Advanced Engine Management: Pectel SQ6M, The Best Value in Motorsports ecus:

Note: As of 2023 it's

End of Life for the SQ6, SQ6M, and SQ6M12

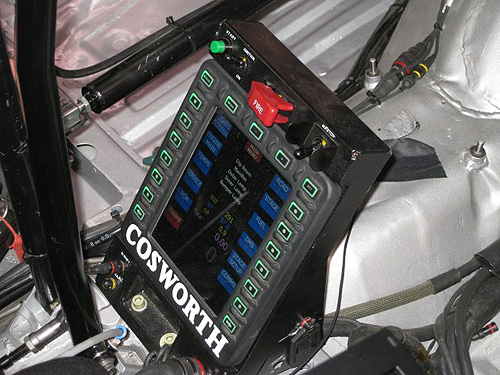

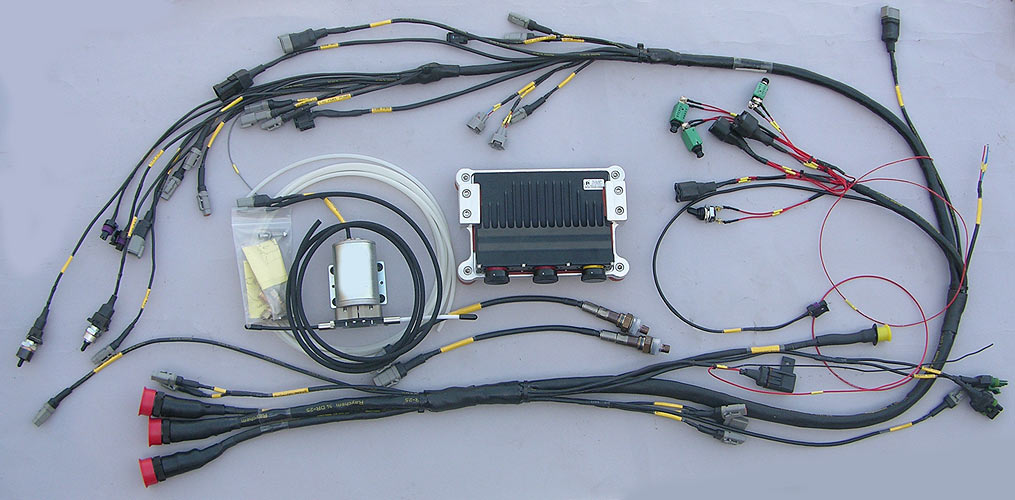

Pictured above the is Cosworth Pectel SQ6M with it's pricey, hardcore, Deutsch Autosport connectors. With two 26 pin connectors and one 55 pin connector it is a competition proven engine management system. This is the engine controller chosen by the BMW factory to run its quad cam V-8 racing engine pictured below. The SQ6M is by far the best "Bang for your buck" as it handles every sensor you can throw at it and it comes standard with 4Mb of of up to 2000Hz data logging, advanced traction control and Fly-By-Wire. It also integrates with dashboard displays and, when you add up the costs of buying upgrades or adding options in lesser systems, the SQ6M comes out a cheaper alternative... Not inexpensive, but competition proven. None of this is cheap unless you just sit on the couch.

When you look at

high-end professional motorsports engine controllers the top

tier are Bosch, Magneti-Marelli, McLaren TAG Electronics, and

Cosworth... Anything else should not even be considered. Of

these, Cosworth offers the best value feature by feature and

is the most affordable. The SQ6M is the controller of choice

for RB Racing. If you want a peek at the high end F1 McLaren

ECUs we offer this PDF Document.

It also uses FPGAs for angle based computations like the SQ6M

does.

A PDF on the Pectel SQ6M outlines the features and the 107 ECU Pins.

Professional motorsports requires state of the art engine control and data acquisition systems to win. Like it or not, computers are here and the days of brass jets and seat of the pants opinions are simply part of a glorious past. We've been around long enough in the racing game to have witnessed and participated in the changes.

Pectel SQ Series ECUs: Used by BMW, Nissan, Toyota, Lotus, Citroen, Renault, Aston Martin, Ken Block (Ford)...You might get the idea that Pectel Electronics is your best choice for professional motorsports by seeing who has chosen Cosworth/Pectel.

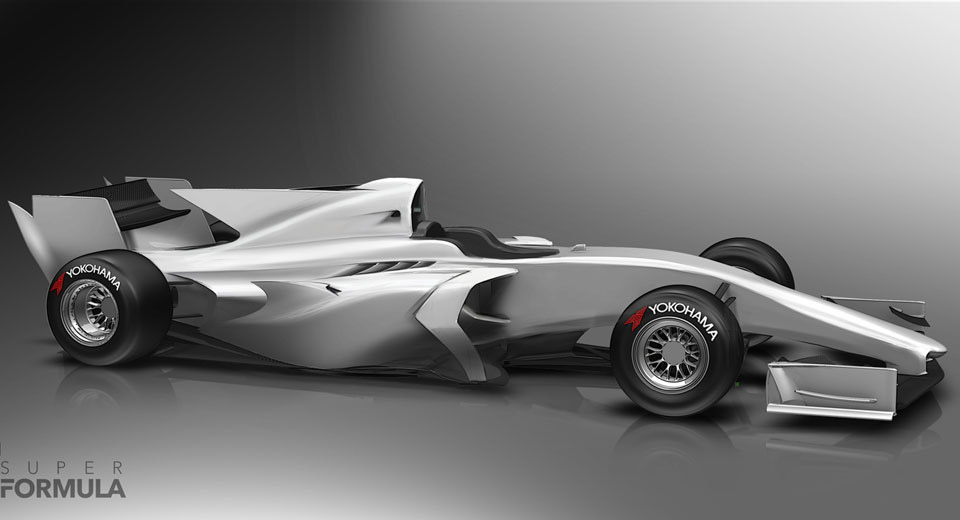

2019 Japan Super Formula Cosworth Electronics

Turbo Honda motor.

Should be as fast as F1. Dallara chassis. Full Cosworth

electronics.

2017-2019 Subrau Motorsports WRX STGlobal RallyCross Pectel SQ6M

2017 WRC Champion

w/ Cosworth Electronics..M-Sport Fiesta

2017 WRC Portugal Win..Cosworth Pectel Electronics

M-Sport Ford with full Cosworth Pectel Electronics in mid-flight to Portugal WRC win.

2016 WEC GTE Pro

World Champion

Aston Martin cinched

the 2016 WEC GTE Pro Championship with full Pectel Cosworth

electronics. MQ12 Engine controller. Winner 2017 Le Mand 24h.

LMP2 2017 Cosworth Electronics

The Gibson 4.2 liter

V8 is the spec engine for 2017 LMP2 cars. All Cosworth

electronics. 25 of these started the 2017 LeMans 24h and one

came pretty close to winning it when the LMP1 cars ran into

issues.

Ken Block's 2016

600HP Ford Focus

The GibsonThe Focus

RS build is a global collaboration between Ford Performance,

Block’s Hoonigan Racing Division and U.K.-based M-Sport.

Featuring all-wheel drive, a new EcoBoost® engine producing

600 horsepower, and a 0-60-mph launch time of less than two

seconds, Ford Focus RS Rallycross cars are optimized for

competition.

Power: 600 hp / Torque: 650 NM ft•lb. Capable of 0-60

mph/under 2 seconds.

Body: 2016 Ford Focus RS, seam welded and reinforced. M-Sport

designed, homologated FIA-spec roll cage. Custom body design

by Ford Performance and M-Sport, UK. Bespoke underbody

protection.

Engine: M-Sport / Ford Performance designed 2000cc 4 cylinder,

Garrett Turbo charged.

Transmission: Sadev 6-Speed Sequential along with Sadev rear

diff and centre diff release unit.

Suspension: Reiger.

Brakes: Brembo.

Interior: Recaro seats, Cosworth

Engine Management and data logging, M-Sport multi

function bespoke steering wheel.

Wheels: OZ 8"x17".

Tires: Avon Rallycross controlled tire.

Aston Martin Vulcan

Only 24 of these are

being made..All controlled by Cosworth

Pectel electronics and a with Cosworth Pectel ICD

dash.

2016 M6 GT3 BMW

2015 Nissan LMP1

Cosworth Pectel

Electronics control the radical 2015 Nissan LMP1. Cancelled

for 2016, Cosworth's engine and electronics worked flawlessly

but the absence of flywheel or battery assist plus other

issues doomed it. They did win thew PR war for coverage.

Cancellation had team members scrambling for new jobs in

motorsport. Tim Whitteridge managed the electrical and

electronic systems for the Nissan LMP1 and is currently

working as a Data Engineer for Magnus Racing.

The 2013 Nissan factory GTR race car is powered by a Pectel SQ6M featuring: Semi-automatic gearbox control, driver adjustable traction control, drive-by-wire throttle control and auto ‘blip’. Serious equipment for a serious race car. About $500,000.00.

Renaultsport RS01

Pectel SQ6M

The Renaultsport RS01 is extremely light at around 1,100 kg with a carbon monocoque chassis and a 500 hp 3.8 litre V6 twin-turbo engine run by a Pectel SQ6M Engine Management system with full traction control. Top speed over 300 kph. A very serious race car that is guaranteed to generate a lot of interest in the new Renaultsport Trophy championship series. A serious car with professional level electronics including the new Pectel ICD display.

Lotus Evora

Lotus T125 Pectel SQ6M

If you have a spare

million dollars or so lying around you can be the owner of a

640 bhp Lotus T125 with a Pectel SQ6M controlling a 3.5 liter

Cosworth V8. Six speed semi automatic with paddle shift.

Customers can purchase these and participate in a European

race program.

2014 World Rallycross Champion Cosworth Electronics

Peter Solberg

(Norway) the 2014 Rallycross Champion with Cosworth

electronics. Motor preparation by Pipo Moteurs.

Pectel Controlled DS3 2.0L 590 Hp Rallycross

Pectel engine management for the closest thing to a Killer B Rally Car. 590 hp from a 2 liter engine. At the highest level of motorsports you only see Pectel, Magnetti-Marelli or Bosch engine management systems. Citroen DS3.

SQ6M Engine

Management Honda BTCC

Subaru BTCC

Subaru in rear wheel

drive only for the British Touring Car Championship. Cosworth

SQ6M Electronics.

M-Sport Ford Fiesta WRC

And another major player that uses Cosworth/Pectel Electronics...M-Sport. Add them all up and you can see the OEM's choose Cosworth/Pectel for their factory race efforts.

