Turbo Electric Oil Feed and Scavenge Pumps

Turbochargers should be

positively scavenged. If you can do it mechanically like we have done

in many installations over the years, then the expense, packaging and

complexity of an electric pump is not necessary. If you have a poorly

designed scavenge system or none at all then an electric gear pump is

your best alternative. We've been dealing with these issues for nearly 40 years.

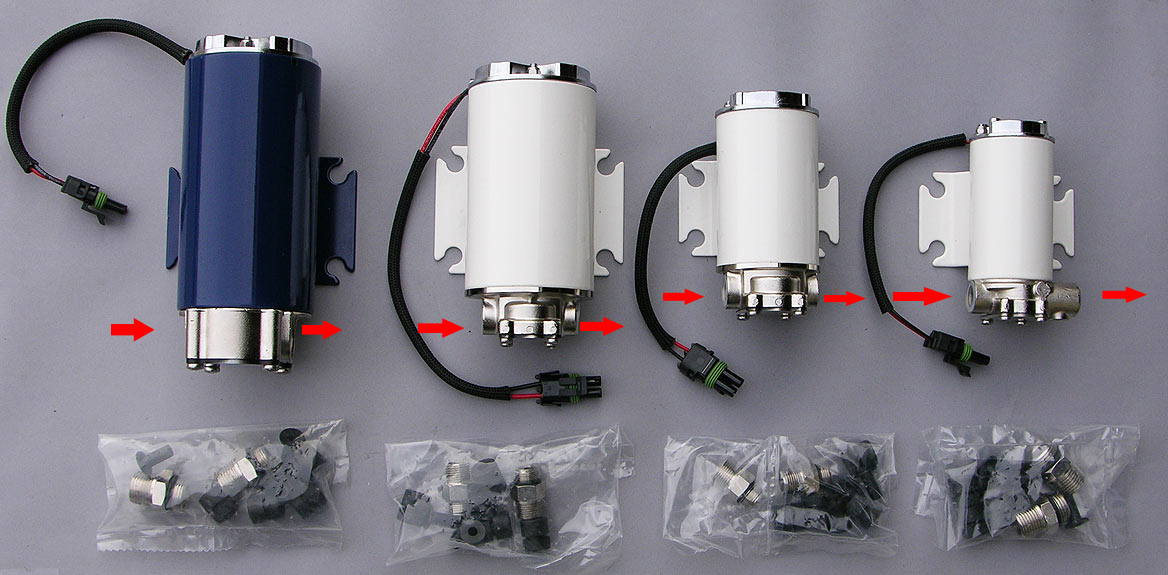

| 03-1040 |

Oil Scavenge Pump Small, 3/8" NPT x 3/8" BSPP Male

exit/entry, 2.000" x 5.000", 1.0 GPM

(15A Fuse); Weight 2.64 lbs |

$275.00 |

| 03-1034 |

Oil Scavenge Pump Standard 3/8" NPT x 3/8" BSPP Male

exit/entry, 2.500 x 5.375",

2.0 GPM (15A Fuse); Weight 3.08 lbs | $325.00 |

|

03-1035

|

Oil Scavenge Pump Super, 3/8" NPT x 3/8" BSPP Male

exit/entry, 3.000" x 6.500",

3.0 GPM (15A Fuse); Weight 6.82 lbs |

$445.00

|

|

03-1054

|

Oil Prelube / Scavenge Pump SuperX, 1/2" NPT x 1/2" BSPP Male exit/entry, 3.200" x 7.500",

4.0 GPM (15A Fuse); Weight 9.46 lbs |

$495.00

|

|

03-1036

|

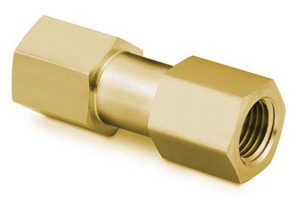

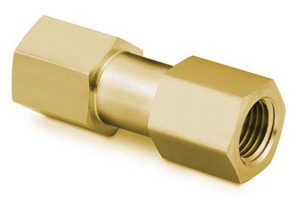

Viton Check Valve, Pump Exit, 3/8" NPT or 1/2" NPT (SuperX), 1 psi

scavenge backflow

|

$49.50

|

|

03-1039

|

Viton Check Valve, 1/8" or 1/4" NPT (specify), 1 psi, turbo oil feed

line. Bleed-down prevention

|

$29.50

|

|

03-1047

|

Viton Pressure Reduction Valve, 1/4" NPT, 25 psi

Garrett GT Ball Bearing Turbos

|

$39.50

|

|

03-1037

|

3 Amp / 7.5A / 10A / 15A Weatherpack (silicone

sealed) Inline Fuse Option

|

$25.00

|

|

03-1042

|

Weatherpack (silicone

sealed) Inline Circuit Breaker Option (Manual Reset)

|

$37.50

|

|

03-1045

|

Stainless Steel Mounting

Bolts, washers, and locknuts (set of 4)

|

$7.95

|

|

03-1046

|

Oil Filter for Inlet of Scavenge Pump, Sub Micron:

3/8"NPT Female

(or) Inline Oil Filter for Scavenge Pump 3/4" x 16 SAE (AN8) |

$49.50

|

|

03-1048

|

Oil Filter for Turbo Oil Feed Line, Sub Micron:

1/4" NPT Female

|

$49.50

|

|

03-1043

|

1/2" Hose Barb Fitting x 3/8" BSPP Option. Per

(1) fitting

|

$15.00

|

|

03-1051

|

3/8" Hose Barb Fitting x 3/8" BSPP Option. Per

(1) fitting

|

$15.00

|

|

03-1052

|

5/16" Hose Barb Fitting x 3/8" BSPP Option.

