Chain Drive Adjustable

Swingarms: FLH/FLT (TC/M8), M8 Softail, and FXR

Twin

Cam and M8 Dressers (0-2";

+1-3" & 0-3" Below)

FXR Swingarms (0-2"

Below)

If you are building a

big inch FXR the stock swingarm is simply not strong enough.

FXR's and FLT/FLH have different shock lengths and shock

eye locations. We make a special swingarm for the FXRs that uses

a late model, 2002 to 2008, FLT/FLH swingarm that we convert to

chain drive.

FLH/T

2" Of Adjustment in Standard Length (0-2") or (+1"-3"

Optional)

Pre 2009 Twin Cam

swingarm shown with 0- 2" adjustment. The

stock adjusters only offer +/-1/4" (12.7mm) of adjustment which

is sort of understandable as the factory belt is a fixed deal

with a certain drive ratio and belt length. This simply does not

work if you want to go chain drive because +/- one link or +/-

one tooth on the rear sprocket and there is no way you can get

correct chain adjustment.

We modify your FL

swingarm for 2" (50.8mm) of movement in stock lengths. We also

offer modification in 3" (+1-3") longer. Shock eye location

remains stock.

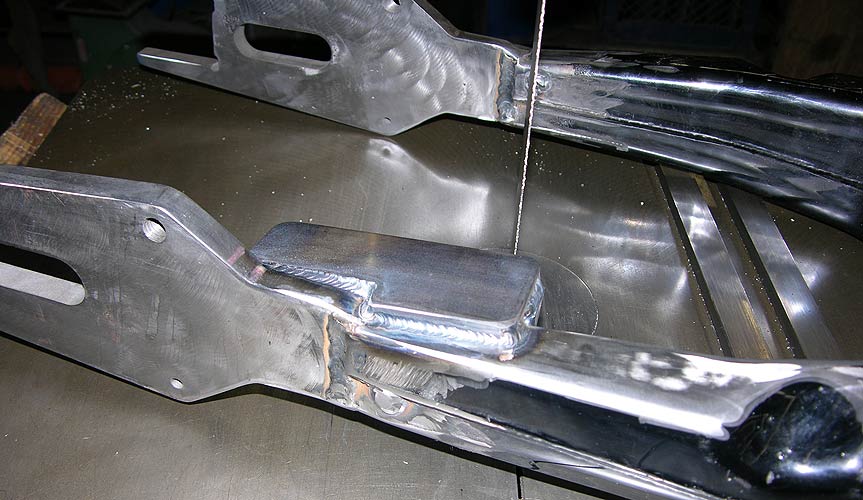

For 0-2", 1-3", and 0-3"

over swingarms we need to remove the old brake anchor shelf and

fabricate a completely new one in a new location.

This involves about four

hours of sawing, grinding, sanding, and refinishing plus the new

fabrication and welding. The OEM Harley brake anchor shelf is

welded completely around, 360 degrees, so all the welds must be

removed on both faces of the formed swingarm surface.

The brake anchor shelf has been resized for the full 0-3" adjustment.

Stock

Belt Adjusters Do not work on Chain Conversions

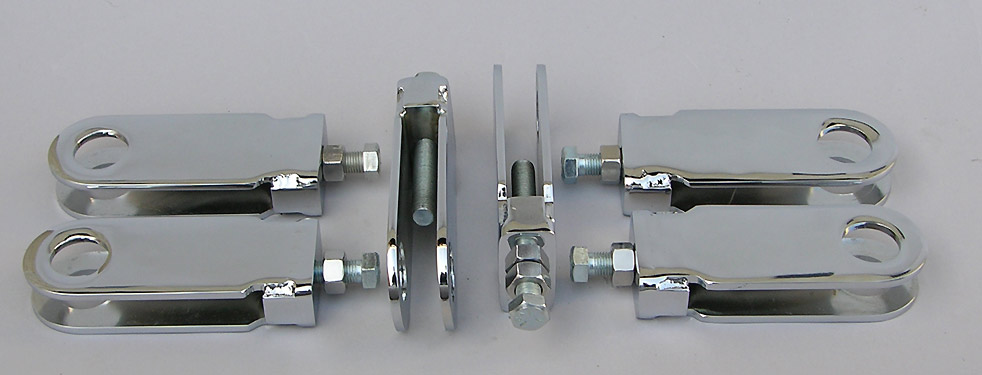

Here are the stock adjusters. Put a 1" axle in a 1.5" slot and you can only move it +/- 1/4" (12.7mm). They have to go.

