Electrons

Getting electrical signals from point A to point B is pretty

standard thing...Put a piece of copper wire between A and B and

the job is done. A century of development has left us with

increased specialization in wiring, connection devices, and

everything in between point A and B. "Mil-Spec" or military

specification, has become the buzz-word in motorsport electrical

harness construction. Actually motorsport wiring has developed

it's own specialized connectors but it's still largely

constructed from aerospace components.

Perhaps "Race-Spec" will become the new buzz-word....Probably

not with the trillions of dollars spent on drones, F22's, and

commercial aircraft.

This is not a definitive guide on building wiring harnesses as

this could encompass two wheels, four wheels or no wheels. It

does give you a perspective on motorsports ecu wiring and

provides access to further literature for you to study and make

your own decisions. We build ecu wiring harnesses for our

production items and for our own racing activities.

Production OEM

Automotive Wiring

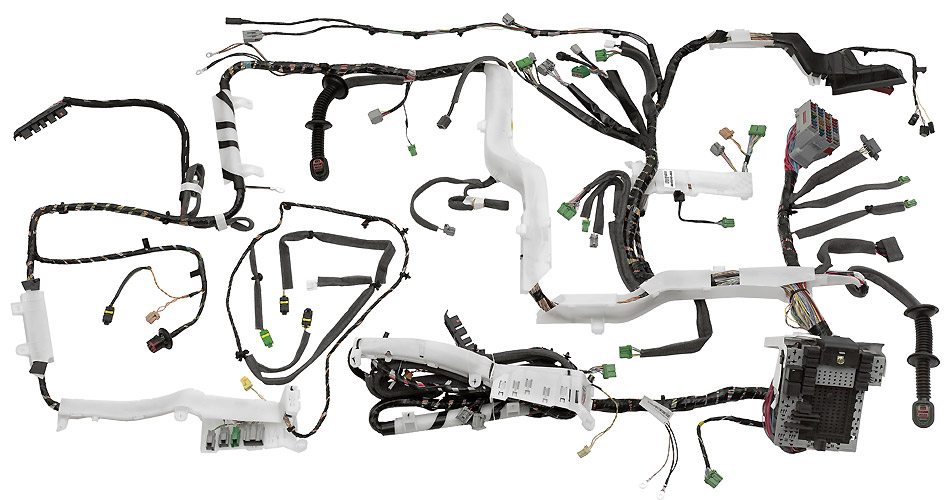

On one end of the scale there is OEM automotive wiring, like on

your new passenger vehicle or truck, wherein costs are paramount

and warranties are offered, in some cases, bumper to bumper for

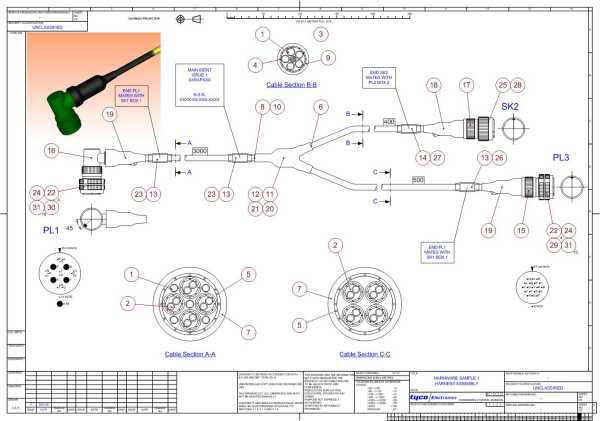

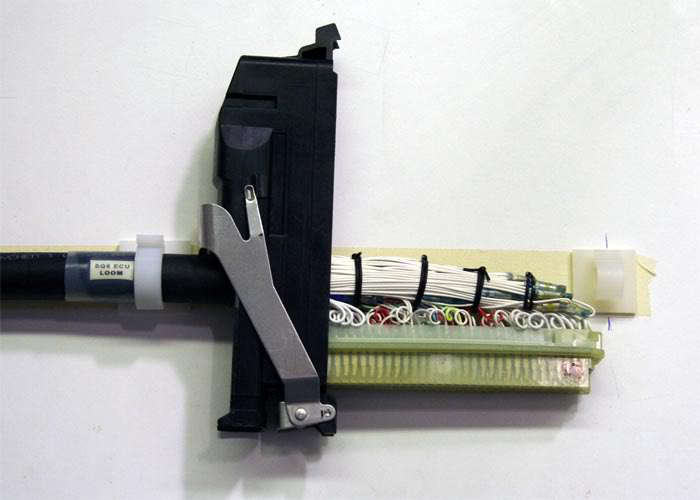

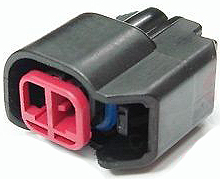

100,000 miles. Pictured above is a production passenger car

harness in GXL and TXL wires.

These vehicles and their myriad of up to sixty microprocessors,

connectors, sensors, relays, and switches are tested for years

on end in extremes of temperature, humidity, vibration, and

electrical interference. There are no mil-spec metal shell

connectors, no airframe tie wrapping or concentric twisting, and

no epoxied or glue-shrunk connections...Only plastic connectors

and crosslinked polyethylene GXL and TXL multi-strand copper

wiring without any silver, tin or nickel plating. Guess what,

they work just fine...amid increasing complexity, for years on

end. A typical mid-sized car will have about 45-70 lbs of

wiring.

One time we scrapped out a 20 year old Honda Civic Wagon and

were amazed at how all the wiring was still in perfect

shape...Connector seals were still sealed and clean inside and

all the grime, water and heat had not caused any failures.

Wiring was still flexible and not cracked. OEM specifications

and engineering are pretty damn good.

People who say this is inferior are full of shit. This takes

sophisticated automated and very expensive machinery and

dedicated tooling to pump out six-sigma quality.

In short, automotive grade wiring and connectors have a pretty

good track record. Not glamorous, but in business, economics and

bean counting it seldom is.

From 1989 to 2019 we manufactured our own RSR Closed Loop Fuel

Injection System and made hundreds of wiring harnesses with

Deutsch ECU connectors, Weatherpack connectors and TXL/GXL

wires. We covered the wires with Varflex fiberglass

sheathing...and we had zero problems. Nothing was sealed with

epoxy or shrunk into DR-25. They were easy to assemble with no

fixtures...just fixed lengths of all runs...no contra twisting

Professional motorsport harnesses have to be completely sealed

and essentially watertight employing harness epoxy and Raychem

boots...this involves a high level of planning and documentation

and is far more labor intensive. Sexy never is easy. Buckle up.

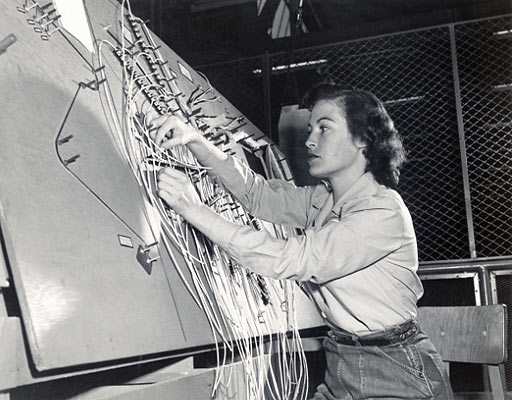

Aerospace Wiring

Airbus 380: With 530Km of wires, cables and wiring

harnesses weave their way throughout the airframe.

With more than 100,000 wires and 40,300 connectors

performing 1,150 separate functions, the Airbus A380 has the

most complex electrical system Airbus had ever designed.

They got to do it twice i.e. rip it all out and do it over

due to incompatibility in various software programs spread

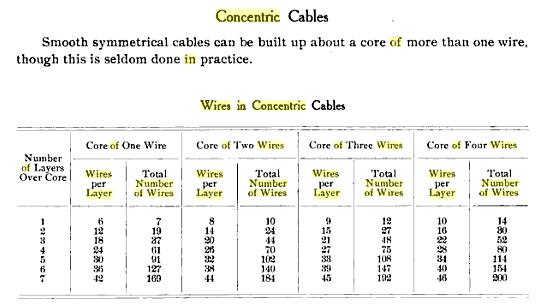

across a myriad of suppliers. No concentic twising, no

DR-25, no RT-125 epoxy. 20,000 flight hours life. Go figure.

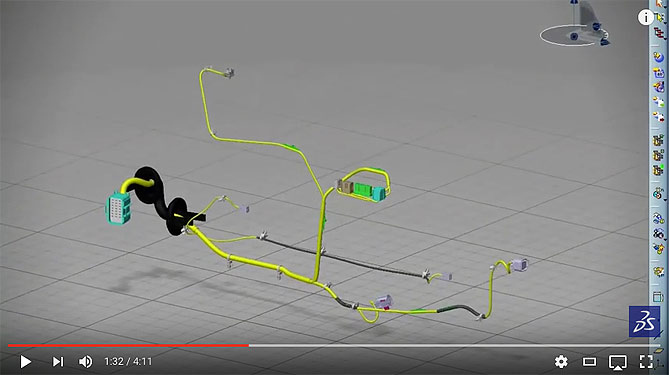

You

Tube Video.

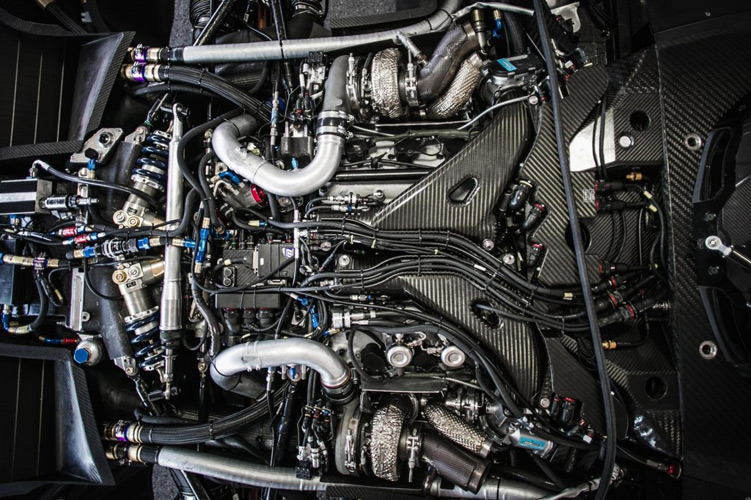

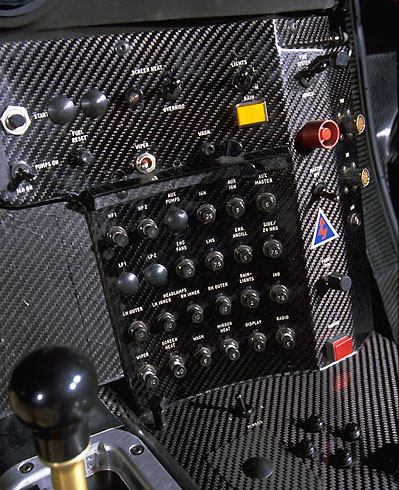

Motorsports

Wiring... Race-Spec

This has evolved from aircraft and military specifications

wherein light weight and reliability are paramount. As

motorsports evolved into an increasingly more sophisticated and

expensive professional endeavor, specific motorsport connectors

have evolved which are even lighter and smaller than their

aerospace counterparts. These products don't have to meet oem

production testing requirements...They just have to be reliable

in a racing environment which is not the same as freezing in

Siberia or bouncing down rural roads in your F150 pickup for

decades.

