![]()

Clutch Technology & Clutch Torque Calculator

Mother Knows Best

Your stock clutch is perfectly fine for the horsepower of a stock engine. Perfectly. "Upgrading" the clutch for a stock or mildly hot-rodded engine is a waste of time, money and effort. Buying wazoo materials promising great improvements only buys you an inferior product that doesn't have the manufacturer's R&D that usually insures grab-free, trouble free, long life performance.

Pressure

In the early 1980's when we started turbocharging Harleys we quickly discovered three things. First, the tricko Kevlar/Ceramo-whatever plates did not work as well as the oem plates. Secondly, we found that the stock clutch held up well through about a 50% increase in power. Thirdly, we found that elevated power levels with high boost caused any clutch to slip. With a fixed clutch pressure from the stock springs or diaphragm, the ability to "hold" is directly related to the number of friction plates. The obvious solution was to "add more plates". This only worked to a point, and adding more plates only added to width and weight.

"We've got to move these color TV's"...Dire Straits

Companies like Bandit , Rivera and Barnett as well as others, added plates and stiffer springs to meet increased horsepower requirements. Stiffer springs meant lever effort went through the roof as the horsepower requirements went up. Hydraulic actuation became necessary to get around the limits of the oem direct cable pull system. Anodization and billet construction kept the magazines writing articles and the racers ran the heaviest stiffest most expensive parts they could buy. Badge of honor. Credit card to identity.

Centrifugal Lock Ups

In 1977, before we were turbocharging Harleys, we were racing Z-1 Kawasakis, in both 24 hour endurance and turbocharged drag racing. Same drill. Extra plates, stiffer springs, hunting for spark plug washers in the pits to increase spring preload...nothing worked. Solution: copy a Crowerglide and create a lock-up clutch. To this day, unless you put a lock-up clutch on a high power in-line turbo bike, the clutch is going to disappear.

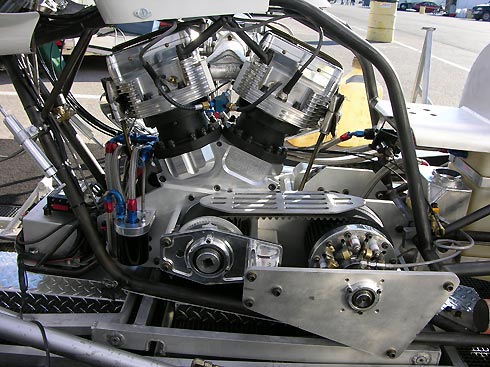

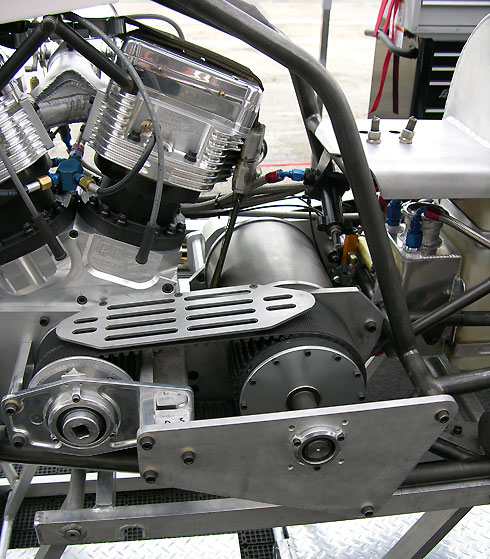

Guess what? Big Nitro burning Harleys have been running versions of the original Crowerglide in one form or another for a long, long, time using belt primaries with outside support bearings. As the clutch was riding under the belt it tended to actually melt the drive belt to the pulley as the sintered iron plates literally go red-hot. Recently, these clutches have started to move inboard away from the heat and the thin Sportster style steels and sintered iron friction plates are being replaced by thicker car type slipper clutches.

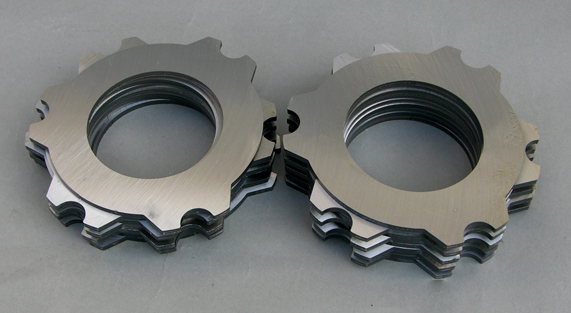

We made up these "steels" for Carl Pelletier's new inboard clutch. They are double disc ground to a bit under .250". You need mass to take the heat. Thin plates will simply bond to the sintered iron frictions, Carl will set the clutch pack and "mike" it after every run and make any adjustments needed based on track conditions and read-outs from the RacePack data acquisition system.

