LSR Megaphone Exhausts

(Discontinued Long Ago)

Here's a 1980's Harley-Davidson EVO Softail

with a RB Racing LSR 2-1 Mega Meg Single Style "B" 2" p/n

00-1081 (discontinued). Handmade merge collector mated to 2"

primary tubes. Expertly heliarced with RB Racing's Turbo

Venturies and a straight-thru non-packable welded-in baffle.

No aluminum butt-plugs or phony anti-reversion

bullshit.

These Megaphone designs were discontinued in

the mid to late 1980's. Our testing at the Orange County

drag strip was thumbs down. Our Turn Out and Slash Cut pipes

with 3", non-tapered tails, worked far better...better

E.T.'s...better MPH...better sound. Win. Win. Win.

LSR 2-1 Designs...This Works

Our testing has shown that the Harley V-Twin is

extremely sensitive to back pressure which is why 2-1's that use

small or restrictive collectors don't breathe well, and why

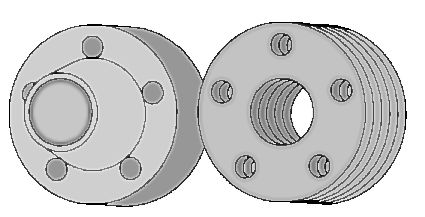

restrictive baffles shut the motor down. Disc type baffles are

good for spark arrestors on dirt bikes but they have no place on

a big inch V-Twin. You don't make power by adding restrictions

to your exhaust system whether it's a bunch of stainless discs

or some damn piece of aluminum billet machined into a Harley

butt plug!

Ever wonder why they had to put a hole up the

center of these discs? Well, one reason was the discs are so

damn restrictive you have to have several pounds of them, 25 or

more, to get enough flow through their waffle shaped passages.

Good mufflers, but they have nothing to do with performance and

they sure as hell do not create vacuum as has been claimed.

All RB Racing LSR 2-1 exhausts have a bypass area equal to the I.D. of

a 2" primary tube, or greater, in terms of our Pro Stock

Systems.

"Baffles" are designed for flow and are not meant

to be altered for "tuning".

No Machined Aluminum &

Fluted Butt Plugs

No Removable Baffles...

When you get confused by all the bullshit simply

ask the following question.." Do they run them in NASCAR or in

Formula One?". Nope, they run straight pipe collector systems

without any stupid discs or aluminum end caps / butt plugs. It's

always funny how when the money is on the line, all the little

things like discs, billet caps, anti-reversion flaps, reverse

megaphones and other such nonsense somehow don't make the field.

Stepped Headers..Are For Clowns

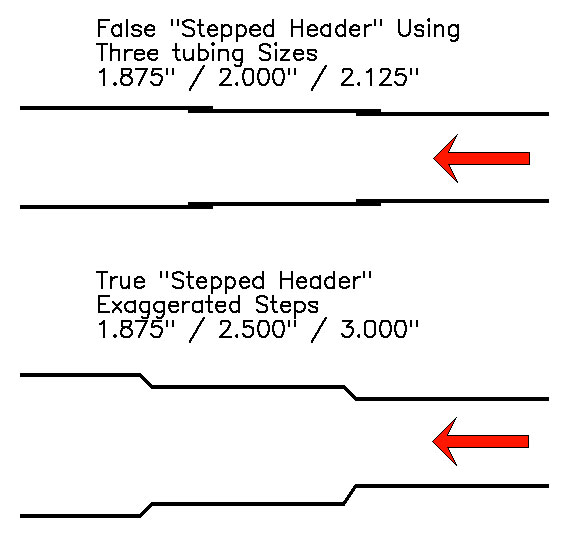

An interesting issue is the buzzword “Stepped Headers". This is a situation that is sort of like a runaway train in a Hollywood movie with John Voight at the controls...It is hard to stop and question it once it gets rolling. What we really need to think about are the volumes and any changes inside the primary tubes. A stepped header made of of three, four, or five next size up tubes, welded together, is just a marketing game.

Simply welding together

"next size up" tubes to produce "steps" leaves 90 degree ledges

that disrupt flow and cause turbulence affecting the mass flow

rate...not exactly what people claim.

True "steps" use a

tapered step which must be experimentally derived as to the

angle, location in the system, and size of the step. In general,

the purpose is to get a secondary reflection at a specific rpm.

At the highest level of motorsports where these are used..only one step

is employed as with multiple steps the reflections tend to

cancel out each other.

For Harleys you need to understand..."Stepped

Headers" as are currently marketed with up to five "steps" are

basically bullshit, conjured up with no scientific verification,

no testing whatsoever, and are just designed to get your

hard-earned dollars. If you think multi-step headers were

developed before they typed up the hype you are mistaken.

A really long time ago we built an inlet manifold

for a BMW Turbo R100 that had the turbo compressor discharge

offset to the left of the center line of the inlet tube that ran

from the left to the right inlet ports. When the bike was run,

the shorter (left) runner ran richer than the right or longer

runner. Before we went to the dyno we cut off the left runner

and bumped the tubing size up a couple of steps...and guess

what, the spark plugs were perfectly equal on the Champion Spark

Plug dyno. We simply tried to equalize the volume and slow the

speed in the shorter runner. It had nothing to do with

steps...just the internal shape and volume.

Logic will tell you that, if your motor wants a primary tube

size of “x, say 1 3/4", to run the best, then it makes no sense,

whatsoever, to step this tube up to 1 7/8”, and 2” by welding up

some sections of three different size tubes. Think volumes,

internal shapes and do not fall for buzzword features like

stepped primary tubes..

No Thin Wall Stainless Reverse

Megaphones Without Heat Shields.."Pregnant Guppies"