![]()

![]()

Top Fuel 2

Update 2006/2007. Play the Odds...Here We Go Again

To keep things going a second frame was ordered from a different supplier but it was not acceptable for Top Fuel, so down one class into Pro Fuel and, working within the rules, another smaller 150 cubic inch PRP Motor and new rear wheel & 13" tire were purchased. After the replacement Top Fuel frame shows up the old 175 cu.in. PRP motor will be re-fit into it with new body work and all the necessary parts. Nitro bikes are a small world. Nitro sits in drums keeping the concrete floor from floating away.

These pictures and slide shows will give you an idea of what it takes to go racing. If you are running Pro Fuel, Pro Dragster, or Top Fuel bike and need expertise in keeping your 6 and 7 second motors in one piece, Carl is the guy to build your engines. It's like lighting a match in a room full of explosives to see where the door is. Better know what you are doing. Contact Carl (208) 373-1222 in Boise Idaho. Or via his website.

There's no end to the ways you can spend money on racing.

Hey, Your Daughter might Marry One

There is an ugly truth about racing...everything gets in the way. If you keep your doors open someone might walk in and offer you work. If you dutifully talk to the customer, the race bike sits all alone while you listen to all of the hopes, aspirations, and instructions the customer has. If you actually work on the customer's bike, the race bike sits and the relentless race schedule ticks closer and closer like the heartbeats in Edgar Allan Poe's the Tell-Tale Heart.

Like an evil mistress, the chrome moly beckons, awaiting your gentle hands. To hell with family, friends, obligations and of course those pesky paying customers who try to keep you in business. Glory awaits. Nitro fumes, broken parts, gas bills, lease payments, $500.00 entry fees and a chance to stand in the winner's circle...$100,000.00 to win a $50.00 plated cup.

Steve's available. Carl has fallen to the Sirens call. The smell of Nitro. Victory.

Bench Racers

Of course if you walk around talking shit but don't race...Well, like they say in Texas about a certain chief executive..."He's all hat and no cattle!". If you can race and win and squeeze in a little time to actually earn money and do good work, it might, and we emphasize might, be worth it. It's an expensive education that can benefit your customers. At least that's the rationale.

Of course it's a lot cheaper and safer to bench race. You always win when you're not at risk and it's a lot cheaper.

Caffeine, nicotine, cocaine, heroin, sex, amphetamies and nitromethane....Choose your addiction and follow Competition Motorcycles as we show you four chronological slide shows of what it takes to build a High Gear Only Pro Fuel Bike.

Four (4) Slide Shows...building a High Gear Only Pro Fuel Bike

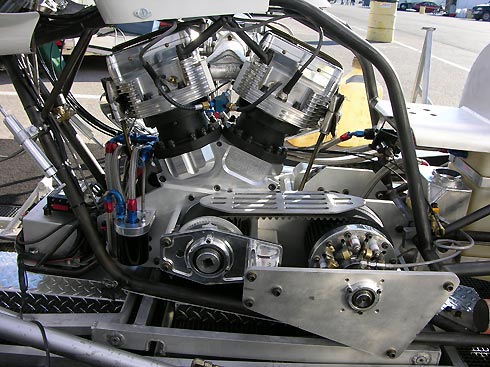

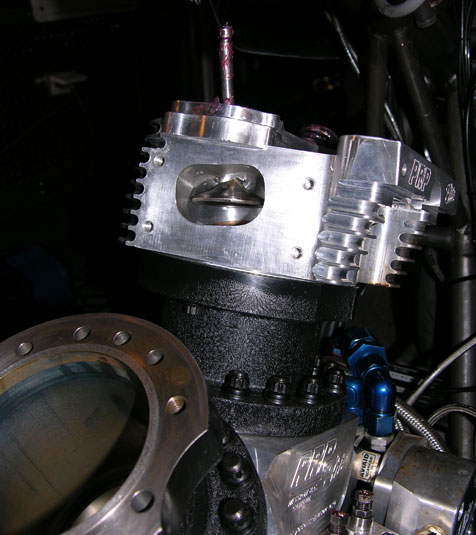

Slide Show #1: Bare frame and insertion of 150 cubic inch PRP Motor. Watch Carl Pelletier and crew wrestle a billet engine into it's new chromemoly frame. You heroes might use muscle. Carl uses an engine cherry picker. Heliarc and machining skills required. Initial motor plates are 6061-T6. These are to be replaced by higher strength 2024 plate that we purchased in Los Angeles.

