![]()

Bonneville

SpeedWeek 2017.... In an era of Decreasing Salt

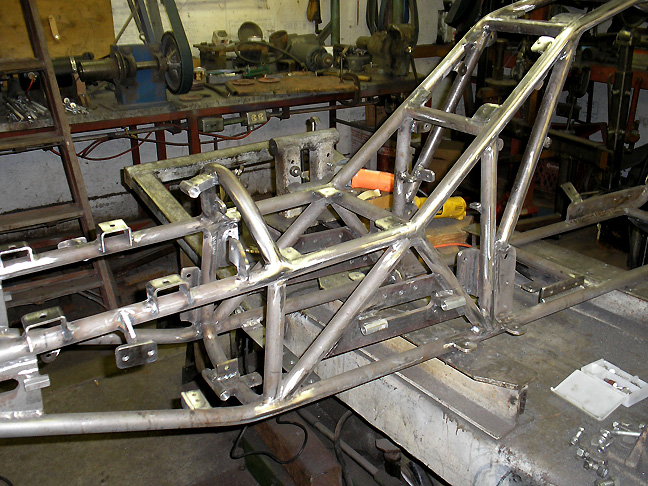

Bullett

Maintenance,

Benefit, and Racing

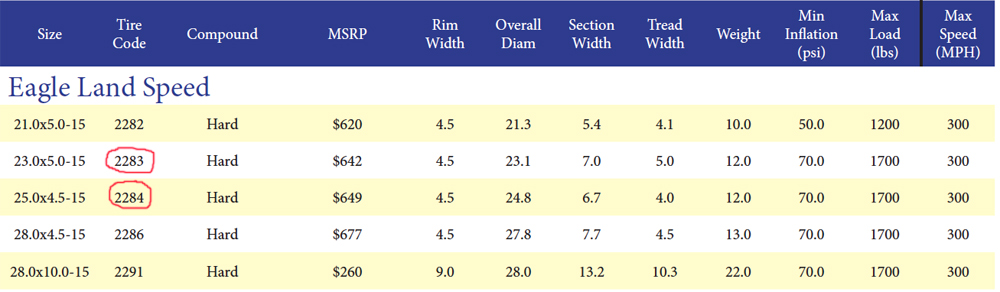

Post 2016 Bonneville: Time for New Tires

One set of these Goodyear LSR 300 MPH

tires was used for the construction of the

Bullett. They became weathered during the long

build process and were cut in half for close

inspection of the thickess of the rubber in

2008 at the request of Nate Jones Cowboy Tire.

Shaving excess rubber was done by Nate Jones

to balance and prep the new tires and to round

the front tire for better handling. The second

set was used for the initial running, gaining

licenses for the Long Course, and setting a

200 MPH Record that stood for 5 years. After

spinning the rear tire at over 260 MPH,

bouncing through some deep ruts at 194 MPH,

and plus the effects of weathering, we decided

to put on new rubber for safety reasons. You

are looking at $1650.00 worth of new rubber.

Our third set. Does get expensive.

The Bullett is about the only long

course (>175 MPH) motorcycle that actually

has legal tires in the eyes if the SCTA-BNI

Bonneville Inspectors. There have been crashes

at Bonneville due to tire failures, and

numerous instances of tires chunking with

Z-Rated tires running well over 200 MPH.

Motorcycles have crashed and people have died

in other Speed Events...Perhaps with tire

failure as one of the factors.

The decision in 1992 was to design

his Bullett around tires that would be safe.

However there was no easy way to test the

handling and no attempt was ever made to get

the bike on a dyno which makes it sort of show

up in the salt and see what happens scenario.

Major unknowns.

The three new tires above were

purchased and then we decided not to use them.

The decision was made to go to a taller front

to better handle the poorer salt conditions

and an even higher speed 300 mph LSR rear

tire.

Now we have better rubber and perhaps the only motorcycle with truly certified 300 mph rubber front and rear. We are now running the two tires circled above in the Goodyear Eagle Land Speed brochure. No they do not have them at Costco.

So we actually ended up buying five

new tires...Two fronts (they would only sell

us two) as we had before, and a rear same as

we had before...Then we decided not to use

them.New 2284

LSR rear tire pictured left above.

Then it was bye, bye $1300.00 on the

second purchase. We decided to put on a 23"

2283 front tire instead of the previous 21"

LSR tire Mike had chosen as it had a more

rounded profile and the rear tire we upgraded

to a true 300mph LSR 2284 rear tire instead of

the 25" Front Runner we used before. Five

tires to get the correct ones.

In 2016 Bryan was sideways on the poor salt at 194 mph on the long course...and after his last run he said he was on the floorboards sawing the handlebars left to right. He's hoping the new front will be better with it's more rounded and taller profile. He has a lot of runs over 200 mph so he's the best judge. The tires will pass any SCTA-BNI inspection.

Does these look like they are worth

$1300.00? Well, If you are Bryan Stock and

sitting on the Bullet with the front tire

going 250 MPH and the rear tire spinning at

275 MPH, it is, from his viewpoint, money well

spent.

New 23" 2283 front tire to the right above. These LSR tires run on Funny Car certified wheels with 70 PSI tire pressure. Rubber bands in the tradition of Sir Malcolm Campbell, Craig Breedlove, Mickey Thomson, the Summers Brothers, and Al Teague. No pops.

Note: Over the course of buying

multiple sets Goodyear LSR tires we found Mike

had originally chosen the wrong, non-LSR rear

tire. In 2017 we corrected this bring out

total outlay to just short of $4,000.00 over

the years from build to our departure in 2017.

Nate Jones LSR Tire Balancing and Shaving

Nate Jones Cowboy Tire in Signal Hill California does everyone's LSR Tires and has done ours since 1985. Tires themselves may or may not be round and Nate shaves them and makes them round. In addition, excess rubber just builds up heat on the long course at Bonneville. Tires can suddenly chunk. There will be piles of chunked tires in the motorcycle tech inspection stand during Speedweek. 200 mph motorcycles must have their tires inspected and stamped after every run. The stamp is checked by the officials at the starting line.

Nate Jones and Son...Nate Jones

Cowboy Tire

Nate Jones and his son with the

Bullett's 2017 Goodyear LSR tires...Mounted,

shaved and balanced. Nate wants everyone to

know that shaving new tires whether it's for

Bonneville, your new pickup truck or your

$200,000.00 Porsche Turbo Carrera will make

the vehicle safer and smoother as even new

molded tires are not perfectly round and, if

not shaved, require more balance weights than

needed to try to correct the out of roundness.

