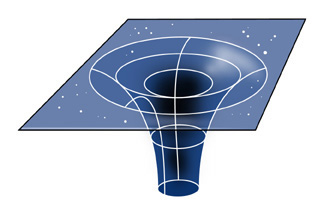

Black Hole Exhausts

The alphabet starts with an "R" as in RB Racing

RB Racing from 1981 to 1995 built a wide range of exhaust systems for BMW motorcycles. Initially we were asked by our BMW Turbocharger distributor to make copies of earlier reverse cone megaphones that were used in the the Butler & Smith Daytona winning BMWs ridden by Reg Pridmore, Gary Fisher and Steve McLaughlin. Subsequently we were asked to copy an R bike exhaust made by another manufacturer, now long since gone, which we declined to do as we don't make copies of people's work and if you are going to do something you should at least try to do it right.

From 1981 to 1995 we built a wide range of exhaust

systems for the air-cooled R series bikes to include the R100, R65, and

GS models. These were primarily 2 into 1 exhaust systems although some

slip-on megaphones were made. The 2 into 1 design was largely praised

by riders as their bikes pulled

higher peak rpms and had more midrange torque, where it counted the most.

In the mid 1980's we built the first performance

exhausts for the K100, K75, K1000, K1, K1100 models and turbocharged

every model BMW made. Everything we did was performance oriented and

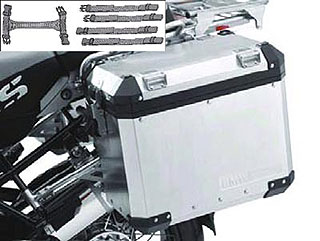

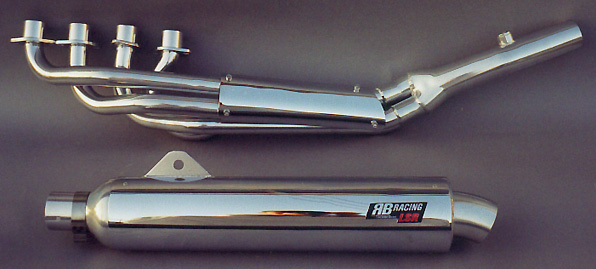

was proved in actual competition. Pictured above is our new K100RS 4-1

Black Hole Exhaust.

These days we're rewriting the book on BMW performance. Better technology. Advanced design and a dedication to uncompromised performance

We Don't Do

We aren't an accessory peddler gathering parts to hawk to the crowd. When we reentered the BMW market after a 10 year absence we were immediately contacted by Web Pirates and Internet K Bike dot com domain squatters. We were informed they were "The center of the K12 Universe" and that they "wanted to evaluate our work for their devoted followers". Get real.

We have no respect for do nothing merchants. It's not our game and it never has been. Get a life, people!

New Cloisonne Tags

Like in the adage "The relentless search for perfection" we have upgraded the logos we put on our LSR Exhaust Systems. Previous tags were stamped and formed aluminum with silkscreened details. The new cloisonne tags are a precision die struck brass, nickel plated, with powdered glass fired in an oven then polished to a jewelry finish. These are direct replacements for our older tags and are available for US $20.00 via US Global Express (foreign) or Priority Mail (domestic US). They come with black headed rivets and are riveted in place with a light coat of high temperature silicone (Permatex 598B) behind the tag.

New Fuel Pressure Regulators

For our fuel system upgrades for both Motronic an early LE Jetronic as well as our turbo systems we have new genuine Bosch Billet Regulators that are fully adjustable and referenced to manifold pressure. You have to make parts like these when you go turbo. We rolled $7,500.00 worth of dice to make the first batch.

K1200 Series RS/LT

Pictured above is our first generation K1200RS Black Hole Exhaust. Ceramic coated primary tubes in a 4 into 2 into 1 header system. A chromed heat shield on the 32mm primary tubes prevents radiant heat from toasting your left boot. The chrome shield goes beneath BMW's shield for double protection... It's held in place by ceramic coated stainless steel allen head cap screws. The Oxygen sensor for the closed-loop Motronic is relocated rearward.

Newest designs feature a rounded end cap. Newest dsigns are also available in double coat SS Titanium or Ceramic Black finishes.

On the K1200RS the muffler section bolts directly to the stock hanger assembly. Also ceramic coated, the Black Hole Muffler features a 180 degree coverage chrome heat shield held in place by ceramic coated stainless steel button head cap screws. There isn't any fiberglass or packing material in the Black Hole Muffler and it will never require any maintenance. The pipe exits to the rear of the bike with a 64mm (2.5") curved snout that clears the rear license plate. No heat intrudes on the saddle bags as the cannister section is further from the bags than is the oem system and the ceramic coating holds the heat inside the system.

The OEM K1200RS system has to sandwich a catalytic converter between the primary tubes and the muffler section... This severely compromises performance, as the primary tubes are way too short for the engine design. RB Racing's Black Hole header corrects this by using equal length, longer, primary tubes to gain torque in a 4-2-1 design. Primaries 1-4 and 2-3 are grouped together as they should be in a 180 degree 4 cyl crankshaft design.