Per (1) fitting

|

$15.00

|

|

03-1038

| Straight AN10 x 3/8" BSPP Fitting Option. Per (1) fitting |

$20.00

|

|

03-1041

| Straight AN8 Fitting x 3/8" BSPP Option. Per (1) fitting |

$15.00

|

|

03-1049

| 90 Degree AN10 Fitting x 3/8" BSPP Option. Per (1) fitting |

$27.50

|

| 03-1050 | 90 Degree AN8 Fitting x 3/8" BSPP Option. Per (1) fitting | $25.00 |

| 03-1044 | Straight AN6 Fitting x 3/8" BSPP Option. Per (1) fitting | $15.00 |

| 03-1053 | Straight AN4 Fitting x 1/4" NPT or 1/8" NPT | $7.50 |

| 03-1055 |

SPST MOM(ON) x OFF Sealed Toggle Switch (Pre-Oiler) |

$29.50 |

| 03-1056 |

Differential Cooler/Pre-Oiler AN8 Pump Screen Filter 250 Micron

|

$15.00 |

| 03-1057 |

Differential Cooler/Pre-Oiler AN10 Pump Screen Filter 250 Micron

|

$15.00 |

| 03-1058 | Y-Block Fittings Specify AN8-AN8-AN8 or AN10-AN10-AN10 |

$29.50 |

| 03-1059 | Replacement Filter Element for 03-1046 |

$19.95 |

| 03-1060 | Adjustable Oil Bypass Valve |

$95.00 |

| 03-1061 | Remote Kit: Adjustable Oil Bypass Valve; Tee Fittings; Pressure Gauge; (2) AN6; (1) AN4 |

$195.00 |

Note: All pump bodies except the 03-1054 (1/2" BSPP) are 3/8" BSPP

straight thread (3/8" x 19) with an O-Ring seal. This prevents cracking

the pump housing with an over-tight tapered pipe thread. The O-Ring

seal prevents leaks. If the fitting is removed it should have Blue

Loctite placed on the threads in addition to the O-Ring seal. As

supplied all four pumps have 3/8" NPT Male fittings facing outward. AN x BSPP fittings are optional.

Note: You should use #AN8 (1/2" i.d.) or AN10 (5/8" i.d.) on scavenge lines. Using lines below 1/2" i.d. will result in a dramatic reduction in scavenging.

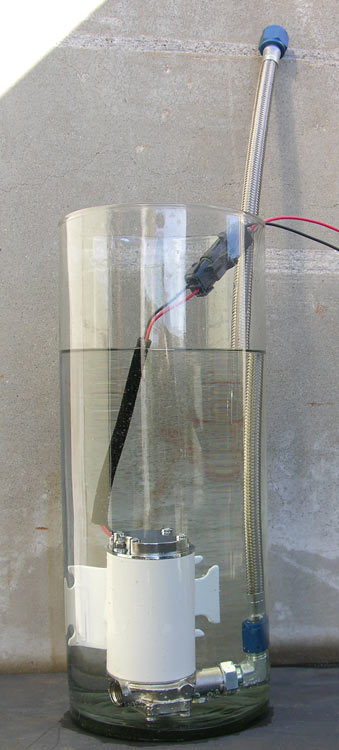

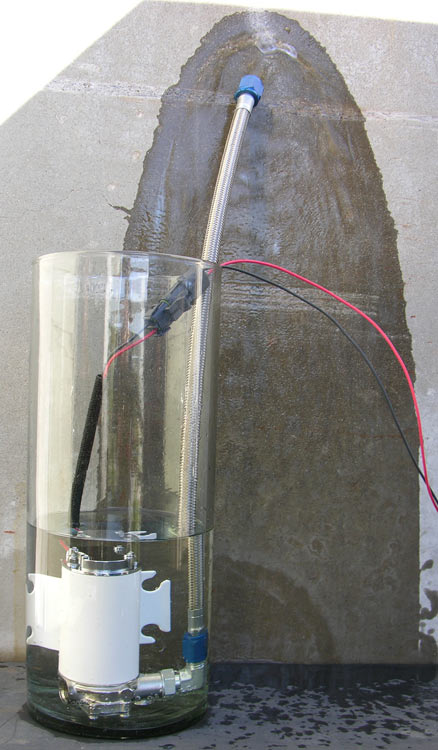

All Four Oil Scavenge Pumps are IP67 Water Resistant

IP67: Ingress Protection 67 standard on all four oil scavenge pumps:

1. No ingress of dust; complete protection against contact.

2. Ingress of water in harmful quantity shall not be possible when the enclosure is immersed in water under defined conditions of pressure and time (up to 1 m of submersion).