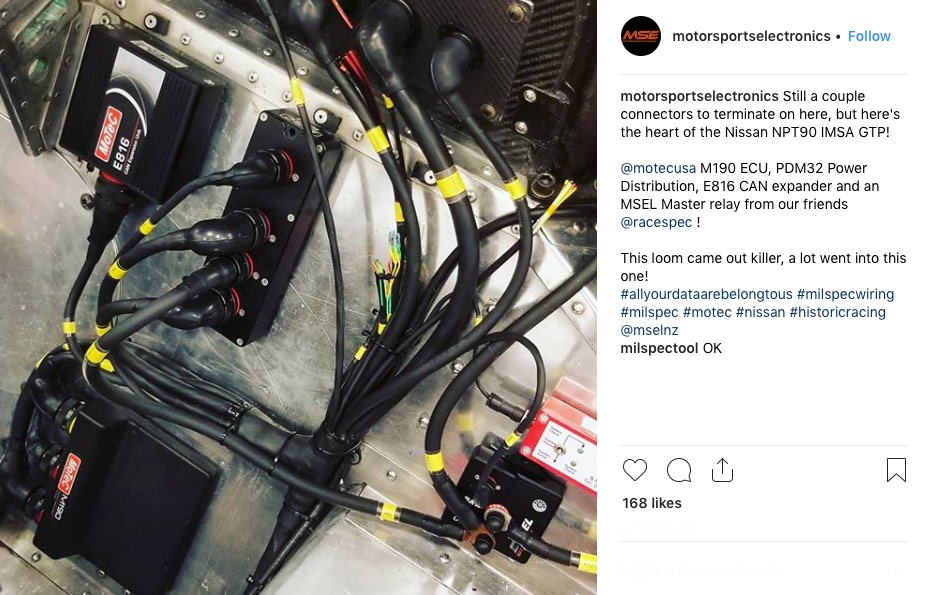

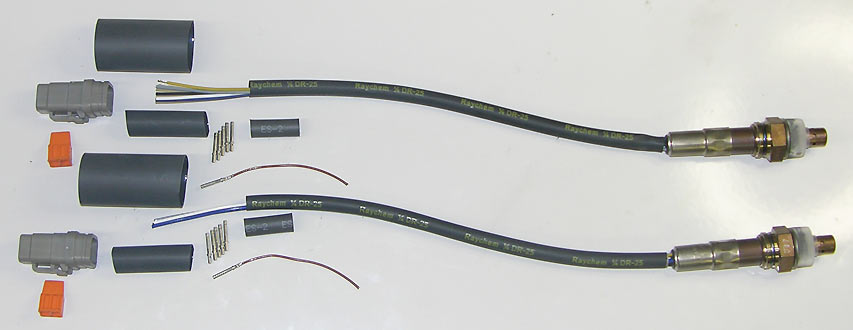

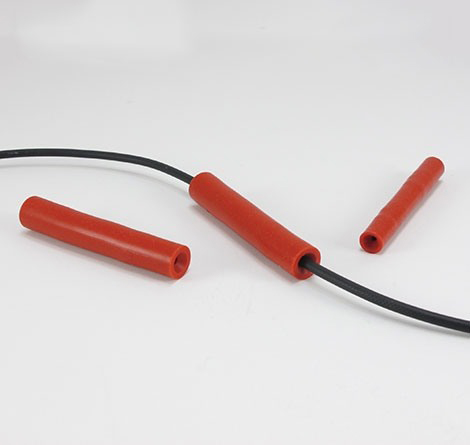

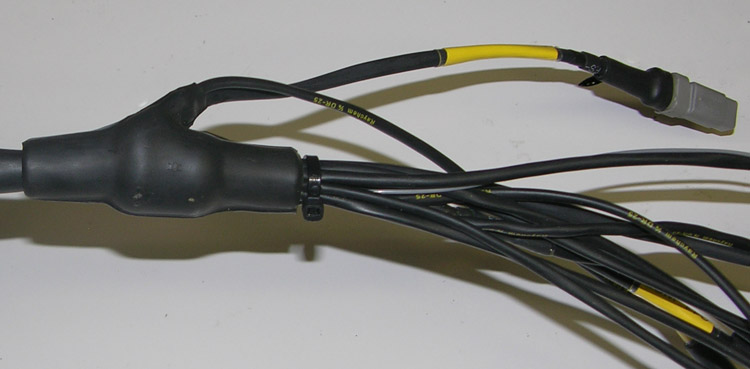

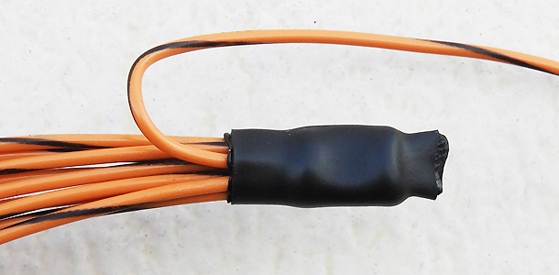

Sort of serious in a Darth Vader, rubber-fetish way. Bondage and

latex in the hell of an engine bay. Above are heat shrink boots

sealing circular connectors and the DR-25 heat shrink wire

protection.

Everything than can slow you down is the enemy....weight of the

wires, weight of the connectors and any kind of outright

failure, or worse, intermittent failure, which is harder to

isolate. This is why F1 might be using tiny 30 gauge wire or why

the new McLaren MP4-12C went to extremes in specifying hexagonal

aluminum wire to save both space and weight.

In motorsport electronics Mil-Spec circular connectors are the

norm, full of all sorts of trickery like strain reducing service

loops and concentric twisting for flexibility and more compact

wiring harnesses. Reliability at 30,000 feet or going airborne

at the Nurburgring...it's all the same thing...well, sort of the

same thing. Mil-Spec...Race-Spec...Autosport.

Service

Loops

and Service Loop Tools

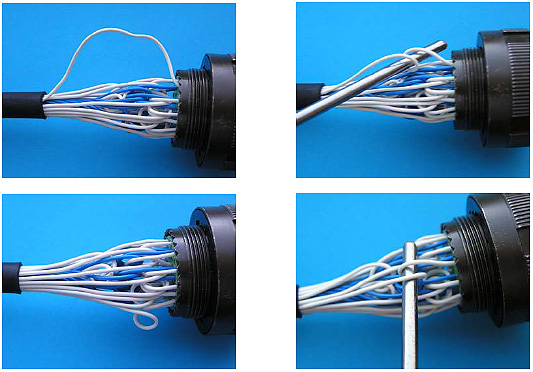

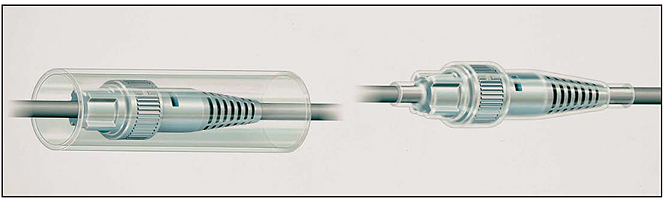

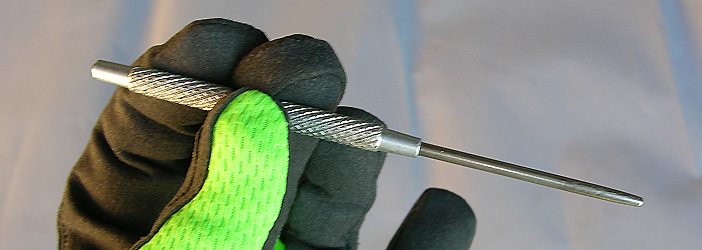

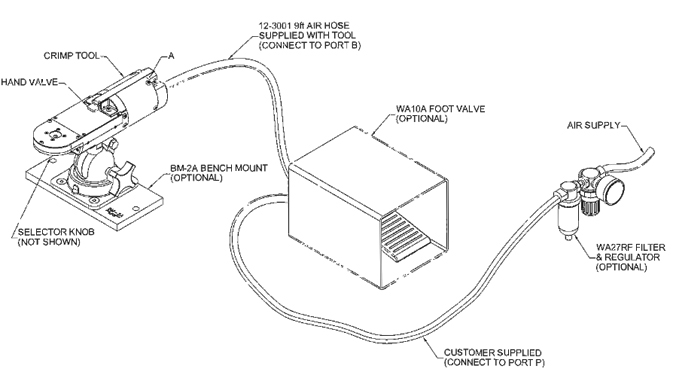

Service Loop Tools allow a loop to be formed, held, and

maintained at your wiring harness connector for strain relief

and later servicing or repinning.

"Service Loops" are used on Mil-Spec / Deutsch Autosport

circular connectors for wire sizes 16 AWG to 30 AWG. The purpose

is to provide strain relief to the wire termination and to

provide a surplus length for repair purposes. It is not an

aircraft procedure per se and is only used in military and

motorsport applications.

Depending on your planning these can go in first or last. The

wires have to be loose so doing them as they are installed in

the connectors easier with a large number of terminals. In

general, it's easier to work from the connector outwards rather

than with all the wires bunch up at the connector as shown

above...planning all this is a bitch.

If you are working outward from the ECU connector, just leave

thewires extra long and cut to length, terminate, and finalize

length in place forming service loops at the sensor if necessary

.

PDF on

Service Loops.

Service Loop

Tools and Procedures

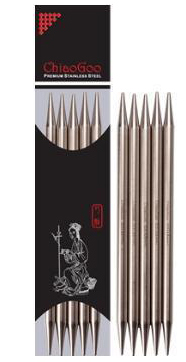

Motorsport Wiring Service Loop Tools:

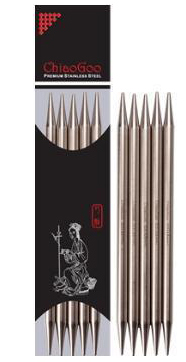

6"

ChiaoGoo

knitting needles come in packs of five. You can get free

shipping and -10% for orders of $30.00. These come in different

diameters (2mm to 8mm). Stainless steel with rounded tips. Use

these to hold your loops in place. If you want to get tricky,

O-Rings sized to grip the needle, can hold them in place so they

don't slip out for each row or column.

Smaller diameters (2.5mm) for circular connectors and larger

diameters (6mm) for rectangular or square connectors. The sizes

are laser-etched on each needle.

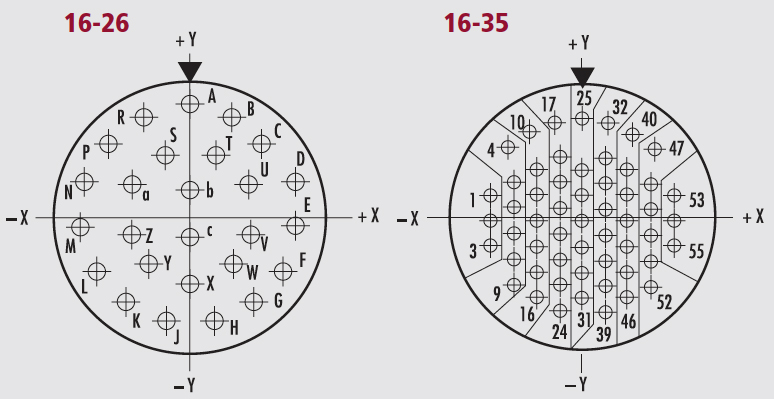

On circular connectors it is recommended to start your loops at

the center and work outwards if the numbering system runs

clockwise or counterclockwise. For rectangular or circular

connectors identified in rows, it is recommended to work row by

row. Loops should face inwards. Loops must be staggered to

minimize any increase in the cable diameter. When looping is

complete all loops should face inwards to give a neat appearance

and to insure that the wires are not trapped or damaged if an

adapter or back fitting is present.

