RB Racing Turbos...Big Twins:

Shovels to M8's (Click on Image or Text Below)

M8 Turbos

Twin Cam

Turbos

Evolution Turbos

Shovelhead

Turbos

Note: As of 2024 we are only doing EFI EVO Turbos on a

custom prepaid basis...only Motorsport level EFI with

Motorsport Programmable ECUs and custom Mil-Spec Wiring.

____________________________________________________________________________________________________________________

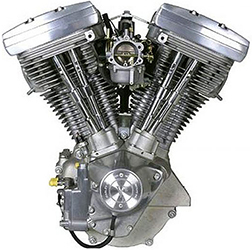

Generation (1): RB

Racing EVO Turbo Kits...Blow Carburetor Through 1985-1989

A long long time

ago we made blow through carb turbos starting with the Mid

1980's EVOs. We tucked a small IHI turbo (RHB52) between the

frame and the engine. No intercooler and a boost sensitive

fuel pump system.

We never did

draw-through EVO Turbos.

Above: Joe Walker's famous "Jap Zapper" our last "blow thru" design (1985-1989)

Blow through

carburetion is a bitch. We had to make all sorts of special

parts to make it work. Joe Walker won innumerable "shows"

with this bike. Later on we fuel injected the bike (RSR EFI)

and Joe added twin nitrous bottles. We simply do not

understand the show mentality.

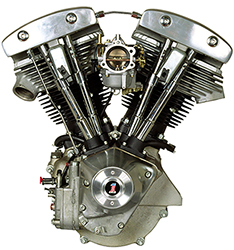

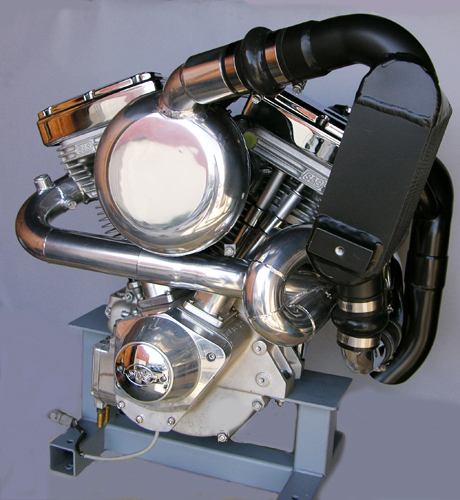

Generation (2):

RB Racing EVO Turbos 1989

on...RSR

EFi Intercooled

(Our

Older Smaller Intercooler design)

