RSR AIC400 Additional Injector Controller...Circa

1985

Note: these were discontinued

more than 15 years ago

Don't rip out the factory stuff

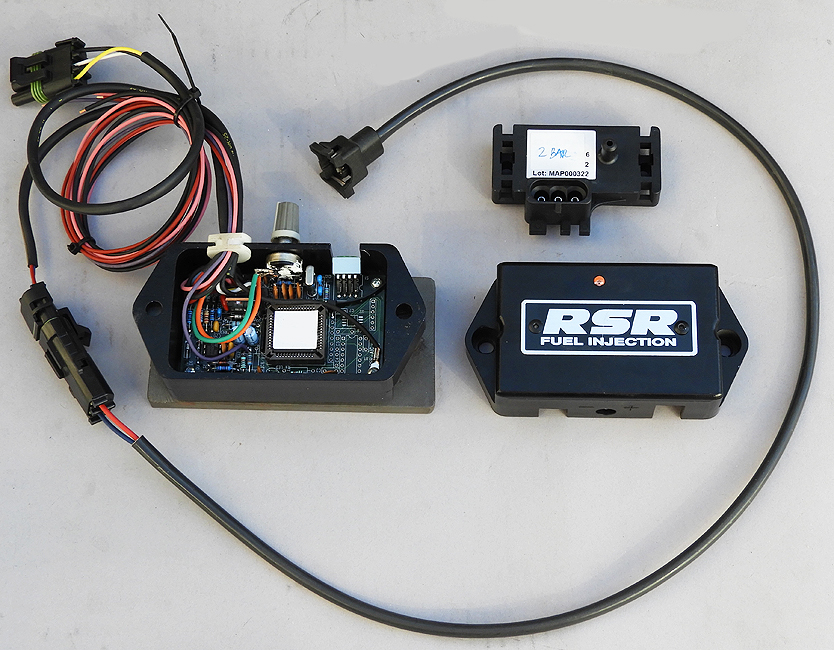

The RSR AIC400 is the answer to fuel control on fuel injected vehicles that employ turbochargers or superchargers. There is no need to rip out the factory fuel injection or emission equipment and there is no need to "reprogram" the stock computer. The OEM i.e. the factory that designed the power train has spent millions of dollars and thousands of man-hours to get your vehicle to run perfectly as possible under every imaginable condition...why in the hell would you try and outsmart them. Trying to reprogram your stock computer is a huge waste of time and money with no guarantees of success in spite of what others will tell you. A practical consideration is the need to have full OEM emission gear in place for smog checks...with the AIC400 you don't have to reprogram anything or go digging around in your garage for all the emission crap you ripped off in your quest for power.

RSR AIC400: Custom Programmed for your application

RB

Racing's RSR AIC400 simply augments your factory fuel injection

by

adding 1 to 4 fuel injectors to meet your engine's

turbo/supercharged

needs. The AIC400 is custom programmed for your application

based on

six parameters: (1) Your maximum vehicle rpm; (2) Your stock

peak

horsepower (you can supply a Dyno Chart); (3) Your expected peak

turbo/supercharged horsepower; (4) Your vehicle's fuel pressure

(Note:

no rising rate fuel regulators ala Cartech etc.!); (5) the

number and

size (use injector calculator and injector list below) of

additional

injectors you wish to run (1 to 4). (6) Whether you need a 0 to

10 psi,

a 0 to 15 psi, or 0 to 30 psi system.

When you order your AIC400 simply

add comments answering these six questions. For you to play

around with the numbers we have created an Excel spreadsheet

AicWeb.xls that you can ![]() download. Fill

out and email back to us the completed spreadsheet and we will

custom program and ship you the RSR AIC400 set to your

specifications.

Our experience after 30 years of this is that people do not want

to

fill out anything. In that case we cannot help you.

download. Fill

out and email back to us the completed spreadsheet and we will

custom program and ship you the RSR AIC400 set to your

specifications.

Our experience after 30 years of this is that people do not want

to

fill out anything. In that case we cannot help you.

Technical Issues

Fuel

pressure has to track manifold pressure in a forced induction

system,

i.e. fuel pressure has to remain constant relative to manifold

pressure.