If your connector is already terminated and the wires are shrunk

with DR-25 it gets a little more difficult as you will have to

press back the connector to bow the wires. You may have to cut

back on the harness DR-25 to free up the wires.

All of this is a bit stiff to wrestle with so holding the wiring

harness, the connector, and the looping tool at the same time is

a bit interesting. Think ahead. A specialized connector fixture

(best) or a vise with aluminum jaws can be used to hold the

connector.

It is a good idea to wrap an Autosport Connector in Kapton tapes

to prevent it being scratched.

The connector above features concentric (twist) wiring, service

(strain relief) loops at the connector, lacing cord and Kynar

clear shrink to hold the wires tightly together near the

connector. Kapton tape will cover the wires and service loops at

the connector to protect them from the specialized boots

(shapes) and RT125 harness epoxy.

The DR25 can be terminated with a short length of Raychem SCL

adhesive lined heat shrink. With the wires covered by DR-25, the

SCL, Kapton tape, and the RT125 sealed boot, the harness

will be protected from the environment and from abrasion.

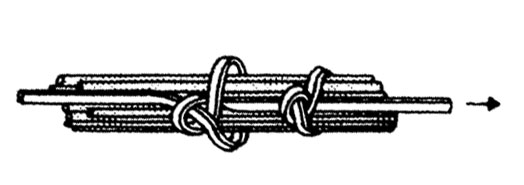

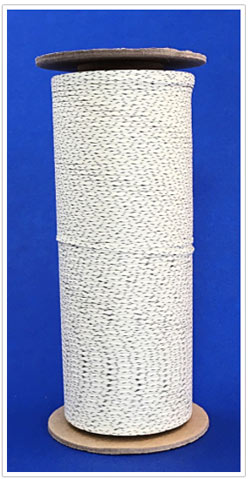

Here flat braided lacing tape is counter-wound to hold the

concentric twisted wires in place. Something to think about:

Were the service loops put in first or last? Generally first and

work outwards.

Guideline for

concentric twisting.

Here a Deutsch Autosport connector has its Spec 55 wires wrapped

in Kapton tape to prevent the adhesive shrink or harness epoxy

from grabbing the wires. The tape allows repairs to be made at a

later date. Once the adhesive or epoxy sets it really grabs the

connector, the DR-25 wire covering, and anything underneath it.

Raychem boots are heat shrunk at about 480F (280C).

You use special tips on your heat gun to focus the shrinking of

these boots. You can't shrink the boot all at once.Generally you

focus on the center and then the ends. By shrinking the mid

point you can "cup" the boot and insert the Resintech RT125

epoxy and then shrink that end first...Then finish the other

end...Wiping both ends with an alcohol wipe and foam tipped

swabs as you go.

There is a video of this using TE Connectivity S1125 epoxy

further down the page that shows the steps in this process.

Low Static Kapton adhesive tape is commonly available in 1/4,

3/8" and 1/2" rolls. The silicone adhesive does not leave any

residue. It is amber in color. It is also used to protect

circular Deutsch Autosport Connectors during the harness

assembly process.

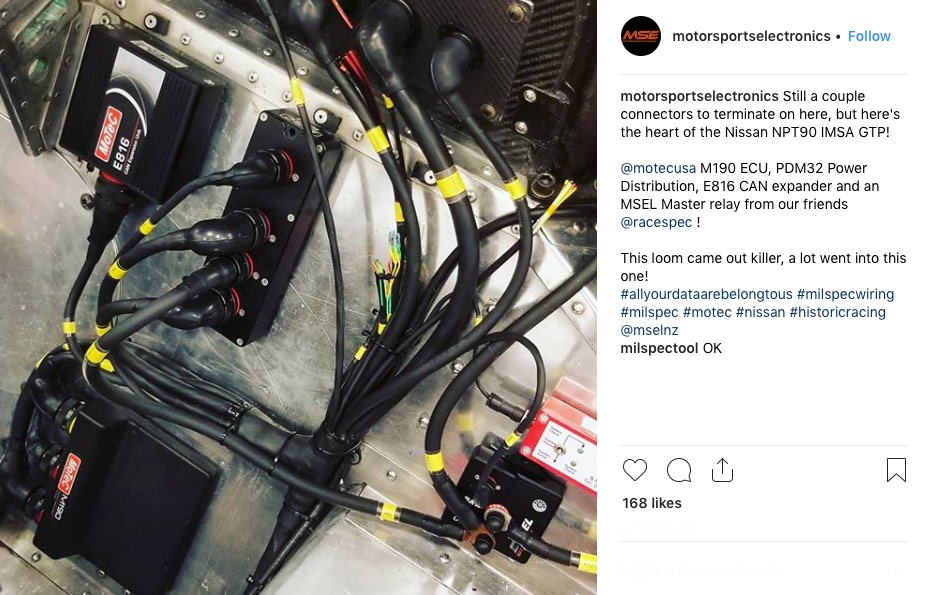

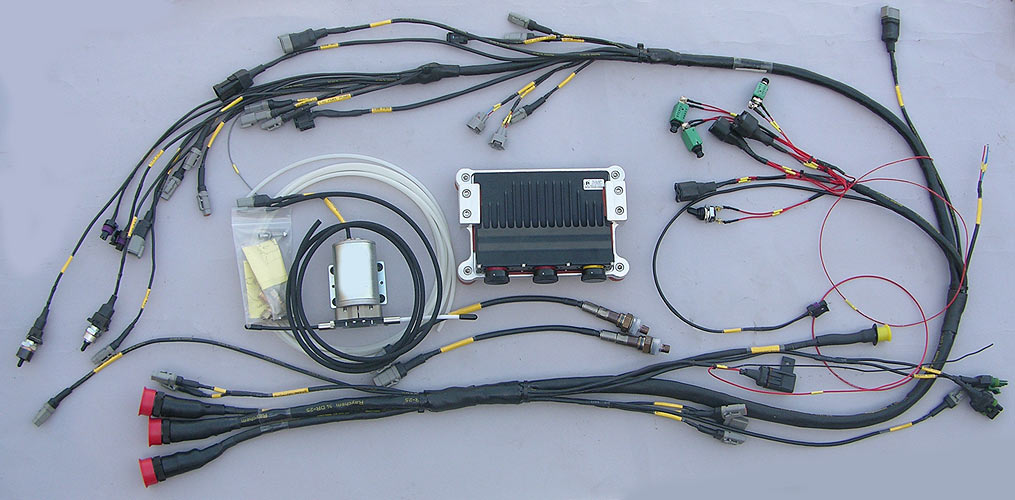

Motorsports

Wiring...Race-Spec

Circular connectors, glue shrunk boots, Raychem DR-25 shrunk

over concentric wound silver-plated Raychem Spec 55 XLETFE

wiring and, of course, the requisite yellow shrink tube labels

covered in Raychem RT-375 clear shrink tubing.

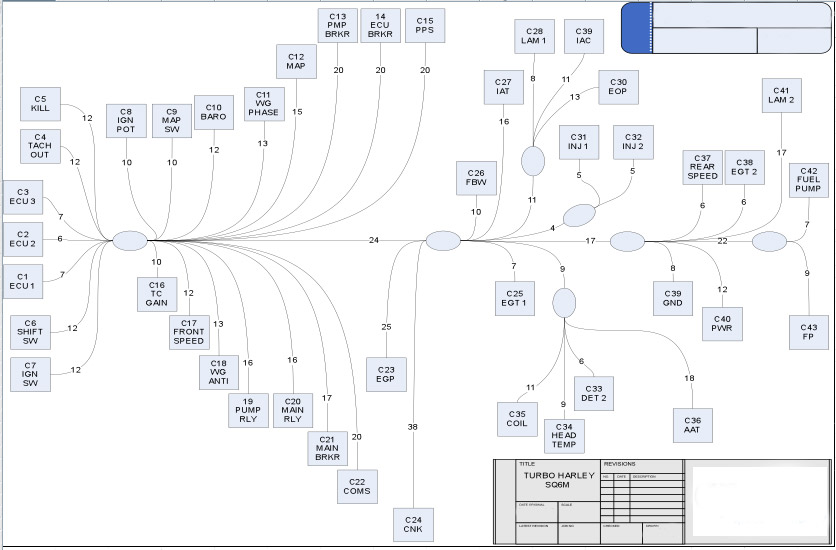

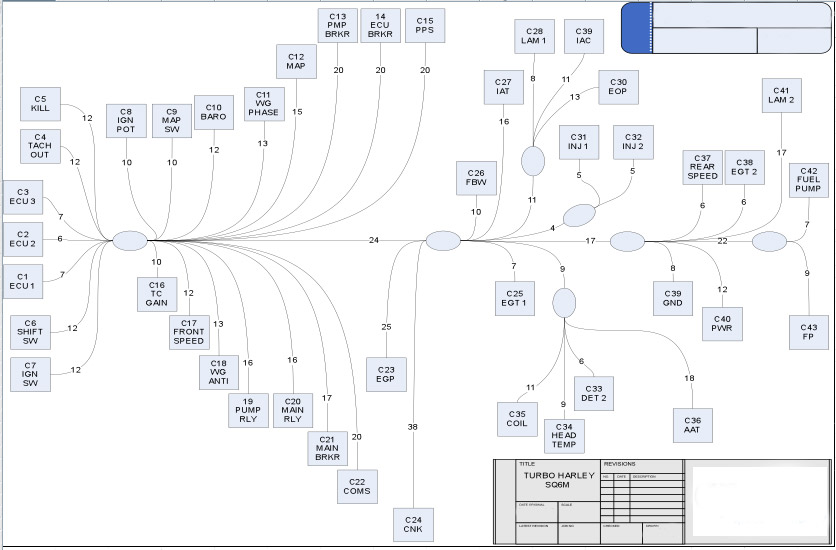

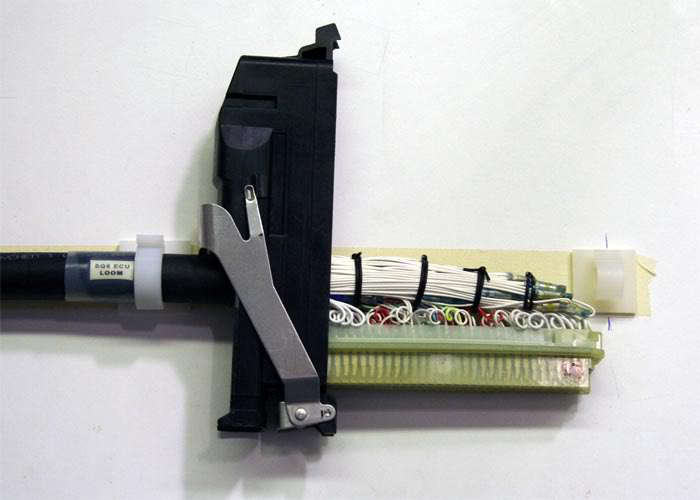

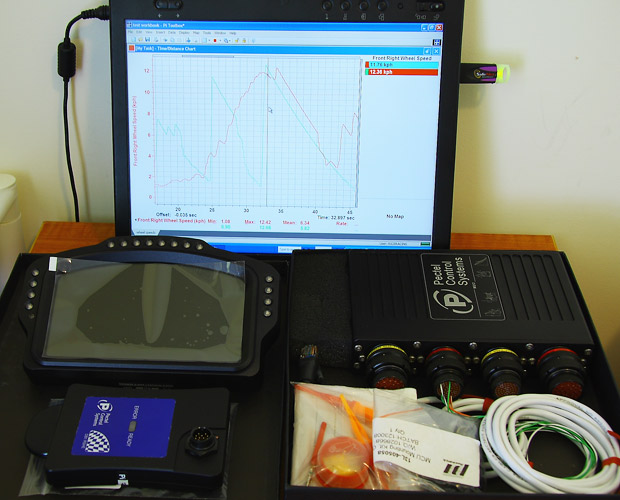

Cosworth Pectel SQ6M ECU. Mil-Spec

evolved into Race-Spec.