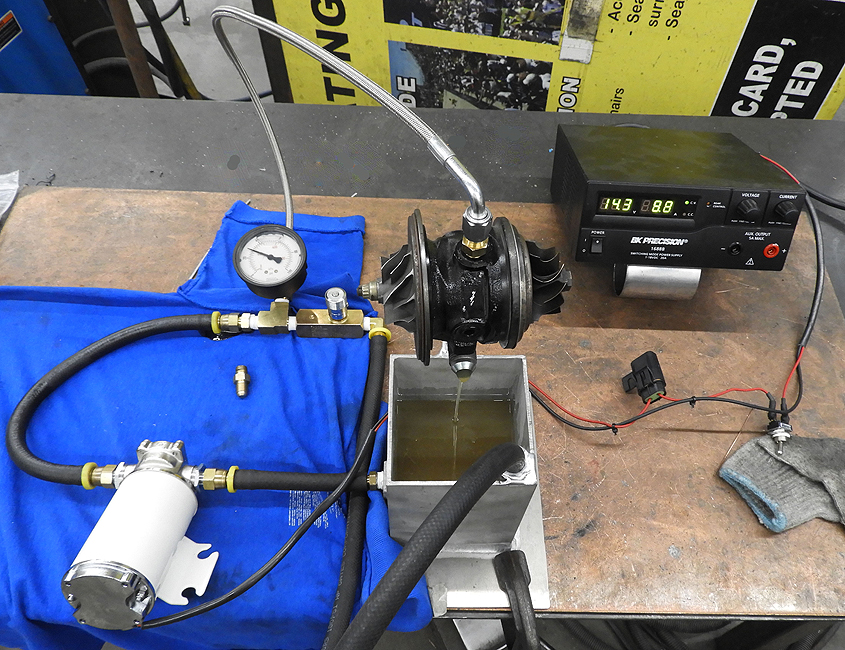

Oil Feed

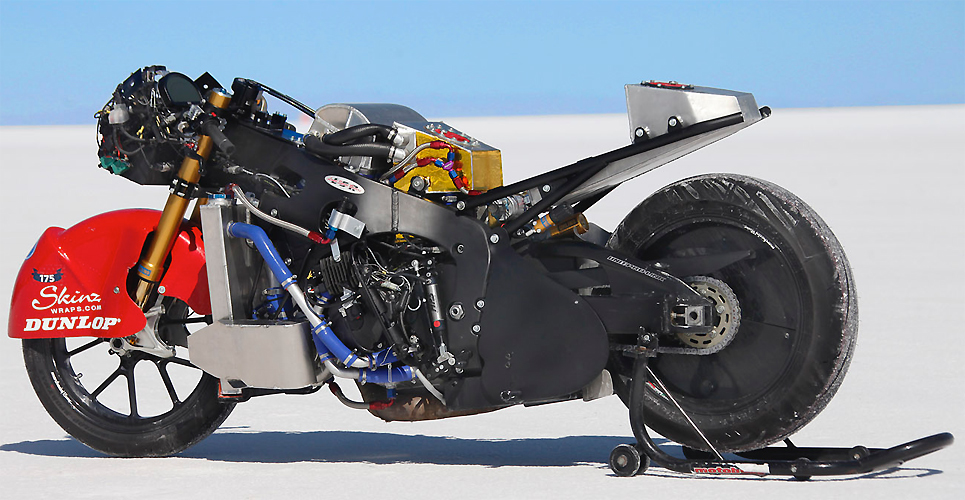

Two Pumps Two Turbos 2800 HP

Going back for 300 MPH

Lee Sicilio's Twin Turbo Daytona before and after. Lee's rebuilding after healing his body a bit...Lee is in the 200 MPH Club and was knocking on the door for the 300 MPH Club Hat when a tire let go at 291 MPH after hitting some debris. 03-1035 Oil Pump for pre-lubing the engine and turbos.

2020: Lee has rebuilt and we have supplied him with another pre-lube pump. He wants that 3 Club Blue Hat.

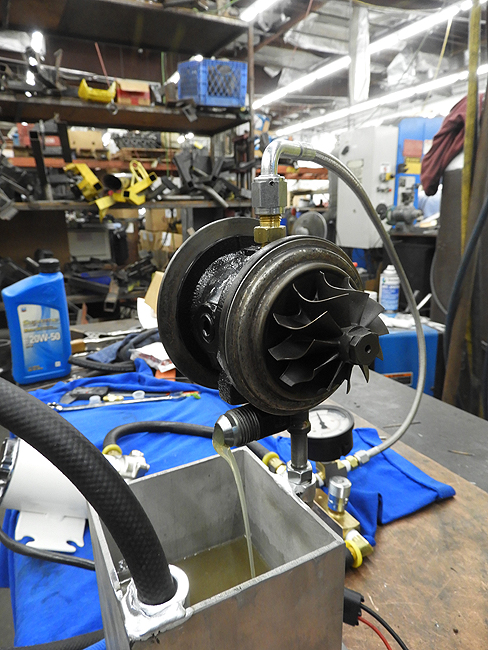

Turbochargers

Turbocharger oil scavenging has always been an issue. You might have 50 psi feeding the turbo but the slightest restriction in the "drain" will immediately send oil past the exhaust seals. In the case of remote mounted turbo systems, or in systems mounted below the engine oil level, some form of positive scavenging has to be engineered. Typically this involved belt driven scavenge pumps from companies like ARE (Avaid), Moroso, Peterson , Barnes and others.

Some people like STS Turbo (Out of Business), Callaway, Lingenfelter and others use auxillary scavenge systems either mechanical or electric. If you have any sort of drain issue you are going to have oil going past compressor and exhaust seals. The slightest restriction will cause immediate "oiling".