Ford Escort..Hoonigan

Ken Block's Cosworth Pectel SQ6 controlled 1978 Gymkhana Ford Escort

Cosworth ICD/IPS32 in 2017 Porsche RSR

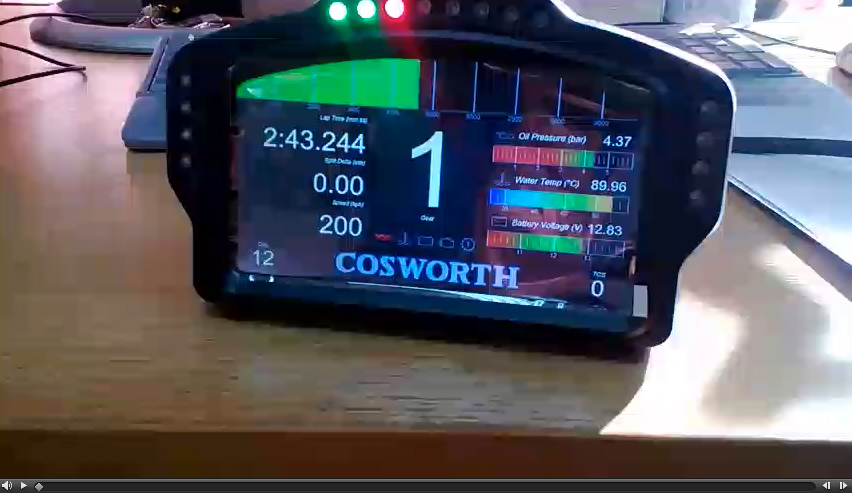

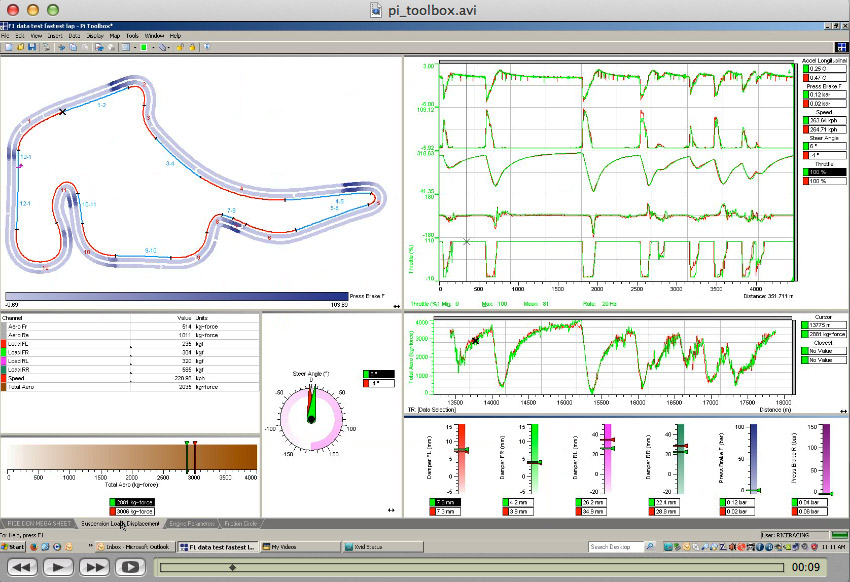

Cosworth Pectel Dash Displays

The SQ6M links directly to a variety of Racing Dash Displays. To the left above is the Pectel Intelligent Color Display and to the right is the Pi Research Omega D4 display. Both dashes feature competition proven Deutsch Autosport connectors.

The Pectel Intelligent Color Display in Digital and Analog Gauge mode. Incredibly flexible display with data logging. Can have up to 256 "screens". Different levels of cost for custom programming. Used by Porsche, Bentley and others on their factory race cars.

Cosworth Pectel ICD

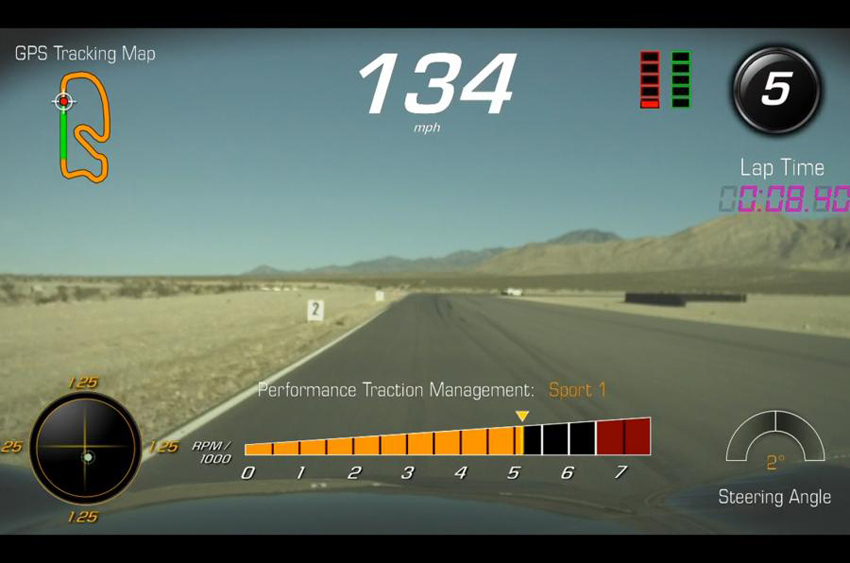

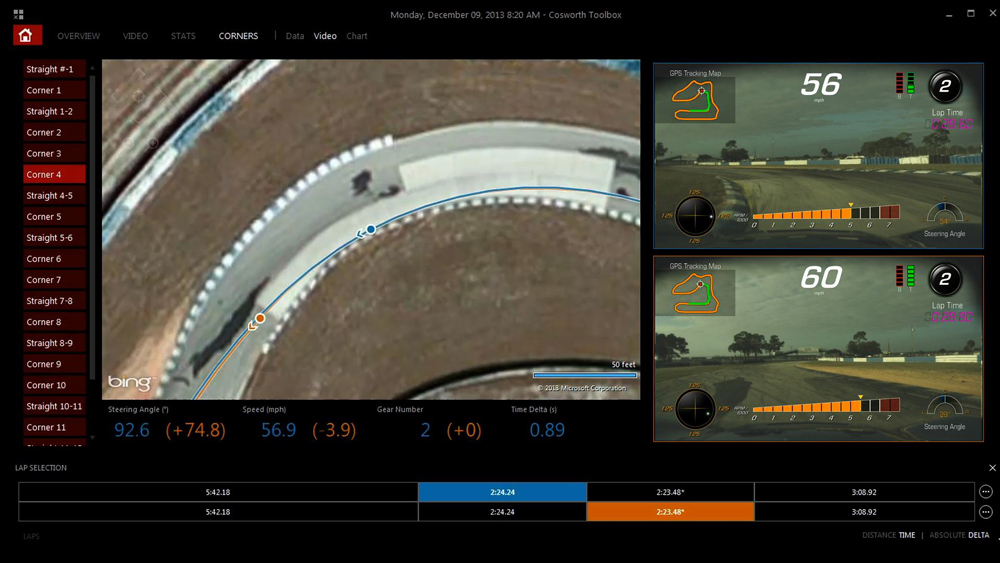

Cosworth AliveDRIVE

Cosworth aliveDRIVE

data recorder/video system in the new Corvette. Also used in

The British Touring Car Championship (BTCC) in it's

motorsports format where it replaced less reliable systems

including GoPro Cameras. Secure data transmission and subject

to side by side playback review of incidents by the Race

Stewards. Full integration into Pi Toolbox, the defacto

standard in data analysis.

Another screen shot

from the aliveDRIVE system. OEM integration in high volume

Corvettes brings analysis, data recording and video recording

to the consumer. Another professional tool for race teams that

is reliable and fully integrated into the electronics.

Cosworth Steering

Wheel

The SQ6M also can

connect to Cosworth's CFW277 (CAN)steering wheel with molded

rubber grips and eight shift lights. Six CAN based switches

and two rotary switches. 3.5" sunlight visible TFT display.

Cosworth video

showing new products. Simon

Holloway giving presentation. Simon has

moved on to RML since his long stint at Cosworth.

Pectel origins began at Advanced

Engine

Research (AER) where engine control units were developed

for racing programs. Pectel was subsequently sold to Pi

Research, and then to Cosworth.

The SQ6M was the result of a multi-year development at Pectel.

One year was devoted to specification planning and two years

to hardware and software development. Add up the number of

engineers involved and multiply it by the number of years of

development and you get a good sense of the complexity. We can

appreciate this having developed our own, much less complex,

closed-loop RSR Fuel Injection System. The development was

geared to provide the maximum flexibility and reliability and

to address accuracy, resolution, timing, and data issues on up

to 20,000 rpm racing engines where crank and cam sensors and a

myriad of many types of sensors are employed.

The SQ6M is protected on both power and ground circuits

against both under and over voltages as well as voltage spikes

from alternators. The ECU will shut itself down if the

voltages are too high and will switch itself back on when the

voltage returns to the more normal 8-18 volt bandwidth. Inputs

and outputs are also protected to prevent damage to the ECU.

Should there be a short or some anomaly these circuits will

switch off to prevent damage to the ECU and will switch back

on automatically when the fault or sensor is corrected.

Extensive engine diagnostics and internal registers will log

intermittent failures which can be viewed in the software to

speed the resolution of issues that would otherwise be very

difficult to diagnose. Simple issues like a faulty switch or

relay, a broken wire, a sensor failure or pinpointing a single

failed injector can save an inordinate amount of time.

Drive By Wire

Capable

Being able to control

single or multiple fly-by-wire throttle systems is an

immensely complex issue that required six months of Pectel

engineering effort. Multiple channels have to be monitored

with complex algorithms to insure the system operates

correctly under all conditions. The SQ6M will shut down the

system if it ascertains there may be any failure or anomaly

that is a safety issue. The computer code to do this had to be

validated and this was an immense undertaking.

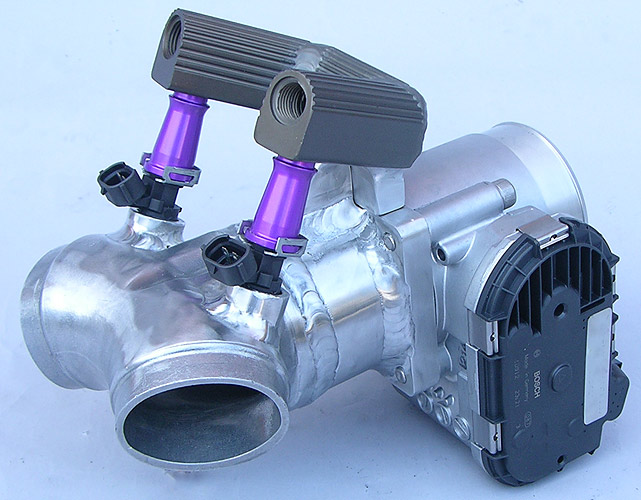

In that virtually all race and passenger vehicles have fly-by -wire systems these days, including some of the Harley-Davidson models and many modern sport bikes, this is an important advantage in choosing the SQ6M. No add-on modules are required. We should note that FBW throttles have to be approved for turbocharger applications...most are not designed for this. Bosch Motorsport DV-E5 shown above.

Here we have

incorporated a Bosch FBW 60mm throttle body to our 139 CID

Harley Bonneville motor. Two 2000cc injectors are used for the

turbocharged engine...all controlled by the SQ6M. The programming is logical but complex and

involved multiple PID functions.

Many of the pins in

the Pectel SQ6M have two and sometimes three uses. Unused pins

of the twelve injector circuits may be used to run valves such

as in wastegate solenoid control. Any Pulsewidth

Modulated (PMW) channel can also be used as an analog

input measuring what sensor or input you choose to specify,

all configurable in software. Users can choose from many

pre-defined sensors or may define the sensor characteristics

themselves. Using existing sensors as opposed to being tied to

specific sensors hard-wired to a dedicated pin gives the user

great flexibility.

Sixteen ignition output channels are available, eight for

external coil drivers and eight for internal coil drivers all

built into the ECU. There is no need to purchase a separate

ignition system. Remaining pins can be configured as analog

inputs or PWM outputs. Nothing needs to go to waste by being

unused.

