LSR Mega Megs

The Original Radical Slash-Cut Megaphone! The Ultimate Show And Go!

(P.S. We don't make these anymore)

LSR Mega Megs - Hollywood and Attack of the Killer Clones

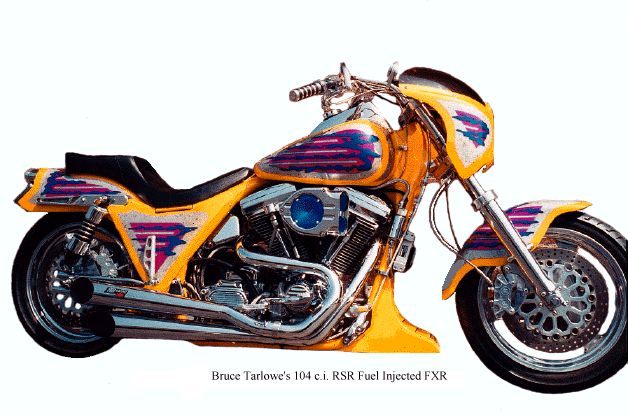

We originally built these designs to be used in the movie "Harley Davidson and the Marlboro Man" starring Mickey Rourke. They didn't make it into the movie but they seem to have been copied by everyone who saw the few sets we made.

Instead of making the same design which was conceived only to put "acres of chrome" on the bike and to be dramatic with its severe angle-cut 4" megaphone, we decided to dump the 1 3/4" primaries for Evo Big Twins and only produce Mega-Megs with 2" primaries and our exclusive CNC machined Turbo Venturies .With the increase in primary tube diameter, these pipes work damn well. We designed these pipes to make a maximum dramatic statement that would set your Harley apart from the crowd. If you can handle the attention, LSR Mega Megs are the ultimate!...a chrome boom-box to serenade the populace.

If the competition was going to copy our originals, they might as well copy only the 1 3/4" designs! If you're really observant you'll notice that we've tucked the front pipe back on top of the rear megaphone's centerline...this insures the angle cuts match each other. For you assholes without an original thought this is the next thing to copy.

LSR Mega-Megs are available in two styles: Mega Meg Duals and 2-1 Mega Meg Singles. If these designs make the statement you're looking for, them you can't get a better pipe. For you Shovelhead and Evo Sportster fans, LSR 2-1 Single Megs are available with 1 3/4" primaries. All LSR Mega-Megs feature triple-plate show chrome and are fully Heliarc welded for maximum strength and flawless weld quality. Dual Megs are available for Evolution Big Twins only.

Harley-Davidson and the Marlboro Man

Mike Geokan stole the exhaust flanges off of Mickey Rourke's movie bike when we built his Blue Bike turbo system. We made three sets of pipes for the movie bike: a set of megaphones, some 1 1/2" primary duals (for the movie), and a set of 2" duals after the movie was shot. The bike was sitting there and Mike needed the flanges. Oh yeah, the 1 1/2" primaries didn't work worth a shit but they did "crackle".

Bartels Harley Davidson's Dave Fournier built the bike. We left the 1 1/2" primaries on the 98" motor for the movie. Before the movie dudes picked up the bike the cops gave us about a half mile chase while testing the bike before we eluded them by pulling a U-Turn and cutting through a gas station and made it back to the shop. They figured out where we were and three partol cars and a Lieutenant later we let them see Mickey's registration and they mellowed out. Cops like Movie work...it's easy money sitting around sets and eating catered food.

We made a few more sets of the Dual Megs for Bartels before Bill Bartels ripped us off. We got even though and later on Bill called it a draw. Water under the bridge. The dual megs were meant for the movie...flashy and eye catching...but not really Harley items although even Harley adopted the style in their V-Rods. Everyone copied them...They really don't work as they were just for show. We sold a few then went back to the 2-1's.

Dave Fournier exited La La Land moved on to Arizona and continued his infatuation with Railroads and locomotives.