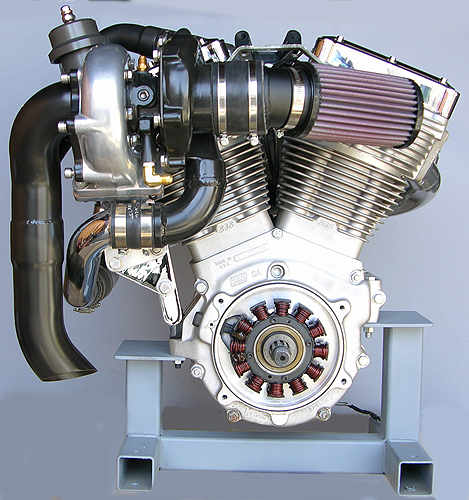

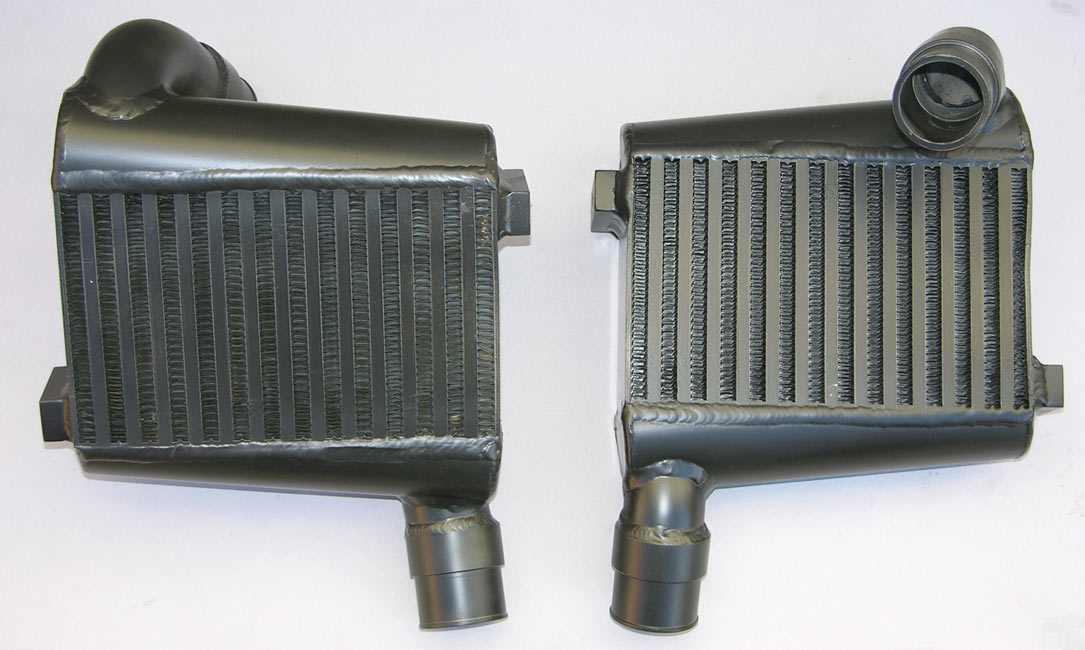

Generation (3): Larger Intercooler design EVO's

Turbos...RB Racing

Horsepower Perspective...32 years ago

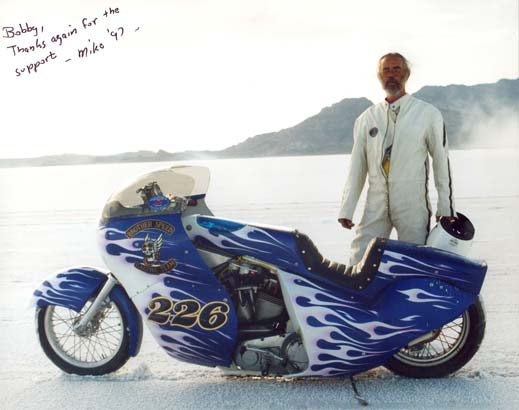

In the Early 1990's we

were making 275 hp out of 104" Evo motors like Mike Geokan's

famous #226 Blue Bike at Bonneville. We did not run them higher

because we limited the airflow with the turbos we chose. The IHI

RHB6 produced 255 hp at 15 psi....312hp at 22 psi measured at

sea level...less at 4500 Bonneville altitude in hot August heat.

The bike featured our

RSR Fuel Injection System with four 50lb/hr injectors running in

a stage mode. We wrote a fuel injection program once for it and

that program was never changed. We wrote the program before the

bike turned a wheel with the turbo. There was no testing. We

asked Mike if we could do a brief test on the bike as we

designed it, built it, and programmed it...His answer.."It's a

handfull and you can't ride it". Riding 8 second Suzikis, 215

mph GSXRs, record holding 375 Hp ZX-11s and 300 Hp BMWs...what

the hell did we know. Egos.

Mike was adamant about

"Not wanting to learn anything new" when it came to programming

our efi. He didn't have to. It was his bike and no one else

could ride it and it was setup by RB Racing.

1990's...Early on at

Bonneville the #226 bike would suddenly shut off running about

22 psi of boost...something we had never seen before with

Suzukis, Harleys, Kawasakis or any other turbo bike. We had

brought spare microprocessors to reprogram if we had to. The RSR

ECU had two microprocessors, one to house the operational code

and one to house the serial programming data. When the bike shut

off we checked everything and switched the microprocessor that

held the data and the bike ran again but in subsequent runs it

randomly shut off again.

We checked the

programming and the RPM limits had been altered to 65535 RPM

(Hex FFFF).

It was electrical interference from the spark plugs as it happened under high load. Mike's solution was he would need a pile of microprocessors and change them after each run. We asked him which glove he put on first before he ran...left or right. All he had to do was alter that order and the bike would run. That went over well. We drove back to LA made some additional changes on the input programming circuits and drove right back up to Boise...that's 1800 miles driving with no sleep and insisted the bike be re-wired to get the plug / ignition wires away from our electronics.

To this day more than

two decades later the bike still starts and runs (retired) and

Mike still believes you have to change the "chips" after each

run. No...It was the gloves.

The bike held a 1997

Bonneville record for about 20 years. The 104" motor died when

the Carrillo rods broke and a 93" ex Bob George (donated)

Streamliner motor was inserted.

139" EVO Turbo

2005-2017...Exercise in spending $$$$

Three years planning

first ran in 2008.

Above picture: Carl

Pelletier of Competition Motorcycles delivering the 139" Turbo

ORCA Motor to be installed in the Bonneville Bullett. RB Racing

designed all the special parts like the 1/2" A-1 cylinder studs

and the water-cooled cylinders as well as the pistons and other

items. John O'Keefe did the porting to our flow specifications

and installed the Ferrea valves we had made. Carl did all the

final machining and assembly. We used the engine to test new

ideas...Some worked and some didn't but we never lacked

power..Over 400hp.

Expensive.

Our Bonneville efforts

these days use sophisticated Cosworth Pectel SQ6M

and other advanced motorsport controllers and 550 hp turbos. Our

street bikes come with 360 hp turbos. Horsepower depends on a

lot of factors

like displacement, rpm, boost level , and cylinder head

design... And, as it rises, the Harleys show their weak

points...clutches, cylinder sealing, cranks and connecting rods,

and final drive belts to name a few.