Pictured above are the

new chromed chain adjusters offering 2" (50.8mm) of adjustment.

Chrome adjusters come with four bolts (two sets): One set for

0-2" and one set for 0-3" over stock.

Alignment measurements can be taken with vernier calipers on total bolt length from rear of adjuster. Locking nuts are supplied. Procedure is to set length with 5/8" socket on the bolt. Then holding the bolt head in place tighten the locking nut with a 11/16" wrench.

Note: When the chain is finally adjusted, hold welded nut on rear axle and final tighten cone nut to 95-105 ft-lbs (128.9-142.4 Nm). Install your e-clip in axle groove.

Chain

Drive Swingarms

Chain Drive Swingarm

Fabrication:

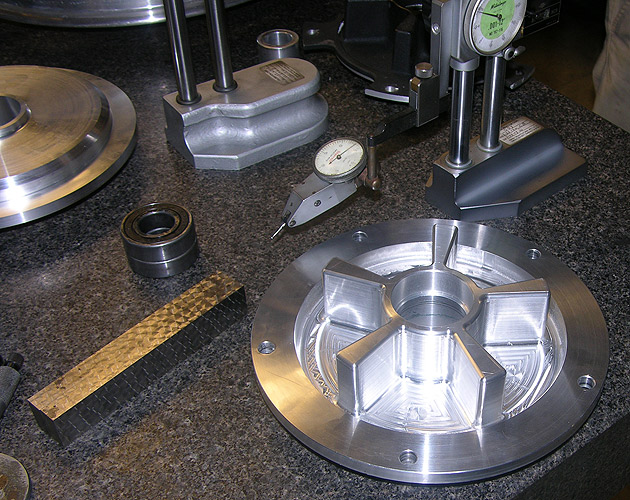

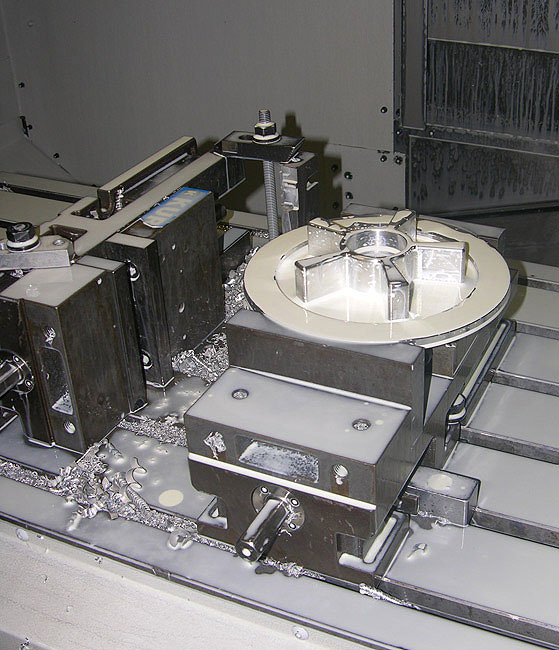

Precision sawing of

aluminum and steel billet parts, CNC mill and lathe machining,

CNC mill and CNC lathe fixtures, manual lathe machining,

multiple welding fixtures, heliarc (TIG) welding. MIG welding,

high speed belt sanding, manual hand sanding and finishing, bead

blasting, powder coating, polishing, chroming, color buffing,

bearing preparation, re-tapping of threads, chrome polishing,

swingarm polishing, touch up finishing, wrapping in plastic

wrap, and packaging and shipping.

Easy… Not!

Adjusters

CNC machined and

fabricated swingarm adjusters...Here off for final polishing and

chroming. Gives full two inches of chain adjustment on our

modified swingarms.

Hot

Rod Baggers

We geared our 2004 Turbo Road Glide a bit taller: 24T transmission / 45T rear sprocket so

we can cruise at 80 mph at a little over 2750 rpm...and

still take it up to 180 mph. There was no simple answer to

getting a chain to work so we redesigned the swingarm. There is

no cush drive on this year.

Hot Rod baggers are the norm these days with street racers pouring money into big 124/126/131/and 145 cubic inch engines, with high lift cams and lots of compression for street racing and bragging rights. Only by going to chain drive can you have a true high performance drivetrain and the flexibility to gear up or down which is impossible with the stock belt drive.

