Advanced Engine Management: CalTool 3.6 Pectel SQ6M, Fuel

Modifiers

Fuel Prediction

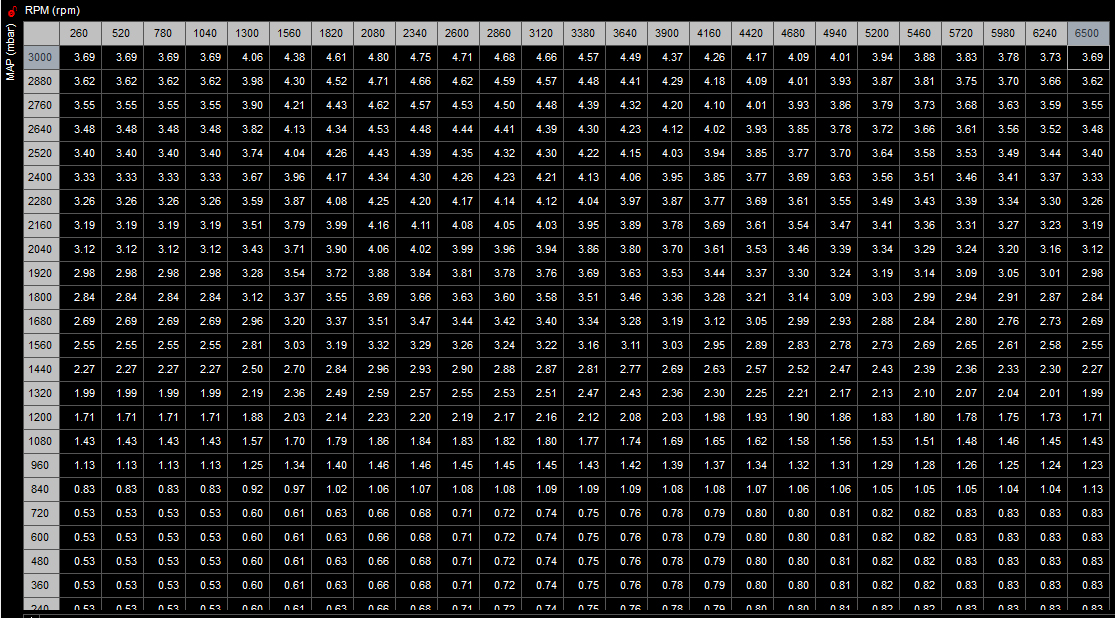

In that there are four

Fuel Maps in CalTool and each can be up to 25 RPM sites by 25

Load sites (625) entries we try to automate the process a bit by

predicting the values in Excel. Here we have constructed a 25 x 25

Excel Spreadsheet that automatically generates the XX.XX millisecond

values based on injector size, fuel pressure, compressor maps,

horsepower and other factors. It provides a starting point that will

get the application running right away with no danger of being too lean

under boost.

This is a sequential fire example. The spreadsheet also predicts batch

fire fuel maps. Up to five keystrokes xx.xx times four 625 matrices

takes a lot of time.

Fuel Maps and Fuel

Modifiers

Groups/STANDARD MAPPING/BASE CALIBRATION

(1-4)