Carl Pelletier above with the RB Racing Bonneville 139" ORCA Single Cam motor with 8" rods, no gaskets, turbo ported SA B2 heads, Inconel valves, custom 1/2" cylinder studs, 32-2 crank trigger crankshaft , 600 psi Inconel head sealing rings, O-Ringed base cyl sealing,and water cooled barrels. Dry sintered iron lock-up clutch in a wet billet primary...Delkron FXR Case with a Jim's Fat5 transmission converted to hydraulic clutch. Not one Harley part. Way past 400 hp.

Carl assembled this motor three times...once to check the lower end, once to replace a cracked engine case, and finally to replace the pistons and install skirt buttons. Carl provided the 8" McClure rods and the Bandit Lock-Up clutch. Later switched to 8" Carrillo / Shaver rods.

Horsepower can be gotten by anyone if you cram the can full and light a match. The question is.."Is the engineering good enough for it to be reliable and is it practical enough to be driven anywhere"...Fast is a given. People forget the rest...like practical air cleaners for high horsepower. Always look at the air cleaner...if there is one...And, would you put that air cleaner on a V8. It's an IQ test.

96" RSR Fuel injected

and Turbocharged Fat Boy....Ran around for a few years in L.A

and some 2500 mile trips. The Turbo was eventually removed

(not exactly paid for) and the bike was sold several times

minus the EFI and the Turbo. Zero issues save a leaky fuel

plump (replaced).

The guy we did the

turbo for said his bike was running rich all of a sudden. We

replaced the O2 sensor and checked the programming and then

traced it down to the guy putting high lead content race gas

in it. He lied to us...wasted our time. Pump gas back in and

it ran exactly the same as when we programmed it.

We ended up repoing it

as "friends" seem to be lax about squaring up finances.

RSR EFI EVO: Does get Complex

Ordering and Payment Details

Turbos are only sold on a

pre-paid cash basis

with a Bank to Bank Transfer of funds. We provide transfer

details when you decide to order the kit. Place your order

online 24/7 so we have your complete particulars. No

credit card sales. Order online 24/7, specify

Bank to Bank Transfer, and we will provide details for

Bank to Bank Transfer of funds. There is a minimum surcharge of $50.00 on all

bank transfers due to bank fees which occur on both ends

of the transaction. Shipping charges are paid for

separately by credit card. We negotiate the best shipping

prices at time of shipment.

Customer is responsible for

transferring the correct amount as the sending bank will

deduct fees and end up transferring less than the agreed

invoice which causes delays. Note: These items are sold on

a direct basis only. They are not an item sold through any

form of "Distributor".

Mandatory Items to Order: Must order Dual O2 Display 06-1003. You must order the Glycerin filled Max Indicating Boost Gauge 03-1013.

Shipment of Turbo Kits

Some people in the past

have picked up turbo kits here. Whenever we ship the kits it

usually consumes several days to custom package, control the

items, prepare the parts for shipment, and cart the boxes over

for shipment with all the paperwork (triplicate for

international shipment). We used to do this for free until we

woke up. There is a $500.00

charge for the packing and cartage to a shipper on

International which requires triplicate sets of documentation

for each package..

As stated above: "Shipping charges are paid for separately by credit

card. We negotiate the best shipping prices at time of

shipment." One turbo kit: Three double wall boxes with all parts

individually packaged. 76 pounds.

Note: Everything is

Fly-By-Wire these days so we are discontinuing the above after

more than 28 years of machining castings, butterflies and

shafts as well other items.