With user configurable map load sites up to a 125 site matrix (50 rpm x 25 load) and the ability to adapt to any cam or crankshaft sensor gives the Pectel SQ6M immense flexibility. It is extremely well thought out and proven in many years of competition.

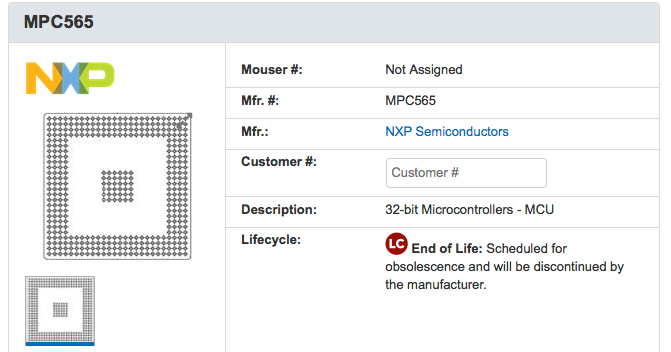

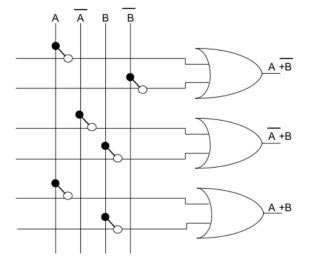

The heart of the SQ6M is a Freescale Motorola dedicated 32 bit, automotive-specific, MPC565 microprocessor running at 56 MHz. An 8 cylinder engine running 20,000 rpm with a myriad of sensors will hardly use half of the processor's capability. To free the MPC565’s workload of running clock cycle calculations for crank sensors, cam sensors, multiple wheelspeed sensors, a second programmable logic controller a FPGA (Field Programmable Gate Array) is employed. Working at extreme speeds the FPGA is infinitely configurable with hundreds of thousands of logic gates and has the calculations ready exactly when the the MPC565’s coded instructions ask for them. Individual cylinder knock control requires this level of sophistication.

Note: As of 2023 it's End of Life for the SQ6 and SQ6M

This ultimately affects also Life

Racing, Syvecs, and ProEFi as they also use the same 56 Mhz

automotive powertrain MPC565 microprocessor.

Most automakers moved more than a

decade ago to the Infineon

TriCore family of processors as has Motec and recently

even Harley Davidson for their M8 abd Revolution motors.

The benefit of the

FPGA handling these issues becomes apparent in the violent

world of motorsport or even the situations in normal driving.

Hunting for traction coming out of a corner or headed down the

course at the Bonneville Salt Flats, those fractions of a

second wherein minute changes in torque are necessary, be it

via ignition timing, throttle position, fuel delivery, or cam

position, and being able to alter things in real time, and not

burdening the microprocessor, can make the difference between

winning and losing...or losing control. Think traction control

and advanced ABS systems. More than 500,000 programmable logic

gates process the angle based inputs like crank sensors, cam

position sensors, and wheelspeed sensors. Bosch Motorsport,

McLaren Electronics as well as Pectel all use FPGAs to support

their ECUs. Bosch uses XILINX FPGAS in their LMP1 race

applications.

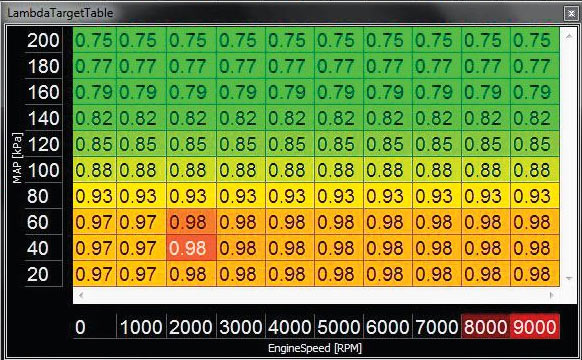

Some people might be fooled by some new system that has 200MHz

clock speed but is hampered by 20 x 20 matrices for timing and

Lambda targets. Sensor latency, time transport of exhaust

gases and other factors are the actual limits in model-based

systems.

The SQ6M offers four fuel and spark maps switchable on the fly or controlled by user defined conditions. Add in 4 Mb of 2000 Hz data logging and fast Ethernet communications, GPS inputs, two NTK wideband control circuits, and more things than we will enumerate here and the SQ6M is by far your best option if you want the “best”...not to mention the fact it is cheaper than stacking up separate systems.

No expensive different license levels or upgrades required.

1. No $1,300.00 license for: Pit Speed Limiting, Switchable Fuel, Ignition and Boost Trimming, Knock Control, Intercooler Sprays, DBW and CAM Control, Traction Control, Gear Change Ignition Cut, Anti-Lag, Anti-Wheelie and Launch Control. These are all standard with the SQ6M.

2. No $2,800.00 Development License as everything you could possibly want to do is already standard. The SQ6M is ultimately configurable as it was designed that way. The trick with "Development Licenses" is that they are tied to the trained developer...i.e. unless you are the trained developer your ecu is tied to the developer. Being tied to the seller/developer is like being married with no chance of divorce.

3. No $1,500.00 Drive

By Wire Expanders. No $1,000.00 Knock Modules. No $900.00

Wideband Lambda to CAN modules.

4. With the SQ6M the costs stop at

the ECU...With others you quickly go past $10,000 in

hardware, add-ons and licenses and are then tied to a

developer/expert at $1,200.00 per day plus travel expenses. We

do our own tuning, wiring and systems integration...and are

not dependent on $1,200.00 per day specialists.

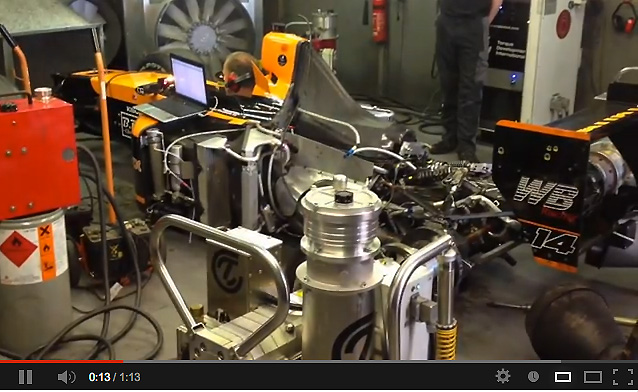

Old F1 Cars Never Die...SQ6M

Arrows F1 car

with Pectel SQ6M controlling things at Torque

Developments International.

RB Racing History...Fuel Delivery

In the 1970’s we were on a never ending quest to master the intricacies of carburetors, those infuriating analog devices that have brass jets, emulsion tubes, slides, needles, venturis, accelerator pumps, enrichment circuits, air bleeds, float bowls, needles and seats..Mikunis, Keihins, Bendix-Zeniths, SUs, Webers and a few others.Before O2 Lambda sensors we were running around with portable CO sniffers up the tail pipes and using strobe lights to monitor and quantify reversion and standoff issues. Making velocity stacks, staggered length ram tubes, heat isolation blocks, and using Magnehelic gauges to monitor ram-air systems we spent enough hours to qualify for a PhD in wasted hours.

If you want to spend 15 years at zero pay it’s a very good way to occupy your time. The shit people won’t do to solve issues about going faster than the other guy. In the end no one cares if you ran a 9.96 quarter mile with a stock 1988 GSXR1100, a 10.97 with a stock GSXR750 or if you got 18 mpg running at the Bol D’Or in 1977 with 29mm smoothbores. Gasoline soaked hands, busted knuckles and late nights at Coffee shops at 2AM hiding from the cops while out testing.

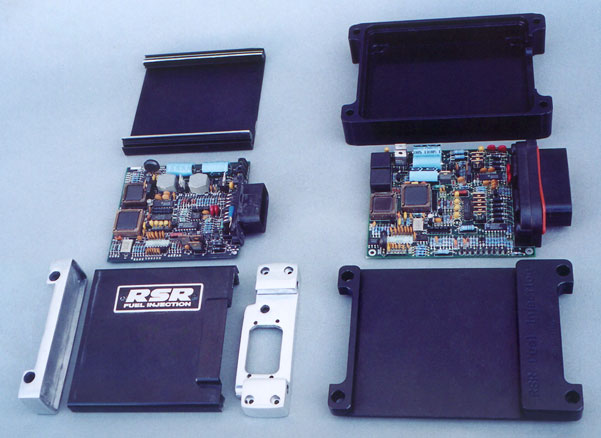

Late 1980’s and beyond: Fuel Injection. Resistors, capacitors, transistors, injector drivers, microprocessors, computer code, memory locations, circuit boards, wiring harnesses, connectors, tooling, fuel pumps, regulators, throttle body castings, throttle shafts, butterflies, sensors, relays...All in all, a very steep hill to climb as we made our own fuel injection system. We also learned that consultants you hire should have actually been shot on sight and, secondly, that you are better off doing it yourself. So we did. First generation to left. Second generation to the right...Four layer, through hole construction.

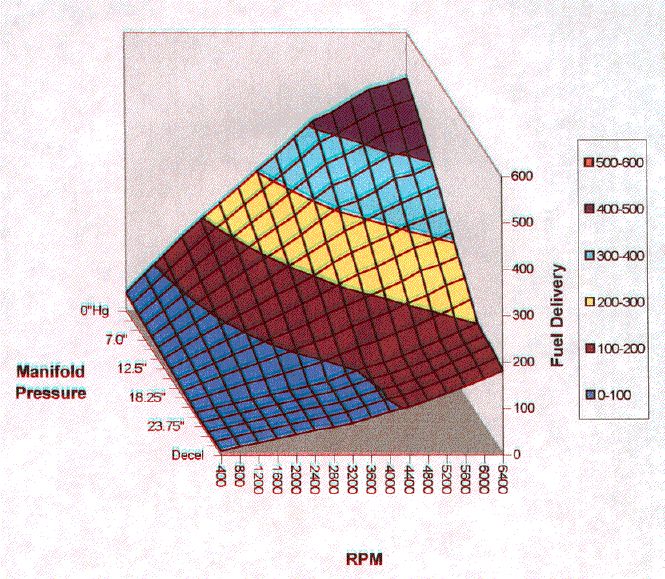

We quickly found out that getting all the digital information correct was not an easy task and that any two people working on the same system never came up with remotely the same tuning or calibration entries. It didn’t take a genius to figure out that in shipping the efi systems to customers that no one would get all the hundreds of entries even remotely correct and guess who would get stuck with all the support issues. We got rid of millisecond entries and converted everything to linear fuel values 000-999, with 000 meaning no fuel, 999 meaning all the fuel and numbers in between representing the linear fuel delivery at the 16 windows of rpm 3000 to 16000 rpm. No one understood milliseconds.

Then there were the people with projects that they wanted to fuel inject and they were going to dump this mass of hardware and software on some unsuspecting mechanic who knew zero about the software and the hardware and you end up with one guy in the middle yelling at both ends wanting his toy to perform “now”.

RSR EFI...1990's Autocal.V6

We decided this was not a good scenario so we spent about 3,000 man hours, one entire Summer plus the intervening years writing predictive software for our efi so “anyone” could write a calibration in about 15 steps for any combination of injectors, fuel pressure, manifold pressure, engine displacement, horsepower and the like. We called it AUTOCAL.V6. Guess what? After 20 years of this and selling hundreds of systems that we made, we can count on one hand the number of people who could actually use our predictive software no matter how easy we made it. We found out that people did not want to think or learn...they just wanted answers and glory. Although we put 8 people into the 200 mph record books, only one of these did his own calibrations. He was an Engineer and thought we had made it incredibly simple to program a 425 hp one liter race bike that ran 221 mph in the standing mile. Only one. The rest ran calibrations we loaded for them, which, if they attempted to modify, totally messed them up.