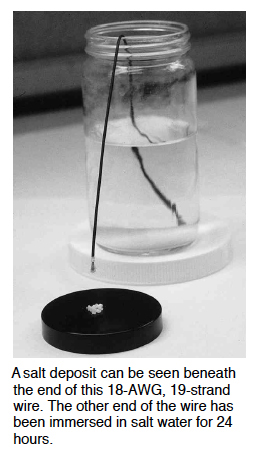

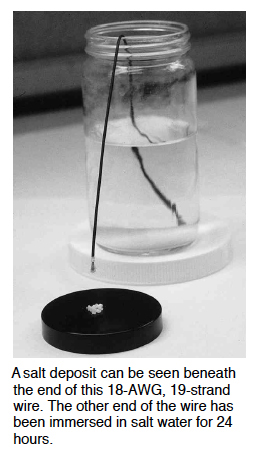

Wicked Wicking

In case you doubt the need for epoxy or adhesive-lined

terminations, the above picture gives graphic evidence of

corrosion traveling down the voids between the strands of copper

wires. Since we go to the Bonneville Salt Flats two to three

times a year for up to a month, and everything gets bathed in

salt, properly sealing the electrical connections is a major

concern. Year one OK...year two fix one or two things...year

three redo everything. Using adhesive-lined or epoxy-based

sealing schemes we can keep corrosion out of our wiring

harnesses.

OEM harnesses employ silicone seals on thermoplastic connectors

to address these issues. Any gap in the harness can provide a

path to internal corrosion.

Sealing

With

Epoxy

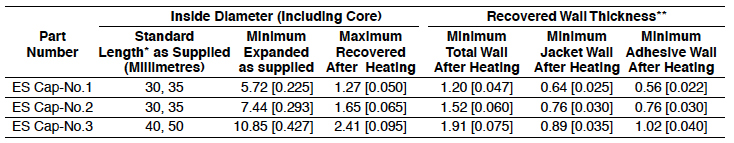

Sealing boots and shapes that do not have adhesive melt can be

done with specialized two part epoxies. Abrading the inner

surface and applying the epoxy to the connector and cable before

the heat shrinking operation. Epoxy is not applied to the inside

of the heat shrink. Here the connector is sealed to the cable

using V25 Deray thin wall shrink tube (2:1) and sealed with

epoxy.

Resintech RT125

Epoxy

The preferred epoxy for sealing wiring harnesses is

Resintech RT125.

It is a two part semi-flexible epoxy that is mixed 50/50. You

can purchase RT125 and a 3M applicator mixing gun from Prowire.

These are standard 50ml cartridges. Note they have a shelf life.

If you are using this in concert with non-adhesive lined boots

do not fill the boot up with epoxy or you will have a real mess.

Only seal the ends one at a time. Be prepared to do some clean

up wiping with a clean cloth and alcohol as the epoxy hardens

much later than the adhesive lined boots.

If the entries and exits of the boot are single round diameters

then either adhesive lined or non-adhesive lined boots can be

used. If non-adhesive then seal the exits with RT125, one exit

at a time, wiping the excess off. Syringes are used for more

delicate sealing of smaller parts.

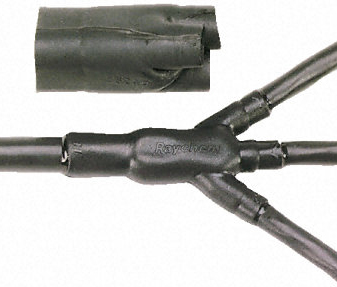

Here we have sealed the multiple branches under the Raychem boot

with Resintech RT125 and shrunk the boot over the epoxy. It's a

good idea to use an additional tie wrap strain relief at the

multiple branch point.

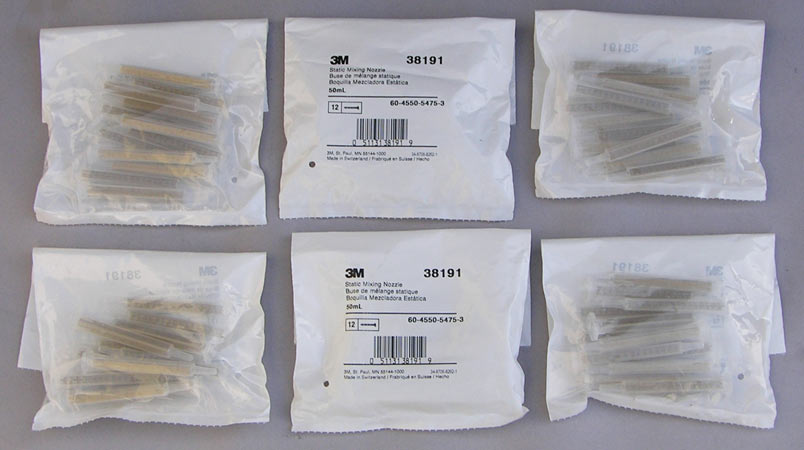

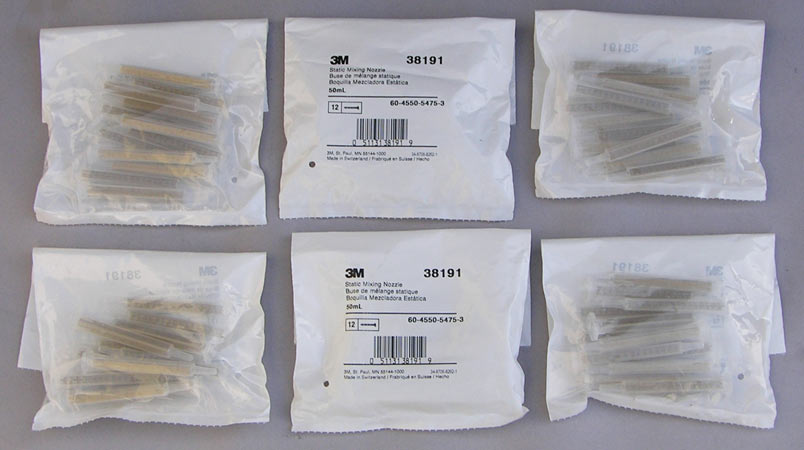

Resintech RT125

3M Mixing Gun

3M EX-PLUS-II-APPLICATOR for the

Resintech

RT125. This makes the application of the epoxy a lot less

messy.

About

$38.00

from Prowire USA... well spent. You throw away the mixing

nozzles after each application as the RT125 starts setting

rather quickly. You should let the applied boot and RT125 harden

as it can get a bit messy before you go off to the next sealing

point. Hanging the harness up so the RT-125 doesn't flow "down"

away from the joint is a good idea.

We buy the mixing nozzles in packs of 12 as we use RT125 for

other projects in addition to sealing wiring harnesses.

Epoxy Syringes

3cc and Epoxy Needles 15 ga &

14ga

When working with smaller

harness components 3cc Luer Lock style disposable syringes

can be used with

15

gauge

Luer Lock stainless steel 1.5" needle blunts to

dispense RT125 harness epoxy. These are inexpensive one time

use items...For less viscous glues or epoxies the larger

I.D. 14ga needles are easier to use.

A wide variety of syringes and 15ga dispensing nozzles can

be

purchased

from Prowire USA.

TE Connectivity S1125

Sold it kits with supporting materials

S1125 adhesive is

used to seal DR-25 and Raychem Boots in the same manner as

Resintech RT125.

This video

shows the proper procedure for sealing and testing the bond on

DR-25 and molded boots. S1125 is more expensive than RT125. The

procedures are the same for both. Here a non-adhesive lined boot

is sealed on both ends.

With Ideal 46-204 Elite Plus Heat Gun use 46-955 Ovelap Adaptor

to shrink the boot.

The Raychem Boots are the last items to seal and shrink in the

harness.

Inexpensive 70% isopropyl prep

pads to wipe the overflow of the harness epoxy from the end

of the Raychem boot.

Motorsport

Wiring Vises

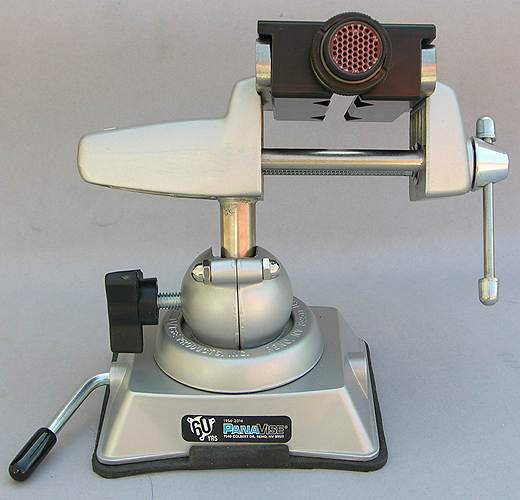

The Panavise 350 Motorsort

WiringVise can be used to hold objects from ecus to bare

wire by just flipping the rubber lined jaws around. In

general, if you are doing concentric twisting, you need to

hold the harness at both ends to do successive layers.

Holding the harness at both ends allows you to

twist exiting leads.

The Panavise 350 is widely used in motorsport wiring and is

firmly attached to a production wiring bench. The small

circular tray around the base can prove useful holding pins

and sockets.

Having a lip around your production bench keeps parts from

taking a dive. Looking for a 22ga socket on the floor and

then rolling your chair over it or stepping on it s not a

recommended exercise routine.

Inexpensive vises for holding

motorsport wiring harnesses and connectors. The SE 8436MVC

3" Universal Table Vise on the left above has slip on soft

rubber pleated jaws.

The vacuum base Panavise Model 381 on the right we modified

with two 4" x 1" x .25" steel plates replacing the

Panavise plasic jaws and added a set of 4" NO-M.A.R

PlastiXrevolution

magnetic polymer magnetic jaws. This gives us a 1/2" to

1"diameter grip on wiring harnesses.

Here we are holding an Autosport AS16 26 position

connector for socket insertion and service loop forming. Any

circular connector clamping diameter beyond 1" and up to

1.250" you will have to fabricate a new lead screw with a

7/16" x 14 x 5" socket head cap screw and drill / insert a

1/4" handle. Use the 350 Vise for larger widths. In gereral,

you should wrap Kapton tape around circular Autosport

Connectors to keep from scratching the anodized surface.

Both vises come with soft jaws. Invaluable when holding

harnesses for concentric twisting, forming service loops, or

pin/ socket insertion. Available from many sources. The

SE8436MVC can mount to the table's edge and the Panavise can

be moved around and fixed in place if the surface is

non-porous.

These are not heavy duty items. Holding wiring harnesses is

certainly light duty. We use all three shown. Daniels Mfg

has a $750.00 vise for circular connector assembly.

Foam Swabs

Chemtronics Coventry

Sealed

Foam 48040 Swabs are perfect for dealing with harness

epoxy as you don't have to mess with the fuzzies in common

cotton swabs.

Available

in

packs of 500 for about $0.12 each. We use all sorts of

potting compounds beyond the harness specific RT125 and have

found these to be the best way to clean and manipulate the

goo.