Carl ran some initial tests at Woodburn and then made some longer fingers from tool steel. The new clutch was tested at Pomona on Nov 2007 and Steve Heidner made some easy 7 second passes to gather some data for Las Vegas. No more melted belts.

He will not, however, have to put in a new clutch pack with thin steels and thin sintered iron plates every run, nor will he worry about melting the transmission pulley to the Top Fuel belt drive. Adjustments are made with feeler gauges from underneath the bike. The clutch is wrapped in a titanium shield upstairs.

Now, 30 years later, lock up or centrifugal clutches are suddenly the rage in the Harley market. Companies like AIM-Tamachi, Rivera, Bandit, Barnett, Belt Drives and others are all offering some form of this old design. It is a somewhat elegant solution to keeping lever effort low and clutch pressure high.

For high horsepower you still need to balance the weights, the springs and the frictions to achieve a result. If you have a normally aspirated big inch big twin then this is a good solution. There are parts to wear and pivots and pressure points best be well-engineered. There are limits to this technology and we are still dealing with a stock clutch design lurking beneath the spinning weights and levers.

Various Materials Used in "Clutches"

Hey, this isn't rocket science, but we should give you some data to think about. Remember what we said about stock clutches being a pretty good deal before you peel out your credit card to buy some other trinket for your sled. First up is friction materials. Not a lot of choice here, the science is pretty well known.

You can see that your Harley has an achilles heel, at least for high, mega horsepower applications, because it is "wet" and running in a primary drive oil bath. This radically reduces the coefficient of friction or the ability of the clutch to "hold" horsepower. This means, even with a new fangled lock-up lever and weight assembly, a wet clutch is limited by a factor of 3 to 5 to that of a "dry" clutch. Now you know why nitro burning Harleys never see a wet clutch.

Running a dry primary with a belt drive is a way around this and "dry" clutches have a torque advantage. Of course you have an open belt to deal with, it's something to injest rocks, small birds, and fingers. If you like to make left hand turns the additional width can be an issue. At Bonneville the width equates to increased frontal area which is a top speed no-no.

Clutch Design

Single plate clutches have lining on both sides of the plate. Multiple plate clutches have friction linings on both sides of alternate plates with "steels" in-between. In multiple plate clutches the number of plates must be multiplied by the number of friction faces to find the torque for the entire clutch. The above photo is a Tilton 3 disc sintered iron clutch.

Basic Racing Clutch Design

Clutches link the engine to the transmission via friction surfaces that can be engaged or disengaged via the clutch lever, either mechanically or hydraulically. Below is a drawing of a typical automotive racing clutch.

Typical Friction Materials (No K-Y)

For a clutch operating dry, the coefficient of friction will normally be in the range of 0.25 (organic); 0.32 (ceramic); 0.40 (sintered iron); and 0.50 (carbon-carbon). Tilton 3 disc carbon-carbon clutch shown above.

For clutches running in oil, the coefficient of friction will typically be in the range 0.075 or higher.

Sintered Iron and Carbon-Carbon cannot be run "wet".

Example Calculation

Example 1: A single plate clutch (2 friction surfaces) can operate at a maximum lining pressure of 1 Newton/mm2. The inner diameter of the lining is 140 mm, the outer diameter of the lining is 200 mm and the coefficient of friction is 0.25. If the clutch is dry and operating in the uniform wear mode, what is the maximum torque that can be transmitted and the required normal force. The answer is 413 foot pounds. Sintered Iron and Carbon-Carbon cannot be run "wet".

Example 2: Quartermaster clutch above wih 5 friction surfaces with an o.d. of 142.6mm and an i.d. of 99 mm. Running dry with a coefficient of friction of .32 (ceramic frictions) and a pressure of 2 Newtons/mm yields a torque capacity of 967 foot pounds.

Example 3: A 1989 Harley Evo with a .5 Newtons/mm diaphragm spring with friction diameter of 153mm o.d. and 134mm i.d. with 6 plates (12 friction surfaces), running in oil with a coefficient of friction of .075 yields a torque capacity of 95 foot pounds or enough capacity for up to 108 hp @ 6000 rpm.

Harley Clutch Dimensions

| Model/Year | O.D. Friction mm | I.D. Friction mm | # Plates |

| 1984-1989 Big Twin and Sportster | 153 | 134 | 6 |

| Late Model Big Twins 1990 up | 139 | 119 | 8 |

| 1984- 1990 Sportster | 149 | 129 | 7 |

| Rivera Pro Clutch | 138 | 107 | 7 |

|

||||||||||

|

||||||||||