Our 126 ORCA 360 hp Turbo Road Glide aka "Road

Toad" has a chain final drive as does Mike Geokan's 139 ORCA 535

hp Bonneville Bullett. Both run the EK530ZZZ chain.

Modification Procedure

RB Racing offers a swingarm conversion service for

Harley-Davidson Twin Cam FLT/FLH models. If

you want your swingarm modified you must send RB Racing the items listed in 1-4 below

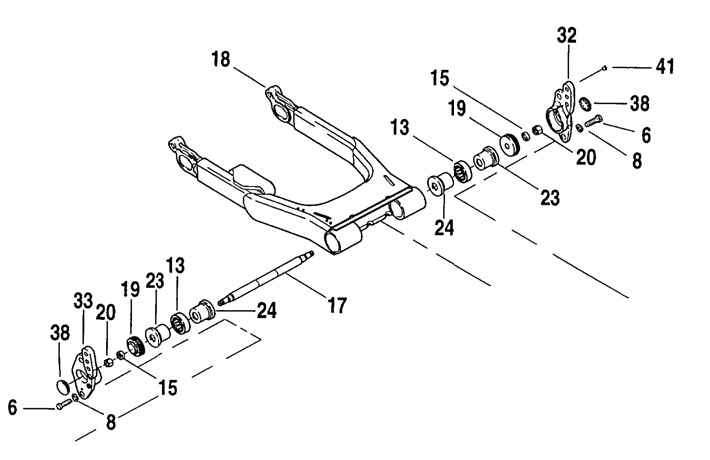

and provide the rear sprocket size required. Below drawing is

just to show that items #13 and #24 must be left in the

swingarm.

You must send the items listed below and fill out the order form at:

https://www.rbracing-rsr.com/orders.html

Ship Swingarm to (with

note in box as to contact info and what you are ordering)

RB Racing, 1234 West

134th Street, Gardena, CA 90247

1. Your swingarm: Dressers Send with bearings (#13

above) and Inner spacers (#24 above) installed. Do not remove

these.

2. Your rear axle and axle nut.

Prices Swingarm

Modification

| Dressers: M8, 2009 and

later Twin Cam: Your Swingarm Modified,

Rear Axle and Axle Nut Modified. Powdercoated Gloss

Black Including Chrome chain adjusters. |

$1,095.00 |

| M8 Softails: Your Swingarm Modified, Rear Axle and Axle Nut Modified. Powdercoated Gloss Black Including Chrome chain adjusters. Specify 0-2"; +1-3", 0-3" | $1,095.00 |

| FXR and EVO Dressers: You

Supply 2002-2008 Dresser Swingarm for 5/8" Transmission

Pivot Shafts : Modified for

5/8" Transmission Boss. Custom

machined adaptors. 0-2" (See FXR discussion lower on

this age) |

$1.295.00 |

New Swingarm

Bearings Installed (Optional)

| (2) New

Swingarm Pivot Bearings Installed OEM 9208 (not generic

aftermarket) |

$150.00 |

Pictured above is a pre 2009 FLT Swingarm. In 2008

Harley started put a bolt-on cush drives on their touring final

drive pulleys. For 2008 models simply ditch the cush drive

and go sprocket direct. For Pre-2008 models the sprocket can be

bolted directly to the hub. Spherical Bearings were first

installed on 2002 models.

The final drive belt can

be removed by placing a scissors jack under the bike and

removing the left side pivot assembly. You don't have to cut the

expensive belt. You do have to be careful not to nick the belt

as this could cause premature failure should it be used again.

FXR Chain Drive

Swingarm Discussion

If you are building a

big inch FXR the stock swingarm is simply not strong enough.

FXR's and FLT/FLH have different shock lengths and shock

eye locations. We make a special swingarm for the FXRs that uses

a late model, 2002 to 2008, FLT/FLH swingarm that we convert to

chain drive.

These are not the same

as our FLT/H Swinarms. Lengths and shock locations are different

Here is a CVO2 swingarm off of our FXR Orca Turbo with a red arrow showing the weak point, among others, in the stock FXR swingarm when used in high horsepower situations like 300 hp turbos or built 130 hp 124" motors. The Cleve Block bushings have to go and we use the 2002 to 2008 Dresser swingarm with spherical bearings. The later model swingarms are twice as strong and we convert them to chain drive with 0-2" of adjustment.