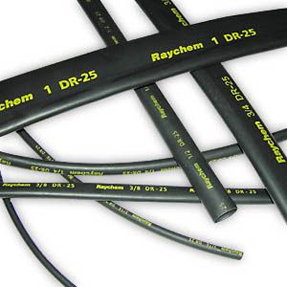

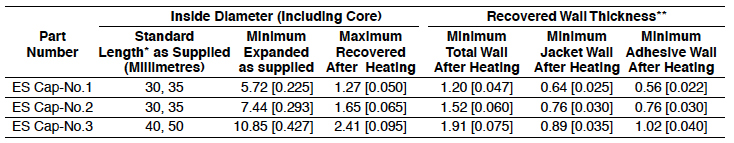

The comprehensive guide is

Raychem Heat Shrink Products. However, it can get a bit

confusing and, in general, you will be using System 25

Specifications for your wiring and connector sealing. For

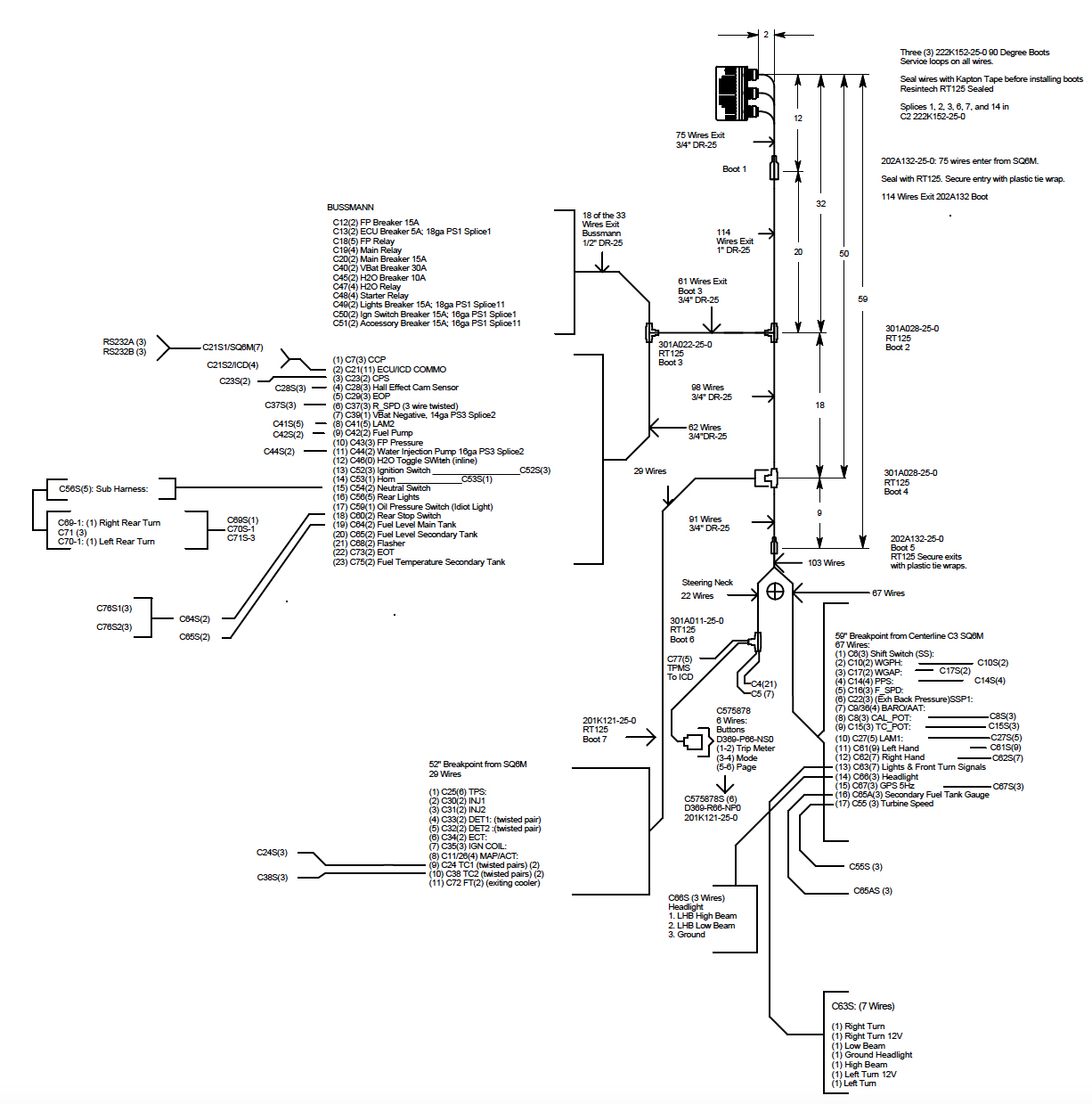

example on a Pectel SQ6M with three Autosport connectors we

might use a 90 Degree Boot with adhesive. 222K152-25/225-0. The

/225 refers to the factory applied adhesive, and the "25" is the

boot material used in System 25 applications.

Whether you use adhesive lined boots or seal them on their ends

with RT125 Epoxy you use about 480F or 280C with your heat gun

with a flat bladed tip.

There is a newer "25L" designation for a lighter boot, not

listed in the literature.

With Ideal 46-204 Elite Plus Heat Gun use 46-955 Overlap Adaptor

to shrink the boots.

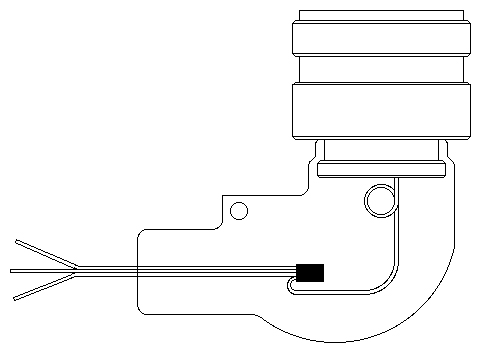

Micro Molded Boots

Instalite

Molded

Boots

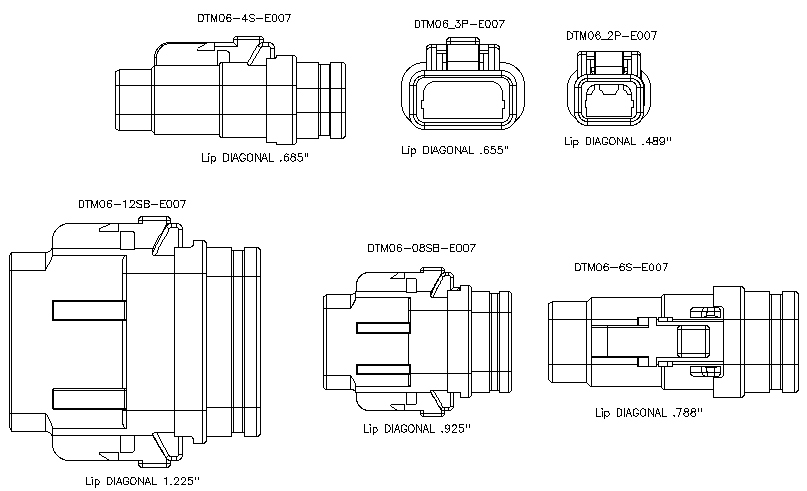

Raychem Instalite

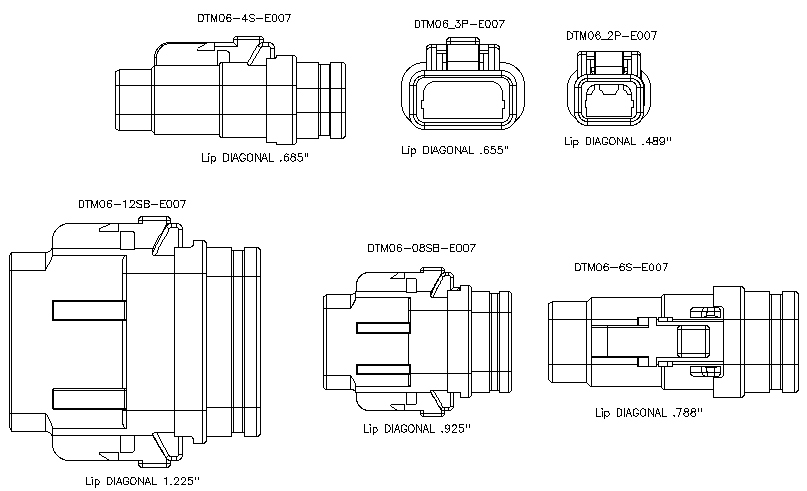

The Raychem boots on

Deutsch DTM06_xS_E007 Connectors.

To provide additional sealing

and strain relief, either

Raychem

molded

shapes (boots), or adhesive heat shrink like ATUM (3-1

or 4-1 shrink ratios) can be used on Deutsch DTM Connectors.

The lip diagonal dimensions above allow you to decide on the

proper sealing boot or shrink tubing.

Raychem

ATUM 4-1 and Raychem

HTAT: Less Expensive Connector "Boot" to DR-25

ATUM

HTAT

4-1

Shrink Ratio Raychem ATUM effectively seals

connectors with boot lips to DR-25. I shrinks 4-1 in

diameter and almost none in length. It ends up way

shorter than a straight boot and is far less expensive.

-55C to 120C rated. Single wall.

A stiffer and higher heat rated -55C to 125C (257F) in a

4-1 shrink ratio is

Raychem

HTAT . HTAT has better adhesion than ATUM and is a

dual wall construction which is stiffer than single wall

ATUM.

Available from

MOUSER.

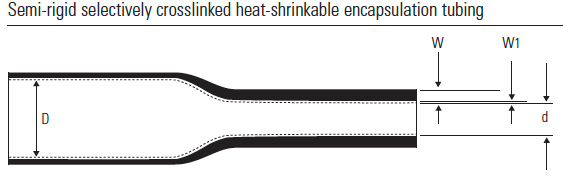

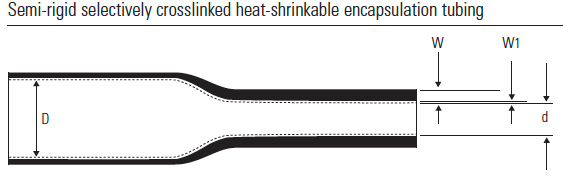

Sumitomo

W5DL Semi-Rigid Shrink Tube for Transitions

and Stain Relief: 3:1

W5DL is the choice for DR-25 transitions

(3-1 Shrink Ratio). W5DL is

recommended in applications for connections and wire

harnesses where filling voids and interstices are of

importance. In addition, W5DL provides good strain

relief because it does not adhere to the substrate

material it can be removed to repair components. Use

instead of Raychem SCL.

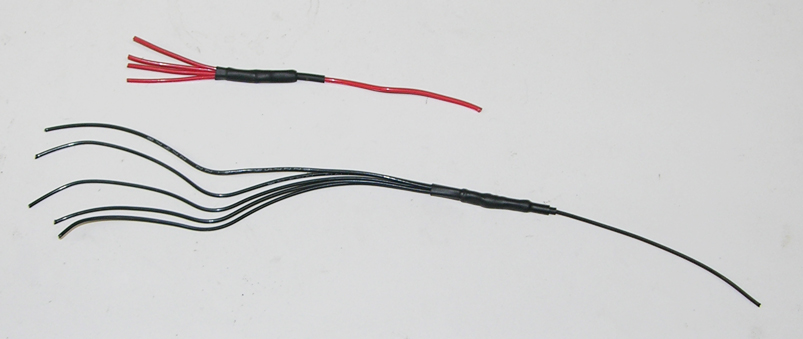

Here we made a test transition 1/4" DR-25 to two 1/8"

DR-25 and some exiting bare wires for a product we

make. 3/8"

W5DL sealing the transition

Sumitomo

W3B2 Flexible Shrink Tube for Transitions

and Stain Relief: 3-1 / 4-1

The flexible cousin of Sumitomo

W5DL.