Slide Show #2: Fabrication of of drivetrain. Clutch and belt drive assemblies. Machining and fabrication to accept new body parts, engine plates and the like. Mill, lathe, heliarc required. This is where the rider Steve shows up. It's easier to make the metal fit Steve than to cut Steve to fit the bike. Steve has run his own high gear Nitro bikes and he knows what works.

Slide Show #3: Here things start getting crowded because the fuel system, the pneumatic system, the electronics to include ignition and data acquisition get hooked up. Pneumatic logic for clutch contol is complicated. All AN/MS plumbing has to be hand-fitted. Catch cans, fuel tank, battery box all have to be built in place. Carl's hands are rumored to come from an unknown Snap-On catalog.

Slide Show #4: Burn the midnight Oil and get to the track for initial tests. New leathers for Steve as he scuffed up the last set when he got blown off Top Fuel #1 at 208 mph. Carl wanted to put "RB Racing" on the leathers as we have always been behind his efforts and help out the best we can on and off the track. We told him "No". He did it anyway. We are definitely behind this Steve this time.

Test and Tune Las Vegas Nov 2006

Barnett Tool & Engineering is a sponsor of Competition Motorcyle's Pro Fuel and Top Fuel bikes. You have to run the stickers of the various sponsors to be eligible for contingency money. Verification of logos and stickers is handled by AHDRA staff.

Barnett supplies clutch friction materials and a variety of clutch products and primary drive systems to the big twin market. Carl has run Barnett products for many, many, years in Bonneville, Pro Dragster, Pro Fuel and Top Fuel applications.

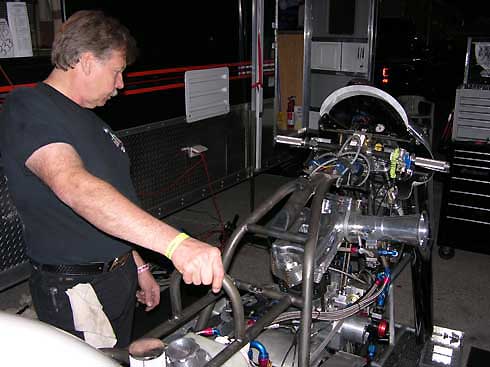

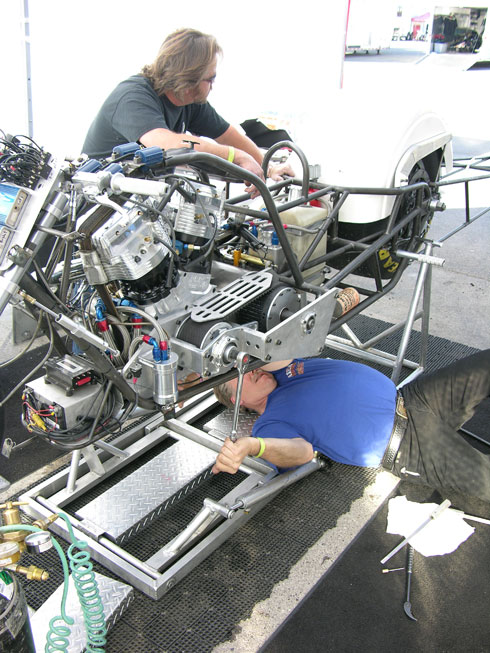

Carl, Steve and Andy getting ready to warm up the 150 cubic inch PRP motor and do a clutch engagement check.

Details, details, details. With around 750 to 800 hp on tap you have to be sure everything is tightened down and adjusted properly before you go for your AHDRA safety technical inspection. Both the bike, the rider's leathers, helmet, gloves and boots must be inspected.

We made up the tooling for the Top Fuel 2-1 headers and gave it to Carl. He's been building these headers for various teams. John Breckenridge's Pro Fuel bike that Steve crews for set a new national record with one of these 2-1 systems with an ET of 6.553 @ 206.86 MPH. Racepak Data Acquisition analysis has shown improved combustion with the system.