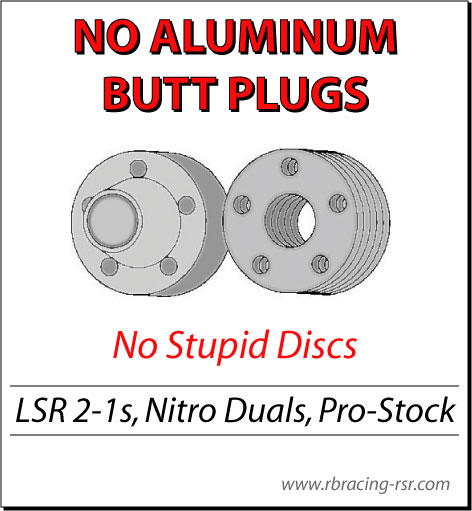

Baffling Alien Discs and Aluminum Butt Plugs

Our testing has shown that the Harley V-Twin is extremely sensitive to back pressure which is why 2-1's that use small or restrictive collectors don't breathe well, and why restrictive baffles shut the motor down. Disc type baffles are good for spark arrestors on dirt bikes but they have no place on a big inch V-Twin. You don't make power by adding restrictions to your exhaust system whether it's a bunch of stainless discs or some damn piece of aluminum billet machined into a Harley butt plug! Ever wonder why they had to put a hole up the center of the discs? Well, one reason was the discs are so damn restrictive you have to have several pounds of them to get enough flow through their waffle shaped passages. Good mufflers, but they have nothing to do with performance and they sure as hell do not create vacuum as has been claimed. LSR Mega Megs use large 2" louvered cores which are welded in place that do not have any internal "shelf" to disrupt flow. These pipes will flow enough for even the biggest motor. With the baffle welded in place there won't be any Aluminum Butt Plugs bouncing down the freeway. When you get confused by all the bullshit simply ask the following question.." Do they run them in NASCAR or in Formula One?". Nope, they run straight pipe collector systems without any stupid discs or aluminum butt plugs.It's always funny how when the money is on the line, all the little things like discs, billet caps, anti-reversion flaps, reverse-lip megaphones and other such nonsense somehow don't make the field.

Click on photos to enlarge

Bonneville Proven

LSR stands for Land Speed Record and that means only one place...The Bonneville Salt Flats, the Great White Dyno. We have the only gas powered street legal bikes over 200 mph and we're damn proud of it. RB Racing doesn't race typewriters, we race motorcycles and when someone says they get a 70% gain from their system, ask them for their 200mph Bonneville Records or any records for that matter. Hell, if we raced typewriters it sure would be a lot easier, not to mention cheaper.

We place an LSR tag on each exhaust system we make so they can be easily identified. Every now and then over the last twenty plus years someone decides to copy one of our designs, usually because some customer is very happy and he "stirs up the pond". They copy the general look but not the features that make them work. The tags eliminate any question about whether it's an RB Racing design or not and allows people admiring your bike to know the pipe's origin. The tags have proven to be very popular and have been used since 1992. Every now and then someone asks us to not place the tag on their system to which we answer..."send us an affidavit certifying that you have removed all manufacturer logos from your tires, engraved Performance Machine logos from your brakes, Mikuni or S&S identifications from your castings, Harley identifications from your gas tank, Nike logos from your tennis shoes etc. and we'll consider it". The last guy we let talk us out of this was getting his bike in Hot Bike magazine and said he'd give us "credit" for a one off pipe we designed. When the magazine appeared on the newsstand all we saw was "computer designed pipe by Sands Racing". That was the end of that.

New Cloisonne Tags

Like in the adage "The relentless search for perfection" we have upgraded the logos we put on our LSR Exhaust Systems. Previous tags were stamped and formed aluminum with silkscreened details. The new cloisonne tags are a precision die struck brass, nickel plated, with powdered glass fired in an oven then polished to a jewelry finish. These are direct replacements for our older tags and are available for US $20.00 via US Global Express (foreign) or Priority Mail (domestic US). They come with black headed rivets and are riveted in place with a light coat of high temperature silicone (Permatex 598B) behind the tag.

All RB Racing LSR Exhaust Systems feature our "new" (we've been quietly doing it since 1985!) CNC machined Turbo Venturies that actually "scavenge" to help your motor breathe. Machined from billet, these allow full 2" flow and eliminate the phony restrictions that other 1 3/4" to 2 1/4" pipes have at your exhaust port.

Our competitors must think you won't notice that they neck their 1 3/4" to 2 1/4" pipes down to as small as 1 1/2" to mate them to your exhaust ports. RB Racing's Turbo Venturis are expertly heliarced to each primary tube eliminating any internal obstuctions and insuring the maximum flow from each exhaust port. RB Racing won't build phony performance pipes...We sure as hell won't ask you to port your heads, put in bigger valves and a high performance camshaft then stick a bunch of stainless steel discs or machined aluminum butt plugs in the pipe to restrict the flow! And we damn sure won't put some silly "1950ish" reverse megaphone pipe with internal flat plates, baffles and air foils to screw up your performance. Our pipes make anywhere from 6 to 18HP over these stupid designs.