SUMITUBE W3B2 is recommended for applications

requiring water-proofing for light cable and wire

harnesses and protection of connector components.

Available at Digi-Key and

Heatshrink.com

it is good to stock this as well as W5DL. These two

types of heat shrink that will cover most

situations.

Raychem

Boots v. Heat Shrink: A Reality Check

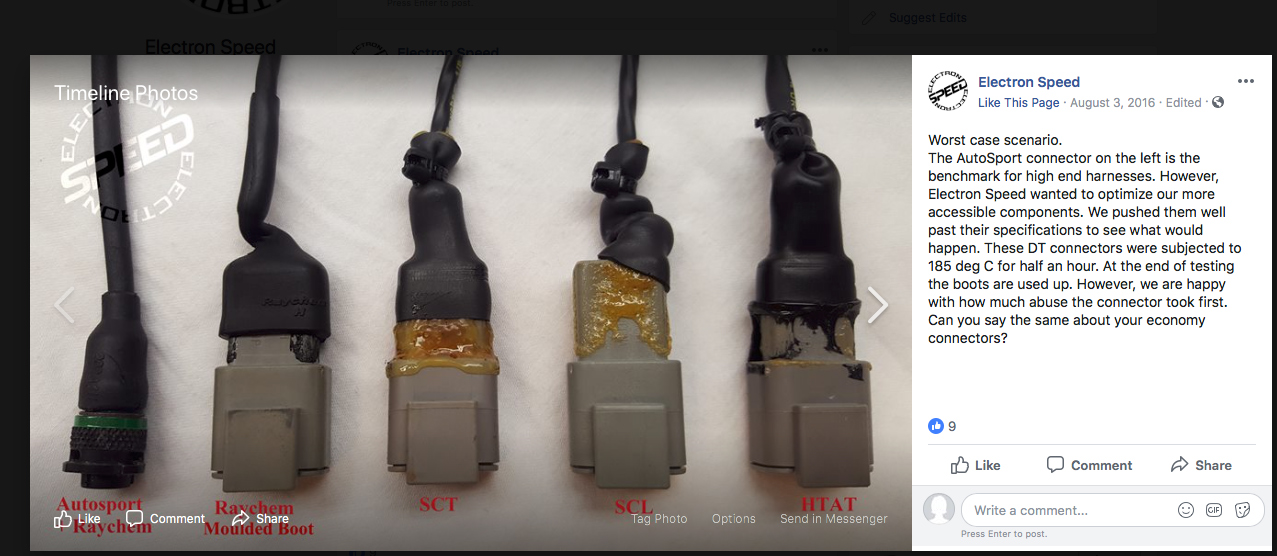

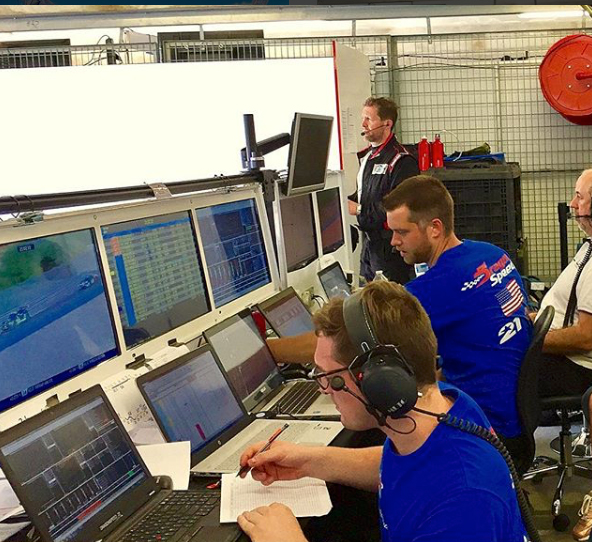

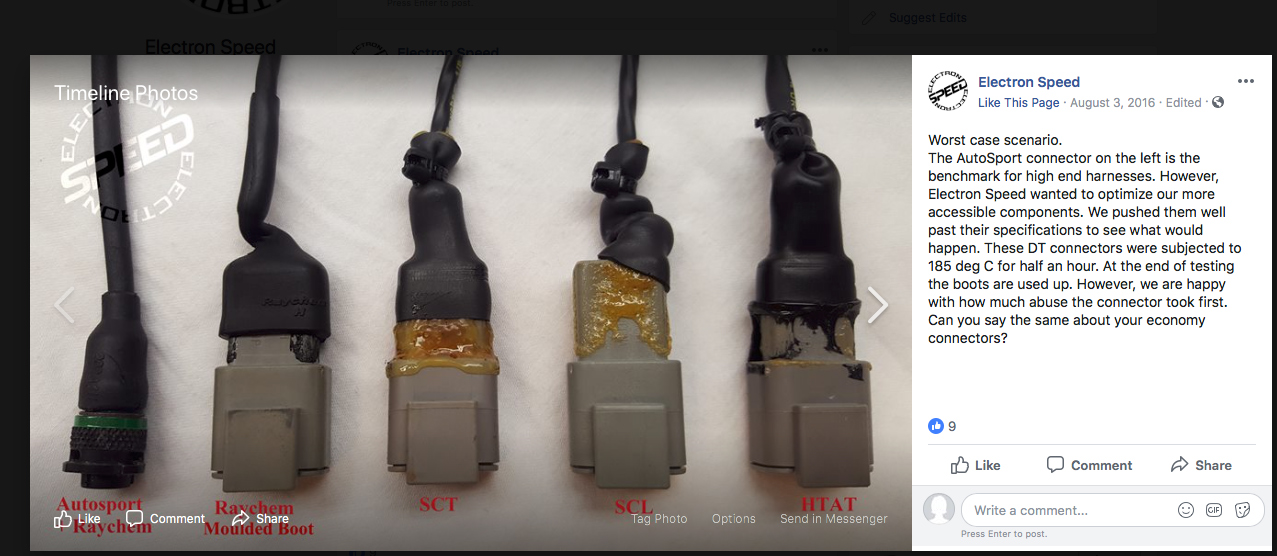

Electron Speed is

a full service motorsports electronics firm. Here they

compared, in a controlled test, what happens when heat

is applied to the various schemes for connector sealing.

It's pretty obvious that dedicated Raychem Boots, albeit

expensive, are the preferred solution when paired with

harness epoxy (RT125).

ATUM (not shown), which is frequently used on DTM

Connectors, will react similarly to SCL. HTAT is rated

up to 125C (257F).

Keep in mind that Plastic does not corrode. Autosport

aluminum connectors will...We know because we spent

years going to Bonneville where the salt and salt air

eats everything. Deutsch D369 Connectors (3 / 6 / 9

position) have the highest temperature rating of any

plastic connector with PEI/PEEK construction and

flurosilicone seals...and they are tiny (26-22 /

24-20ga).

Get

your Raychem Boots at Prowireusa

Prowire Designed "SuperSeal"

Boots

Prowire has recently introduced

a series of friendly, flexible, connector specific, rubber

boots that provide both strain relief and sealing with no

need to use the more expensive Raychem boots that have to be

shrunk with heat guns. DTP and DTP variants coming Spring

2023.

Prowire designed these and had the molds made (covered by

Design and Utility Patents) to give you an elegant flexible

sealing system. Speed your harness design with these.

If you are familiar with the Bosch family of OEM rubber

connector boots you will appreciate these. Even more so when

you use

Prowire

solid contacts designed for the Deutsch Superseal

Connectors.

Prowire: " Introducing our brand new patent pending in-house

designed solid contact specifically for use with Superseal

1.0 connector housings. The time of using the

factory-stamped contacts with either hokey or expensive

tooling is over.

Our SSC-N is a nickel-plated hoodless solid contact with a

nickel-plated body and a beryllium copper gold-plated clip

just like OE.

You can terminate your ECU, PDM, or dash at breakneck

speeds. Our SSC contact is currently available in an

18-24awg version, with a 16-24 ga version releasing

May/2023"

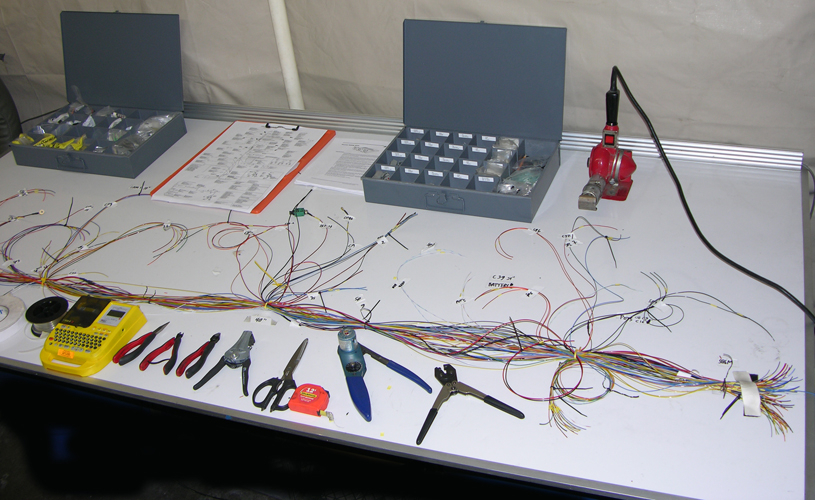

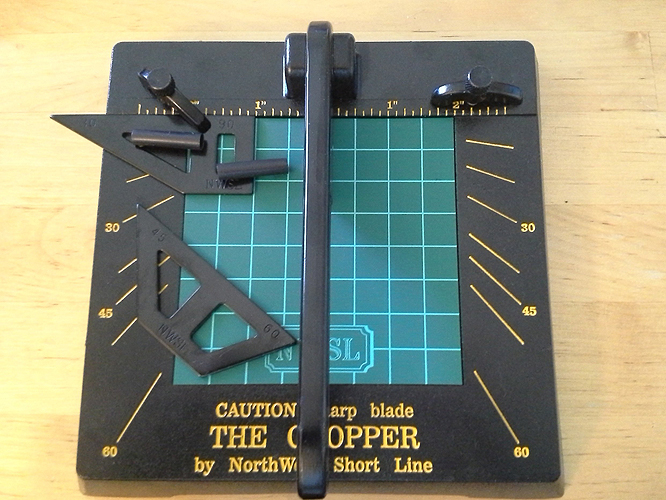

Motorsport Harness Layout

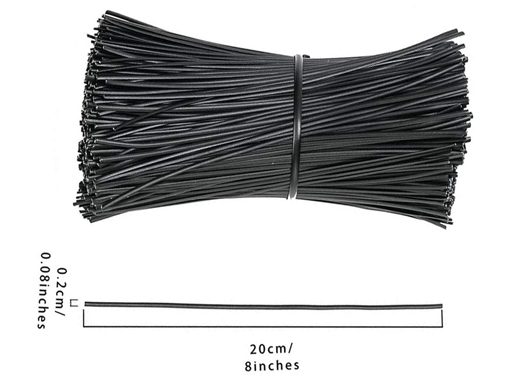

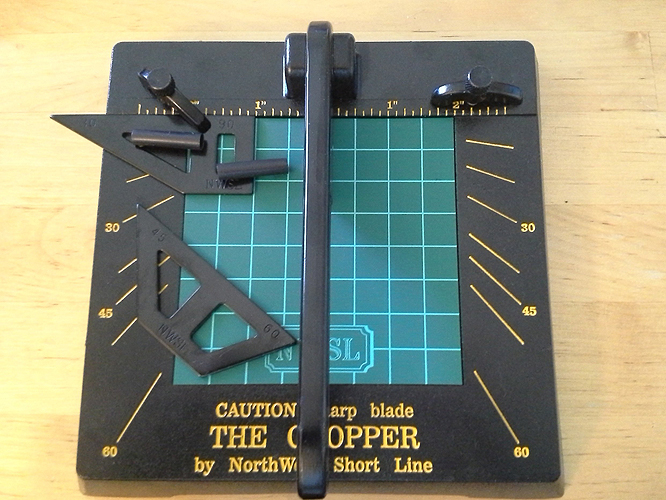

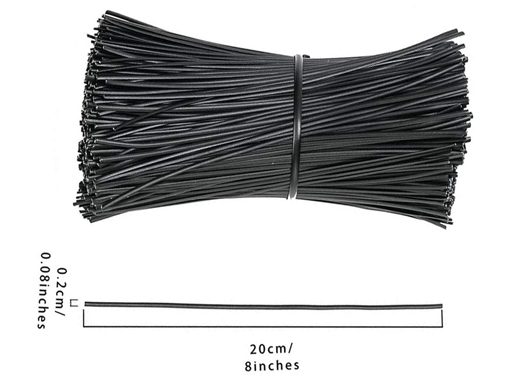

Assembly: Don't use plastic cable ties when laying out your

wiring harness on your workspace, as you will have to

continually cut them off and you end up with a bunch of

wasted ties and run the risk nicking the harness

wires. 1000 twist ties for about $16.00.