A brief look at how this has been handled by RB Racing and others can be helpful in solving turbocharger issues.

History...Dry Sump Wet Sump

RB Racing has, for nearly 40 years, engineered out solutions for turbo oil feed and scavenge systems. Early SOHC Hondas had the pen-ultimate dry sump systems that were bullet-proof. Later on, all the motorcycle engines went wet sump which mixed up clutches, transmissions and everything in the same oil bath. Harleys remained dry-sump systems but, with roller bearing crankshafts, were low pressure designs with lousy dry sump capability and leaking check balls that routinely filled the lower end with oil.

Hondas, with their plain bearings, had excellent oil pressure and you could not kill the turbos due to the superb design of their dry sump oil systems. Oil pressure bypass and back-flow valves were incorporated in the design. We still see 30 year old CB750 SOHC Hondas running around. Early Kawasaki and Suzukis had roller bearing cranks and had problematic turbo feed and drain problems due to low oil pressures and a propensity to send debris to the turbocharger bearings. This lead us to separate electric oil feed systems.

In any of these systems the rider had to avoid stupid mistakes like having the turbo spinning 180,000 rpm and then suddenly killing the engine and pulling in the clutch to do a "plug check". Bye bye turbo bearings.

In the early 1980s we used to put close tolerance Weldon 8000 series 12v electric vane aircraft transfer pumps on our race bikes to feed or scavenge the Rajay and IHI turbochargers. The pumps were extremely sensitive to debris and, if manually activated, were subject to rider brain fade which resulted in destroyed turbocharger bearings when the rider forgot to turn on the pump before a burn-out began. Then came the phone call..."Your turbo went bad". They all lie.

Above is a Weldon Tool 8000 series pump that we used to use. Customers were fond of tearing them up. Our competitors bought a few from us and then we told them to just buy them from Weldon. Model 9200 vane pump pictured below.We moved on. Last we checked these pumps were $892.00...

Clean oil. We tell people the turbo has to be free of debris and they routinely pipe unfiltered oil to the turbocharger. Filters clog or bypass oil when things are cold and all the crap goes to the turbocharger. Don't pump any debris through these.

Oil Scavenge....Mystery Era 1985 Up

Lay on the floor for four to six months taking oil pans on and off. Plumb sensitive Magnehelic gauges into various cavities. Take oil pans on and off hundreds of times on different bikes. Drench yourself in oil. Machine parts. Remachine parts. Make complicated custom internals, mill fixtutres, cad programs. Test and retest. Bring the parts to market. Then for the next 20 years have people call you on the phone saying they have copied your designs and they want to "buy the oil system". Sell a turbo kit to a customer. He creates a website to tell of his speed conquests and implies that he designed the parts and will tell everyone how he designed the oil system. He never does. He has no knowledge.

Watch the Result (Movie)

Mechanical system that is really difficult to make. We won't go into the details even if waterboarding is authorized. However if you have certified proof that you have waterboarded Dick Cheney we might talk to you.

For People Who Couldn't Figure it Out

Tilton has a differential oil pump that people have resorted to who gave up trying to buy "Just the Oil System" from us. Usually it was the Suzuki crowd. Flojet makes pumps like these. These are diaphragm pumps not spur gear nor gerotor pumps. They were never designed to hot pump oil. They work, but there is always a question. 2135 series.

Shurflo makes a similar diaphragm pump that has been used for scavenging of oil on turbochargers. These also were never designed to pump hot oil. 8000 series. One of the people we dealt with in the past has attempted to make a mail order business out of selling these for three times the cost after he gave up trying to figure out our mechanical scavenge system on the Suzuki GSXR series. He tried to pry the information out of us for more than a year. We told him to go sling hamburgers as this would be closer to his engineering expertise. These are not spur gear nor gerotor designs.

One Born Every Minute

When you have a company

selling pumps they rebrand...and they do not have a phone number, only

e-mail and fax contacts you pretty much know they have regular job.

They do not make the pumps but imply that they do and then write up

copy saying how their product is wonderful and everthing else is

inferior. Simple routine. Buy the items and mark them up 3x.We know the manufacturer. With straight cut gears these are

NOISY.

Fins, to be effective, need

to be part of the motor's casing, not slipped over, acting like an

insulating blanket, over a powdercoated motor casing.

Typical Customer Comment: " I've got a setup we're building for a twin turbo automotive deal where the turbos are mounted below and require a scavenge pump. We are using Garrett GT series ball bearing turbos and the engine produces somewhere around 60 psi of oil pressure at redline. This said, can you please tell me what of yours I will need so I can order the parts from you? Sadly I bought into the Turbowerx b.s. in the past and do not wish to repeat that."

We seem to replace a lot of these that fail or the supplier will not support them after the sale. Be aware.

German VDO Pump

VDO has a pump (part # 4050400010001) that was used primarily to send engine oil to an oil cooler. Expensive. Don't ask us where to get them. They are prone to failure in scavenge situations as they were really designed to pump non-aerated oil to coolers.