The truth of the matter is that 99.999% of the people have no business trying to play with efi systems. They might get things working but the reality is, at the OEM level, ECU/ECM calibrations require many thousands of manhours with perhaps more than a million lines of code and proprietary eTPU code which you will never see or understand.

Unlike most aftermarkert ECUs the Pectel SQ6M was designed for ultimate flexibility. Instead of being hard-coded for specific sensors with every pin being dedicated for a specific input/output the Pectel is user configurable for the type of sensors employed and pins can be used for different purposes. This flexibility brings increased complexity to the mix and it is assumed you are a motorsport engineer or that you have hired one.

A steep, but necessary, curve in the pursuit of precise control. A front end FPGA to do angle-based calculations and a 56 MHz Freescale MPC565 processor to control things. It's a very logical but complex bit of engineering.

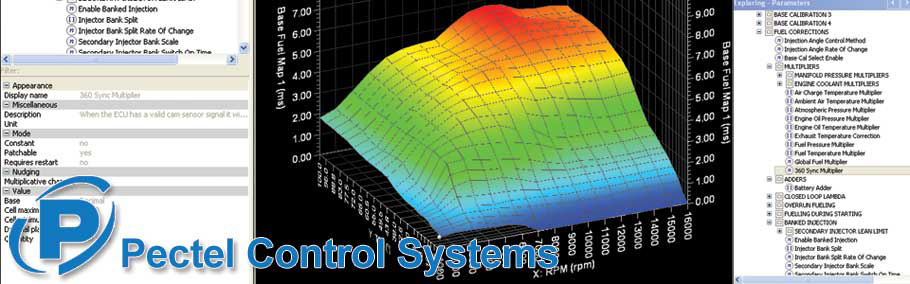

The good part about spending 3,000 man hours writing the AUTOCAL predictive software is that we know how to predict, fairly accurately, a fuel map for the SQ6M and simply cut and paste it into place in the Pectel software. Mapping in the SQ6M can be as large as 25 load x 25 rpm or 625 sites. Automating the initial pass saves a lot of time entering all these numbers. An interesting point is that you do not have to make the axis break points equally spaced i.e. if you have a region that requires greater resolution, you can make the spacing closer in that area. Clever stuff.

Formula1 Maps these days are on the order of a 48 x 64 matrix or 3072 sites with multiple maps for changing strategies.

10 x 10 is too much of a compromise.

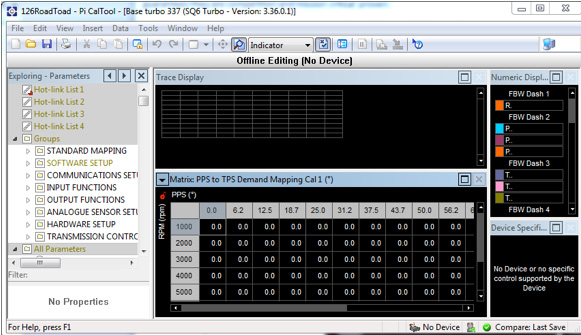

Pectel Caltool 3.6 Workspace (Currently 4.0)

In the case of Caltool 3.6 you must, on an annual basis, update the "Personality File" in your Pectel Caltool file structure. This maintains control of the software for the original purchaser.

Everybody needs a personality. That is to say, one is required to communicate with a Pectel ECU and to open datasets. Personalities exist on a PC and authorise that PC to communicate with the equivalent Pectel ECU.

Personalities are small executable files that you run a single time on PC to install. These files are distributed by Cosworth or the appropriate developer. Only one Personality can be installed at a time, however they are easily over written by simply clicking a different one. The currently installed personality is visible by hovering over the little man in the lower right hand corner in Pi CalTool.

Most Pectel ECUs will be of the "Pectel External" (PEXT) personality type. This will allow access to almost everything the ECU has to offer. The vast majority of people will be using a PEXT personality as most ECUs are programmed as PEXT ECUs.

There are additional developers which will configure Pectel ECUs to use their own personalities (common ones include M-Sport and Mountune). If you have come across one of these ECUs and only have a PEXT personality, you will not be able to communicate with it. Developer specific personalities are distributed by each developer. Cosworth cannot supply these personalities. Developer specific personalities can be used to restrict access to certain maps or areas of the dataset on the ECU.

Datasets can be password protected for additional security, and the level of restriction can also be altered from:

· Everybody – allow access to everybody regardless of personality

· My Team – allow access to anybody with the same personality as me

· My Team and Serial Number - allow access to anybody with the same personality as me, but only on the current ECU (determined by serial number)

Personalities are only used for Pectel ECUs and have no bearing on Pi products.

There is no manual as the "Help" is embedded in the software. "Mouse Over" balloons and Help Menus provide built-in assistance. The complexity, i.e. the flexibility, of the software is geared for the professional motorsports engineer. As stated above 99.999% of the people have no business fiddling with any engine management software. The exponential nature of the number of inter-related entries requires an experienced approach strategy and, in general, both dynamometer and real world testing.

We have put together a 298 page PDF of Caltool 3.6 Software to give you a brief glimpse of it's structure and capabilities. There are about 8800 parameters possible within the Pectel software. Since a late model OEM Corvette has 8,627 variables in their ECMs this seems to be about the right level of complexity. Direct Injection Diesel ECUs currently employ about 12,000 variables. As stated above, it is, truly, the "Swiss Army Knife" of engine management software... Professional level to be sure. The PDF is 12.8 Mb.

For a complete listing of the programmable parameters in CalTool 3.6 we have prepared a 219 page PDF listing these. If you can't control what you are planning to do with this you might as well contact a higher power or go back to bench racing.

We determined that point editing still had to be done and that you had to have complete control of the base injector on-time. These days people like AEM (Infinity) and Motec (M1 Series) have gone to model based VE (Volumetric Efficiency) tuning where you enter basic data like engine size, injector characterizations, fuel pressure etc and then start adjusting relatively small VE tables, typically 20x 20 or 20 x 17 martices. They no longer have large base maps like the Pectel SQ6M (Up to 1250 sites) where you can fine tune base values down to 1/100th of a millisecond. Advanced math and interpolation functions in the SQ6M's CalTool Software make tuning very precise.

Being able to point edit gives you 100% direct control over everything. If you generate spark and fuel maps plus all their modifiers in advance, like we do, you can concentrate on the fueling without worrying about the other things that modify it. In F1 they have over 3000 sites on their fuel map as they do not want to deal with sensor latency issues...Every sensor has a response time. For example the fastest wideband sensors have response times of about 1.36 Ms.

With the SQ6M we have four switchable fuel and spark maps...think 8 x 1250 sites to get things perfect for different fuels and conditions.

Harley Davidson Delphi ECMs use VE model based tuning and it sucks. On the face of it VE model based tuning is seductive but it's sort of like making love through a bed sheet. It's better to predict then have absolute control of things so you can be a hero or a zero. Let your hand or fingers do the shifting and skip the automatic slush boxes.

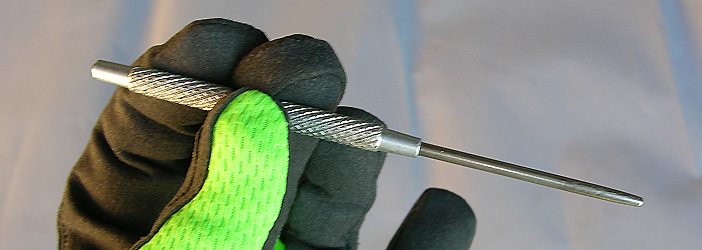

SQ6M Communications Cable

Ethernet (4 wires), Serial (3 wires) and CAN ( 6 wires) in one cable. Ethernet for fast tuning. CAN for displays like Cosworth's ICD and data acquisition. Serial for SQ6M firmware updates. Six foot cable on left 12 foot cable on the right. For dynamometer work we extend the Ethernet cable to up to 25 feet.

Ethernet, serial, and CAN communications take up 13 pins of the Pectel ECU. One way to handle this is to use a Deutsch Autosport 13 pin connector. We use a flanged AS010-35PN Bulkhead Receptacle on the motorcycle and make a commo cable using the mating AS610-35SN Plug. Deutsch Autosport caps seal the connectors and Raychem adhesive lined boots seal the 13 wires on the harness and the communications cable.

In this particular case we

are not using an ICD Display (CAN). We can add this

in the future. We chose to populate the harness with

the six CAN wires to add the display later.

PDF on

SQ6M communications cable. Macintosh: Option

Click to downloads. It's important to get the TX/RX

correct on the Ethernet wiring.

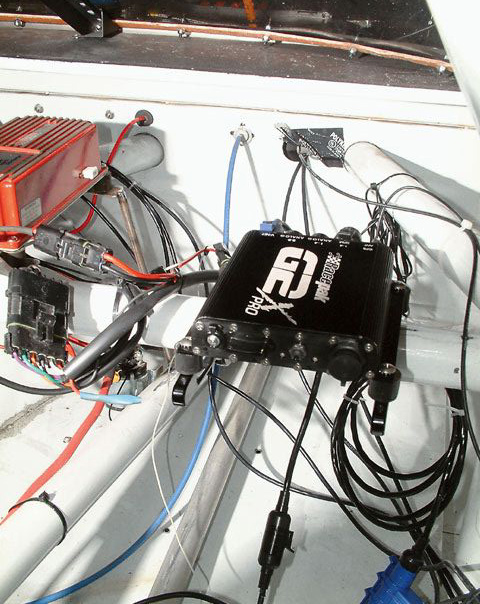

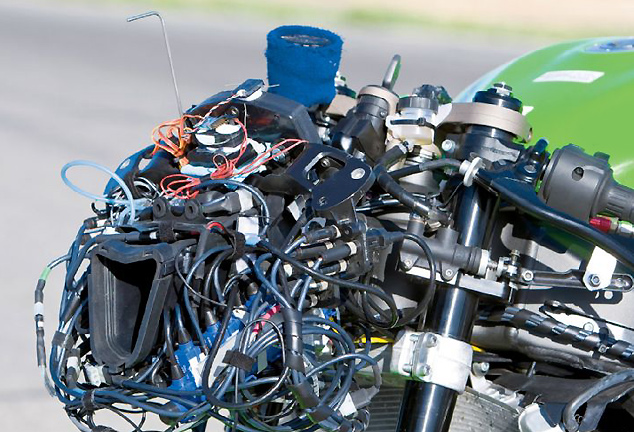

Simplify Your Engine Management

Mike Geokan's Bonneville

Bullet is being upgraded from a MSD MC-4 and our

own RSR Fuel Injection to the Pectel SQ6M. We get rid of

these two boxes and a tangle of separate wiring systems

and gain a sophisticated data acquisition system in one

small SQ6M controller.

You don't have to spend $4,000.00 for a Racepak data logger and

sensors as the Pectel SQ6M does all of that. You can log

4 Mb worth of dozens of channels at sample rates of

2000Hz (2000 measurements per second). In addition, you

don't have to spend $10,000 on a Motec Engine Controller

by the time you keep adding options and additional

boxes. There is no need to add on knock or wideband

lambda modules. Thermocouples, wide band NTK and knock

sensor inputs, as well as sophisticated PID functions

are all standard. Racepak systems only log at 100 to

1000 times per second. It's best to keep it in one box,

one integrated software system.