Left to right: Andy, Carl, Lesa, Dan and Steve getting ready for a test run. Basically the motor was too powerful for the clutch and smoked the Top Fuel spring and centrifugal lock-up clutch. Carl ran out of spring adjustment and fiddled with the primary and secondary activation to gain valuable data for 2007. The sintered iron plates welded themselves together on one test run. Carl figured out a work around and got a good handle on the fuel and pneumatic logic system. Only other problem that cropped up was a leaky oil tank fitting that was replaced and Carl rewelded an oil tank on a seam that was leaking.

One advantage or disadvantage of bringing you heliarc to the track is that Carl gets to weld up everyone else's broken parts. Everyone helps even if it's your competitor.

The bike rests on an aluminum lift that is used to raise the bike for servicing things like the clutch and oil changes between rounds. In competition Carl can actually change the main rod bearings between rounds via an access plate on the bottom of the engine.

Clean work from Competition Motorcycles. This was a test session. Over the winter Carl will machine new engine plates out of 2024 Aircraft aluminum and lighten them by milling pockets with reinforcing ribs.

Starter Cart and nitrogen bottle for the pneumatic system and the tires. It takes a lot of equipment to go racing. Front tire is run with about 35 psi and the rear tire is adjusted for track conditions, typically around 6 psi. Cold weather temperatures complicated things with track temperatures as low as 50 deg F (10 deg C).

During the burn out all teams shoot an infrared temperature check of the rear tire. On one run after a 4 second burn out the tire temperture only reached 112 deg F (44 deg C). Temperatures of the rear tire should be about 140 deg F (60 deg C). It was easy to "smoke" the rear tire with the low temperatures.

Stay Tuned for the 2007/2008 Season

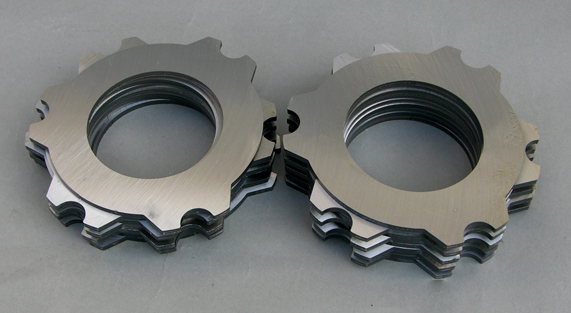

New center mounted clutch for the 2007 season. These are the "steels" for the center mounted clutch. We made these extras up so Carl could do the final fabrication. They are a little under a quarter of an inch thick and are double disc ground out of a special high friction but wear resistant steel.

The center mount clutch will get rid of the thinner "steels" and friction material that the old clutch hub had. It also moves the clutch away from the primary drive belt which would actually melt and bond itself to the old outboard clutch hub.

Top Fuel is all about experience. Carl made a few tests with the new inboard clutch so we went ahead and made up some more plates for his 2007-2008 season. He put in bigger bearings after the intial tests and got a pretty good idea of the centrifugal weights he will be using.

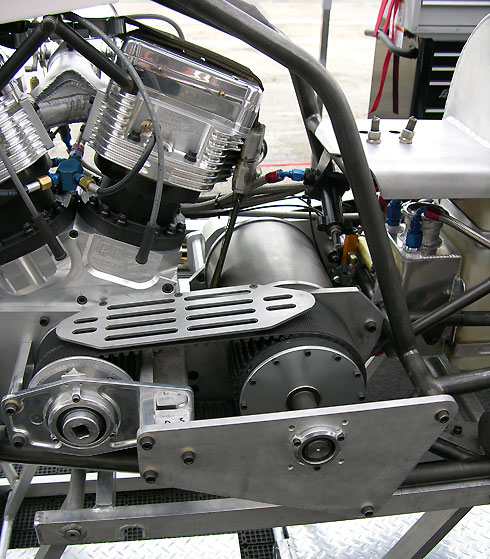

Center Mount Clutch Assembly

Based on testing Carl machined up some longer clutch fingers out of A-2 Tool Steel and had them hardened to 62 Rockwell. New, longer, studs allow two additional floaters to be added to the assembly as the "tune" is increased. It's all based on experience, which always comes at a cost.

New inboard clutch wrapped in a titanium shield. You adjust the clutch from underneath with feeler gauges.

Driveline Support Bearing

Everything has to be custom machined. Nothing is "off the shelf". It all takes time. The instantaneous torques will rip things apart if they are not properly supported. Here Carl has machined some 2024 plate to build a support for the hub that the rear pulley is attached to.