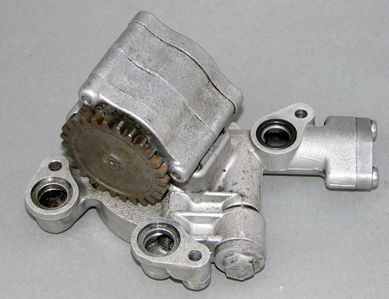

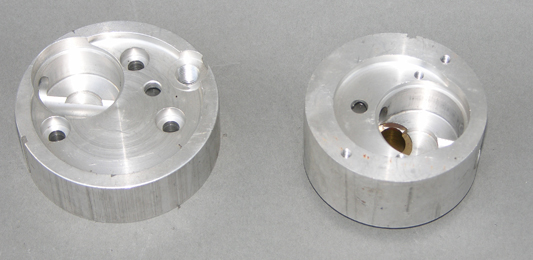

Real Oil Pumps Use Gears

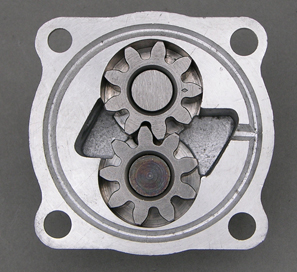

Jim Feuling has passed on but his oil pumps are still keeping Twin Cam Harleys running better than the oem part. This is gerotor design as opposed to the normal spur gear. Take apart any new Japanese bike and you will find gerotor pumps submerged in their wet-sump systems. They offer smooth oil delivery which is directly related to the number of teeth. They work best submerged, not lifting oil.

Virtually most oil pumps use some form of spur gear design. It's cheap. It works, and it's really good at scavenging oil where it is not submerged in the sump. Tolerant of much abuse, it is a time tested design. Some Harley aftermarket pumps use spur gears to scavenge the crankcase and gerotors to pump the oil. There is a reason for this. VW pump pictured. Straight cut gears are more "noisy" than helical cut so we use helical cut gears.

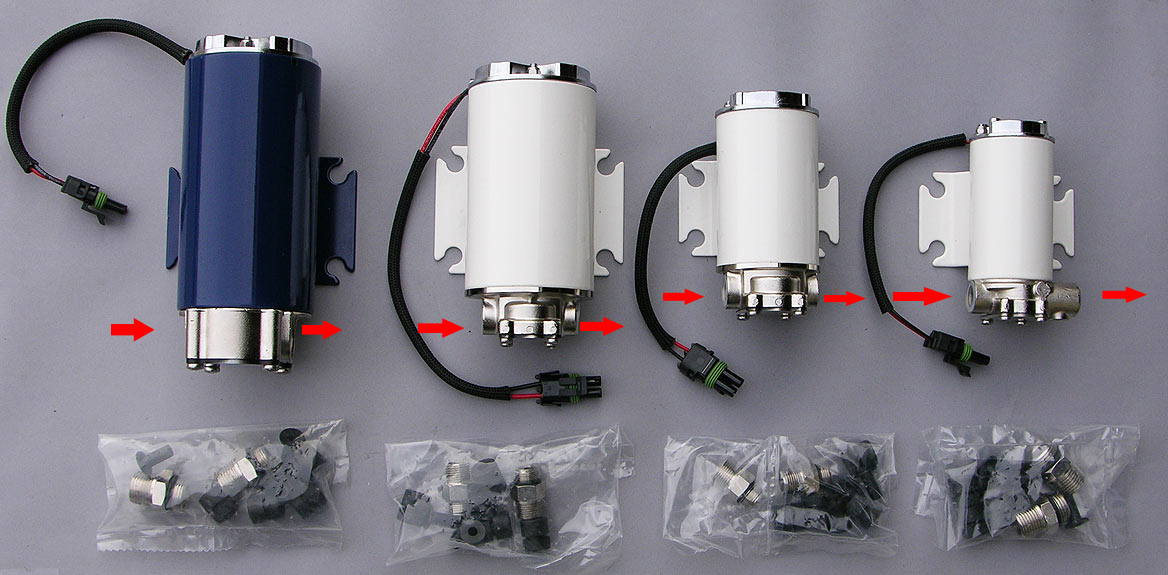

RB Racing Electric Helical Gear Oil Feed and Scavenge Pumps

Bronze

helical (quiet) gears. Bronze nickel-plated pump body. No diaphragms to fail. Gear

design for maximum scavenge. 12Vdc with splash resistant wiring.

Silicone seal Weatherpack connector. Proven in years of use. Metric

thread O-ring boss seal (3/8" BSPP) on pump body. 3/8" NPT male entry

and exit. 03-1054, the leftmost pump above, uses 1/2" BSPP fittings.

These pumps are suitable for remote turbo systems as oil scavenge pumps. In this case the engine supplies the oil pressure and the pump simply returns the turbo oil to a point above the sump level. They are also suitable as turbo oil feed pumps where gravity drain is possible and are often used where a separate turbo oil supply is used which keeps engine oil and turbo oil separate.

The pump should be mounted vertically as

shown above as there is a shaft seal between the pump section drive

shaft and the electric motor. Other orientations, like horizontal can be used but are

not suggested. Mounting the pump vertically with the pump section

facing "up" is a definite no no.

Bronze helical gears are precision ground

and are quiet in operation. The different pumps use different size

gears and are rated for 1 to 4 GPM.