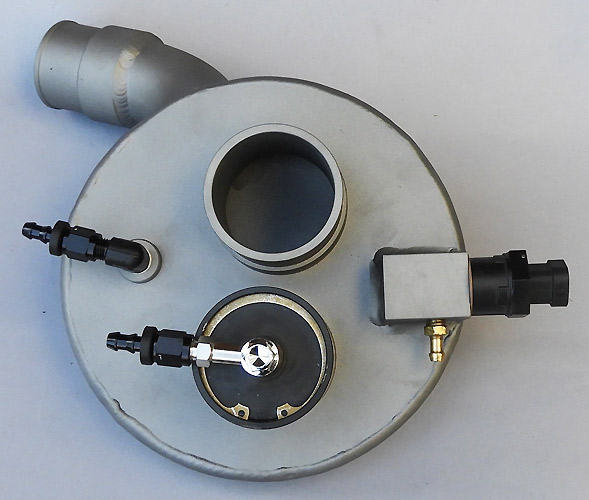

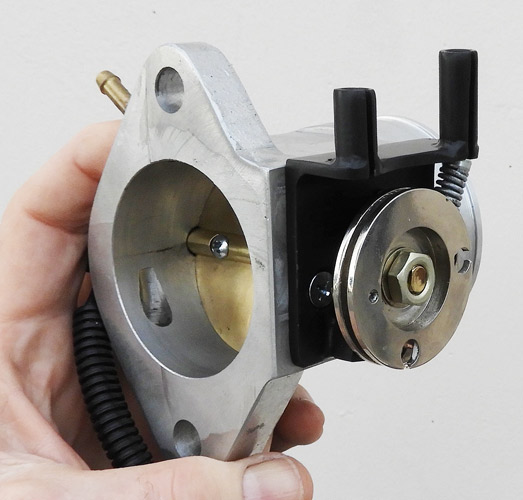

We have a completely integrated inlet system with a 56mm (2 3/16") throttle body with integral stepper motor Idle By-Pass, and ball bearing shaft support with shaft seals. Combine this with a full 1/2" fuel by-pass fuel rail and port injection in either 2 bar or 3 bar systems with up to 6400cc/min delivery capability and you have the ultimate turbo package. Fully engineered and proven.

The throttle body incorporates push pull cables, screw adjustable idle stop, vacuum/boost port, TPS mount, Idle Air Bypass circuit, and a two bolt flange using 7/16" Allen Bolts that hold the fuel rail and throttle body to the inlet manifold. The TPS is bolt-on and forget. There is no need to "set" it. The throttle shaft rides in sealed ball bearings.

Here is a system with our RSR EFI set up with two (2) 650cc Bosch EV6 Injectors in a 2 Bar system for an 80" EVO motor programmed for 195hp @15 PSI.

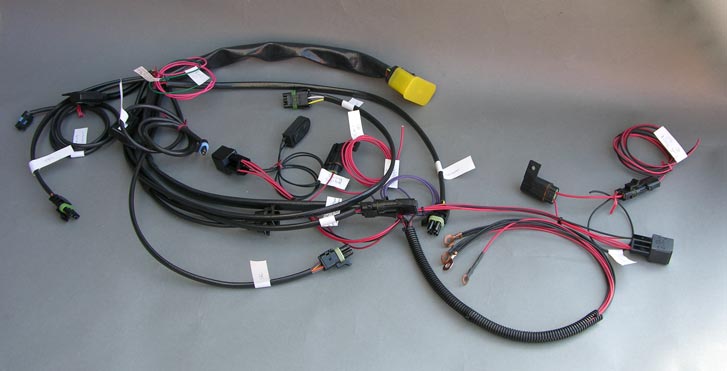

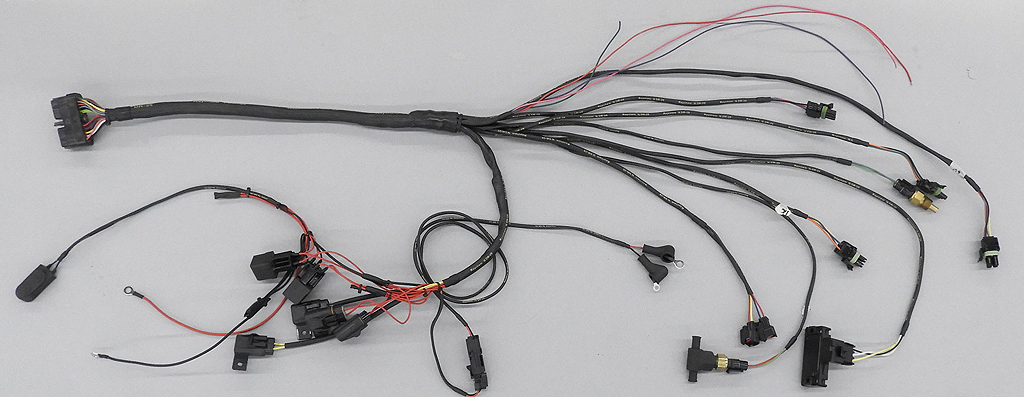

Killer Wire...RSR

Closed Loop EFI (Discontinued)

Later

on we switched to Raychem DR-25 coverings sealed with Raychem

SCL and Resintech RT125 Epoxy.

Water-proof, abrasion

-proof, Harley-proof wiring. Never a wiring failure since we

started doing them in 1989. Automotive grade high temperature

wiring with waterproof connectors, gold plated and silicone

sealed Deutsch ECU 40 pin connector, Weatherpack silicone

sealed sensors, and fused peripherals, all sheathed for

abrasion protection. Very professional.

There is also a waterproof tuning switch that allowed programming with the ignition "off".

One of

the last RSR Closed Loop Fuel Injection Harley Turbo Kits

being shipped....What you see is 30 years of development. In

1990 there was nothing remotely like it and these systems went

on to set Bonneville Land Speed Records and win Drag Racing

Championships.

This one

is headed for an 80" EVO Dresser...The RSR EFI is

pre-programmed for 195HP in a 2 Bar (15 PSI) system. These

systems shipped complete with a laptop, software and tuning

cable . Time to move on to more sophisticated Motorsport

engine control systems for Scratch Built ORCA EVO Motors that

we have been developing for a number of years. Our Twin Cam

Delphi systems remain the same in either 2 or 3 Bar

configurations.