All Bonneville motorcycle tires whether

Z-Rated or Road Race slicks should have

additional shaving to remove excess rubber to

cut down on heat build-up on the long course

at Bonneville to prevent chunking. Even the

Bullett's $650.00 tires get shaved and

balanced. Nate Jones Cowboy Tire

1-562-597-3369.

When we first went to Bonneville in

1985 the late Jack Dolan, of two and four

wheeled Bonneville fame, advised us to get

Goodyear Road Race Slicks and have Nate Jones

shave and balance them. It's something we have

done ever since. Zero problems with the

Bullett's LSR rubber prepped by Nates. People

have died using tires not rated for these 200+

mph speeds and it's damn stupid to have the

excess rubber that a street tire has. Z-Rated

does not cut it on the great white dyno. Tire

shaving has been around a long

time.

If you have ever looked at the tires,

or pictures of the same, of Sir Malcolm

Campbell, Craig Breedlove, Al Teague, Mickey

Thompson, and others you will find an

extremely stiff carcass (bitch to mount) with

very thin rubber and no treads. Nate Jones

does pretty much all the SCTA-BNI Bonneville

tires as well as Duallies, Rolls Royces,

Bentleys and Porsches.

Bullett Pistons..CP

When you stick a 560 Hp turbo on the

139 CID Bullett Orca Motor the pistons, piston

pins, and rings get subjected to a lot of heat

and pressure.

We cut the skirts for clearance and

ceramic coat the piston tops and graphite coat

the skirts. No cylinder head gaskets or base

gaskets with Silver-plated Inconel 600 psi

Nitrogen seal rings on the cylinder heads. We

have even run PEEK Buttons on the skirts. Drop

$2,500.00 on the pistons...and more on the

machining and coating. We have had zero issues

running high zinc content Brad-Penn Oil.

The 139" Orca motor has been used as

a test bed to experiment with new

technologies...electronics, closed loop boost

control, traction control, bearing designs,

piston sealing, vacuum pumps, ceramic

coatings, high temperature valves, cylinder

head porting, camshaft design and more..

Somethings have worked and somethings have

failed. It is definitely not short on power as

Bryan Stock can attest...His first words after

a 214 mph run...."I want one of those in my

Dresser!".

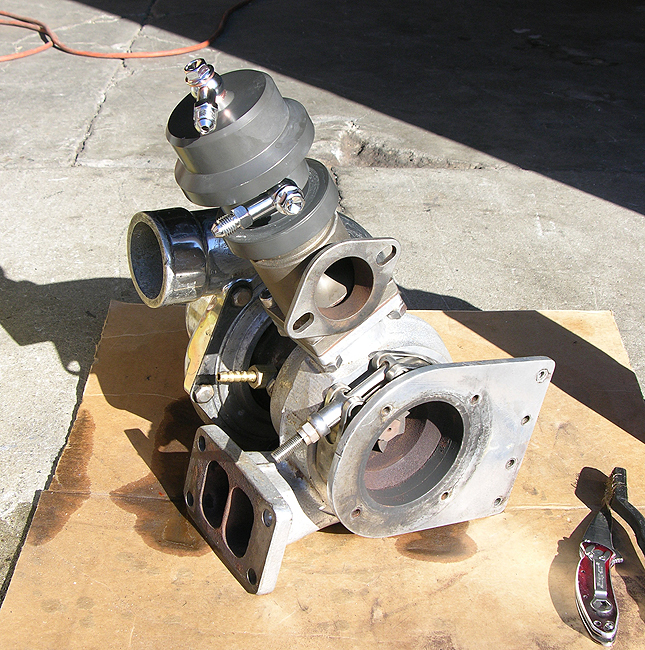

Bullett Turbo

New chromed AN fittings installed Bullett's turbo wastegate replacing the lightly corroded gold irridited cad plated ones. Either chrome or hard anodization will withstand the salt corrosion. The wastegate was bench tested and checked out O.K.. The Bullett's Garrett 560 hp turbo was inspected and its bearings were in perfect shape. A light touch up with ceramic spray coating and she is good to go again for 2017 with closed loop phase anti-phase boost and traction control.

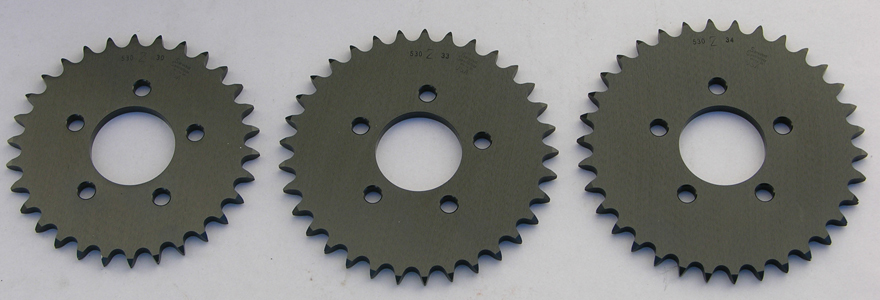

New Teeth for the Bullett

New custom 7075-T6 Hard-Anodized

sprockets from Sprocket Specialists for the

jackshaft and rear wheel...312 mph gearing

@6750 rpm in 5th gear. New EK chains were also

purchased and installed.

Five 7/16" chromed Grade 8 fasteners secure each of these sprockets. Chrome survives the salt slush. Zinc plated parts corrode instantly. Stainless, save specialized Aircraft A286 fasteners are not strong enough. The bouncing on a rough long course has already bent a rear axle and snapped a primary chain. Safety is paramount. Maintence and replacement of parts is mandatory.