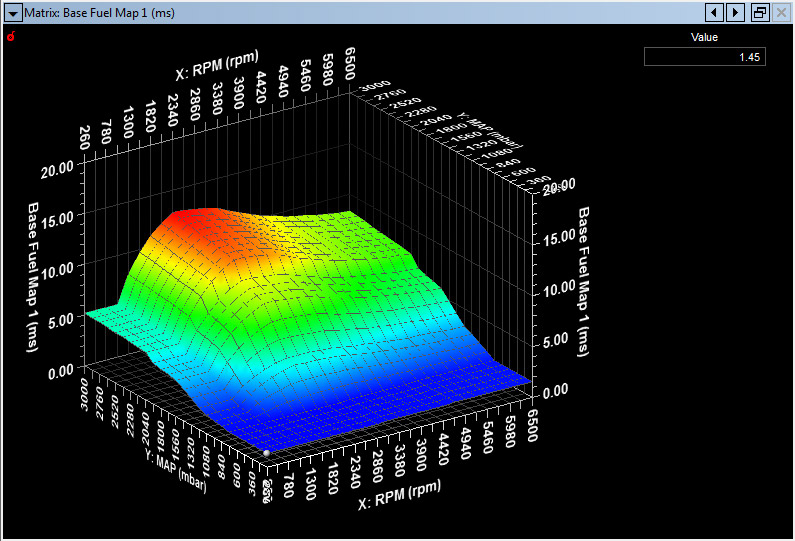

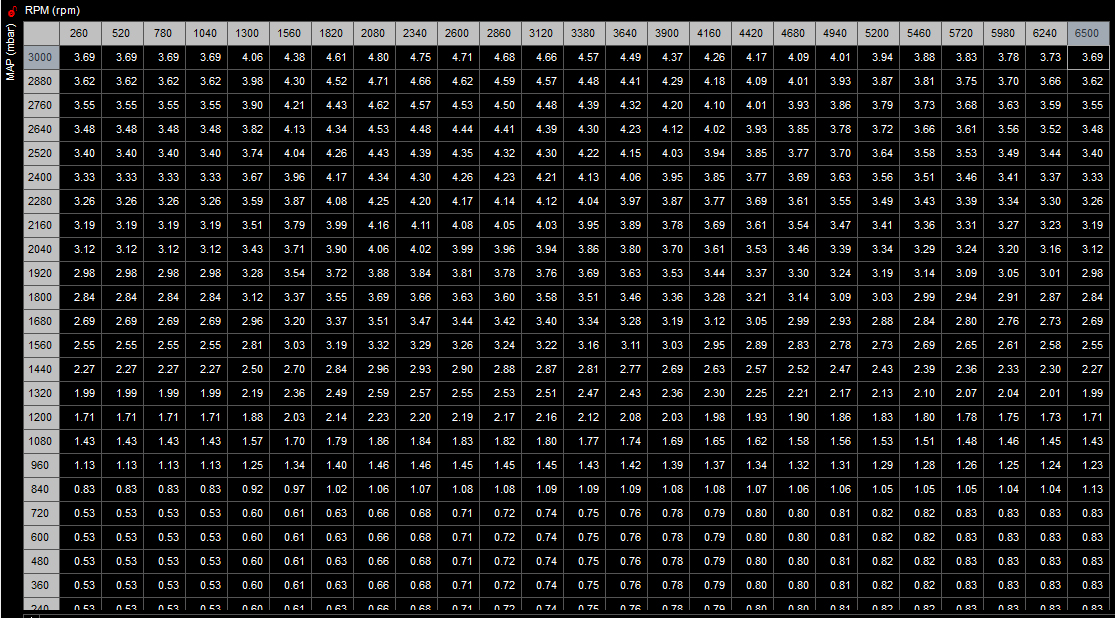

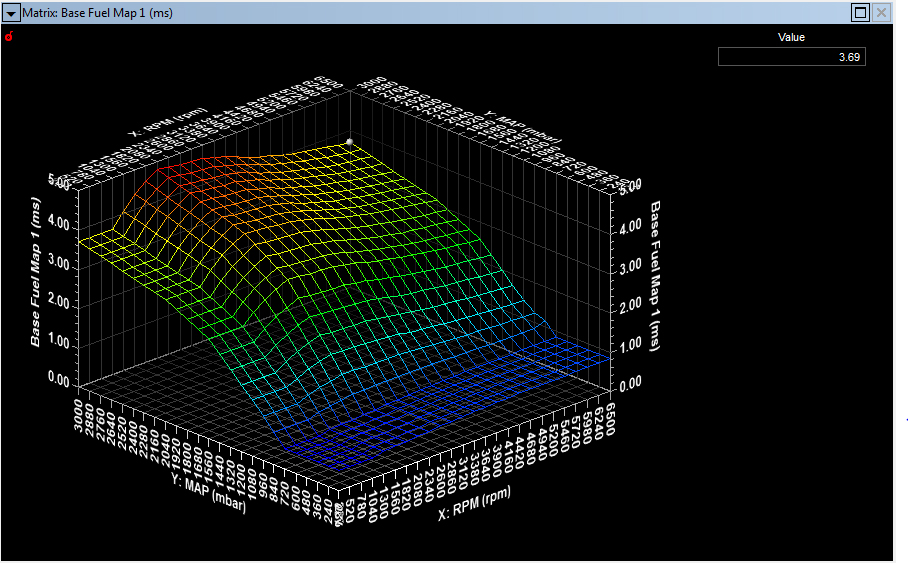

Fuel Maps in CalTool 3.6 can

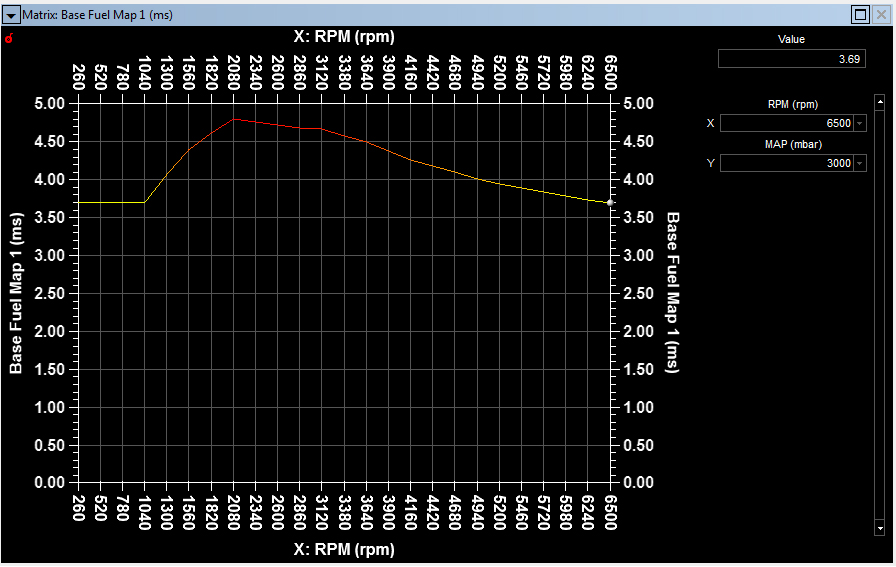

have up to 50 RPM sites and 25 Load Sites. In the picture above we have

set up

a 25 x 25 fuel map for 3 Bar and 6500 RPM operation. A unique feature

of CalTool 3.6 is that the RPM axis does not have to be equally spaced

i.e. if you need increased resolution in a certain rpm range you can do

so. There are four (4) base calibrations in the SQ6M engine controller.

The user can switch these "on the fly" with a Cal-Pot rotary switch.

