RB Racing Turbos...Big Twins:

Shovels to M8's (Click on Image or Text Below)

M8 Turbos

Twin Cam

Turbos

Evolution Turbos

Shovelhead

Turbos

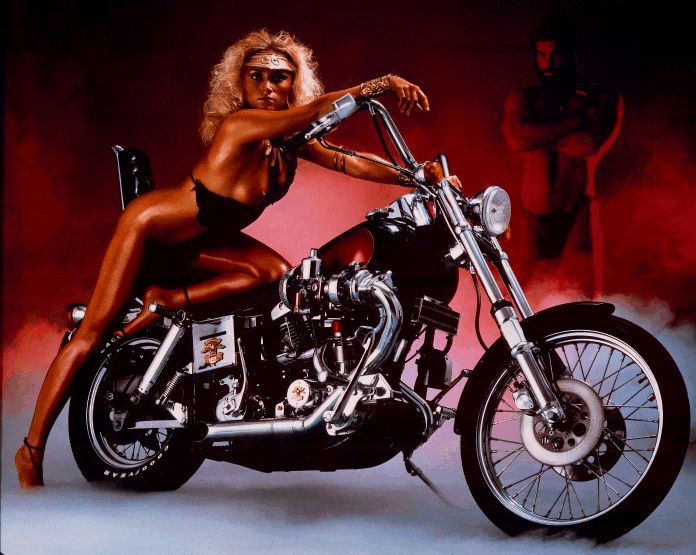

Models: Shelby Sawyer. Harley FXWG

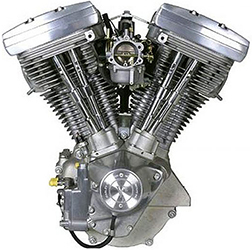

The first successful turbo for the Harley big

twin was our design which featured an IHI Turbo, a

draw-through SU CV Carb, equal length primary tubes joining

into a 2-1 turbo header; a 2 1/2" turbo exit pipe with a 3"

diameter turn-out muffler.

The RB Racing kit featured an RB Racing billet

Boost Master wastegate, a chromed inlet plenum, and a

glycerin filled boost gauge. These kits produced 125 to 150hp

@15psi of boost.

No heat on your leg with exhaust routed forward

Some 25 years later Shelby got in contact with

us and we got her some prints of the photo shoot. She was at

the audition for the shoot with a friend and did the shoot

after another model sort of dared her to give it try. Pro

photographers Mark Rice and Ron Tuso did the shoot. Small

world. Shelby is doing fine these days, involved in religious

art.

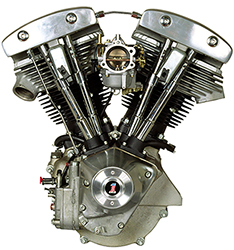

Some kits were produced with black

chrome headers

The black chrome pipes indicate

this was one of the first 33 units we produced. Draw through

SU Carb. BDK Needle 101.5 main jet, 2 1/2 turns out...can't

seem to forget that for some reason. Actually there are a lot

of reasons we can't forget that. These were the first

successful Harley-Davidson turbo kits. If you ran them up to

15 psi and worked on the engines they would produce up to

150hp...Of course you couldn't stop but that was another

story.

We even built, in his shop, a turbo for Dick

Evalesky of Atlas-Precision Frames (closed /retired) for a big

money grudge race that he won. Testing against a CB750 his

Chopper would thunder by after the CB750 got it out of the

hole.

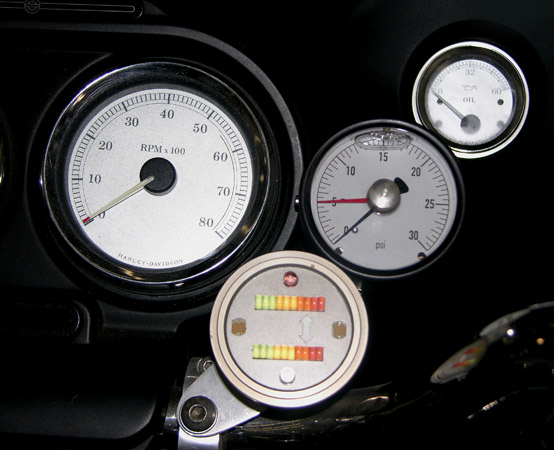

Mechanical Boost Gauge

3 Bar Boost Gauge with

Tattle-Tale indicator showing maximum boost actually

run. Glycerin filled to resist vibration. Easy to

reset, even with gloved hand. Not lighted.

Part Number 03-1013: Center back mount w/12mm x 1.5 locknut and integral push-on hose nipple. On Harleys you can mount this gauge directly off of the back of our RSR Dual Air Fuel Ratio Gauge. Viewing the tach, the air fuel ratio, and the boost all in one location. Only O2 feedback is fast enough for real-time monitoring.

Boost Control

(Optional with External Wastegate)

Black Knob controls the boost.

Clockwise increases the boost. Turn the boost all the way

off (full counter-clockwise) and it's about 6-7 PSI.

Just remember, leaving it set at 8 psi, you can outrun about

anything. When you're cruising at 75 mph and roll the

throttle on it will instantly produce boost pressure. Rider

adjustable when you are riding.

Turning dial up to 11 turns: 6-7

PSI (Wastegate Spring) to 25 PSI.

Dual RSR

Air Fuel Ratio Gauge is to the right. We have no idea

how anyone thinks they are going to get their tuning right

without actually riding and observing the Single or Dual O2

Display. The O2 Display is a mandatory purchase with the

kit.

Barely nudge the throttle and it goes to 0" Hg and anymore than that and it goes directly into boost. Hit a long steep grade at high speed and the turbo will hold at about 2 psi boost. It's not a good idea to beat your bike to death on a dyno if there is not enough airflow especially with a turbo. Best to ride.

Single or Dual RSR Air Fuel Ratio

gauges. Which one depends on the system or rider preference.