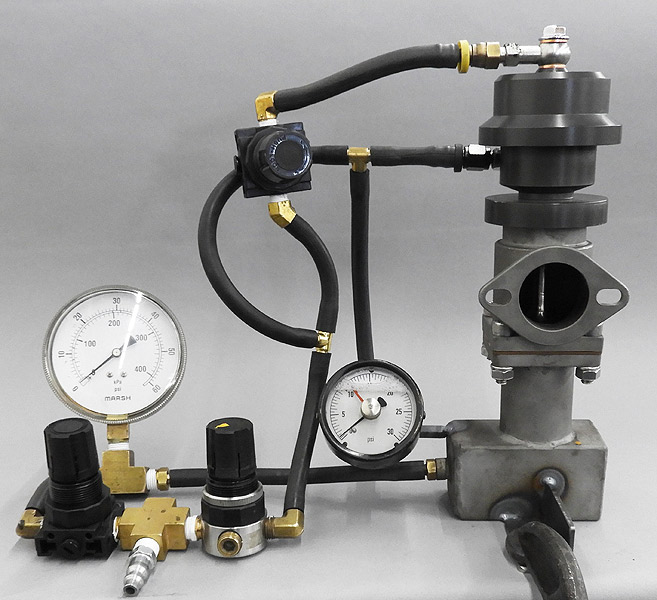

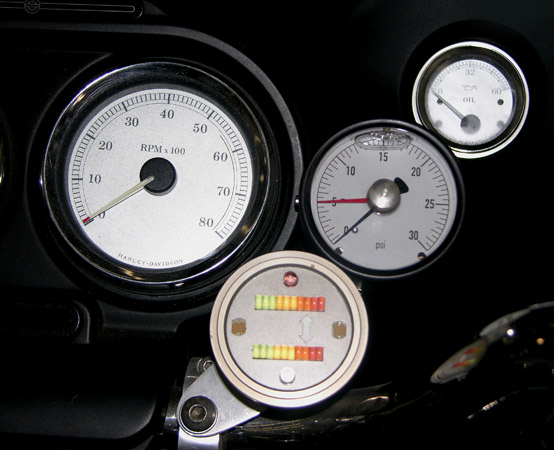

Mechanical Boost Gauge

3 Bar Boost Gauge with Tattle-Tale indicator showing maximum boost actually run. Glycerin filled to resist vibration. Easy to reset, even with gloved hand. Not lighted. If you do not order the ORCA Turbo Dash you must order this part.

Part Number 03-1013. Center back mount w/12mm x 1.5 locknut and integral push-on hose nipple. On sequentially injected Harleys we mount this gauge directly off of the back of our RSR Dual Air Fuel Ratio Gauge. Viewing the tach, the air fuel ratio, and the boost all in one location. Only O2 feedback is fast enough for real-time monitoring.

Boost Control and Fuel Programming

Black Knob controls the boost.

Clockwise increases the boost. Turn the boost all the way

off (full counter-clockwise) and it's about 6-7 PSI. For

very high boost levels like on our Pro Street Kits we

require you upgrade your fuel pump and regulator system.

Just remember, at 8 psi, you can outrun about anything. When

you're cruising at 75 mph and roll the throttle on it will

instantly produce boost pressure. Rider adjustable when you

are riding. 6-7 PSI to 25 PSI.

Dual RSR Air Fuel Ratio Gauge.

We have no idea how anyone thinks they are going to get

their programming right without actually riding and

observing the Dual O2 Display. The O2 Display is a mandatory

purchase with the kit. For instance, our Turbo with some

higher end, higher lift cams, pulls 10" Hg. in a high speed

(80 mph) cruise on level ground.

Barely nudge the throttle and it goes to 5" Hg and anymore than that and it goes directly into boost. Hit a long steep grade at high speed and the turbo will hold at about 2 psi boost. These figures are way more air and manifold pressure than you are used to programming for and it's not a good idea to beat your bike to death on a dyno, especially with a turbo. Best to ride.

Single or Dual RSR Air Fuel Ratio

gauges. Dual if sequential fuel injection.

First Fuel Injected Harleys in the 9's, 8's and 7's..RSR EFI

We've been at this for awhile from our early 80's 150hp Shovelheads up through our new 360 hp Turbo Kits . We put the first fuel injected Harleys into the 9's, 8's and 7's at the drag strip. The only fuel injected intercooled Harleys that hold national drag racing championships and Bonneville records come from one place..RB Racing.

Whereas people love to talk about about turbos and, if they have touched one once in their life they become experts, we have been at this long enough to know what should be done and what the difficulties are. It's always amusing the see the poor engineering that comes and goes in this market. It's not about plumbing and band-aids.

No Turbo...Think about it

Hers's a perfect Video example of one of our

customers with our LSR 2-1 Pro

Stock pipe and no turbo. If you think one of the "in

your leg turbo" vendors can outrun this bike think again. If

you see this bike pull over and park. No turbo and it's FAST.