If Used For Oil Feed

If used for pressure feed, our two largest pumps will pump up to 40 psi or greater. The Standard pump is rated at 25 psi constant. Trying to run higher pressures will overload the pumps and burn up the motors. It's a question of the torque required. Keep in mind that turbos do not need 3 gallons per minute feed, so to prevent overworking the pump motor the oil must be by-passed back to the feed side of the pump or to the oil reservoir. Typically this is done in a "Tee" fitting after the pump discharge with an AN4 feed to the turbo and an AN6 bypass line with an orifice restrictor to the oil reservoir. All pumps must be fused as indicated.

Garrett GT series ball bearing turbos only need about 9 to 30 psi of oil pressure so their flow rates are less than plain bearing units. We use a separate oil system to feed the ball bearing turbo on the Bullett race bike.

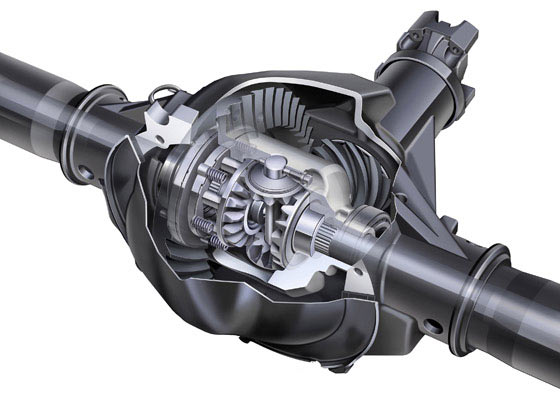

If Used For Differential Cooling

Normally our 03-1034 pump is used with a 03-1041 AN8 inlet fitting and a 03-1056

AN8 250 Micron inlet screen. Various size exit fittings can be used either AN6 or

AN8 headed for the customer supplied differential cooler. AN10 fittings

and inlet screens are also available.

If Used For Pre-Oiling Operations

Pre-oiling newly assembled race motors, specialized race transmissions, antique motors, or whatever you want to get the oil to where it wasn't before you hit the starter button, our 03-1054 pump is the most powerful solution of the pumps we offer. Simply add a 03-1055 SPST Mom(ON) / OFF switch and a 03-1036 check valve. The momentary ON switch means it can't be left "ON" and the check valve prevents backflow from the system when the engine is running. Roll you own. We sell the parts but not specific installations. AN8 and AN10 screen filters to keep sump debris out of the pump are available 03-1056 / 03-1057.

Customer writes:

"Thank you for the pump. I replaced a noisy diaphragm pump

with your 03-1034 as a pre Oiler on my 05 Range

Rover. It builds pressure in about ten

seconds. Excellent and quiet. I am pulling from the

oil pan through a pre filter and back flow preventer feeding a port by

the pressure sender. All AN-6. Richard"

03-1036 Check Valve on Pump Exit

Pumps are available

with a viton seal backflow 1 psi check valve (03-1036) with 3/8" NPT

female fittings for oil scavenge applications. This is installed on the

pump discharge port and prevents oil from backflowing into the pump

section. Typically wherein the oil return line is all the way from a rear mounted remote turbo to the front of the car.

Turbo Oil Feed Check Valve

A 1/8 NPT or 1/4", 1 psi

viton seal check valve (03-1039) is available for the turbo oil feed

port. This prevents capillary bleed-down of oil in the engine from

entering the turbo after engine shutdown.

We also can supply a 1/4" female NPT, 25 psi viton seal check valve (03-1047) for high pressure oil feed lines on Garrett GT series ball bearing turbos to drop oil line pressure 25 psi. This also serves as a capillary bleed-down prevention.

03-1047 25 PSI Oil Pressure Reduction Valve

Reduces line pressure by 25

psi. Used where line pressure is too high for both plain bearing and

ball bearing turbochargers. On very high pressure systems with ball

bearing turbochargers these can be used in conjunction with an oil

restrictor fitting on the turbo inlet.

If idle oil pressure is 45 psi

then 20 psi will be the turbo feed pressure. If peak oil pressure

is 70 psi the turbo pressure will be 45 psi.

On plain bearing

turbochargers pressures above 65-70 psi oil tends to get by the

compressor and exhaust seals. Ball Bearing Garrett GT series

turbochargers only require 9 to 30 psi. Above 30 psi and flow rates can

go by both compressor and exhaust seals.

Fittings: AN6/8/10 or 3/8" and 1/2" Hose Barb Options

Pumps 03-1040/1034/1035 can be ordered with special O-Ring sealed 1/2" and 3/8" hose barb

fittings. The cost is an additional $15.00 per fitting or $30.00 for

two. Keep in mind with barb fitting you have bend radius considerations

with hoses.

We recommend that pumps be fed with 1/2"

ID lines (AN8) or AN10 (5/8" I.D.). 3/8" (AN6) inlet feed lines are too restrictive unless very short.

37 Degree Flare AN6, AN8, and AN10

fittings are available. 03-1054 pumps can be supplied with AN8 or AN10 fittings.