On the ignition side you also do not have to

purchase a clunky $1,100.00 MSD MC4. From the ignition

standpoint you can support a very sophisticated closed

loop knock sensing strategy without any additional

boxes. The MSD does not do knock detection.

Add up the Racepak and MSD numbers and add in

a lesser engine controller for $3,000.00 and you are way

more expensive that using a Pectel SQ6M, not to mention

the three software packages instead of one.

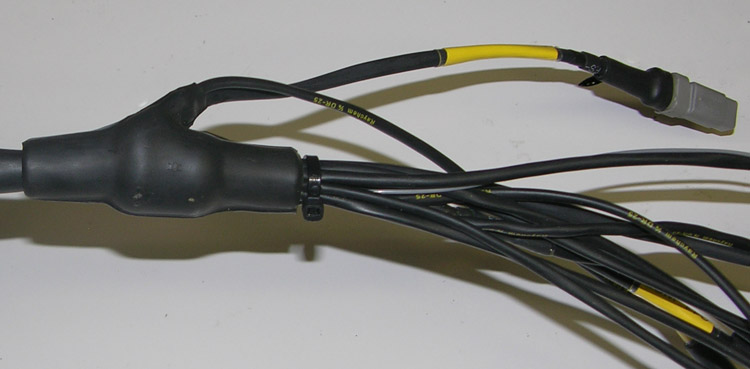

You don't want to end up with two or three different systems and a spaghetti mix of wiring in your engine control and data acquisition. The Pectel SQ6M can log all of your sensors and engine parameters keeping everything neat and tidy with Deutsch Autosport and DTM connectors all wrapped in DR25 heat shrink and adhesive boots and transitions.

Raychem 90 degree boots are shrunk to the

three Deutsch Autosport connectors.

1st

Generation

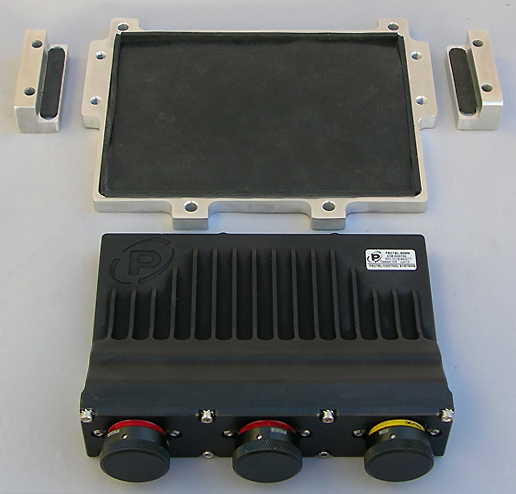

Pectel SQ6 / SQ6M /SQ6M12 Mount

The Pectel SQ6M does not come with any mount...that's always up to the installer. We machined up a prototype mount for testing that isolates the SQ6M in rubber and also allows the mount itself to be mounted on rubber isolators or directly to a flat surface. After we verified the mount in the installation we sent it off for hard anodizing and will do the final installation with stainless steel hardware.

Hard anodized black finish, with the SQ6M surrounded by rubber and held in place by stainless steel hardware with four point rubber isolation mounts or directly mounted to a flat surface.

Mounting

the

Pectel SQ6M

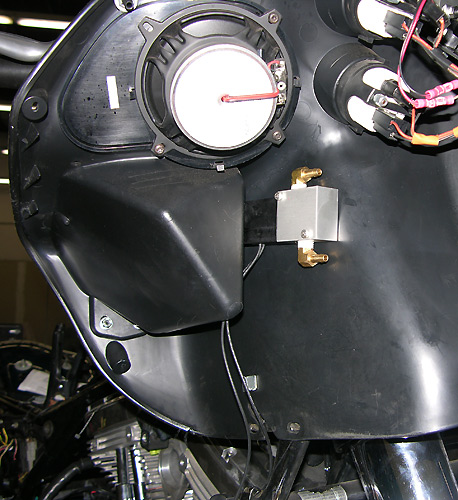

We

found the perfect place for the Pectel SQ6M inside the

Road Toad's fairing. Although the Mil-Spec wiring harness

will be sealed, we prefer a protected environment for the

electronics. Four bolts (turn signals) and six screws and

the Road Toad's fairing shell pops off. We machined and

anodized an aluminum rubber isolated mount for the SQ6M

and bolted it in the metal tray.

Oh yeah...The metal tray... That's where the radio was. We don't need no stinking radio...and the radio's faceplate opening becomes part of our new turbo dash.

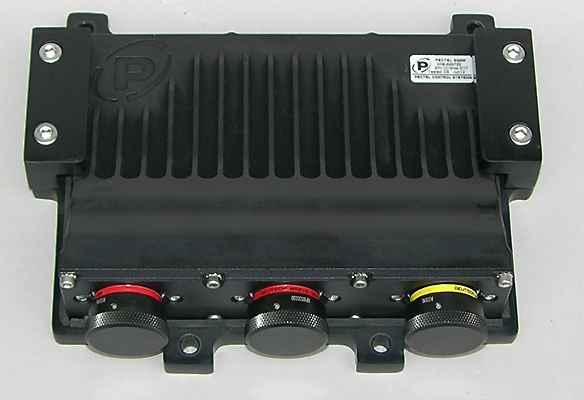

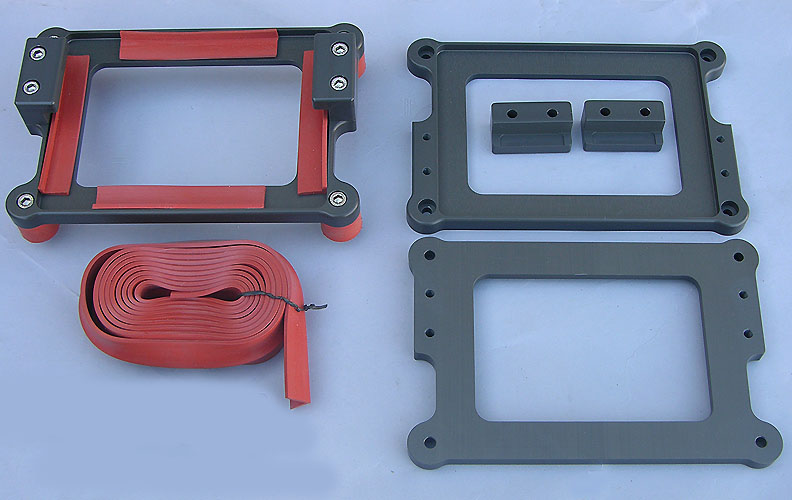

2nd Generation SQ6, SQ6M, SQ6M12 Mount

Here,

prior

to anodization in hardcoat grey, is the new mount that

fits both the SQ6 and SQ6M Pectel ECUs. Six high

temperature 90 degree silicone extrusions hold the ECU on

four sides, the bottom and under the hold down clamps on

the top and sides of the ECU. Stainless steel metric 6mm x

1.0 socket head cap screws with stainless lock washers are

provided.

The

two hold down clamps have 90 degree silicone rubber

extrusions that hold both the sides and the top of the SQ6

and SQ6M series ECUs. Four 6mm x 1.0 x 25mm stainless

socket head cap screws with lock washers hold the ecu in

the mount. An important consideration is the effect of

vibration on connector pins and sockets. Encasing the SQ6

or SQ6M in rubber and further isolating the billet mount

reduces the stress on the ecu connections which, if

solidly mounted, would increase fretting of the pin socket

interface over time.

High

frequency

vibrations keep the motorsport harness makers in business

i.e. predicted service life and planned replacement

harnesses based on hours of use and the usual teardowns.

The mount is designed for four optional isolation mounts,

also in high temperature silicone. These are available in

different durometer ratings. 70A high temperature silicone

orange durometer mounts pictured above.

30A,

40A,

50A, 60A and 70A durometer mounts are available from the

industrial distributor McMaster-Carr, Part Numbers 4403K

plus 588, 622, 644, 67, or 71 respectively for the varying

durometers. We can supply these at our cost US $40.00

(purchase cost plus shipping) if you so choose. Colors:

30A (black); 40A (green); 50A, 60A and 70A (orange). These

are secured to the mount with four 6mm x 1.0 x 16mm

stainless socket head cap screws with lock washers.

If

the isolation mounts are not used, 6mm x 1.0 socket head

cap screws can be directly used on the four corners. The

cost for the mount is $250.00 without the four isolation

mounts or $290.00 with the isolation mounts.. The mount is

hard anodized dark grey. Included is one extra foot of 90

degree silicone extrusion.

The

six extrusions are held in place by red high temperature

RTV (supplied). Apply the RTV to the underside of the

extrusions, wipe off any excess, and bolt in the SQ6/SQ6M

and let the RTV cure 24 hours to hold the extrusions in

place.

Fully

captured,

there is no metal to metal contact with the ecu.

Compatible with Deutsch Autosport connectors as well as

the 88-Way SQ6 Bosch Junior Timer connector pictured

above. The fin structure and case thickness where the hold

down clamps are located is the same for both the SQ6 and

SQ6M.

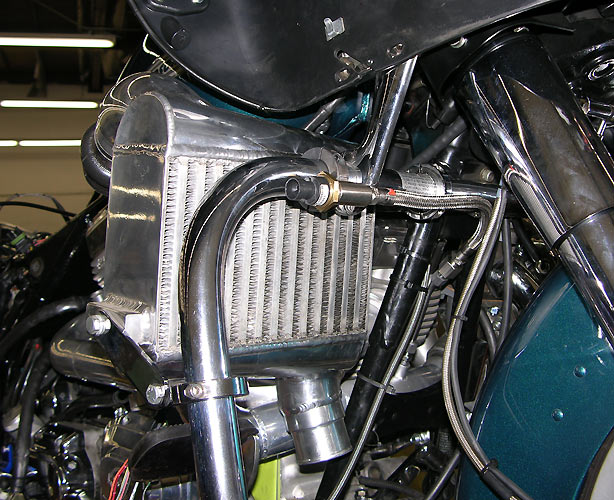

Pectel Anti-Phase Boost Control

Using

two fast-acting and quick-venting solenoids the Pectel

SQ6M will control the boost pressure to both sides of the

wastegate's diaphragm. Being able to quickly vent and

pulse width modulate (PWM) the solenoids allows a very

precise boost control. Gone is the old Dial-A-Boost

venting pneumatic manual controller. Boost strategy gets

tied into gear selection, traction control, and

other factors including throttle position. Deutsch DTM

connectors connect the solenoids to the SQ6M harness. We

use 1/4" (6mm) reinforced slicone hose for boost

pneumatics as it does not kink, is highly durable and is

high temperature (engine compartment) rated.

Cosworth

Engine Control

Cosworth

MQ12

series

engine controller doing its thing with

650hp and Ken Block. Cosworth

Motorsports are well proven at the

highest level of competition. The MQ12

is the bigger brother of the SQ6M that

we use. Ken Block videos show what is

possible with a high boost four

cylinder, four wheel drive, WRC hot

rod. The central nervous system is Ken

Block and the MQ12 controller.

Cosworth

Pectel Multi Function Display (MFD)

used in Ken Block's Fiesta.