In vacuum the pressure will be lower and as boost rises it

will rise

with the boost pressure on a one to one basis. If your fuel

injection

system does not reference manifold pressure you are going to

have to

change your fuel regulator. If you do not change the fuel

regulator as

the boost rises you will get less and less fuel delivery.

Do not use the incredibly stupid large diameter rising rate regulators that a favored by the technically impaired. These large diaphragm regulators exponentially increase your fuel pressure as the boost rises virtually insuring your fuel curve will be absolutely incorrect everywhere except one tiny little point...anything above or below this pressure ratio will be absolutely wrong. Fuel injection has enough variables to deal with and the correct method is to keep fuel pressure constant relative to manifold pressure. We have seen more blown engines from incorrect fuel pressure and stupid engineering than we care to mention. Just remember, when that injector "opens", it "sees" the manifold pressure.

Four fuel maps and a trim knob

The RSR AIC400 has four user selectable fuel maps and a +/- 10% Trim Knob...all of which can be switched or adjusted while the vehicle is running. RB Racing will custom program your AIC for your vehicle's specific requirements and with the switchable maps and the Trim Knob you will be able to go ten percent above or below these levels in a vernier fashion. Simply use the RSR Air/Fuel Ratio Gauge to quickly set your vehicle for a perfect maximum power mixture.

Sand Rail pictured above with a Hayabusa engine and a large Garrett GT Turbo with water injection...600 rear wheel horsepower with RSR AIC400 controller, 3 Bar, programmed for four 06-3650 (650cc) injectors.

Ready to go, not ready to blow

The key to the success of the RSR AIC400 is that it is a digital microprocessor based system that does not rely on a series of analog based potentiometers or slides to guess you fuel needs. By the time you figure out one of these glow in the dark wonders you will probably damage your motor, or simply go bonkers over the five to seven adjustments they present you. How people expect you to accurately set these with any form of "repeatability" is beyond us!

Your RSR AIC400 is shipped to you with an absolutely correct fuel curve based on the five inputs. It will be shipped with the switches set to the middle of the range, exactly to your specific hp requirements. In order to evaluate your fuel needs we suggest you purchase one of our RSR Billet Air/Fuel Ratio Gauges, without which it is impossible to evaluate engine conditions in "real-time".

AIC activation can be displayed on our Air Fuel

Ratio Gauges by connectiong the L.E.D Warn light to the purple

wire of

the RSR AIC400.

2 models: 15 psi, 30 psi

RSR

AIC400s are available in two models: (1) 2 BAR [0 to 15 psi]

Turbo/Supercharged; and (2) 3 BAR [0 to 30 psi]. In addition to

the AIC

you will need to order a wiring harness for 1 to 4 injectors and

either

a 2 BAR or 3 BAR map sensor. If you need to order injectors we

can

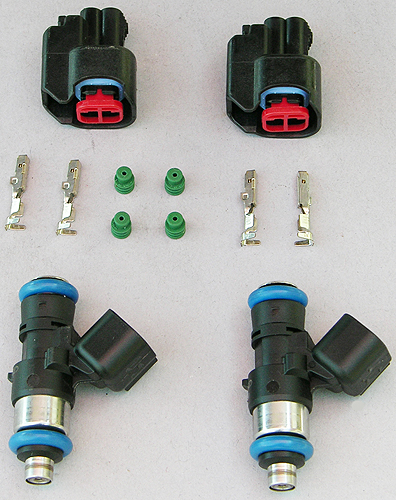

supply the 1 to 4 high impedance

Supports 1 to 4

(12-16 Ohm): Example: 236hp and 328 hp

Injectors

RB Racing Bosch High Impedance

Injectors

rated at 236 hp or 328 hp at a duty cycle of 80%. Used in

our

Harley Turbo Kits and in big inch motors. Direct insertion into

stock

fuel rail/throttle body. Two or 3 Bar Map Sensors required with

Delphi

or aftermarket ECMs. Typically we use just one injector in our

applications.

9.3 Gram Injectors (236 hp @80% Duty Cycle): Come with 20 gauge 22759/32 Mil-Spec Wiring Pigtails. $295.00 (pair). 03-1014. In stock shipping.

12.9 Gram Injectors (328 hp @ 80% Duty Cycle): Come with 20 gauge 22759/32 Mil-Spec Wiring Pigtails. $395.00 (pair). 03-1015. In stock shipping.