Testing Pomona / Las Vegas 2007

Steve Heidner made some easy 7 second passes to test the clutch for Las Vegas. Steve was uncomfortable with the "bite" of the front slick when the wheel came down so Carl put on a new Metzler race tire with a bit of tread pattern (not shown). 2-1 designs with large diameter collectors are a bit of the norm these days. Vancil came around.

Here's the other cost side of racing. Work 7 days a week so you can get a new race trailer to haul the White Nitro Bitch around. Nitro mistresses are high maintenance. Shower, bed, and kitchen facilities so you don't have to stay at hotels. Live in box, work in a box, take your box with you. Maybe if Frank Gehry designs race trailers we might be freed from boxes.

Las Vegas AHDRA 2007...Friday Night...KaBoom!

During a qualifying pass in Pro Fuel on Friday too much fuel caused the engine to undergo a small thermonuclear explosion contained by the Kevlar safety strap that the rules mandate. It was already late at night and the PRP engine was mortally wounded. This is a surprisingly common occurence in Nitro Harleys. Here Carl surveys the damage. Carl, Andy and Jeff come up with a plan to strip the top end and cylinders off a larger PRP Top Fuel motor.

Playing With Dynamite

The power of Nitromethane. Enough explosive force to push the valve through the Inconel valve seat and smash it into the roof of the inlet port. On it's journey it broke the rocker arm and pried open the rocker box. The explosion sent the butterfly off into the Nevada desert.

On PRP Top Fuel and Pro Fuel engines you service the rods from the bottom. When they blow up you find all sorts of debris hiding in the pan. The milky oil is what happens when the Nitro mixes with the special Bardahl Oil that Competition Motorcycles specifies for all its competition motors. The 8.5" 7075 connecting rod was snapped. The crank survived.

Cannibals

Jeff and Andy wrestle the Top Fuel motor to the Pro Fuel bike and begin their scavenging. Bloodlust fueled by oil, nitro and caffeine, they pass gas to keep themselves amused and to keep other scavengers at bay. The food you eat at AHDRA events is best labeled as toxic. Carl, Andy and Jeff tackle the beast and the clock. It keeps ticking.

Saturday Morning...No sleep

No sleep. The sun is too bright. Steve Heidner, Carl Pelletier start the beast. After an all-nighter the Nitro bike starts up with the fresh parts installed. Night of the living dead. Andy, Jeff and Carl got the job done.

Steve Back on the Line...Saturday and Sunday...Easy 7 second pass!

With no hope for the points championship Carl ran Saturday and Sunday during eliminations and in the "Outlaw" class to continue testing the new inboard clutch. After all the work and lack of sleep, Competition Motorcycles finished this year's AHDRA National Points championship in 8th place and 2nd place in the Western Division.

To adjust the new inboard clutch Carl uses long feeler gauges to set the "air gap". New frictions were tried and new "steel" designs were figured out to get better bite without warpage. Different heat treatments were tested to see what effect they had on slippage. Multiple tests were made on primary and secondary centrifugal weights and in the air logic timing. It's complex and you only have six or seven seconds at a time to figure it all out. It's an expensive puzzle.

New Plates for 2008

New, thicker 3/8" clutch steels and more aggressive frictions will allow more runs between clutch inspections and also easier clutch management. Next step, double-disc grinding post heat treatment. New design has twelve expansion slots that serve also as "edges" for the frictions to improve clutch "bite". Even when you're not racing you still are going full speed.

The only time you relax is driving home when you are thinking about building things like these.

Baby Light My Fire

Carl had a small electrical fire at his shop in late 2007. No fire damage, but those hoses and fire axes can sure make a mess looking inside of walls and ceilings. Carl took the opportunity to separate customer service and installations away from the machining, fabrication and race shop by building a new race-only shop. His old shop is back in operation after everything was put back to city, local fire, federal and intergalactic specifications.

Carl is better setup to handle his race engine building clients away from the turmoil of actually making money. Carl can be reached at 208 373 1222 for your race-only engine building needs. Pro Dragster nitro burning engines are a Competition Motorcycle specialty.

Pro Dragster pictured. Nitro Burning, carbureted, high gear engine. Competition Motorcycles 2-1 header system.