For high hp it does no

good just to upgrade the bearings in a stock FXR swingarm. Go

straight to a late model rear wheel with the 25mm rear axle and

upgrade your caliper at the same time. You can run a 150 rear

tire upgrading from the OEM 130 size, using a 16" or 17" rim.

25mm wheel bearings.

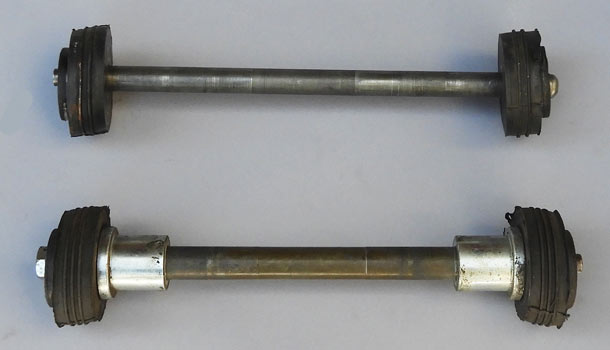

Above: Top swingarm pivot axle is 5/8": FXR or EVO Dresser. Lower photo is later 2002-2008 3/4"transmission shaft.

FXR with conversion

to TC (pre 2009 Dresser) Swingarm w/ 5/8" Shaft Spherical

Bearing

In the picture above, at

the top, are some really questionable White Delrin spacers that

are sold with tubular inserts that, with the help of some

grease/paste, are supposed to act as swingarm bearings . This is

by no means a bearing in any sense of the word. It is patently

stupid...Crude in execution, a low-tech bushing.

Black Machined Spacers

for 5/8" transmission pivot by RB Racing.

White Delrin

Spacers: Built-in stiction you are

supposed to ride through. Those go in the trash. Kitchen sink

inventor tech. Here testing Delrin bushing stiction with a

weight on a moment arm..It did not move. Don't send these in to

us...The Delrin melts in the powdercoating oven.

The original

rubber-mounted FXR/FL's had complex Cleveblock swingarm pivots

that were designed with rubber internals, derived from Norton

Isolastic mounts, that had a singular purpose of damping

vibrations beween the swingarm and the engine-transmission-frame

assembly. These were part of the reason why FXR's became so

revered for their handling and smoothness...But the Cleveblocks

do wear out a long way down the road.

They subject of perhaps

misguided scorn these days...But in anno 1984, with 58hp EVOs,

it was a revolution,

Harley then transitioned

with the TC Dressers to spherical bearings which are free

rotating bearings, non-rubber isolated, which eliminated the

Cleveblock rubber isolation.

For FXRs transitioning

to pre 2009 TC swingarms RB Racing machines up some spacers, the

black items pictured above, that allow you to use the OEM 9208

Spherical Bearing...that is actually a real bearing...This

allows you to retain your one or two-piece 5/8" axle. We install

these in the pre 2009 Twin Cam swingarms we modify for 2"

adjustment, on high horsepower, FXRs. The original FXR swingarms

are crack-prone and not meant for 111" and 124" motors.

If you choose to do this

be aware you must change your rear wheel, axle, and brake

assembly for the 25mm rear axle and later model brake

calipers. Do not attempt to drill or ream your

transmission case for the late 3/4" axle. There used to be

Delkron FXR cases with 5/8" and 3/4"pivots...Delkron went away

long ago.

We can supply the complete swingarm ready to fit your FXR or earlier EVO Dressers. FXR and Dresser swingarms have different shock locations.

Cut Your Chain to Length

Best to measure things twice before you cut the chain by grinding and pressing off the links you do not need. Using a couple of plastic tie wraps allows you to move the adjusters back and forth to see exactly what links you want to remove. In this case we ended up with a location about 5/8" futher back than stock. The longer adjuster bolts are not needed so we'll put in the shorter bolts supplied. 2004 FLTRI shown.

Note: When the chain is

finally adjusted, hold welded nut on rear axle and final

tighten cone nut to 95-105 ft-lbs (128.9-

142.4 Nm). Install new e-clip in axle groove.

Note: If you intend to

use the lower plastic belt cover you will need to cut off the

inner lip.

Billet Hub

History