Y-Block Fittings AN8(3) or AN10(3)

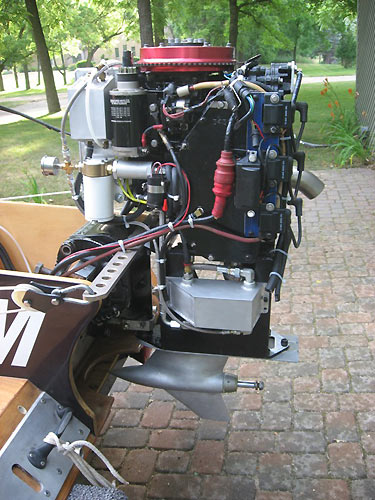

Two Stroke Turbo

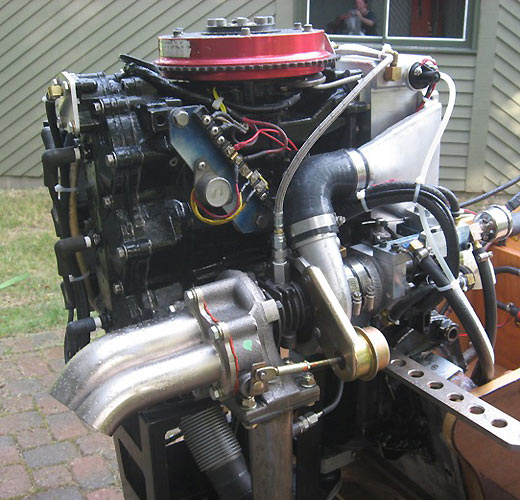

There are no end to "projects". Here is a turbocharged, intercooled, two stroke Johnson 56.6 CID engine with water injection. 03-1034 pump and filter supply the turbo with oil. Excess oil is bypassed back to the oil reservoir. Put this on a 13 foot long boat and....Well, we'll stick to two wheels, gears, rubber tires, asphalt, and the Bonneville Salt Flats...although, sometimes, it does flood at Bonneville.

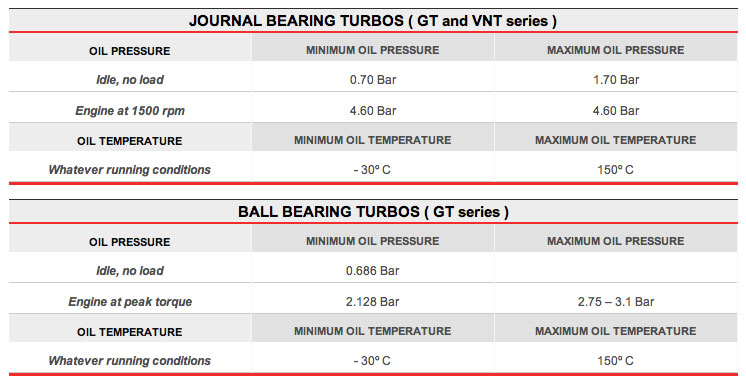

Garrett Oil Pressures

This is the system we use on our Bonneville bike as it keeps the turbo oil and the engine oil separate. As you can see from the chart above the ball bearing turbo we use is well supported by the 03-1034 pump. If you are using engine oil to feed a Garrett GT Series turbo you may need our 03-1047 25 psi check valve to drop line pressure 25 psi.

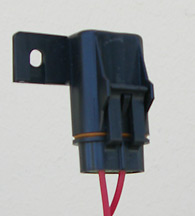

Fuses...Sealed Weatherpack 03-1042 Option

All pumps should be on a fused circuit. We offer an inline Weatherpack sealed fuse option for $25.00. Failure to run the pump on a fused circuit will cause pump failure if the pump is jammed by debris.

Is In Out? Is Out In? Which Direction?

Since these are DC motors you can simply reverse the leads from the sealed Weatherpack connector, i.e. the red and black wires, to change direction of the pump. This simplifies mounting the pump and running the lines to the "inlet" and "outlet".

“When you come to a fork in the road, take it.” ~Yogi Berra

Typical Use

Everyone wants to go fast and do it themselves. It's often the journey that's the important part.

Customer writes: " I would like to thank you for setting me up with your super scavenge pump 03-1035 for my remote turbo project! I took my 1997 mustang gt and built a twin turbo set-up for it in my back yard. I used your pump for the return oiling. I just wanted you to know how impressed everyone is when they see how well this thing works. I used stainless tubing to help with quality and looks. The set-up completed my project and if it wasn't for the pump set-up my dream would have not become reality.

I drive this car as my daily driver and the pump has worked flawlessly for 12,000 miles now. The car makes 412rwhp and 427ftlbs. to the rear wheels on 8psi. I have enclosed a few pics of my build for you. Thanks for the great product! This winter my goal is to swap out my motor to a built 4v cobra motor and turn up the boost for a goal of 750-1000rwhp. I eventually want to take my daily driver to the salt flats with a goal of 200+ mph. Thanks again I look forward to supporting your business, even my tuner was shocked at the quality of the pump system and loved the idea. Thanks, James M."

| 03-1040 |

Oil Scavenge Pump Small, 3/8" NPT x 3/8" BSPP Male

exit/entry, 2.000" x 5.000", 1.0 GPM

(15A Fuse); Weight 2.64 lbs |

$275.00 |

| 03-1034 |

Oil Scavenge Pump Standard 3/8" NPT x 3/8" BSPP Male

exit/entry, 2.500 x 5.375",

2.0 GPM (15A Fuse); Weight 3.08 lbs | $325.00 |

|

03-1035

|

Oil Scavenge Pump Super, 3/8" NPT x 3/8" BSPP Male

exit/entry, 3.000" x 6.500",

3.0 GPM (15A Fuse); Weight 6.82 lbs |

$445.00

|

|

03-1054

|

Oil Prelube / Scavenge Pump SuperX, 1/2" NPT x 1/2" BSPP Male exit/entry, 3.200" x 7.500",