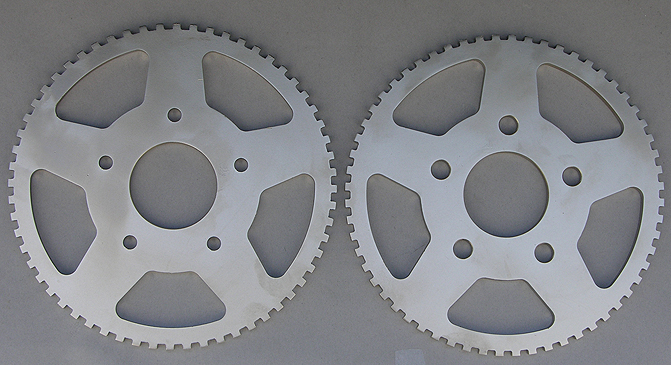

More Teeth for the Bullett

The Bullett's 60 tooth front wheel

speed sensor disc for the Cosworth Pectel SQ6M

Hall Effect (3 wire) speed sensor. We compare

front and rear wheels speeds to determine the

amount of wheelspin to activate the traction

control system. We allow more slip in lower

gears and less slip (10%) in 4th and 5th

gears. Boost is controlled by both gears and

vehicle speed and fuel cuts are used to

control traction. Ignition timing is a matrix

of four maps each with 625 sites. We do not

use ignition retard as a traction control

strategy but activate it via other inputs.

Corrosion resistant Electroless Nickel Plating for the 60 tooth discs applied by Chromeplate Company in Inglewood California (310-641-4922)...Established in 1961 and aerospace certified and now Bonneville Salt Flats certified. Two day quick turn around with excellent dimensional control as specified. We have to plan for salt getting onto everything.

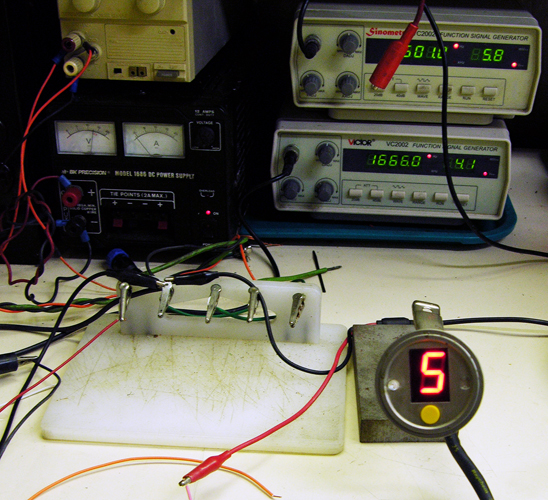

Gear Indicator

So Bryan doesn't have to count to five at over 200 mph...Like when he's a bit sideways on the Bonneville Long Course coming up on the two mile marker and can't remember if he's in 5th or 4th Gear. No point in hitting the pneumatic shifter again if you are already in 5th gear on the Jims Fat5 Transmission. Here verifying the programming on the test bench with two function generators to simulate crank position sensor speed (rpm) and transmission mainshaft output rpm off the 4th gear teeth.

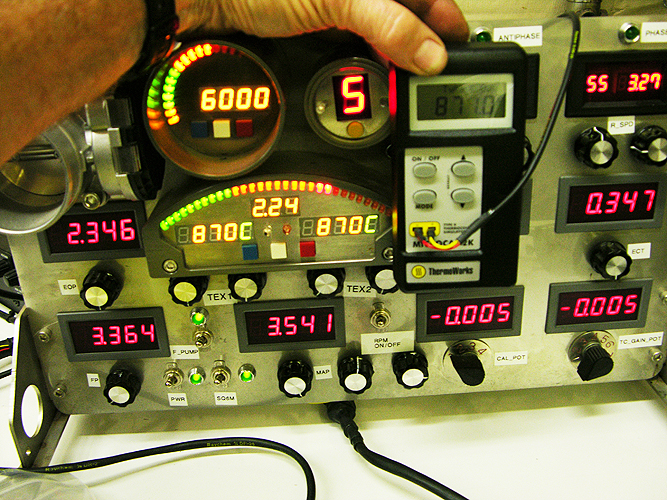

Exhaust Gas Temperature Calibration

Calibrating the Bullett's programming

for Exhaust Gas Temperature (EGT) Correction.

Here Bryan is at about 19 pounds of boost and

6000 rpm in 5th Gear with an EGT of 1600

Degrees Fahrenheit (871 Degrees

Celsius). We program extra fuel as the

combustion temperatures go beyond a certain

point to prevent engine damage. A precise

thermocouple simulator is used to output the

specific temperature, in this case 871 Degrees

Celsius, to verify programming.

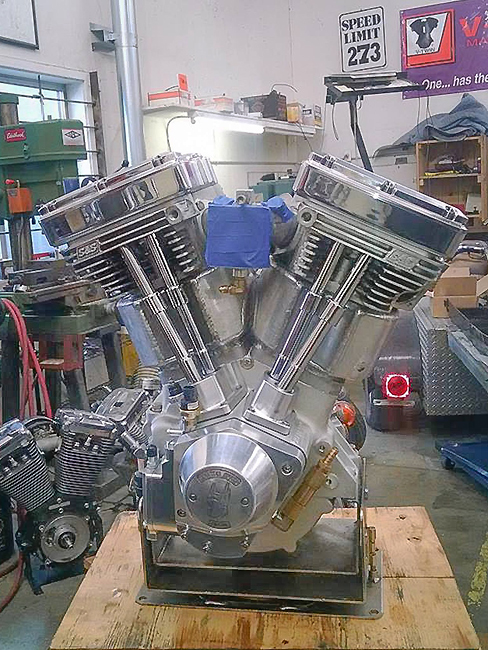

Bryan Stock...139" ORCA

Motor freshened up by master mechanic

and bike builder Bryan Stock with new

Torrington and Timken pinion shaft bearings.

Bye Bye ball bearing and its clips that got us

at the 2016 World of Speed. New rings and new

S&S oil pump. Ready to roar. Fuck the

trouble, it's time to party and roll again.