190 HP fast

Bonneville Testing 1989 to 2017

Here's the 139 Inch Orca Bullett with it's large diameter stainless steel merge collector exhaust system and large air to air intercooler. Pretty much state of the art insofar as pushrod Dinosaurs go. Designed for the long course at Bonneville. 600 HP Turbo. 500 hp @30 psi on this 139" engine. In testing we have run 212 mph @ 4700 rpm with 9 psi of boost. Next step 230 mph plus. It only runs a couple of minutes at a time...not much time to insure it is safe. It has passed all SCTA-BNI and AMA/FIM inspections and Bryan Stock, filling in for Mike Geokan, has got all three licenses 150, 175 and 200 mph and is cleared for long course at Bonneville.

With Brother Speed's

Bryan Stock in the seat it held a 200 mph record at

Bonneville for several years in "low boost" testing. We held

Bryan to 4800 rpm to let him get a 200 mph SCTA-BNI record.

It has run 214 mph with just 9 psi of boost. Next up is more

advanced electronics and 230-250 mph.

Mike Geokan's RB Racing Turbocharger uses a separate oil system that has a stainless steel oil tank and an electric feed pump that maintains a constant 30 psi to the ball bearing turbocharger. The engine runs 50 weight PennGrade1 (ne Kendall) "Green Stuff" oil and the turbo runs Brad Penn 20-50W.

Black Strips Lasting Longer Than 6 Miles

If you experience black strips lasting longer than six miles seek immediate mechanical attention and replace your RB Racing components with stock ones. Continued use can cause loss of licenses, premature tire wear, and infuriate your competition. Bonneville Salt Flats...where we prove our products...and have done so for more than 30 years.

Mike Geokan's #226 Bonneville Harley...30 years of RB Racing Turbos

Can you take your 250 hp Harley race bike and cruise around to thank the people who have helped you set records? It takes a lot of people to build a bike from scratch and to support a race effort.... Painters, welders, fabricators, engine specialists, fellow club members, and even professional dancers like Salina. You never do it alone and if you don't take the time to thank those who helped out it's going to be a cold lonely night with you and your time slip to keep you warm.

Salina moved on long long

ago...you can't feature dance forever.

Mike was running 199 mph in

Bonneville Slush with 22 lbs of boost and 275 horsepower way

back in the 1990's. These days Mike's attention is devoted

to his 139" ORCA powered Bullett. His friend of 55 years

Bryan Stock has taken over the riding chores.

In 2017 we bid farewell to the

Bullett Project. Mike was finally well enough to open up his

ugly take on the world. One's true nature always comes to

the front sooner or later. What the hell..It was fun with

Bryan and the crew and we got Bryan and the Bullett a 200mph

record. No wheel turned, zero testing, multi-step rider and

bike licensing to record in 3 years.

Mike can now pout, scowl, and

keep getting people to pay for his project while he putters

around watching TV, eating out twice a day, and talking

about the distant past through rose-colored glasses...saying

he does not want to learn anything new.

Mike Geokan's #226 world record

holding RB Racing Turbocharged Harley Davidson is

featured in an old video. More innocent times.

It's a complete system

A complete systems approach is

why our RB Racing turbo kits produce so much power at low

boost levels and why they work so well in day to day

operation while giving excellent fuel mileage and

drivability. More often than not people come to us after

spending some astronomical sum of money on their engines

only to be disappointed in the result. When we tell them

they have to start over with different pistons, cams,

gaskets etc they reply that their motor will be just fine

turbocharged at 10.5:1 compression ratio and 15 pounds of

boost.

Since everyone is an expert we no longer try to advise them differently if they so object...Everyone has to learn sooner or later. We do recommend 8.5:1 if anyone wants to listen...of course this all depends on cams but that is another story all together. When you purchase an RB Racing turbo system we ask what your intended use is and structure our advice based on the latest information we have. Look at the early RB Racing turbos above and the pictures in this section to see how far we have come in nearly 30 years.