If it looks right, it is right...In airplanes, boats, or exhaust systems, good design and performance are synonymous.

The K1200RS Black Hole Exhaust is sold by itself or as a complete system with new higher horsepower injectors, a high-flow fuel rail and a new pressure regulator system. The finish on the system will not change over time and can be cleaned without any fear of scratching. The chromed heat shields (2) are durable, as chrome is the toughest surface finish you can have. The ceramic coating is incredibly tough.

Take a 2002Tii and Lay it on it's side

When the K100 series was announced in the mid 1980's we built an equal length 4 into 1 primary system with a slip-on tail section. The tail section had a tapered section that was welded into a straight section with a reverse lip on the baffle, that we debuted at the Anaheim motorcycle show. As the four primary bends were somewhat complicated, with one of them being "compound", there were all sorts of nooks and crannies, so we opted to black porcelain coat the exhaust. The exhaust proved to be a great success, with the only downside being that the porcelain process was a pain in the ass and chips in the coating or any defects were not repairable. Then there was the time that the porcelain coater, by mistake, delivered our pipes to another manufacturer who copied the design and took a hammer to our parts...God, we love this business! An inside secret at the time was that although we used a 3" slip at the collector we had an internal baffle set at an angle with a tapered entry that reduced this to a manageable 45mm. The surrounding area was packed with fiberglass.

We sold hundreds of these exhausts and even made versions of the system for the short-lived 3 cylinder K75.

"Loyalty, We ain't got no stinkin loyalty!"

Since the K series exhausts were such a hit our ever practical distributor thought it would be a good idea to have someone else copy our work and when we saw a part that looked a bit strange due to the poor welding and other short-cuts the proverbial shit hit the fan as they say. Hell hath no fury like a spurned and burned manufacturer who hadn't been paid one cent for the R&D.

Reaction....Bring in the Cans

We simply introduced a complete line of cannister exhausts for the range of the BMW models complete with billet endcaps and a variety of stainless steel, carbon fiber and aluminum tail sections that would compete with our earlier designs or their copies. We called this K-Mart marketing as the customer would have a wider choice, but, in any case, the market share of the earlier products would be diluted. Our distributor then decided it wasn't such a good idea to copy our products as he didn't want us competing against his efforts. He sure didn't like the ads we drew up for BMW News, which we never ran. We rewarded this good behavior by raising the prices which he simply passed on to you, the customer, by raising his prices even higher. Isn't business a lot of fun?

History in a Can

We made stainless steel cannisters with a polished surface. These would eventually, if run hard enough, turn a gold color even with internal fiberglass insulation. Rivets were involved and since aluminum rivets would not hold up we used stainless steel ones. Riveted seams still left "open" seams that could ooze carbon deposits when moisture condensed in the systems.

We countered the oozing and discoloration of the stainless with fully machined aluminum cannisters that eliminated the rivets and had high temperature silicone o-rings fore and aft. End caps were CNC machined from billet aluminum blanks...sort of an overly-complicated part, with recessed stainless steel allen cap screws holding them in place. Hot corrosive exhaust does not like raw aluminum although customers love the sight of a brand new machined part. The cannisters were offered in polished raw finishes, and high temperature black coatings.

Carbon fiber cannisters were also designed with internal aluminum foil. High temperature resins and different weaves were used but no matter what anyone thinks, carbon is not a good exhaust material and it sure isn't cheap, or at least it wasn't in the early 90's. Some of these made it on early R1100RS twins as well as a scant few 4 into 2 exhausts we made for the K1.

A Dry Well and Area-51

Seeds of destruction were sown due to megolomania and a fascination with checker board tiles surrounding executive offices and "conference rooms". Stir in a mix of leased watercoolers and Chevy Suburbans, and a 5 bay service department with no service business and the well runs dry. Orders pile up, suppliers dry up and the situation goes critical. No money for parts so they don't get built. Competitors smell blood and move in on the market with bog standard shit that can at least be delivered. No one races, no performance benefits, no integrated solutions, no one has any new technology...parts peddlers and vultures, they are all the same.

Time to do something radical and invest in a new, overwhelming, technology. The Skunk Works and Kelly Johnson did it with the SR-71 and the U-2 and later on with the F117A stealth fighter. We had to create our own Area-51 technological leap...The Black Hole Muffler. It was our ace in the hole should our distributor con some fool out of a lot of money to rescue his company. Didn't happen, but one never knows...desperate people do desperate things. The Black Hole was born in secrecy and although testing was finished, it wasn't introduced to the public.

It goes in but doesn't come out...Black Hole

Nothing escapes a Black Hole, not even light. We had a lot of dealings with members of the motorcycle press over the years and like shooting stars they flame out after a few years with few exceptions. One individual who has survived forever told us in the mid 90's that his magazine, now since sold a few times, although like the cockroach he still remains employed there, "Was sick of aftermarket exhausts that were too loud and...that they weren't testing any fkkking loud pipes!" That was sort of a challenge to us and it ringed true because we knew the relationship between sound and power and how everytime we made the exhausts quiet with our louvered and perforated cores, surrounded by nasty fiberglass, power fell off. Therein lies the challenge and the story. Aerospace technology hidden in a muffler. The sound goes in but doesn't come out. Something to kill the parts peddlers and vultures hawking their decades old technology. We had to find our "Black Hole".