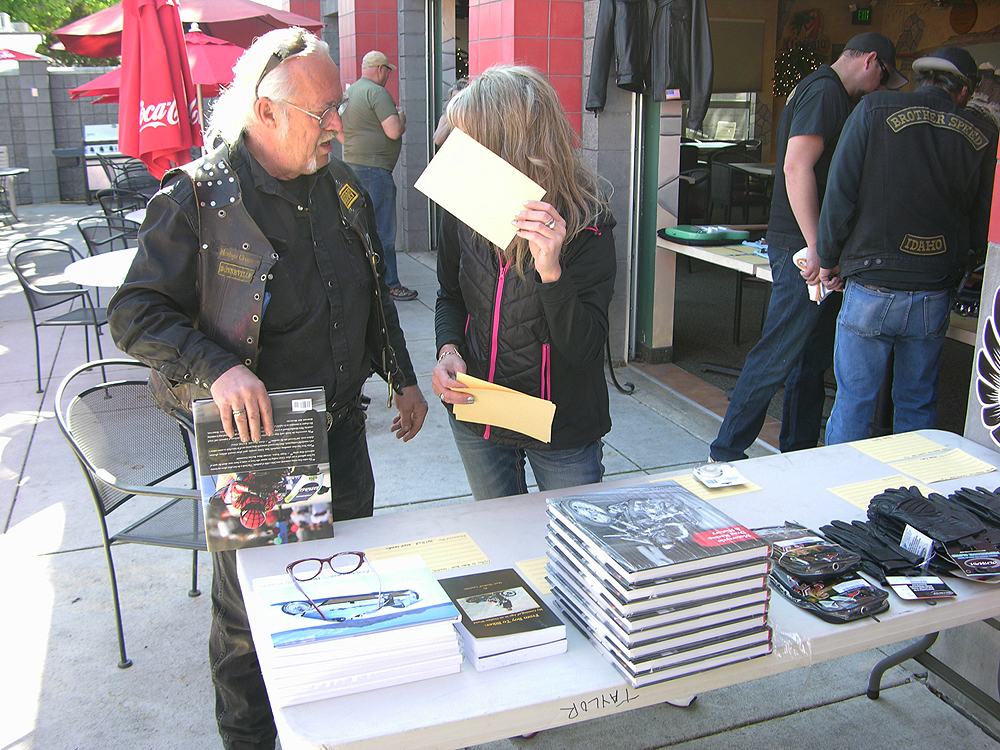

2017 Benefit to help pay for

the trip to the salt. Takes a lot to put your wheels on

the salt...Here in 2016.

Tenatively scheduled for 29 April 2017 in Boise Idaho there will be a benefit for the Bullet Race Team. Shane's Chopper on the salt in 2016.

Pink: Get the Party Started...lyrics by Linda Perry..

I'm

comin' up so

you better you

better get

this party

started

I'm comin' up

so you better

you better get

this party

started

Get this party

started on a

Saturday night

Everybody's

waitin' for me

to arrive

Sendin' out

the message to

all of my

friends

We'll be

lookin' flashy

in my Mercedes

Benz

I got lotsa

style, got my

gold diamond

rings

I can go for

miles if you

know what I

mean

I'm comin' up

so you better

you better get

this party

started

I'm comin' up

so you better

you better get

this party

started

Pumpin' up the

volume,

breakin down'

to the beat

Cruisin'

through the

west side

We'll be

checkin' the

scene

Boulevard is

freakin' as

I'm comin' up

fast

I'll be

burnin'

rubber, you'll

be kissin' my

ass

Pull up to the

bumper, get

out of the car

License plate

says Stunner

number one

Superstar

I'm comin' up

so you better

you better get

this party

started

I'm comin' up

so you better

you better get

this party

started

Get this party

started

Makin' my

connection as

I enter the

room

Everybody's

chillin' as I

set up the

groove

Pumpin' up the

volume with

this brand new

beat

Everybody's

dancin' and

their dancin'

for me

I'm your

operator, you

can call

anytime

I'll be your

connection to

the party line

I'm comin' up

so you better

you better get

this party

started

I'm comin' up

so you better

you better get

this party

started

I'm comin' up

so you better

you better get

this party

started

I'm comin' up

so you better

you better get

this party

started

Get this party

started

Get this party

started right

now

Get this party

started

Get this party

started

Get this party

started right

now

Be in Boise 29 April and hear the Bullett Roar. Burn some rubber.

Bullett Benefit Boise 29 April 2017

Bryan Stock buttoning up the Bullett's fairing after a three day slog to install the turbo system, redo the Bullett's pneumatic shifter harness, install the new 23" LSR front tire, new LSR rear tire, trim the fairing for the taller front tire, and reinvent the front fender for the new front tire...Just finishing on Friday afternoon before the Saturday benefit. Parts and people coming in from many directions.

Assembly

Fun

Commonly heard phrases:

1.

Chrome bolts

are the best

for the

Salt...Where

are my damn

chrome bolts?

Walt stole my

bolts!

2. I should have made this damn thing a foot longer!

3. Which part goes on first?

4.

Lets see your

checklist.."What

checklist"

Starting

the Bullett

Friday the

28th..Bullett

is Alive.

On Friday morning, the day before the 2017 SpeedWeek Benefit, we started the Bullett up (video) and let her warm up and check for any issues. There were none. Brother Speed's Gary Brant stopped by and captured the moment on his phone. Bryan Stock gave it the thumbs up. One big swig of whiskey to celebrate when the Bullett barked to life..

Then

it was time to

call in Chad

Kirby of Apex

Professional

Mobile

Detailing to

polish the

Bullett's

aluminum skin.

Everyone

started

showing up

once the word

went out and

Diana Sterk

was there to

take more

pictures.

There are many

people to

thank for

their support

and pictures

tell the tale.

Even a long

lost sister

showed up at

the fortuitous

moment. The

sun shone.

Karma.

Mirror

Mirror on the

Wall

After you have put 60 manhours into detailing into some guy's restored zillion dollar car or polishing some corporate jet, you take a break and slide down to the bottom of the financial pyramid and donate your expertise to a worthy cause. Apex Professional Mobile Detailing. 1-208-713-8842 (Chad Kirby) We got the Bullett started and buttoned down and Chad made the Bullett look the best she ever had.

Bullett

Benefit Turn

Out

After

several days

of rain and

extreme winds,

Saturday 29

April was calm

and sunny and

absolutely

perfect for

the Bullett

Benefit. We

don't know who

ordered the

weather but

many were

ready to take

credit for it.

The Crescent

parking lot

was divided up

into various

categories for

the bike show

awards..FXRs,

Dynas,

Dressers,

Sportsters,

Customs,

Rigids

etc....and

there was lots

of room at the

Crescent

lounge for all

who showed up

for the

Brother Speed

Bullett

Benefit. Many

different

clubs and a

diverse set of

people

provided

support.

We kicked off the Benefit at 11AM but many people arrived early to get their bikes in the show or line up for the Dyno Contest run by Nick Stock.