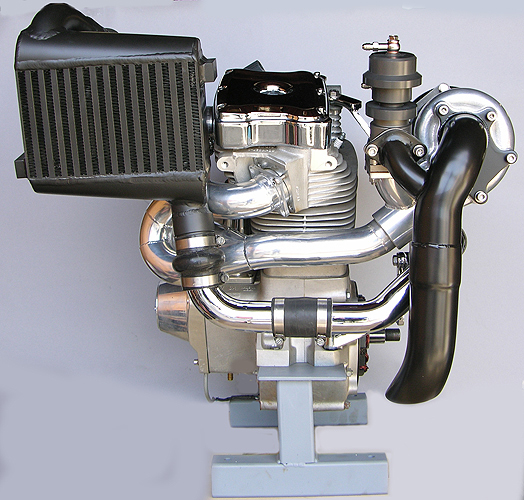

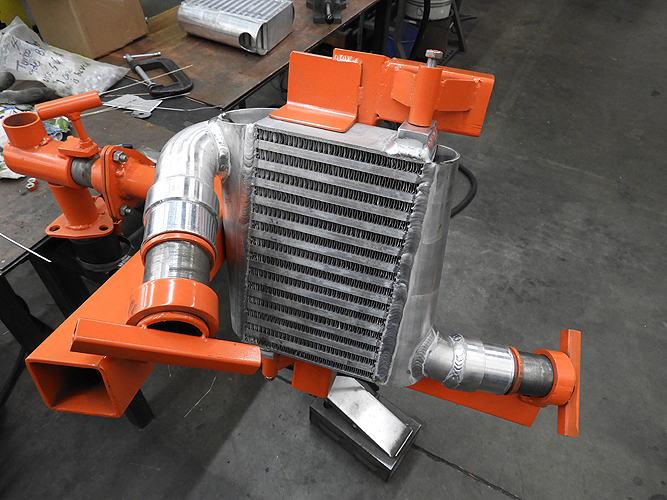

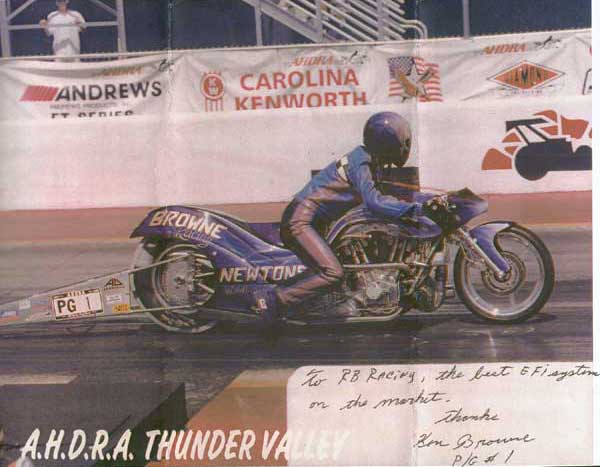

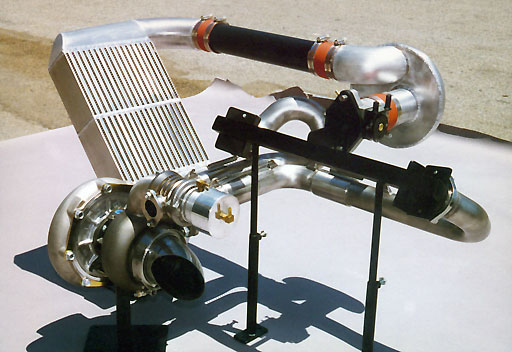

7 Second Old Pro Gas Champioship Design...Way More than Two Decades Ago

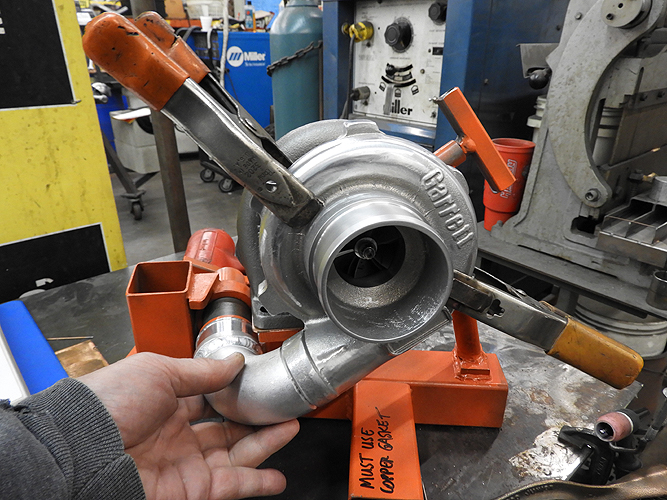

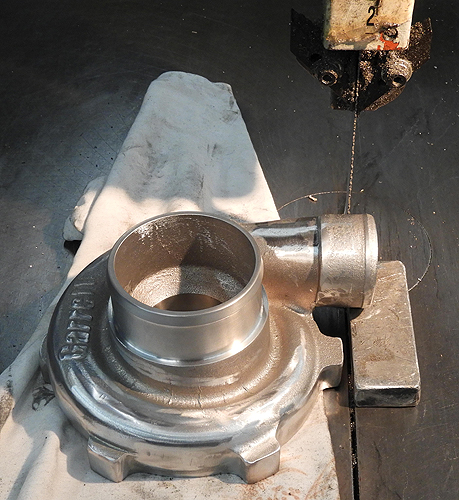

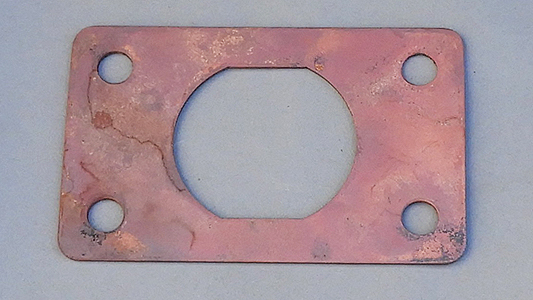

This Pro Gas 500+Hp system is custom

built for race application and involves fabrication for

intercooler mounts etc. at the builder / fabricator level. The

Pro Gas system pictured below was built for National Modified

Champion Wayne Pollack of Fuquay Varina, North Carolina. Wayne

flew out to see us and agreed to build a bike around the

system we would design instead of vice-versa.