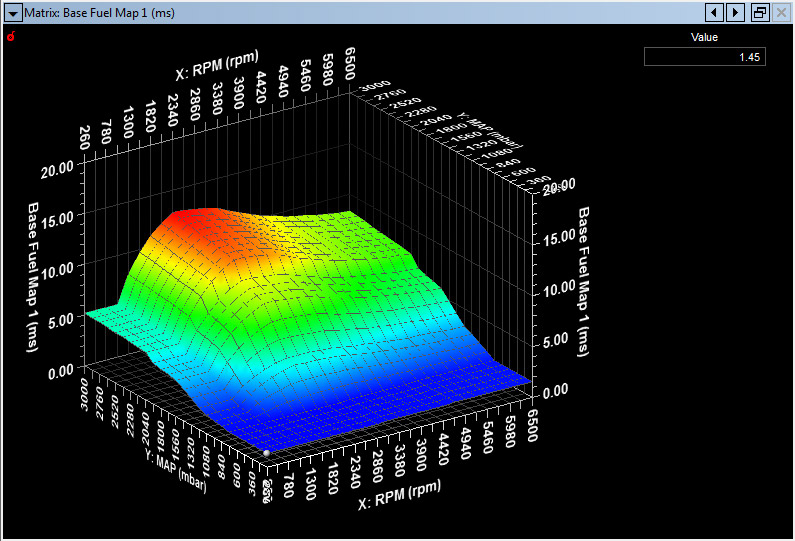

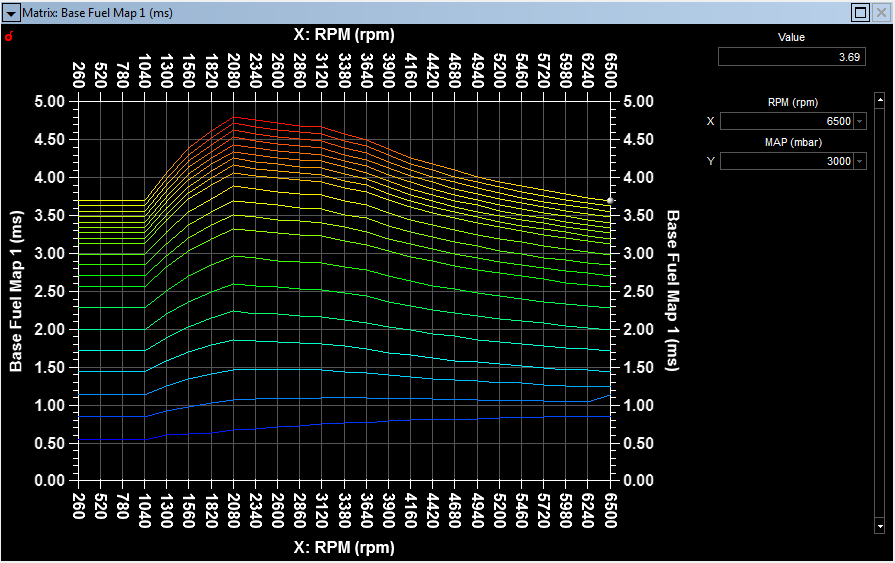

You can edit in either the

3D "Matrix Surface Editor" shown above or on in a 2D "Matrix Editor"

table format shown below.

Editing is done in a

number of ways, either by direct one cell edit, by the entire map, or

selected areas. Math functions are available for editing. Basic

resolution is .01 millisecond or .00001 seconds. Any finer gradation

than this is meaningless. We generate our four

base maps in Excel using predictive equations to save time...If you

have four spark maps and four fuel maps and they are maxed out at 50

RPM x 25 Load sites that is up to 40,000 digits and 10,000 decimal

points you get to manually enter. We automate the process and use copy

and paste from Excel to CalTool 3.6.

In either format you use the arrow keys to navigate about

the map. In the 3D format you use the CTRL Key and the arrow keys to

rotate or flip the map.

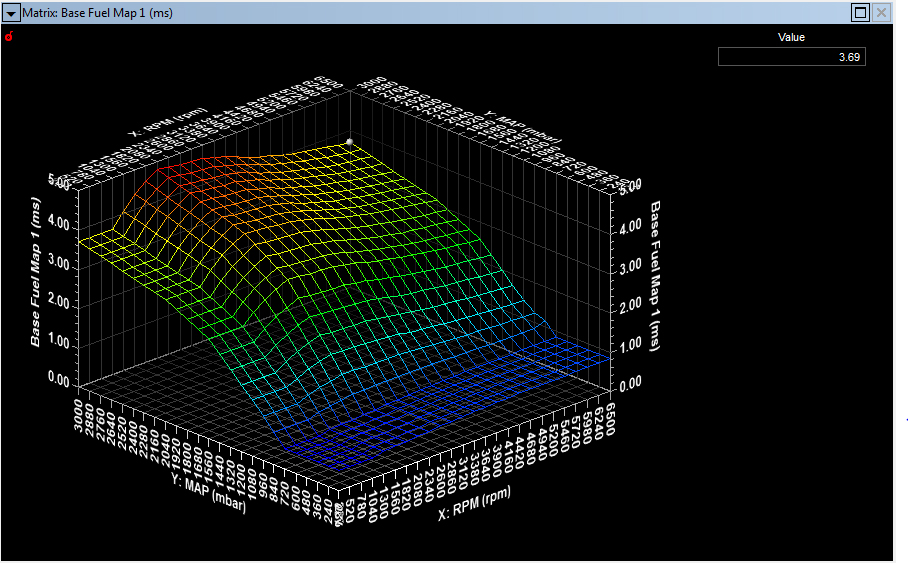

When in the Matrix Surface

Editor mode (top image) if you "right click" your map, a dialog

box will pop up and in "View" you have a number of ways to view your

fuel map data. Pictured above is a Wireframe view.