Brother Speed...Bonneville Iron

Brother

Speed's

current, past

and future

legacy. Fred

Wiley (founder

Brother Speed)

and 200 MPH

Lifetime Club

Member's BMW

Bonneville

Bikes..(Fred

did it on an

RB Racing

Suzuki Turbo

in 1992). The

record setting

#226 Blue Bike

and Bryan

Stock's 200

MPH record

setting #8228

Bonneville

Bullett. All

turbocharged.

#226 Blue Bike

Some

20 years after

it last ran at

Bonneville the

Blue Bike

still amazes

people. 255 Hp

@ 22 PSI of

boost and it

sits and idles

and drives

like a stock

bike. Fuel

injected,

intercooled

and water

jackets on the

cylinders.

#226 begat

#8228. Long

history and

even longer

hours. If you

only knew. RB

Racing

designed turbo

and fuel

injection.

Dyno

Contest

Nick

Stock was busy

all day doing

three dyno

pulls for each

bike. KC ran

off with the

prize for his

built Dyna

(not the bike

above). We did

not enter the

Bullett or the

#226 turbo

bikes.

Bands...Pumping

up the volume.

Diana Sterk and Shane Taylor arranged for several bands playing at the Benefit ...They kept things at full volume all day long. Good times..

You had to pass tech at the Benefit

When you go racing at Bonneville you have to qualify at speeds of 150, 175, and 200 MPH to get your license to run on the long course with the big dogs. Bryan Stock runs with the big dogs. At the Bullett Benefit we had a similar qualifying procedure...Those who qualified for long course got a red arm band. Anything associated with the Bullett is long course. Everyone who helped with the Bullett is now qualified for long course.

Flyin

Bryan

Unintended Consequences

As Mike Geokan said after the event..."I used to go to Bonneville with my pickup truck, a small trailer, maxed out credit cards, and Bryan riding his Dresser. I had no idea back in 1992 when Bryan and I started the Bullett that it would ever get completed much less that so many people would become involved".

Mike

is hoping to

get to

Bonneville in

2017 as a

series of

medical issues

have prevented

him from

seeing the

Bullett run

except for a 1

day visit in

2011 when

Bryan ran back

to back 200

mph runs and

into the

record book.

After Mike's

last operation

they say he is

good to go to

see Bryan go

for 230 MPH

back to back,

and then 250

MPH.

Bishop,

California

300

Miles to La La

Land. Lock and

Load. 10 hours

down 4 to go.

A

tradition...stop

in Bishop for

gas and a

Hershey

Bar. 865

miles in one

shot. Did so

multiple times

over the years

both on four

and two

wheels.

Cruisin'

through the

west side

We'll be

checkin' the

scene

Boulevard is

freakin' as

I'm comin' up

fast

I'll be

burnin'

rubber, you'll

be kissin' my

ass

Post Bullett Benefit...The Work Never Ends

That dwindling patch of white above draws people together. People who never knew each other before and who now share a common experience...and have a newfound reason to keep going in this crazy world. Flat out together...

A

special thanks

goes to all

who attended

the Benefit.

Rolling

Thunder and

good times for

all. Up close

and personal

with the

Bullett.

2016 SpeedWeek at the Rainbow Casino...sharing a meal together in a sea of one-armed bandits...with Donna Summer's "Hot Stuff" blaring in the restrooms... and plenty of beer in our motel rooms. Party Time before the show.

Raise your hand in the air just before the nine team members rise to go to the casino buffet and ask "Raise your hands if you donate money each month to Hillary Clinton's campaign"...loud hissing. Idaho, bikers and the FOX News junkies and one sole hand raised from La La Land...California. Red line drawn as they say. No politics on the starting line.

Drink

the bottle of

wine

counteracted

by lots of

bread and

butter and

head back to

the hotel roon

to commune

with tiny bars

of soap and

shampoo.

Anyone

who

has been

involved in

racing knows

both the highs

and the lows

of the

process. We

ended our

Bullett

Benefit in

Boise on a

very high note

due to all the

hard

organizational

work by

Brother

Speed's Shane

Taylor who

pulled out all

the stops to

make it

happen.

The Bullett Crew worked their butts off to get the Bullett buttoned up and started the week before the benefit with the newly refreshed 139 Inch Orca Motor assembled by Bryan Stock. She never looked better.

Static Testing Turbo Water Injection

We

can verify the

water

injection

activation in

our software

programming on

our SQ6M

Simulator...However,

we also need

to verify

actual water

spray (1000

PSI) in the

Bullett's

inlet

manifold. You

can't just

"turn on" the

water

injection pump

because it is

triggered by a

chain of

events in the

SQ6M which, in

turn,

activates a

relay that

powers the

pump.

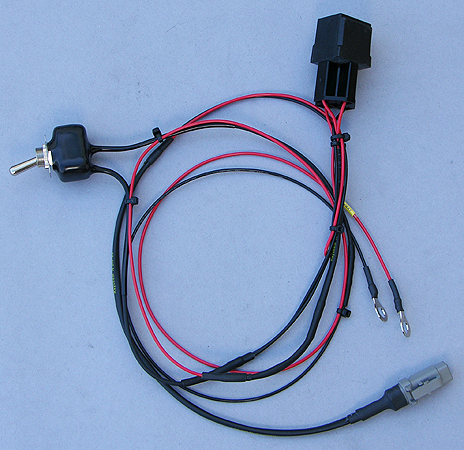

To test the actual water flow and priming of the system we made a harness that plugs into the water injection pump on the Bullett. We can put water in the Bullett's stainless steel left side saddle tank, install the harness, remove the Bullett's plenum chamber, and watch for the ultra fine fog (1000 PSI) in the Bullett's inlet manifold. There is a single nozzle in the bottom of the inlet manifold. We can verify the system is primed (There is a 15 psi check valve in the nozzle) and that the nozzle is not clogged.

This is all part of the preparation we go through before we head for the long course at Bonneville.

