Professional Fuel Injector Pulsewidth Calculator

This calculator will generate pulsewidth values for specific rpms, from idle to peak speeds. The constants used are 160 CFM per 100 HP, and an 85% duty cycle for maximum injector pulsewidth. Injectors will go static at about a 92% duty cycle and should be sized for an 80% duty cycle to leave some "wiggle" room.

Beyond the 85% figure horsepower can actually drop as the pintles or discs in the injectors are essentially "floating", trying to open and close before they can complete each event. At this point the injectors actually put out less fuel until they are fully pulsed static and then the final output goes to 90% of their rated capacity. Injectors should not be pulsed beyond an 85% duty cycle.

Injectors are rated when shorted open @ 43.5 psi (3 Bar). The injectors will, when pulsed, only achieve 90% of this figure. Also calculated is the expected injector ccm flow at the selected rpm and load (KPa).

RB Racing uses RC

Engineering Fuel Injectors, and Injector Dynamics Fuel

Injectors(Bosch) in high impedance with ratings up to

2200cc/mim.

We knew the late Russ Collins, who was inducted into the Motorcycle Hall of Fame, since 1974. Like the Don McLean song "Bye-Bye Miss American Pie"....motorcycle drag racing died and hasn't progressed technically since Russ Collins retired. Only one Buddy Holly...only one Russ Collins. The "Sorcerer", Russ's Nitromethane burning "V8" with two SOHC Hondas held the Top Fuel record for 12 years.

Doubles, triples, V8's, Hilborn Injection, Nitro, Superchargers, rear facing zoomies, Cobra Motors, Golden Rods, Sidewinders, Webers, Strokers, Flow Benches, Dynos, 4-1's, rotational firing collectors, magnetos, belt drives, slipper clutches, data acquisition, white leathers, professional presentation, feathered hats and a victory cigar.

If you ever wonder where Terry Vance and Byron Hines got their start....Well, everyone needs someone to lead the way. Anyone can copy.

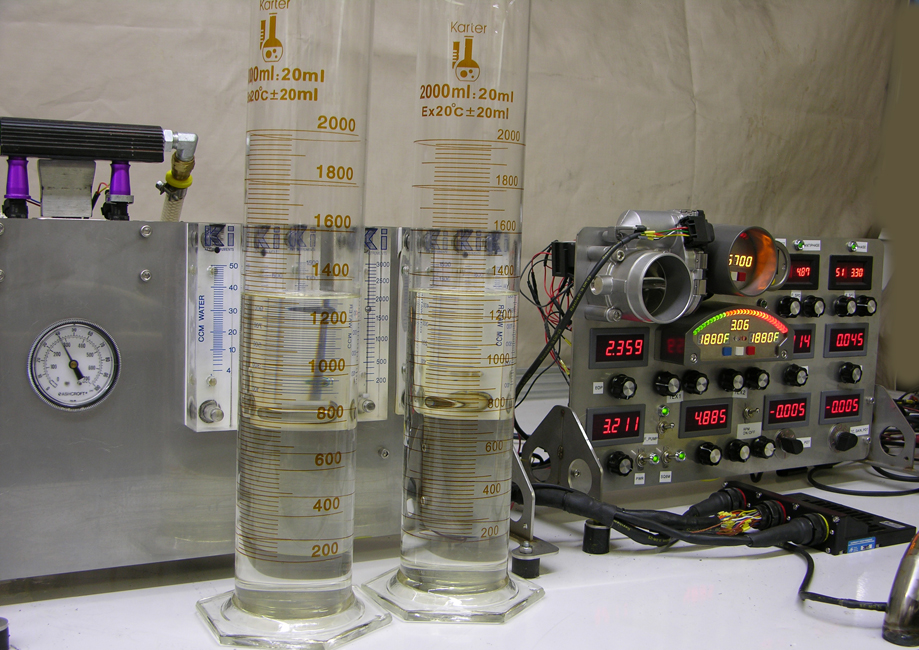

First Injector Wet Flowbench...1989

At RB Racing we wet flow our RSR Fuel Injection Systems to see

the actual horsepower outputs. We can test specific fuel

pumps, regulators, injectors and set fuel pressures to meet

the particular requirement. We also simulate temperature

changes in the engine as well as the inlet air temperatures.

Variables on our RSR Wet Flow Bench are Air Temp, Engine Temp,

TPS, O2, Manifold Pressure, RPM, start functions, battery

voltage, fuel pump size ( 300, 400, 600, 1000 hp), and fuel

pressure. We can visually monitor horsepower output and bypass

fuel. All RSR ECU's are tested on the flow bench prior to

shipment.

Injector Wet Flowbench...2008

Volumetric efficiencies are related to inlet tract design and inertia considerations. At idle your V.E. might be as low as 15% to 20% whereas at higher and peak rpms in some systems V.E. can be 100% or greater. Typically full power or higher rpms are calculated @ 85% V.E. as an average. V.E. usually rises quickly off of idle as inertial filling takes place. If the inlet system is too restrictive then V.E.'s can fall off as the rpms pass their most efficient flow.

Mach Indexes in the inlet system need to be considered in engine design.

Professional Fuel Injector Calculator (Idle & Peak Values)