All LSR 2 into 1 exhausts require special close tolerance aircraft nuts to bolt the LSR Turbo Venturis to the exhaust port. Standard 5/16" x 24 hex nuts will not fit. Each exhaust comes with the required four nuts. It is recommended that you order an extra set (4) of these nuts, part number 00-1001, when you order your exhaust.

Our CNC machined Turbo Venturis are not compatible with the "bowl-shaped" late model OEM exhaust port gaskets and require early style "flat" gaskets for the LSR Exhaust Systems to both fit and seal properly. The narrow machined flat face of the Turbo Venturi must seat against a flat suface, not the bowl-shaped late model gaskets. Using the LSR Exhausts in combination with the wrong gasket will cause misalignment, inability to tighten the provided close tolerance aircraft nuts, and will force the bowl-shaped gasket into the exhaust port. The correct gaskets to use are: Harley OEM 65324-83 or Drag Specialties DS 174742.

Optional for a nominal charge of $ 9.95 are a pair of our LSR CNC machined gaskets which mate perfectly with our Turbo Venturies. These are proven in over 16 years of use on our race and turbo applications...the only gaskets that will stay in a turbo bike for 25,000 miles! These gaskets prevent any gasket "creep" into the exhaust flow and are one more thing that will give you "an edge" on the competition. We always wondered why people would port their heads, put in bigger valves and then squish the gaskets into their exhaust ports. We bet you never paid attention to what was going inside your exhaust ports for one very simple reason...you can't see what's going on in there once the pipe is tightened! The LSR CNC machined gaskets also insure perfect alignment of the exhaust system. Most fitment and alignment problems are traced to using either the wrong type of gasket or using old gaskets that have taken a "set". We've always used these on our race applications and it's time everyone who's concerned about performance should do the same.

All RB Racing LSR exhaust systems come standard with a machined and heliarced oxygen sensor boss just below your front exhaust port. This port is designed to accept and oxygen sensor (18mm x 1.5mm) which will allow you to use our RSR Air/Fuel Ratio Meter to tune and monitor in real-time your air/fuel ratio. Also, if you really wish to get 55mpg and kick ass, our RSR Fuel Injection's closed-loop heated O-Sensor will plug directly into this port.

Custom Made for Your Application

Every LSR Exhaust is custom made for your particular application. We can handle offsets for wider frames and even build "taller" pipes for those applications that have cylinders that may be 3/4" or more taller. No wire feed bubble gum welds! All LSR Exhausts are fully heliarced for the cleanest possible appearance. It takes five times longer and is much more expensive but itis the best way to do it.

Chrome or Black: All chrome is full automotive grade duplex nickel, triple plate; Black finishes are a two layer process with an underlying alumina ceramic covered with $200.00 per gallon satin black. "Black" pipes are fully polished as if they were to be chromed to remove any surface defects, then are blasted, ceramic coated, baked, tumbled, cleaned, shot with black satin and then baked a second time to complete the process. We've tried everything you can think of and these are the best finishes.

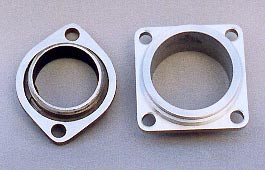

RB Racing LSR Exhaust systems are now available for S&S Cycle Special Application "SA" heads with 2 inch diameter primaries. The standard SA exhaust valve is a whopping 1.75" diameter with a special (non standard) exhaust port configuration. These are the best production castings going with their raised inlet and exhaust ports. Oh, you can fool around with the usual porting bullshit, but you'll end up where these castings start out in terms of cfm. Progress is progress and year to year the only horsepower gains come when you make the cylinder heads more efficient. The problem with the SA heads is that nothing fits their four bolt pattern and the shallow non-standard pocket is decidedly bigger than anything sitting on the shelf...stock flanges need not apply! S&S figures you are going to fab your own exhaust so they provide a machined spigot that slips through the four bolt flange. The idea is that you get some springs and make up a slip joint and go creative...this doesn't work on street chassis.

Compare the oem size exhaust flange on the left that is used on "billet" motors with the "SA" flange on the right...get out your calipers and see what's holding these other motors back. RB Racing is familiar with these four bolt critters as we use them in our 113" RSR Fuel Injected ORCA motors both turbo and normally aspirated. For our 113" ORCA motors we use cnc machined special Turbo Venturis that capture a laser cut four bolt flange and are in turn heliarced to our 2" LSR primaries. The Turbo Venturis flow 8 to 12% more than a straight section pipe.

If you have a set of these "SA Heads" and want a specific exhaust be sure to tell us at the time of your order. Adding an "SA" suffix to a listed part number will do the job. Remember they are only avaiable for LSR 2" primary designs.