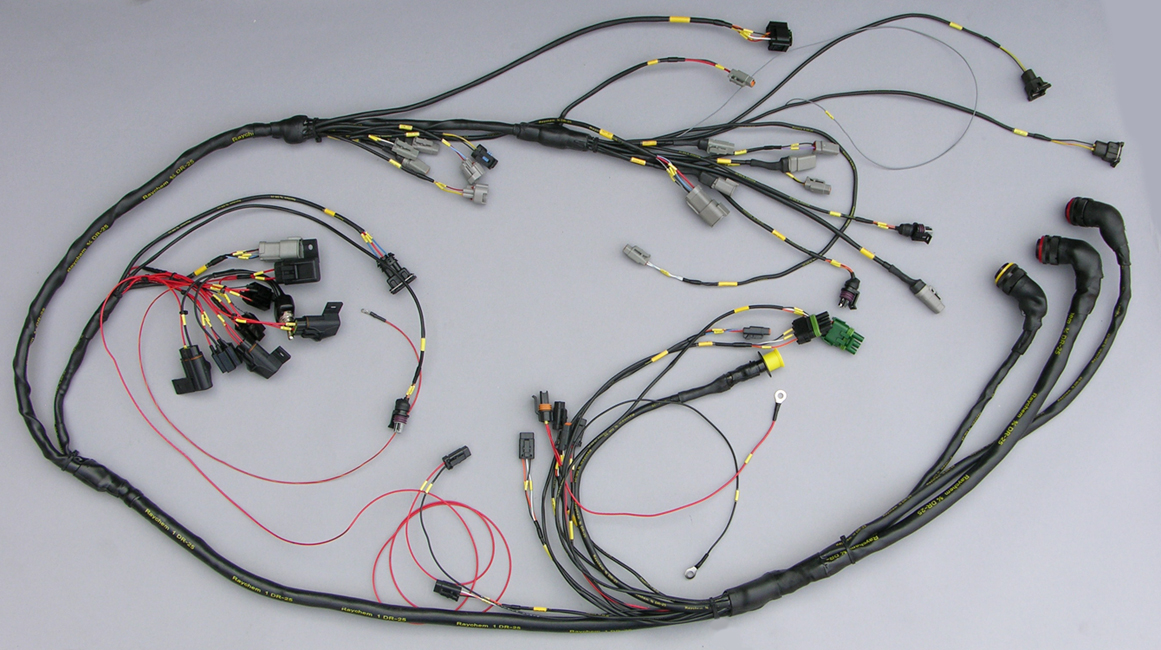

Wiring

Harness

Connectors

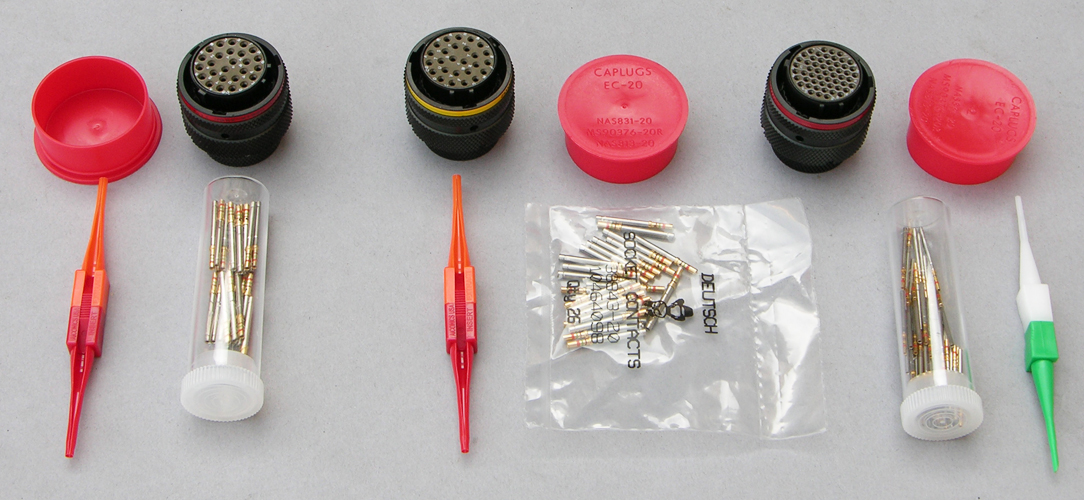

These three connectors for the Bullett wiring harness are about $500.00. There are a total 49 connectors in the Bullett's Wiring Harness. These three are Deutsch Autosport Mil-Spec connectors for the Cosworth Pectel SQ6M Engine Management System (ECU). There are up to 131 wires in the wiring harness for the various sensors. All of this does require a bit of planning and specialized tooling. The salt will try to eat everything and the harness needs to be completely sealed.

The

Bullett's

wiring harness

has 49

outboard

connections

with up to 131

wires

slithering

here and

there. Because

of the

environment at

Bonneville

everything is

sealed to

prevent

corrosion. It

takes more

about 200 or

more man hours

to plan and

build the

harness. This

involves

creating 20Mb

of

documentation

on how the

harness is

constructed

down to each

individual

pin, socket,

connector, and

wire as well

as the

specification

of every

component and

internal

diagrams of

all the wires.

You figure Mike Geokan and Bryan Stock documented 3000 man hours over a 25 year period building the Bullett and then add items like the wiring harness and the 139" watercooled Turbo Orca Motor and RB Racing's fabrication. including all the travel exceeding 3000 man hours on top of it all. It does require a bit of determination mixed with insanity and little appreciation of how far it was down when you stepped off the ledge. Hell of a trip.

This

harness never

made it on the

Bullett. The

plan was to

return to

Boise after

SpeedWeek and

update the

harness. But

plans changed

and the

harness

returned to

Los Angeles.

Nice practice

as we say.

2017 SpeedWeek

Documenting

the

scene at

SpeedWeek.

Disrupt your

whole life

tilting at

windmills and

end up with a

few pictures.

No raceable

salt, so it

turns into a

photo-op. For

many that is

all they

want...a photo

for the bucket

list. Others

will see the

pictures and

add it to

their bucket

list...Unaware

of the lack of

a raceable

long or short

course. Sooner

or later you

will find it's

always one way

street where

you get to the

dead end and

are left with

thousands of

hours for zip

and often

destruction.

Understand

this before

you click the

shutter. Some

die. Photos

left to lure

the seekers of

fame.

Our

involvement

with

Bonneville

goes way, way,

back...As far

as 1958... Not

so for those

newly climbing

on board

wide-eyed and

full of

enthusiasm...volunteers

for the cause.

The

Bullett crew

was fighting

the worst long

course track

we or any

other

competitor had

ever seen, a

blown trailer

tire (rotten),

and a broken

wire in the

Bullett's

Fly-By-Wire

system.

Waiting times

on the Long

and Short

Course was 5

to 6 hours. We

worked on the

Bullett's

programming

hoping to get

some 200 mph

passes in the

bad course

conditions.