You have exhaust pulses entering the Black Hole cannister...the flow goes through unrestricted and the sound is trapped and dissipated. No repacking. Polished silver ceramic finish. Chrome heat shield. Taming 11.5:1 compression motors requires a lot of research.

Test Test Test

Take your stock BMW and wind it to redline 1st, 2nd, 3rd, 4th, 5th and in some cases 6th gear...very little noise. No cops dropping their coffee and donuts two streets over to put you in a world of hurt and no people blown off of bus stop benches. Put on an aftermarket exhaust and the opposite is true...and because everything mechanical stays the same, even with "chip" tuning, you really don't go any faster. We know about this because we spent countless hours programming new chips for the K series and R series bikes and noise does not equal speed.

We put probes in our K series and R series exhaust systems as well as in the oem exhaust sytems to measure backpressure and found the results to be predictable. The oem systems had quite a bit of backpressure at peak rpm and when we tried to quiet our systems which all had straight through louvered or perforated cores they had a little less than stock backpressure numbers but a lot more noise. The oem systems reverse the exhaust flow several times and have a series of expansion and acceleration chambers that dissipate and cancel the sound waves. In short, our systems were not quiet and if they performed well were "cop bait". The magazine editor had issued a challenge and we now had data to start our search...for zero backpressure and infinite power with no noise. Hell, if you don't look for it you won't find it.

Black Hole Equations

We built a series of prototypes over a period of months and got nowhere. Increasing complication involving pre-chambers, multiple internal cores, reflecting cones, angled planes etc. got us nowhere. It was the same old problem, decreased noise meant increased backpressure and increased complication meant increased size. Graft on a large car muffler from a big V8 and there were positive gains in noise reduction and backpressure readings but you ended up with an aesthetic disaster. Might as well leave the oem system in place unless you liked a lot more noise for little performance gain. We hit the wall. Nowhere to go except back to blank sheets of paper, Ashlar Vellum and a calculator. The answer is always hiding in the math and that's where we found our answer. The solution is always elegant and simple. It only took us 17 years to find it. Define the problem mathematically and the arrow points to a solution.

Test Test Test

Twins are harder to make quiet than the inline fours so we started with a R1100RS for our sound and backpressure tests. The stock muffler with the catalytic converter had a little over 3 pounds of backpressure at 8200 rpm and was pretty quiet both sitting still and wailing by at the top of third gear. Put on the Black Hole Muffler and the bike had a throaty sound at idle, louder than stock, but pleasantly throaty and not objectionable. Bringing the bike up to 8200 rpm the Black Hole Muffler had less than .2 (point 2!!) pounds of backpressure and was as quiet as stock. Wailing by at the top of third gear the bike was as quiet as stock and a lot quicker and freer revving with the Black Hole Muffler. Cruising at 4000 rpm the bike was completely quiet and not tiring except for the usual wind noise.

We have posted a movie of or original version (2003) K1200RS exhaust system in action on a deserted street with no background noise. Click on the picture to roll the Quicktime Movie (3.9 Mb). In the following years we have contiuned to improve the design. Other manufacturers have abandonned the K12 as soon as sales fell to zero. We still make the systems.

Back to Back Testing and Verification

We also tested the Black Hole technology on other bikes to include: K1100RS, Honda CBR600, CBR900RR, and a Suzuki GSXR1100. Raced at Laguna Seca on a Honda 600 it passed the sound tests with great ease. We also tested the technology on a Corvette and on a Chevy V6 pickup as well as the noisiest animal in the world a RX7 Wankel. In all cases we got a well performing quiet muffler. Then we put it back on the shelf with the Alien spacecraft for further study at a later date. There was a large investment to be made and too many details to work out and there were other racing obligations and day to day practical matters to attend to. There were records to chase at Bonneville and El Mirage and the exploding RUB Harley market fueled by aftermaket engines and an explosion in racing activity to attend to. Also our distributor self destructed and to properly attend to the BMW market required even more research to provide integrated solutions and not just parts. The time just wasn't right.

Integrated Solutions

We offer integrated solutions that couple our Black Hole technology with our 15 year involvement in fuel injection development and testing and our knowledge of internal combustion engines. Computer chips, larger injectors, revised inlet systems and of course turbochargers.

These are just air pumps when you strip away all the bodywork and hype and unless you increase efficiency and pump more air you just aren't going to get any meaningful increases. Not everyone will want a Turbo and our Black Hole exhaust systems will be one part of the equation in an alternate solution.

As Bette Davis said..."Hang on it's going to be a bumpy ride". As for our competitors we say "What competitors?". Nuclear warfare in a land of bows and arrows.