Use plastic-coated, solid wire, twist ties to holds

together temporarily. The coating won't harm any wiring and

the wire can be reused. 8" lengths.

When laying out your harness on a table or board use

4

way adhesive mounts to locate the harness and leads in

place and use the twist ties to hold the wires.

It's easy to remove and to add, or subtract wires, for

concentric or sensor lead twisting. No wasted plastic ties

or nicked wires.

20 Gauge Plastic

Coated Wire Spool

When you need to hold wire

bundle leads together, typically near a multi-pin ecu

connector, use plastic coated solid 20 Gauge wire.

Buy a roll and snip off a piece. This saves wasting cable

ties. No chance of nicking the wires.

This wire is too fat to slip into the 4-way adhesive mounts

linked above.

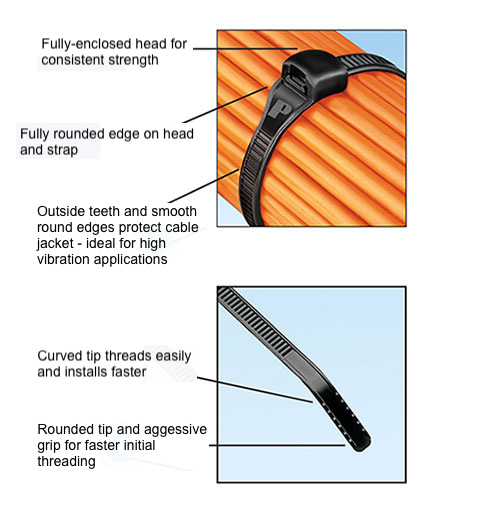

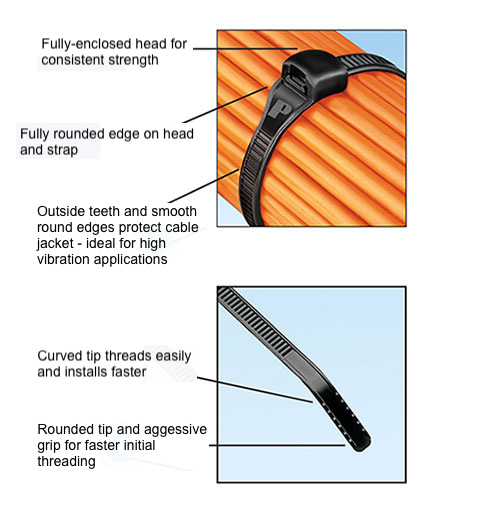

Cable Ties

We have found the best Cable ties are

Thomas

& Betts Ty-Raps with a stainless steel locking

mechanism. Metal locking tabs are a NASA requirement

(NASA-STD-8739.4 [7.3.4])

An alternative is the Panduit Contour-Ty (right picture).

Normally you use Black Nylon cable ties...be sure they are UV

Stabilized and only purchase Brand Names like Panduit, Thomas

& Betts Ty-Rap, or Hellerman Tyton. Once at Bonneville we

bought some cable ties from local auto parts store and they

broke when you tightened them

Peek Cable Ties

PEEK Cable ties

are rated up to about 500 Deg F... way, way, beyond normal Nylon

cable ties (185 Deg F). There are priced in the

$1.00

each

price range for 100 6" ties. Available from Panduit in

4.0" (PLT1M-C71); 5.9" (PLT1.5M-C71); and 7.4" (PLT2S-C71)

lengths.

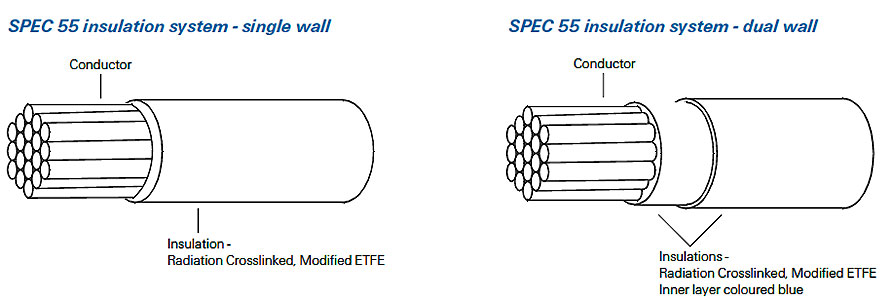

MIL-W-22759/32-35

and

MIL-W-22759/41-46 or Raychem "Spec 55"Primary Wire

(Race-Spec)

Raychem Spec 55 wire has become the de facto standard for

motorsports wiring. "Spec 55" is a trademark of Tyco

Electronics. The actual designation is MIL-W-22759/32-35 and

41-44. MIL-W-22759/44 is the normal wire of choice with silver

plated copper stands. Silver plated copper (SPC) strands have a

higher temperature rating than does Tinned copper (TC) strands.

Spec 55 Single Wall or "interconnect" wire carries the

designation 55A011-xx-xx. Spec 55 Dual Wall or "airframe" wire

carries the designation 55A081-xx-xx.

"XLETFE" insulation refers to Cross Linked ETFE Polymer (Tefzel)

which provides increases abrasion resistance over Tefzel

insulation. Dual wall construction is commonly used in aircraft.

ETFE is described as a "modified radiation cross-linked

polymer”.

Specification

|

Insulation

|

Conductor

|

AWG

Range

|

Temp

|

Voltage

|

Wall

Type/Thickness

|

M27500

Symbol

|

MIL-W-22759/32

|

XLETFE

|

TC

|

30-12

|

150C

|

600

|

Single

.006"

|

SB

|

| MIL-W-22759/33 |

XLETFE |

SPHSCA

|

30-20

|

200C

|

600 |

Single

.006"

|

SC

|

| MIL-W-22759/34 |

XLETFE |

TC

|

24-00

|

150C

|

600 |

Double

.010"

|

SD

|

| MIL-W-22759/35 |

XLETFE |

SPHSCA |

26-20

|

200C

|

600 |

Double

.010" |

SE

|

| MIL-W-22759/41 |

XLETFE |

NPC

|

26-00

|

200C |

600 |

Double

.010" |

SM |

|

| MIL-W-22759/42 |

XLETFE |

NPHSCA

|

26-20

|

200C |

600 |

Double

.010" |

SN

|

| MIL-W-22759/43 |

XLETFE |

SPC

|

26-00

|

200C

|

600 |

Double

.010" |

SP

|

| MIL-W-22759/44 |

XLETFE |

SPC

|

28-12

|

200C |

600 |

Single .006"

|

SR

|

Dual wall (normal weight) "Spec 55" will have an inner layer of

a contrasting color (blue) to indicate when the wire has been

nicked, abraded or cut.

TC refers to Tin Plated Copper. SPHSCA refers to Silver Plated

High Strength Copper Alloy. NPC refers to Nickel Plated Copper.

NPHSCA refers to Nickel Plated High Strength Copper Alloy. Note:

24-30 AWG should use SPHSCA conductor

Nickel has a higher melting point than does silver but this is

of little consequence in motorsports ecu wiring.

More importantly, silver is more conductive than either copper

or tin. MIL-W-22759/44 wire is usually always white in high end

motorsports and aircraft. Use Prowire colored ident kit shrink

tubes to keep track of things downstream.

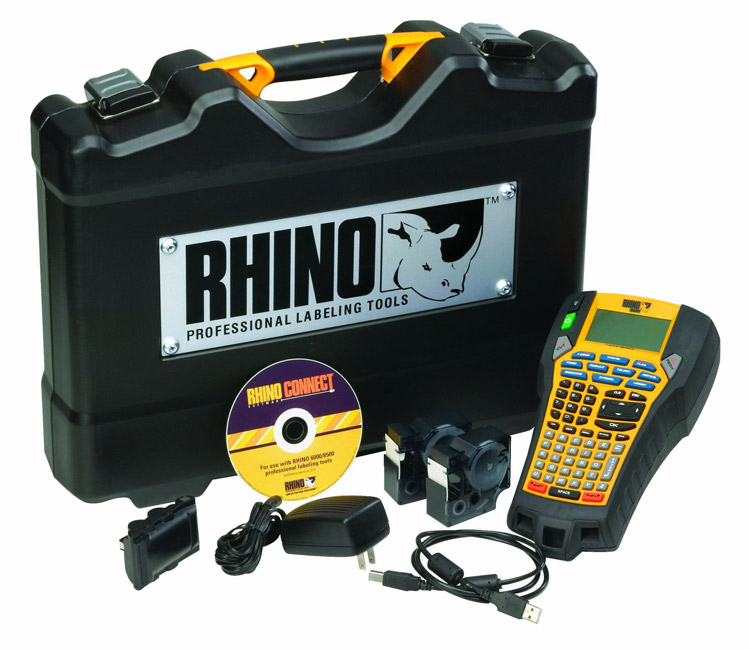

Best deal in town for these 3-1 shrink tube wire markers

for 22759/32, 22759/16, and TXL wires. ...and all White

22759/44-xx-9 wires.

If you are going "Pro" and intend to use 22759/44-xx-9

wire then this is your ticket to sanity. 2500 pieces for pennies

each. Refills of 250 pieces ship immediately.

Use all White wires like in F1 and WRC and go crazy. Why all

White wires?...Well with all White you just cannot make

assumptions and 100 percent inspection and Hi-Pot testing is the

rule.

Alternatives to

MIL-W-22759/44 "Spec 55" Race- Spec Primary Wire

A less expensive and more commonly available wiring is the

single wall Tin Plated (TC) Copper strand wiring MIL-W-22759/16

or the thinner wall 22759/32. It could be argued that silver has

a better conductivity and higher temperature rating than tin

plating...but, both offer increased protection against corrosion

over bare copper wires.

| Specification |

Insulation |

Conductor |

AWG Range |

Temp |

Voltage |

Wall |

M27500 Symbol |

MIL-W-22759/16

|

TEFZEL

|

TC

|

24-00

|

150C

|

600

|

.011"

|

TE

|

| MIL-W-22759/32 |

XLETFE |

TC |

30-12

|

150C

|

600

|

.006"

|

SC

|

The main benefit of Spec 55, MIL-W-22759/44 and MIL-W-22759/32,

over the alternative MIL-W-22759/16 is that it is "tougher" i.e.

it has better abrasion properties due to its irradiated jacket.