4.0 GPM (15A Fuse); Weight 9.46 lbs |

$495.00

|

|

03-1036

|

Viton Check Valve, Pump Exit, 3/8" NPT or 1.2" NPT, 1 psi

scavenge backflow

|

$49.50

|

|

03-1039

|

Viton Check Valve, 1/8" or 1/4" NPT (specify), 1 psi, turbo oil feed

line. Bleed-down prevention

|

$29.50

|

|

03-1047

|

Viton Pressure Reduction Valve, 1/4" NPT, 25 psi

Garrett GT Ball Bearing Turbos

|

$39.50

|

|

03-1037

|

3 Amp / 7.5A / 10A / 15A Weatherpack (silicone

sealed) Inline Fuse Option

|

$25.00

|

|

03-1042

|

Weatherpack (silicone

sealed) Inline Circuit Breaker Option (Manual Reset)

|

$37.50

|

|

03-1045

|

Stainless Steel Mounting

Bolts, washers, and locknuts (set of 4)

|

$7.95

|

|

03-1046

|

Oil Filter for Inlet of Scavenge Pump, Sub Micron:

3/8"NPT Female

|

$49.50

|

|

03-1048

|

Oil Filter for Turbo Oil Feed Line, Sub Micron:

1/4" NPT Female

|

$49.50

|

|

03-1043

|

1/2" Hose Barb Fitting Option. Per

(1) fitting

|

$15.00

|

|

03-1051

|

3/8" Hose Barb Fitting Option. Per

(1) fitting

|

$15.00

|

|

03-1052

|

5/16" Hose Barb Fitting Option.

Per (1) fitting

|

$15.00

|

|

03-1038

| Straight AN10 Fitting Option. Per (1) fitting |

$20.00

|

|

03-1041

| Straight AN8 Fitting Option. Per (1) fitting |

$15.00

|

|

03-1049

| 90 Degree AN10 Fitting Option. Per (1) fitting |

$27.50

|

| 03-1050 | 90 Degree AN8 Fitting Option. Per (1) fitting | $25.00 |

| 03-1044 | Straight AN6 Fitting Option. Per (1) fitting | $15.00 |

| 03-1053 | Straight AN4 Fitting x 1/4" NPT | $7.50 |

| 03-1055 |

SPST MOM(ON) x OFF Sealed Toggle Switch (Pre-Oiler) |

$29.50 |

| 03-1056 |

Differential Cooler/Pre-Oiler AN8 Pump Screen Filter 250 Micron

|

$15.00 |

| 03-1057 |

Differential Cooler/Pre-Oiler AN10 Pump Screen Filter 250 Micron

|

$15.00 |

| 03-1058 | Y-Block Fittings Specify AN8-AN8-AN8 or AN10-AN10-AN10 |

$29.50 |

Note: All pump bodies except the 03-1054 are 3/8" BSPP

straight thread (3/8" x 19) with an O-Ring seal. The 03-1054 uses 1/2" BSPP straight thread fittings. This prevents cracking

the pump housing with an over-tight tapered pipe thread. The O-Ring

seal prevents leaks. If the fitting is removed it should have Blue

Loctite placed on the threads in addition to the O-Ring seal. As

supplied all three pumps have 3/8" NPT Male fittings facing outward.

Note: You should use AN8 (1/2" i.d.) or AN10 (5/8" i.d.) on scavenge lines. Using lines below 1/2" i.d. will result in a dramatic reduction in scavenging.

Bonneville

Mike Geokan's Bonneville Bullet. 139" Watercooled ORCA engine. Dry sump engine (Harley) and Dry Sump Oiling system for the larger Garrett turbocharger. Check out Mike's progress as he goes for Bonneville speed records. Viet Nam Vet. Uses 03-1034 electric turbocharger feed pump. Mike has used electric oil pump systems from RB Racing for 25 years.

In this feed situation we use 1/2" inlet hose and a 1/2" exit hose to a "Tee" fitting with AN4 to the turbo and 3/8" return line with a calibrated restrictor to the dry sump tank. Oil pressure is maintained at a maximum of 30 psi to the Garrett Ball Bearing turbocharger. It works well at Bonneville. We run 25 to 28 psi feed.

Al Lamb, Dallas Honda uses

our small 03-1040 oil scavenge pump. Post 2019 Al re-designed his bike

and moved the turbo up as high as possible and skipped the scavenge

pump.

There are number of Speed Contest cars and bikes that use the pumps for pre-oiling and turbo scavenge.

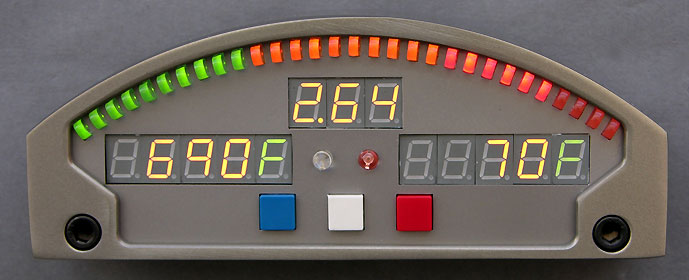

ORCA Turbo Dash

Read more

about these dual egt and boost dashes that we manufacture. We use these

on our turbo systems and on our race projects.