Motorsports does get expensive...no

Stewart Warner or Autometer gauges.

More Deutsch Autosport connectors.

Keeps tab on everything that is going

on in the vehicle. Twelve user

programmable switches and a TFT VGA

color display to keep the driver and

co-driver informed.

The Cosworth MQ12 has an additional 300Mhz processor to support the MPC565 and FPGA...plus a 4th Deutsch Autosport connector for a total pin count of 180. It does get complicated. These are used in top tier two-wheeled World Super Bike, four-wheeled Le Mans, and no-wheeled Offshore boat competitions. First Class.

Prodrive WRC VW's and Rallycross Minis use Pectel MQ12

The

Cosworth

MQ12 is the one controller that

operates at this level of motorsport

that you can buy off the shelf. It's

main competition are the far more

expensive engine management systems

from Bosch Motorsport. VW Golf SCRC

for Chinese Rally Championship and the

Mini for WRC (World Rally Car) and RRC

(Regional Rally Car) competitions.

MQ12

engine

controller

for the Aston Martin run at Le Mans.

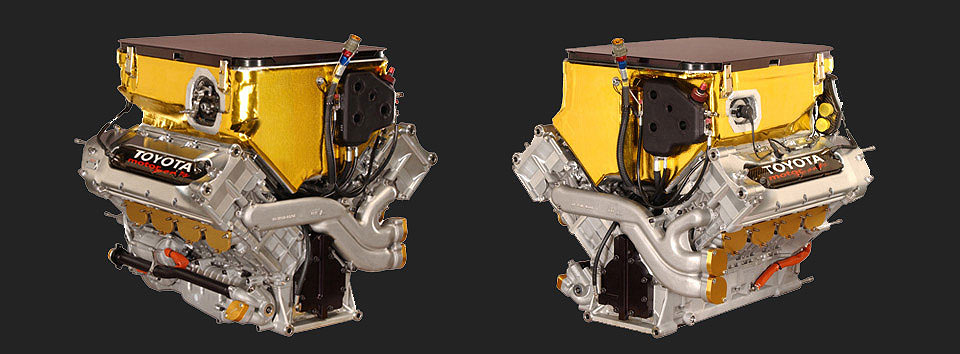

Endurance racing Toyota factory RV8KLM engine that uses the Cosworth Pectel MQ12 controller. The gold insulation shields the inlet system.

V8/Hybrid

2014

Le Mans Factory Toyota TS040 uses

Pectel electronics. 1000 Horsepower.

2014 Endurance Championship with the

Pectel MQ12.

World Superbikes also use Cosworth Engine controllers.

Cosworth Antares

2018

Cosworth

Antares ECU. The new high end

controller from Cosworth. Capable of

in cylinder pressure monitoring.

Latest processors.

SQ6M Traction Control

The

Pectel

SQ6M comes standard with a complex

traction control strategy. When you

have 300-360 hp on tap on two wheels

it's a good idea to have full

electronic control over traction.

We've added front and rear wheel speed

sensors to the Road Toad. Our advanced

electronics ecu will monitor front and

rear wheel speeds and can adjust

boost, timing and fuel in real time.

Important when wheelspin gets beyond

certain parameters.

This

becomes

very

important at Bonneville where a

torque-based strategy is useful to

find traction and keeps speeds going

upward where the conditions vary as

you head down the salt. Front end FPGA

keeps track of the angle based

computations...way faster than "seat

of pants".

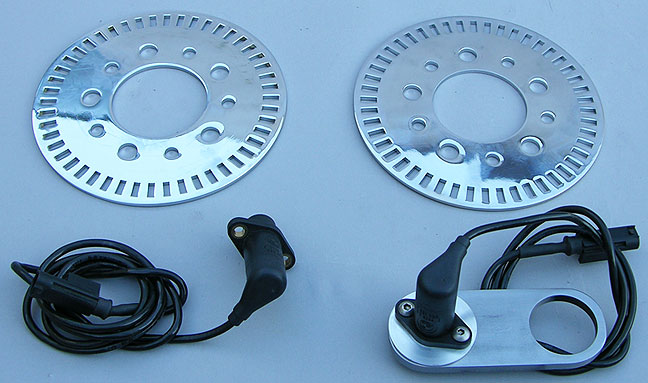

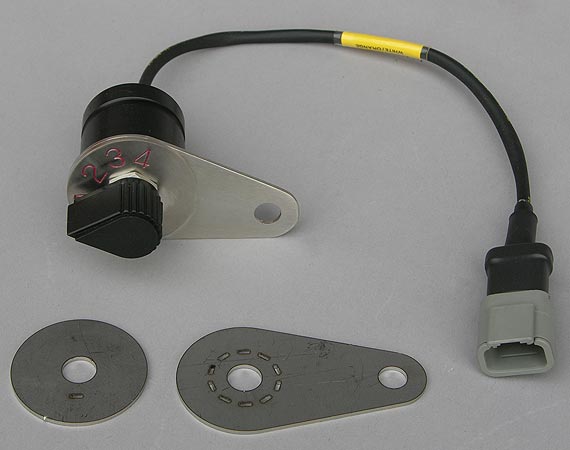

Wheel

Speed

Sensor for SQ6M

Traction

Control

When

the

rear

wheel starts going way faster than the

front wheel and we're losing traction

and speed we can use algorithms to do

something about it. Things learned on

the Road Toad get transferred to the Bonneville

Bullett. The SQ6M has a very

complex advanced Traction

Control strategy. Take a read of

this document before you decide on

some lesser form of engine management.

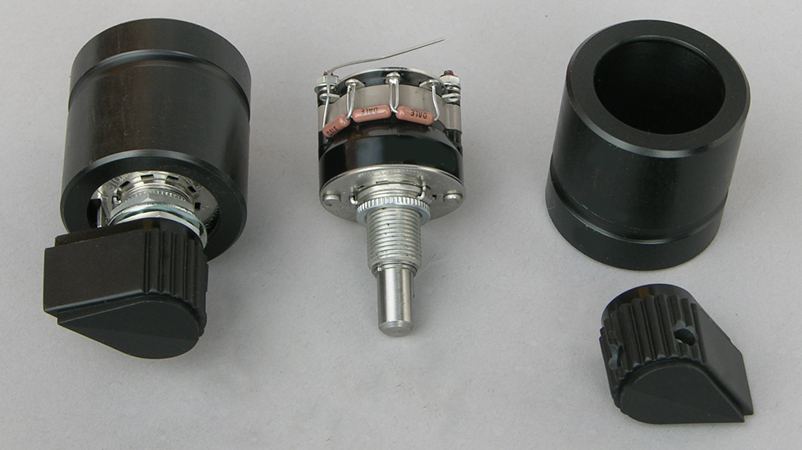

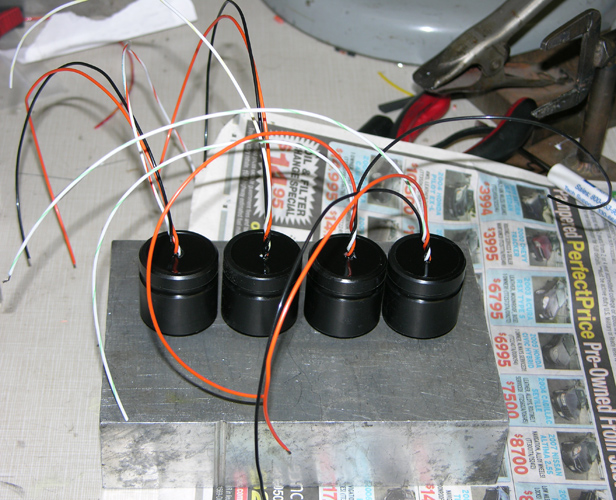

Rotary ECU Map Selection Switches

We encapsulate the Rotary ECU Map Position Switch in epoxy to waterproof it and use DR-25 heat shrink and formed boots to protect the wiring and install a three position Deutsch DTM connector. Now if we could only get paid as much as Lewis Hamilton to ride around on our 126 Orca Powered Road Toad. Three wires: 5V, Ground and Signal. We use 22759/16-22 gauge wire with the signal wire color coded for the intended use. A fixture holds four switches while the potting compound, a two-part epoxy, cures over 24 hours.

SQ6M Knock Sensor

The Pectel

SQ6M has inputs for two acoustic

Knock Sensors. Shown is a mount

kit for our ORCA Harley

Motors...we only use one knock

sensor on the V-Twin. A

PDF on Pectel Knock Control

Strategy shows the

complexity of it.

Aircraft Circuit Breakers..Not Fuses

For the

Pectel SQ6M portion of the

electronics we are using Aircraft

circuit breakers that "pop up" and

are push to reset. A lot more

expensive than fuses but these do

not "blow" and you can see the

offending circuit immediately.

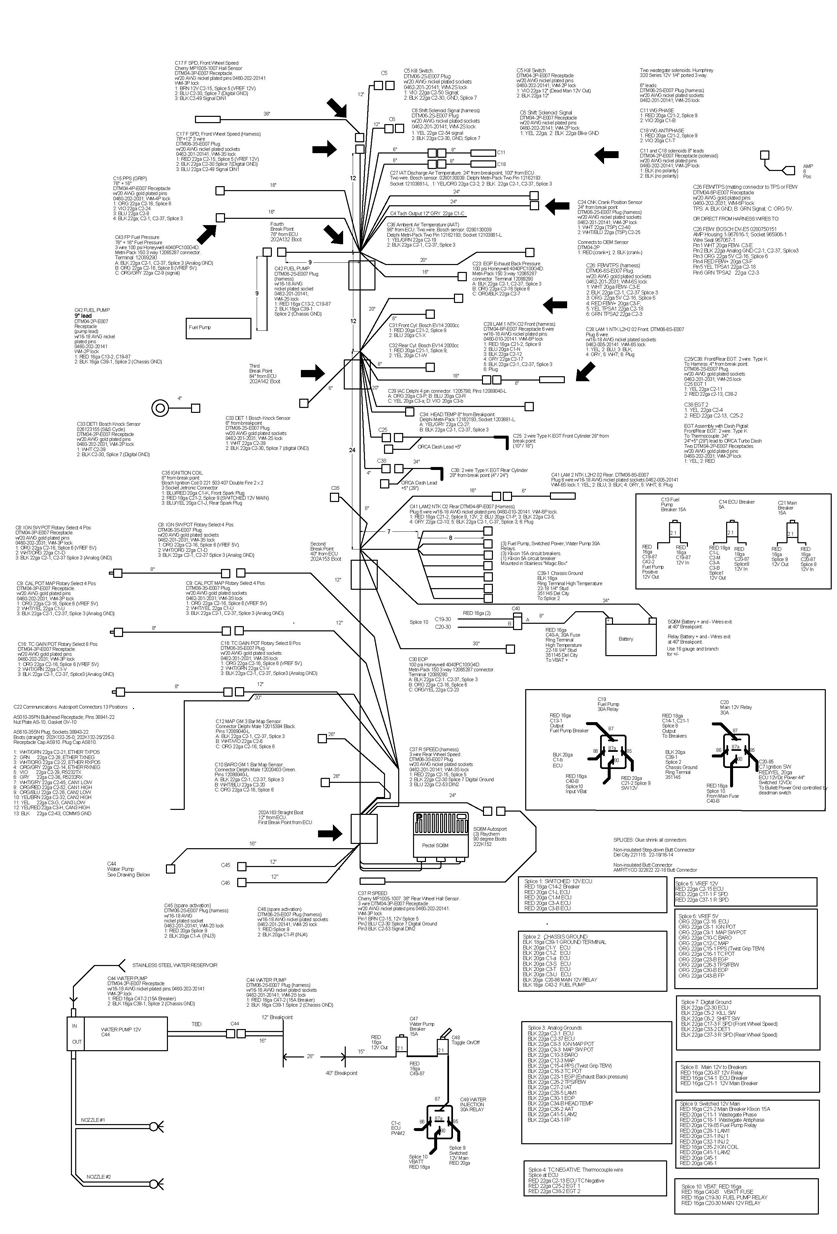

Pectel

SQ6M Wiring Diagram...Bonneville

Bullett Turbo Harley

We make an

initial drawing of the wiring

diagram but this will only aid in

planning purposes. The actual

harness has to be measured on the

bike with all the hardware in

place. It is critical that there

be no strain or interference

issues and that serviceability is

planned for.