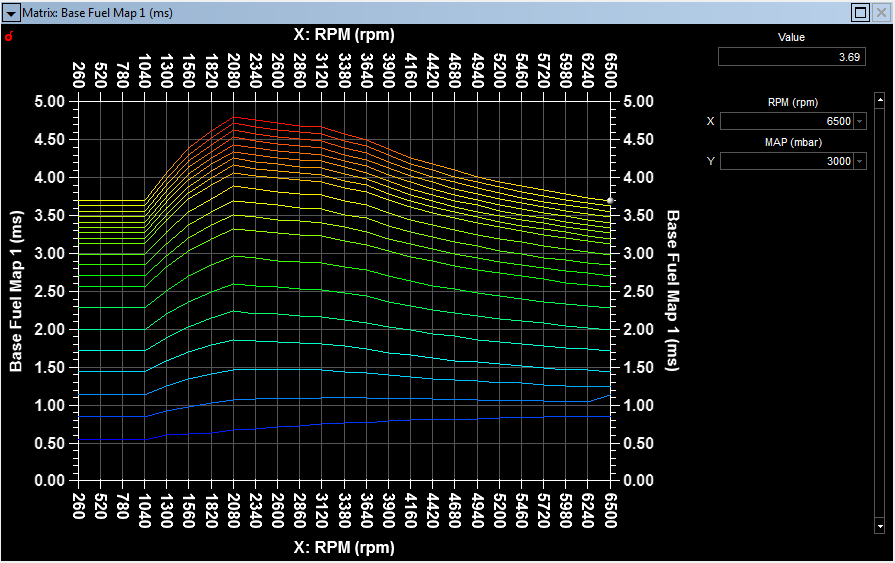

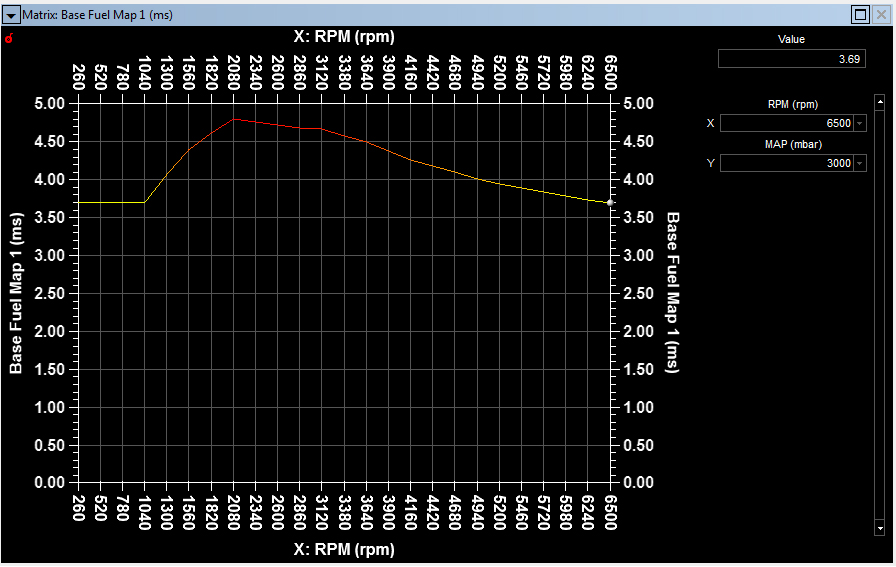

Above is the X Axis Slice. This is very useful, especially in Turbo maps to look for mistakes in manual editing.