There was some

issue with the

bike that was

not resolved

as the same

exact

programming we

had run at

194mph with 19

psi under

closed-loop

boost control

at

194mph+

at the 2016

SpeedWeek

suddenly acted

lean.

Apparently

there was a

hose

connection

venting

pressure but

time ran out.

You can't

reprogram an

air

leak...something

the unintiated

do not

understand.

Mike

Geokan

declared the

problem to be

a bad ignition

coil as he

said that's

always the way

a bike acts

with a bad

inition coil.

We told him it

was not the

coil. We had a

spare Bosch

Motorsport

Coil. It was

installed. No

it wasn't the

ignition coil.

When it pops

and bangs and

does not make

boost you tear

it down and

find the

plumbing leak.

No point in

that the track

was shit.

John

Munro Burt

Munro's Son

(Left)

2017

SpeedWeek...Meeting

Burt Munro's

son, and we

got to

exchange lies

and tall tales

about

motorcycles.

His tall tales

were

better..like

riding through

town in New

Zealand at

full throttle

standing on a

motorcycle

seat running

all the lights

all the way to

the harbor.

We

countered with

a 1985 story

about exiting

the salt on a

twin turbo

Suzuki going

135 mph back

up the access

road and then

realizing we

had no brakes

and a 90

degree left

hand turn was

coming up. Of

course we

died...Plus

financing a

trip to visit

the ladies in

Wells.

Mike

Geokan who

started the

Bullett 25

years ago and

who had been

supported for

over 27 years

by RB Racing

who designed,

tuned, and

manufactured

the turbo

system on his

record holding

#226 bike was

finally able

to attend the

event post a

VA operation,

and spent the

week being

negative and

ended with a

vacuous,

childish

threat at

Thursday

dinner to

shoot the

author of

this. I

promptly

reminded Mike,

face to face,

"To be careful

what he said

and that the

only reason he

ever got any

record at all

was that we

designed,

manufactured,

supported,

paid for, and

tuned his #226

turbo system".

He

had zero

success off

and on for

over a decade

until we did

so. Childish

self-absorbed

actions. We

thought he was

a better man.

We were wrong.

Character

always shows

up sooner or

later.

We

simply removed

our Cosworth

Pectel SQ6M

electronics,

wiring

harness,

fly-by-wire

system and

completely

ended our

support...Loaded

up and drove

back to LA

that Thursday

night. Over.

Done. A few

suggested we

stay the night

as it was

late...Not one

minute longer.

An all night

drive. Piece

of cake

compared to 4

days of no

sleep in 1977

on another

race project.

We donated in writing:

The 139" water cooled ORCA engine, 8" Carrillo-Shaker rods, Delkron FXR Transmission Case, Jim's Fat5 Transmission, Barnett Billet Primary Cover, Sintered Lock Up Clutch (paid for by Carl Pelletier), Air and electric Shifters (4 versions), all turbo components, two Garrett turbochargers (one and second center section), Six Goodyear LSR tires $4,000.00 (Shaved and Balanced), Miller Econo TIG welder and Argon tank, 24' Haulmark $6500.00 Race Trailer, one Dodge Van we bought for $1,500.00, a $3,000.00 water-cooled Honda generator, air compressor, SnapOn hand and diagnostic tools, Steel table and Vise, Snap On Tool Chest, $2,500.00 worth of promotional books, and all support equipment to the team...plus many LSR 2-1 exhaust systems for the cause as they say. 10 years worth. Machined and anodized from a 30lb 7075T6 billet a sealed lock up clutch hub. Machined and anodized from billet a 7075T6 jackshaft assembly with gilmer belt drive vacuum pump. Three complete mil-spec wiring harnesses made for the bike (since removed)...One for initial running a with the RSR EFi System and two for the Pectel electronics totaling about 500 man-hours for planning and execution for the 45 outboard sensors and components. All in all about $100,000.00 in time and money expended over 12 or 27 years depending on when you start counting. One Twin Cam engine for Bryan Stocks Chopped Dresser and One CVO2 Evo motor for Nick Stock, Bryan's son.

Thousands of hours of time. Over 50,000 miles of driving and flying to and fro L.A. to Boise and Bonneville.

Each

trip L.A. to

Boise to

Bonneville to

Boise and

return to L.A.

was 3,000

miles.

Used

to stay with

Mike while in

Boise...Then

after he

unintentionally

locked his

house and went

to bed after

we had driven

13 1/2 hours

(twice)...and

we had to stay

at a flea bag

motel. After

that we stayed

with Bryan

Stock while in

Boise. You

don't go for a

third strike.

We

did get a 25

year

appreciation

plaque for

supporting

Brother Speed

from Brother

Speed's Nampa

chapter's

Bugsy. Nice

gesture and

much

appreciated.

Two

bikes #226 and

# 8228, two

records..decades

apart..All

with zero

testing. Just

theory. Try

that with zero

testing bippy.

Three

years to get a

200mph record

with the

Bullett...all

the way from a

bare frame

with rotted

tires..Sorting

things out,

getting Bryan

Stock his long

course license

( 150, 175,

200mph) and

seat time.

Mike tried for

a record from

the mid 80's

with his #226

Blue Bike and

only got a

record after

we

turbocharged

his bike in

the late

1990's...more

than 10 years

later. For us

it was full

time job 865

miles away

from

Boise...back

and forth.

13.5 non-stop

hours each

way...all

nighters.

Untold # of

trips. Staying

at Bryan

Stock's home

added another

30

miles...i.e.

lots of 900

mile days.

Generally

about 3,000

miles if all

the loops La

to Boise to

Bonneville to

Boise to

LA often

two times or

in some cases

3 times per

year.

Mike

and Bryan got

the frame and

body

ready...We

filled it in.

Mike figured

2000 man

hours.

Interesting fact: Fred Wiley, Brother Speed (200 mph club Member 1992), Bryan Stock Brother Speed (200 mph record holder for 5 years..2011-2016); and Mike Geokan, Brother Speed 196 mph record holder were all at SpeedWeek 2017. All their records set on RB Racing Turbos built and tuned by RB Racing. Fred was there this year on a BMW Airhead with a 36 year old RB Racing BMW turbo kit looking for a new record but conditions were terrible. There's some sort of common thread there.

No RB

Racing...no

records.

Period.

Multiple

people. Time

after time. No

spark no

flame.