Funny story: We wanted a twin

scroll small A/R exhaust housing with a 500HP compressor

housing from Turbonetics...They said we were wrong, but we

insisted, and tempers flared. We got what we wanted by going

through their castings. Bob Keller (owner) insisted that we

apologize for our insistent rude behavior...We refused. We got

what we wanted. It worked. They got paid. End story.

Wayne wanted to build a

sophisticated Turbo bike but he made the serious mistake of

ordering some cylinder heads from Nigel Patrick who did zero,

zip, for a year after he took Wayne's money. The year delay

caused Wayne to miss a complete season and his sponsors cut

the purse strings and his "crew" dispersed to other projects.

We had to reason with Nigel in a forceful manner.

Wayne sold the parts to Ken Browne, who continued with the project, but cut up the parts and left off the 500hp intercooler. There went 1% in hp for every 11 degrees F the charge cooling would have provided. Those of you unfamiliar with how much air heats when you compress it...at 22 psi the discharge temperature can be 265 degrees F. You can't find any turbocharged race vehicle without a large charge cooler.

Ken still managed to run 7.55 @ 173mph (176mph best mph) in the quarter mile and 4.80 @ 147mph in the eighth mile, and built a new bike with a bigger tire!

Ken's new bike is (2002-2004-2005 etc.) was further away from "what should be" and didn't work well. More weight, poor turbo location etc. Ken is a nice guy, but bad ideas, no matter how nicely executed, simply won't work. We talked to Ken, hoping he would just execute our original design, but everyone wants to do "his own thing". There is always a price for this. Hey! It's not death..It's a hobby!. Hey, he's even building a third one. Ken had to quit riding after a not too successful neck operation.

Wayne Pollack went on to wrench and ride the beautiful Majestic Turbo bike, initially with twin turbos (didn't work well) and later on with one very large turbo similar to the one pictured. We sent Wayne the turbo specs and drawings for a new design so he could shit-can the two turbo deal that Kevin Draper and Don Vesco cooked up. Wayne got to deal with methanol and Hilborn injectors with nitrous added to the mix. Boom! Blow up an Overkill Engine.

Wayne was always straight with us, he's a hard-core racer and like Wayne, we think there's nothing much better than kicking ass and trying to be the best at what you do...Wayne went off to ride Ray Price's Top Fuel Harley and to stay in shape just ran a 242.587 mph World Record ( Sept 2003) on Rich Yancy's turbo Hayabusa at Maxton. In 2005 Wayne upped the Maxton record to 258mph on Rick Yancy's Hayabusa.

Here's Wayne on Ray Price's Top Fuel Harley (Oct 03). Ray got a bit banged up and Wayne was tapped for the ride. In August 2004 Wayne retired with back problems...no more spine crushing acceleration. Wayne went on to set a speed record of 258mph on a Hayabusa at Maxton in 2005.

We get a few calls each year about Pro Gas systems. We suggest you call us before you start building. Everyone wants to do their own thing but decisions can haunt you and they get expensive. If you're already far along we'll sell you some parts and keep our mouth shut in the advice department because it will already be too late.

Click on the below pictures for more details on these parts and people.

Ken Browne's original record

setting 120 cubic inch 4 cam Pro Gas bike. RB Racing Pro

Gas Turbo / RSR 400i Fuel Injection System. Best 1/4 mile

E.T. 7.55; best mph 176. This gives you and idea of how

much power is hiding in our street Blackbird and Pro

Street systems.

Final Point

People who don't do this for a

living have all sorts of advice. They specialize in being

"persons of authority" even though they have not done the

work. They give advice about cams, turbo design etc. and

they can't walk the walk. There is more bad, incorrect, crap

floating about turbocharging around than there are turbos

running.

We've been at it for over 40

years and, since we actually make the stuff, we know even

how little we know...which is a lot more than those who

don't do the work. We aren't here to correct misconceptions,

only to support the art.

Take a

203 mph pass on the Bullett.

Bonneville

200 MPH Pass ... Bullett

Make no mistake about it, when

you deal with the big twins you are dealing as much with art

as with science. Everything is hanging out in the open for

everyone to look at and it is extremely difficult to blend

function with aesthetics, especially in this era when every

other bike is a "show bike" with every piece of billet

trickery and chromed what nots glued or bolted to every

exterior surface.

We think our new turbos will meet the most demanding needs of any big twin whether it is trailer bound for the next show or caked in wet salt on its final record pass at Bonneville.

We will not compromise functionality however...so don't ask.