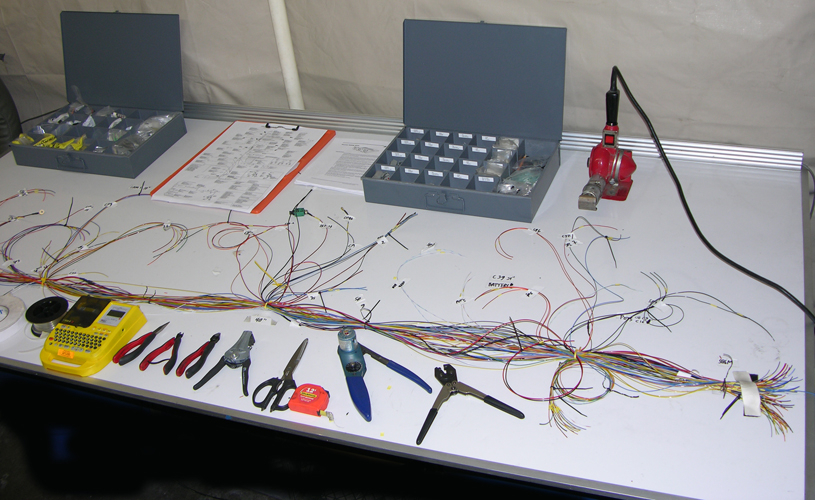

Next we

use a 4' x 8' whiteboard to layout

the wiring harness. We use 3/4"

adhesive tie wrap pads, plastic

tie wraps, velcro, and white

gaffers tape to hold the main

harness and connector leads in

place. The adhesive pads can be

removed or relocated without

damaging the boards surface.

Wires in this harness are MIL-22759 16/18/20 and 22 gauge. Deutsch DTM Plugs and Receptacles use a mix or gold and nickel plated pins and sockets. Deutsch Autosport Connectors are used for the SQ6M. Different wire colors prevent confusion and we also label each wire. This particular harness has 49 outboard connectors. The SQ6M itself has 107 pins. In the case we are using 73 of them.

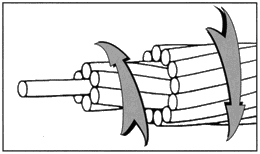

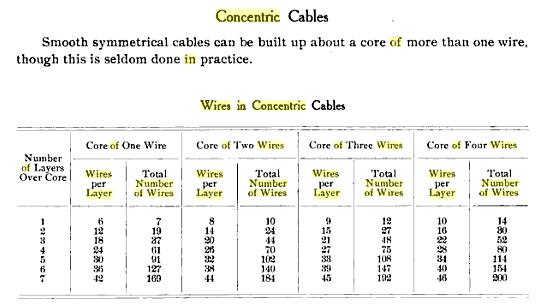

Concentric Twist Layers

The stiffness of the harness will depend largely on how the underlying wires are arranged. The correct method is concentric twisting where successive layers are twisted in opposite directions...One wire surrounded by six wires, with each successive layer adding six additional wires i.e. 1-6-12-18. The twisting of the wires gives the harness additional flexibility and reduces strain on the wires. The above table provides some insight into the methodology.

We twist the wires CW and CCW the best we can

by the above format, but we always run into issues with

2-1 and 3-1 splices so we don't go the extra mile to put

in dummy filler wires to get the 1-6-12-18 etc layers.

We do the concentic twisting and secure the runs with Mil-T-43435B Lacing

Cord. We label each wire with 1/8" yellow shrink tube

covered by clear Raychem RT-375 clear shrink tubing.

We leave the exit branches about 4" longer than

necessary and then trim the wires to length for the

connector. You can slide the labels up and down the wire

with a bit of force. Labels are necessary for us as we

are constantly interrupted and brain fade sets in.

Raychem DR-25 covers the main harness and the branches. Connectors are installed and sealed. Each branch is labeled with the connector number as well as the function. Kapton tape covers exposed wires before they have Raychem boots heat shrunk. In this application we have over 50 outboard connectors to keep track of. Without documentation future issues as well as current assembly would be very difficult.

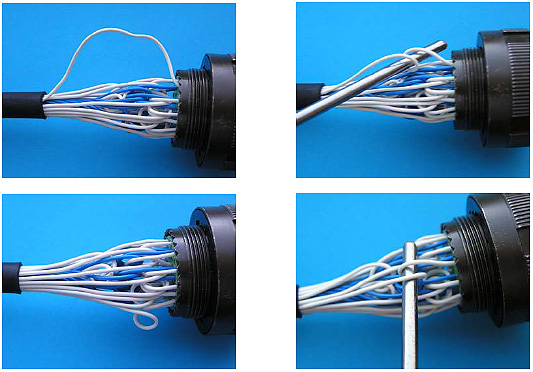

"Service Loops" are used on Mil-Spec / Deutsch Autosport circular connectors for wire sizes 16 AWG to 30 AWG. The purpose is to provide strain relief to the wire termination and to provide a surplus length for repair purposes. It is not an aircraft procedure per se and is only used in military and motorsport applications.

On circular connectors it is recommended to start at the center and work outwards if the numbering system runs clockwise or counterclockwise. For rectangular or circular connectors identified in rows, it is recommended to work row by row. Loops should face inwards. Loops must be staggered to minimize any increase in the cable diameter. When looping is complete all loops should face inwards to give a neat appearance and to insure that the wires are not trapped or damaged if an adaptor or back fitting is present.

If your connector is already terminated and the wires are shrunk with DR-25 it gets a little more difficult as you will have to press back the connector to bow the wires. You may have to cut back on the harness DR-25 to free up the wires.

All of this is a bit stiff to wrestle with so holding the wiring harness, the connector, and the looping tool at the same time is a bit interesting. Think ahead.

Pressure Sensors

The stock in-tank pump and regulator simply will not suppport 360hp. We convert the Road Toad to an external 700 hp racing fuel pump, filter and regulator assembly. The gas tank is modified for a return or bypass port and all fuel lines are upgraded to 3/8". Rubber isolated components, laser cut mounting brackets, AN fittings and fiberglass sheathed fuel lines all make sure the 126 Turbo Orca will not run out of fuel.

We

use a 0-100 psi pressure

transducer to monitor fuel

pressure.

The

turbo

exhaust manifold is

plumbed for the 0-100 psi

back-pressure sensor. High

temperature stainless tube

and flexible high temp

wire tubing allows for

engine movement. As boost

pressure rises you need to

plug in correction factors

for the NTK wideband

sensor's output.

We also monitor oil pressure. The Pectel SQ6M allows you to set safeguards and correction factors in software for changes in sensor readings. Planning out all the sensor locations for speed, pressure, temperature and Lambda readings takes a bit of planning. At lawyer rates we'd go belly up quickly. The curse of speed and technology.

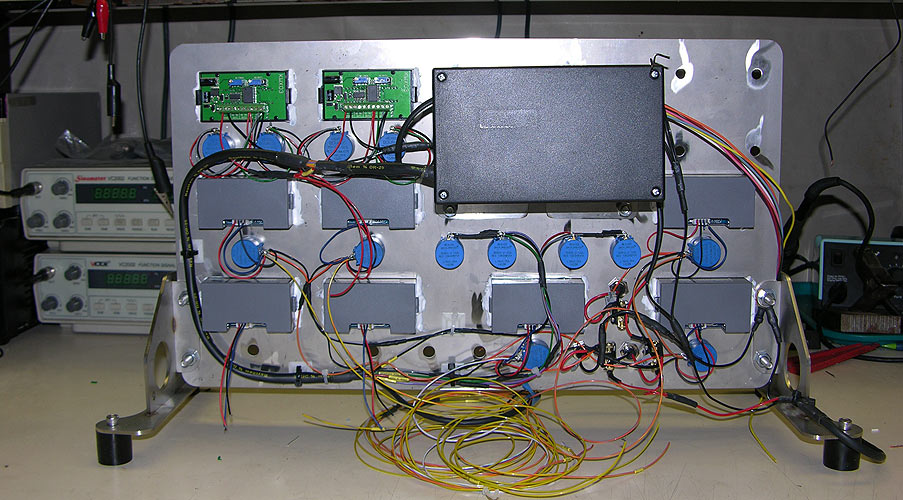

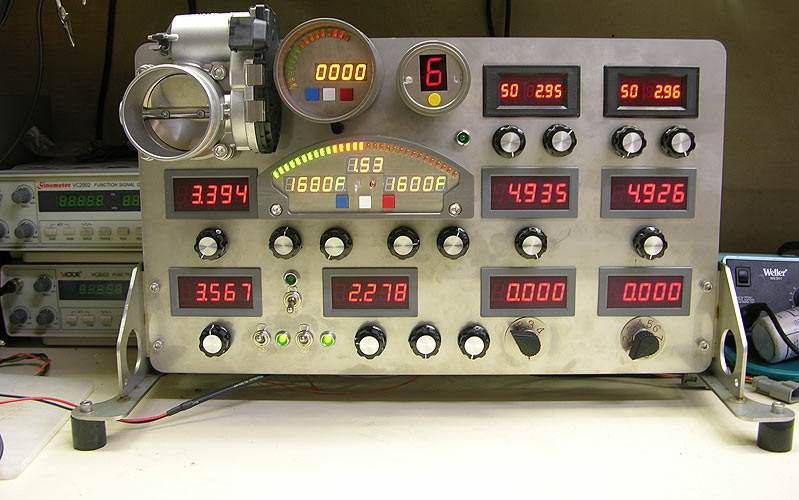

How do you test an SQ6M

before you go to Bonneville...SQ6M Simulator

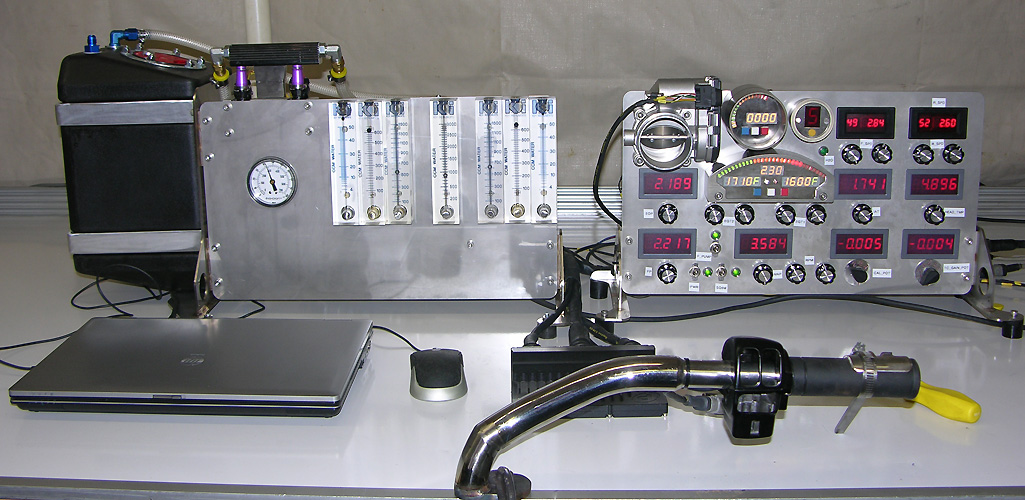

All inputs are simulated including: map switching, traction control switching, front and rear wheel speeds, engine oil pressure, fuel pressure, 3 Bar MAP sensor, inlet air temperature, engine temperature as well as dual thermocouples. Laser cut stainless steel panels. Fuel pump output to flow injectors on separate flowmeters. Digital gear indicator and Bosch DV5-E5 60mm FBW throttle body. L.E.D.s for panel power, SQ6M power, external fuel pump and water injection activation.