In

2016 Mike

asked us what

the Bullett

was

worth...Our

answer was

that race

bikes were

worth either

nothing or

whatever some

fool will pay.

When asked

"why" he

stated that

when he died

he was going

to leave his

motorcycles to

his daughter

with a special

needs child

and his house

and property

to his then

girlfriend.

Biker. Mike

always said he

was looking

for someone to

act as his

nurse.

When

Mike spent

$46,000.00

upgrading his

home, by

refinancing

his $25,000.00

home he had

never paid off

in 25 years

still owing

most of the

purchase price

and building

his girlfriend

a Shovelhead

from scratch

for $8,000.00,

rebuilding a

Pan Head

Chopper for

even more

money

including

$1,800.00 to

chrome the

front forks,

and wasted

$5,500.00 of

Benefit

donations on a

useless old

POS Dually

truck...Did no

testing, and

turned down a

dynamometer

that RB Racing

negotiated a

deal for

$29,000.00

(for Bryan

Stock's shop)

versus

$45,000.00 and

never checked

the Race

Trailer's

tires (they

rotted) that

he walked by

everyday, and

couldn't

manage to keep

12V Batteries

charged...All

while others

spent their

money and

effort on his

race

bike...Well

that qualifies

you as an

expert. Just

start writing

checks.

Mike

however, will

not spend any

of his money

...He whines

and says he

has none (VA

100%

Disability

pension and

Social

Security). We

asked him if

he had a

choice of 100%

health or the

two guaranteed

income

streams...He

did not

answer. We

asked him

where his

checklist was

for the race

bike...none.

He

will continue

to get others

to pay and do

the work. His

dream. Your

pocket. All he

has to do is

wake up

another day

and drive down

to the local

eatery for

breakfast and

lunch. Biker

ethics...me me

me. He will

tell you he

knows how the

Pyramids were

made...but he

cannot produce

a checklist

for the race

bike...We even

made a color-

coded wiring

diagram as

none existed

for the wiring

Mike had done.

Who is

responsible

for what? Lots

of people to

help you have

zero

knowledge...not

the definition

of a crew.

Each

year we would

show up and

find salt and

corrosion from

the previous

year. Very

comforting.

Corroded

relays, salt

still in

crevices on

the bike, open

frame tubes

holding

salt-water

solution

inside. Dead

battery. We

ended up

bringing a

Yuasa AGM

battery.

At RB

Racing we had

lot of nice

people

involved from

all over the

world from as

far away as

Great Britain

and China (no

joke) as well

as in L.A. and

Idaho. Just

one to spoil

the mix. Mike

did not thank

anyone at

SpeedWeek, nor

at the 2017

Benefit for

helping out.

Not one "thank

you" for the

effort to get

the Bullett on

it's feet all

the way from a

rusted bare

frame with

rotted tires

and a 200 mph

record. Ego.

Bryan Stock

told him he

had to

apologize for

that. Hope he

did.

As

for rotted

tires and the

rusty, bare

frame...RB

Racing spent

$4,000.00

alone on

Goodyear LSR

tires. The

tires Mike

Geokan

originally

chose were

wrong...a

square, hard

to drive,

front and a

rear that was

a drag racing

tire, not an

LSR tire. Tire

pressures for

drag and lsr

tires are

vastly

different...40

v 70. We got

all that

straightened

out, plus all

the tire

shaving and

balancing

issues here in

L.A. by Nates

Cowboy Tire.

It's

interesting

how egos are

large and

memories are

short. Memory

gets a bit

variable over

time when

basking in the

glory

pontificating

on your own

self

importance,

casting aside

the real

facts.

One's

character

eventually

rises.

Postscript

In

our long

involvement

with the

Bullett we put

an

extraordinary

effort into

building the

Bullett's

water-cooled

cylinders. The

problem with

these, aside

from the

week-long

final

fabrication

plus multiple

trips to Boise

to take

measurements

was that, if

they were

damaged, there

would be no

easy fix. Zero

spare

cylinders.

We

designed a

wet-sleeve

system, a la

the Diesel

World, and had

custom sleeves

cast and then

machined up,

from solid,

cylinders to

make dropping

in O-Ring

sealed liners

a long term

solution with

the $2,500.00

worth of CP

pistons we had

made up.

Expensive.

Lots of design

time.

As it

turned out we

did damage the

bores when

Mike Geokan

never cleaned

out the debris

in stainless

fuel tank

cutting the

fuel flow not

the pressure

and we burned

both pistons,

Carl Pelletier

of Competition

Motorcycles

honed the

cylinders and

put PEEK

buttons on the

4 3/8" ceramic

coated CP

Turbo pistons

to take up the

extra

clearance.

Filter jammed

with stainless

shavings. We

took the gas

tank off

ourselves and

cleaned it

while Mike was

watching TV.

These unfinished parts (two complete sets) remain as paperweights at RB Racing until Hell freezes over.

Pistons

for

these...no

spares either.

Our custom

design. We had

CP make

$2,500.00

worth of

pistons and

had then

skirts and

crowns ceramic

coated. Carl

Pelletier of

Competition

Motorcycles in

Boise did the

flywheel skirt

cuts.

Expensive.

Edith Piaf - "Non, Je ne regrette rien". It's what we do.

Addendum

2018-2025..Post

RB Racing

Support

The

Bullet

continues

without our

support.

RSR

EFi and

Cosworth

Pectel

electronics

and RB Racing

wiring harness

and Bosch FBW

throttle

system were

removed.

Brother Speed

had to up the

money (not

Mike) for a

Haltech ecm

and wiring

harness,

instrumentation

and additional

fabrication.

Start from

scratch.

Post

RB

Racing

Involvement:

Bonneville

2018 / 19 / 20

/ 21 / 22 / 23

/ 24 / 25

Bullet has

multiple

issues and has

never again

made it into

impound...Barely

cracking 180

mph a few

times...30 mph

short of a

class record

and 50 mph

short of a 200

mph Club Red

Hat. Lots of

money spent.

Lives

disrupted for

zero results.

RB Racing went

from not

turning a

wheel to

licensing

passes and a

200 mph record

in 3 years.

Without

RB

Racing

dropping

$2,500.00 for

motel rooms

and picking up

dinner and

breakfast tabs

not as many

people can tag

along for the

show.

All slower than anything we did or paid for in a long journey starting in 2008. No spares. No checklists. No Dyno testing. No results.

Dreams

die hard. It's

a blood sport.