Here we are looking at a Single X Slice. Wherever you have left the cursor that X Axis row will be displayed.

CalTool 3.6 Fuel

Modifiers

Beyond the basic four fuel maps there are about 75 programmable

modifiers for the final injection event. The level of detail is of

professional motorsport requirement and way beyond lesser engine

management systems.

Groups / STANDARD MAPPING / FUEL CORRECTIONS

1. Injection Angle

Control Method: END_ANGLE or START ANGLE

2. Injection Angle Rate of

Change (deg/Cylinder): 0.25 to 719.75

3. Base Cal Select Enable: ENABLED

or DISABLED

Groups

/ STANDARD MAPPING / FUEL CORRECTIONS / MULTIPLIERS / THROTTLE

MULTIPLIERS

4. Throttle Multiplier: Correction

for TPS Angle; Matrix of TPS degrees v. RPM

5. Enable Fuel Map Multimaps: ENABLED

or DISABLED;

If disabled a matrix of RPM v TPS degrees modifies the base fuel map

from 0 to 200% i.e. an entry of 1.00 means no correction. If

enabled six (6) multipmaps with matrices of RPM v MAP are activated,

also 0 to 200%.

Groups / STANDARD MAPPING / FUEL

CORRECTIONS / MULTIPLIERS / ENGINE COOLANT MULTIPLIERS / SINGLE

CALIBRATION

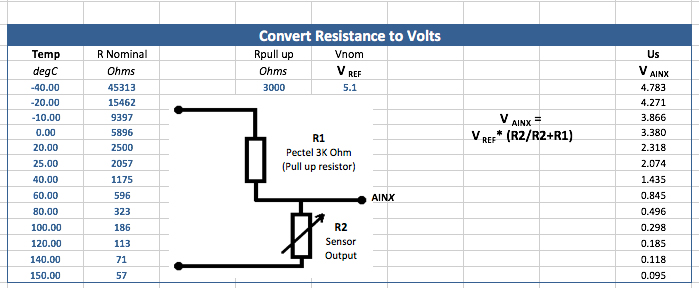

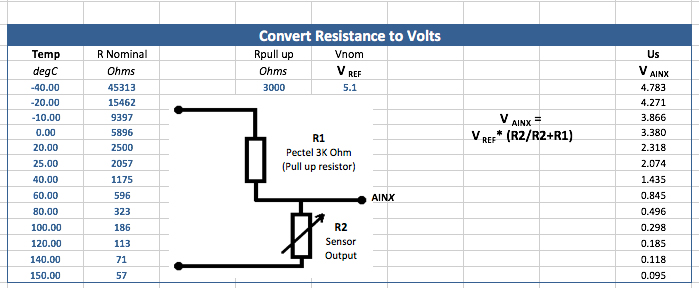

Sensor Data is often given in resistance v. temperature.

Use this calculator (Excel Spreadsheet) when using 3K pullup resistor for temperature calibration.