Pectel SQ6M firmware times out the FBW motors if the engine is not running after 1 minute. The SQ6M Simulator allows us to "run" the motor and work on PID functions and programming of the 167 FBW categories.

In order to check gear change programming we added a momentary shift button.

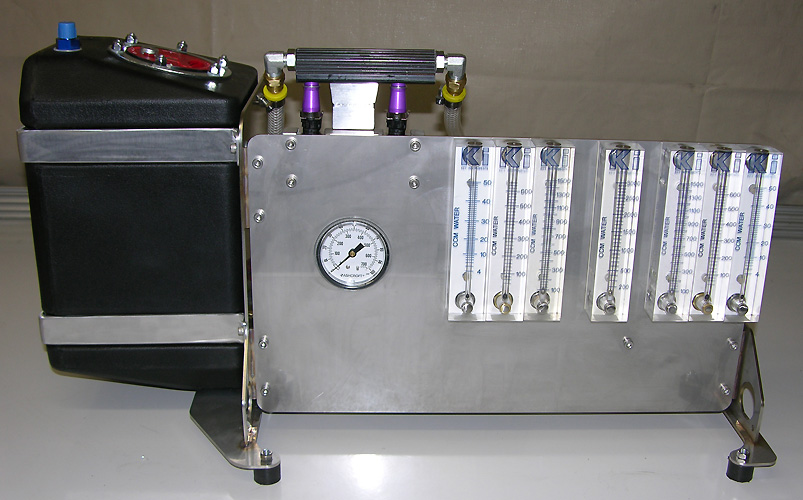

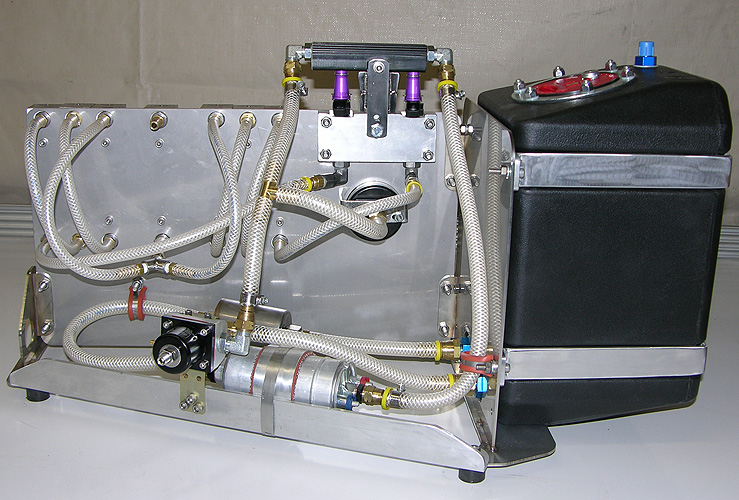

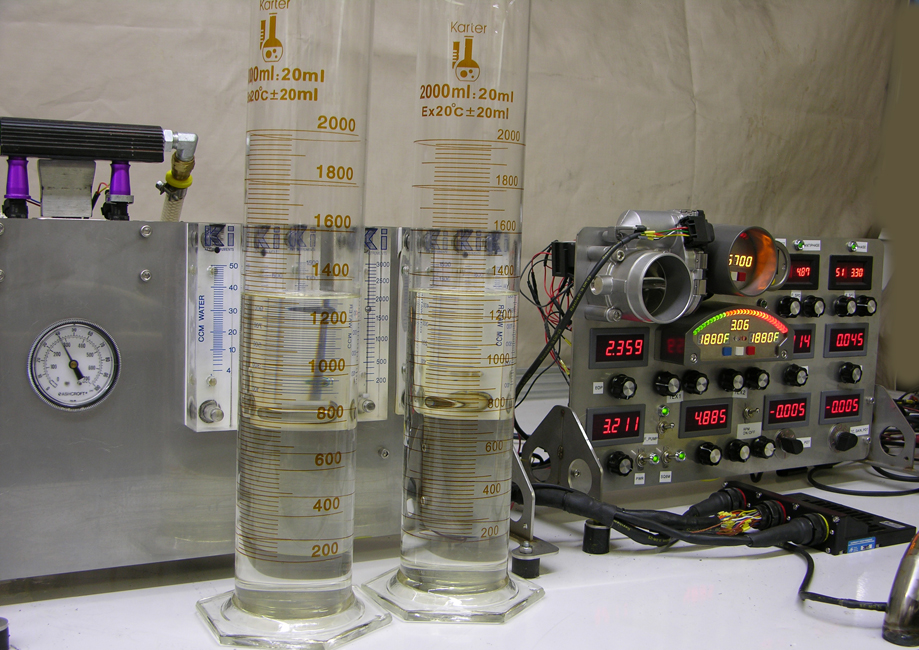

NTK L2H2 Lambda Test Stand Calibration

NTK L2H2 Test Stand for sensor linearization:

Propane with a variable air bleed and three 18mm x 1.5

ports. Used for calibrating two NTK L2H2 Lambda meters

against a known calibrated meter. Flowing Nitrogen gives

Lambda 1.0 (14.57:1 AFR). Free Air at one end of the

scale and propane/air mixtures for richer points .780

Lambda (11.36 AFR).

Pectel SQ6M engine controllers have 33 points to linearize or calibrate for each of the two NTK sensors. The SQ6M has internal NTK amplifier and heater circuits, so no external devices are required. Alternatively you can purchase a $1,200.00 drum of test gasoline and a $1,200.00 bottle of Lambda calibration gas to do your testing.

Alternatively, simply use the Cosworth/Pectel "Band 10"

NTK Lambda Sensors with Deutsch Autosport

Connectors. Pectel CalTool Software lists twenty "Band"

designations i.e. 1-20 for NTK Lambda sensors but

only the "Band 10" is the Pectel supplied one. The

"Band" numbers were used to account for sensor

variations but only Band 10 is supplied these days.

CalTool software also lists AUTO_CALIBRATION for NTK

sensors but this was never operational.

The SQ6M is also configurable for a 0-5V input

from an externally amplifed wideband sensor (Bosch

LSU4.9 ot NTK) as well as simple narrowband (0-1VDc)

sensors. In this regard it offers ultimate flexibility.

Keep in mind O2 or Lambda correction is just a trim

function and that base fuel maps and fuel modifiers

have to be correct.

Word

of Advice...On your

project

Once

you

decide on a project

involving some form of

advanced engine management

be aware of the

complexities and costs

involved...Then there is

the issue of "experts".

Your project can go

soaring cost-wise and you

won't have a clue on

setting up the wiring, the

software or tuning issues.

Time and money as they

say. Someone has to be

paid for their time and

expertise. Be

prepared.

Be wary of those who offer

delays, excuses and who

are spreading fear,

uncertainty, and doubt

(FUD) about

Cosworth/Pectel and other

suppliers products because

they have burned their

suppliers and customers by

using them as ATMs to

float their failing

business. We do our own

work as we have firsthand

knowledge of the

intersects between people,

their projects, and so

called "experts"... People

who drank the purple

Cool-Aid, dropped 20+

large ones and got years

of promises and delay.

Specifically,

we

know of two customers who

paid well North of

$20,000.00 for high end

motorsport ECUs and ended

up having to pay twice, as

the first seller, who held

the developer license,

totally screwed up. This

got straightened out by a

second developer at

$1,200.00 per day for

on-site trouble shooting

and, later on, custom

software updates at

$3,500.00 per pop. Does

get out of hand.

There are a few reputable engine management consultants and dealers out there for higher end engine management systems like Pectel, Bosch Motorsport, Motec, Life Racing and Syvecs (nee Life Racing). Check their references with former clients before you fork over your money. Make phone calls to recent clients. If they do not provide references do not deal with them. Motec tuners like John Reed , Shane (Tuned by Shane T) Tecklenburg, Tim Whitteridge (tim@motorsportselectronics.com) of Motorsportselectronics , and Eric Scheib of Electron Speed are reputable.

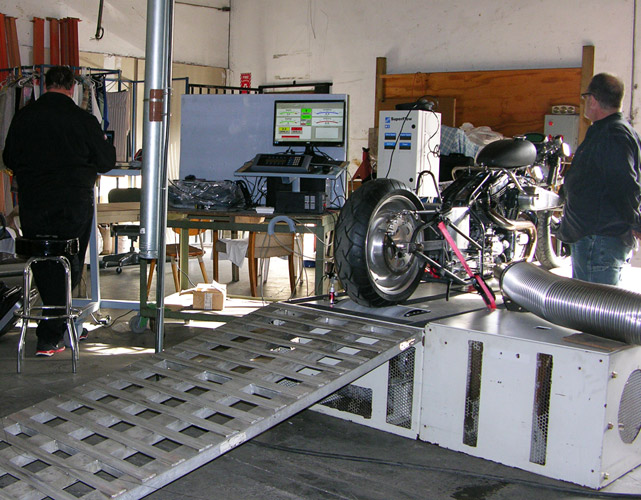

Shane Tecklenburg

tuning a Motec M130 on Tom Bookhamer's 120 Inch Bonneville

bike on the RB Racing's Superflow CycleDyn. We use 30 feet

of 8" stainless tubing for exhaust extraction with an 8"

Blower. The blower draws in 1725 CFM of free air mixed with

the exhaust and extracts it far away from the operators and

the building. Shane has more time on dynos in more places

all over the world than about anyone we have ever met. Shane

is the "go to guy" when you get serious about Motec

electronics.

Shane stepped off

the airplane after a 25 hour flight from Bahrain ...tuned a

Harley and headed home. He lives close by so it was a tight

but convenient schedule for Tom and Shane. Tom all the way

from Florida and Shane all the way from EKanoo racing in

Bahrain. Strange world of racers. As for costs, tuners like

Shane charge less than half of what a new lawyer charges per

hour or per day. By the time tuners like Shane, John Reed ,

Eric Scheib, or Tim Whitteridge arrive they are the least

expensive part of the project. Figure at least $1,000.00 per

day plus expenses to have them calibrate your system plus

aditional expenses for licenses and custom ecm code

development.

In

our case we deal with

Cosworth directly. They

are engine and engineering

people...we can deal with

that. Racers. The SQ6M can

do anything. No

development licenses. We

do our own tuning.