Groups / STANDARD MAPPING / FUEL CORRECTIONS / MULTIPLIERS

7. Air Charge Temperature Multiplier

8. Ambient Air Temperature Multiplier

9. Atmospheric Pressure Multiplier

10. Engine Oil Pressure Multiplier

11. Engine Oil Temperature Multiplier

12. Exhaust Temperatrure Correction

13. Fuel Pressure Multiplier

14. Fuel Temperature Multiplier

15. Global Fuel Multiplier

16. 360 Sync Multiplier

Groups / STANDARD MAPPING / FUEL CORRECTIONS / ADDERS

17. Battery Adder

Groups / STANDARD MAPPING / FUEL CORRECTIONS / CLOSED LOOP LAMBDA

18. Closed Loop Lambda Update Rate

19. Lambda Correction Minimum

20. Lambda Correction Maximum

21. Closed Loop Lambda Target Exhaust Temperature Correction

22. Closed Loop Lambda Target Multiplier f(ECT)

Groups / STANDARD MAPPING / FUEL CORRECTIONS / CLOSED LOOP LAMBDA /

ENABLE/DISABLE

23. Closed Loop Lambda Enable: ENABLED or DISABLED

24. Lambda Correction Minimum

25. Lambda Correction Maximum

Groups / STANDARD MAPPING / FUEL CORRECTIONS / CLOSED LOOP LAMBDA / PID

PARAMETERS / SIMPLE LAMBDA

26. Simple Lambda Rich Lambda Error

27. Simple Lambda Lean Lambda Error

Groups / STANDARD MAPPING / FUEL CORRECTIONS / CLOSED LOOP LAMBDA / PID

PARAMETERS

28. Closed Loop Lambda Proportional

Gain

29. Closed loop Lambda Integral Gain

30. Integral Total Minimum

31. Integral Total Maximum

Groups / STANDARD MAPPING / FUEL CORRECTIONS / CLOSED LOOP LAMBDA /

DISABLE TIMERS

32. Closed Loop Disable Time Sensor

Warmup

33. Closed Loop

Disable Time Starting

34. Closed

Loop Disable Time During Fuel Cut

35. Closed Loop

Disable Time During Transient

36. Closed Loop

Disable Time During Gear Shift

Groups / STANDARD MAPPING / FUEL CORRECTIONS / CLOSED LOOP LAMBDA /

CATALYST ADJUSTMENT

37. Lambda Target Adjust disable

f(RPM)

38. Lambda Target

Adjust enable f(RPM)

39. Lambda Target

Adjust disable f(TPS)

40. Lambda Target

Adjust enable f(TPS)

41. Lambda Target

Adjustment

Groups / STANDARD MAPPING / FUEL CORRECTIONS / OVERRUN FUELING

42. Overrun Fuel Cut Off Cal (1-4

Maps): RPM entries f(ECT)

43. Overrun Fuel Reinstate Cal (1-4

Maps): RPM entries f(ECT)

Groups / STANDARD MAPPING / FUEL CORRECTIONS / FUELING DURING STARTING

44. Injection Start Angle in Crank

Groups / STANDARD MAPPING / FUEL CORRECTIONS / FUELING DURING STARTING

/ SINGLE CALIBRATIONS

45. Preliminary Injection: Ms v.

ECT: Wets manifold walls at start event

46. Base Fuel in Crank: Ms v. TPS: Base value during cranking

47. Cranking Multiplier: Matrix ECT v. Cranking engine turns

Groups / STANDARD MAPPING / FUEL CORRECTIONS / BANKED INJECTION /

SECONDARY INJECTOR LEAN LIMIT

48. Secondary Injector Lean Limit

Function Enable: ENABLED or DISABLED

49. Secondary

Injector Lean Limit Minimum Lambda

50. Secondary

Injector Lean Limit Minimum Throttle Angle

51. Secondary

Injector Lean Limit Minimum Engine Speed

52. Secondary

Injector Lean Limit Minimum Lambda Correction

53.

Secondary Injector Lean Limit Error Time

Groups / STANDARD MAPPING / FUEL CORRECTIONS / BANKED INJECTION

54.

Enable Banked Injection

55. Injector Bank Split

56. Injector Bank Split Rate of Change

57. Secondary Injector Bank Scale

58. Secondary Injector Bank Switch On Time

59. Secondary

Injector Bank Switch Off Time

60. Primary Bank Switch Off Time

61. Switch-over Multiplier

62. Switch-over Decay Multiplier

Groups / STANDARD MAPPING / FUEL CORRECTIONS / TRANSIENT FUEL CORRECTION

63. Maximum Engine Speed

64. Start Cylinder Count Before TFC

65. Enable Time Based Transients: ENABLED or DISABLED

66. Maximum Throttle Angle

67. Minimum Delta Throttle

68. Accel Positive Gain

69. Accel Positive Decay

70. Accel Positive Clamp

71. Accel Negative Gain

72. Accel Negative Decay

73. Accel Nggative Clamp

Groups / STANDARD MAPPING / FUEL CORRECTIONS / INDIVIDUAL CYLINDER TRIM

74. Enable Cylinder Fuel Trim: ENABLED or DISABLED

75. Cylinder (Cylinders

individually 1 to 12): MAP v. RPM