This is less of a concern if the harness is sheathed in DR-25

heat shrink, which is a common motorsports practice. In short it

is an acceptable alternative to the more expensive 22759/44

silver plated wire.

In 20 AWG it weighs 5.18 lbs/1000 feet as opposed to Spec 55 20

AWG which weighs 4.3 lbs/1000 feet. It is also larger in

diameter in 20 AWG .060" versus .050" for the Spec 55 wire.

A thinner and bit tougher insulation alternative to the /44 wire

is the MIL-W-22759/32 and saves a few thousandths in diameter

and weight...It's the same price as the /16 wire. Both are tin

plated copper ("TC").

Available

from

ProwireUSA. A thinner tougher wire in the 22759/44 and

22759/32 variations.

Wire is really the cheapest part of the equation. It's the labor

stupid. We use both /16 and /32wire for our products and

harnesses.

A word of advice: When you stock up on 22/20/18/16

gauge wires be careful to keep the various gauges physically

separated as it's easy to grab, say, some 20ga (22759/32-20-xx)

wire when you really are installing 22ga (22759/32-22-xx) wire.

This mistake makes it interesting when you go to install the

terminals.

Note: Tefzel is Ethylene-Tetrafluoroethylene (ETFE)

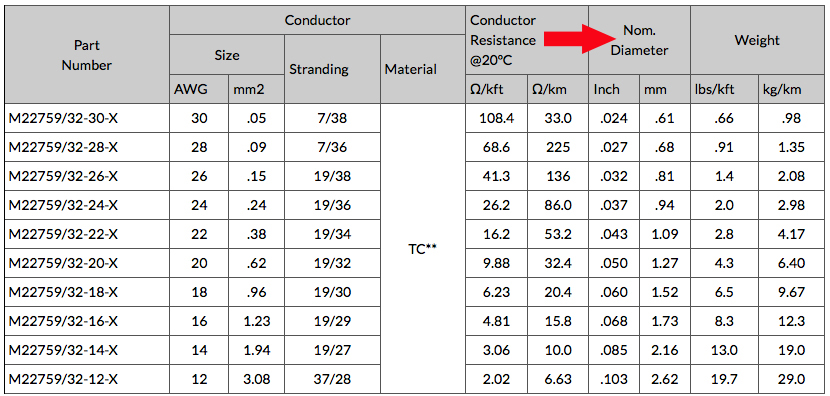

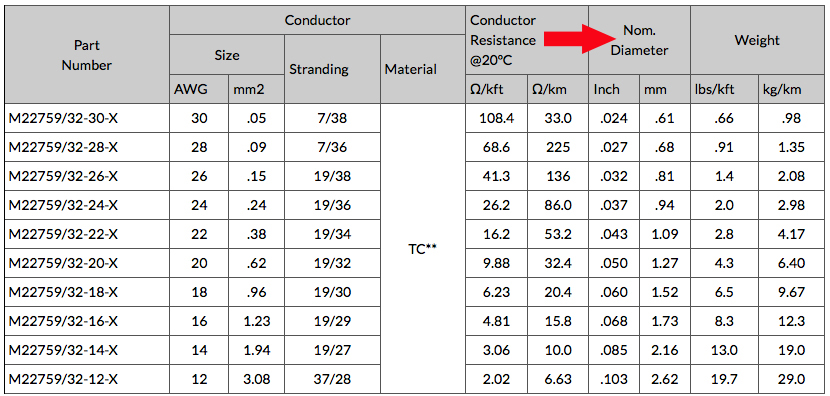

Dimensions

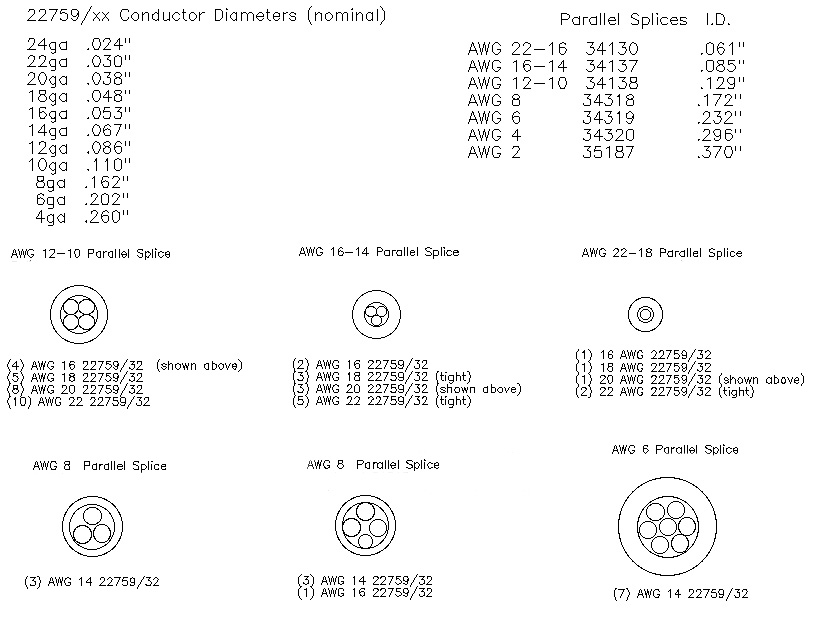

22759/32- Wire

Wire dimensions for both the

conductor and the insulation must be known when you are

choosing the terminal and seal for a particular connector.

Often you will order a connector and seal only to find the

terminal is the wrong size for the wire and insulation and

or the seal supplied with the connector does not seal the

wire. The conductor is expressed in mm2 and the wire

insulation diameter is expressed in mm. Metri-Pack 280

Series Injector / Sensor connector example above.

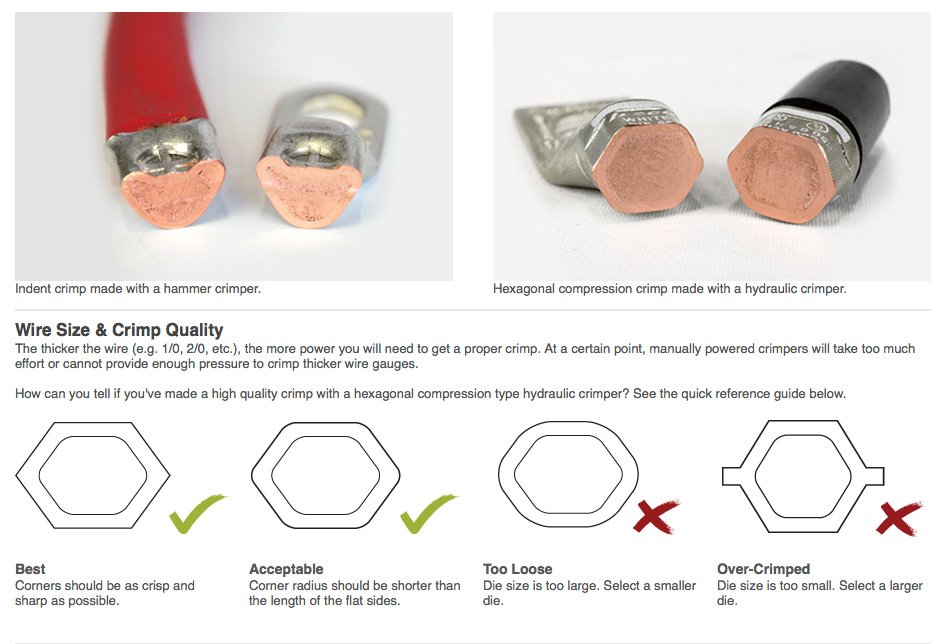

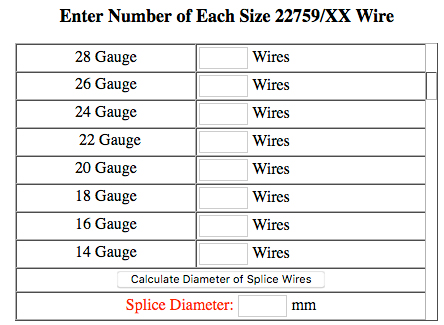

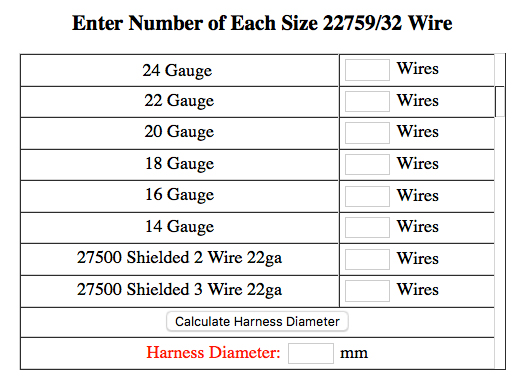

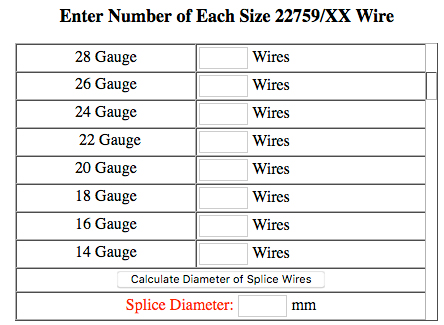

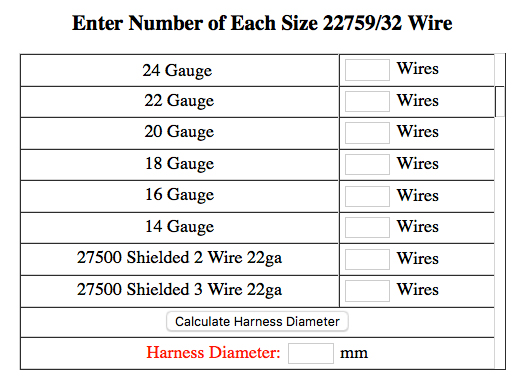

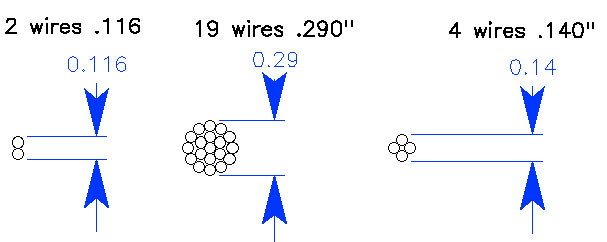

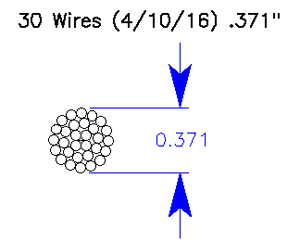

The above link allows you to determine the harness diameters

for 22759/32 wiring. When planning your harness you need to

know the diameter of each branch to plan for your

transitions and Raychem Molded Boots.

The Wire Harness Diameter Calculator takes inputs for 24 to

14 gauge MIL-W-22759/32 wires to determine the bundle

diameter.

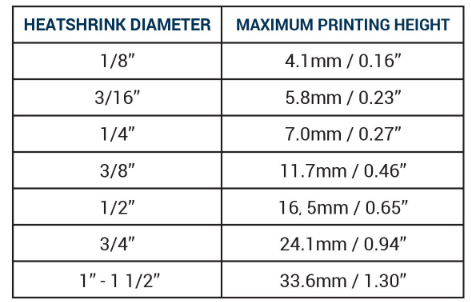

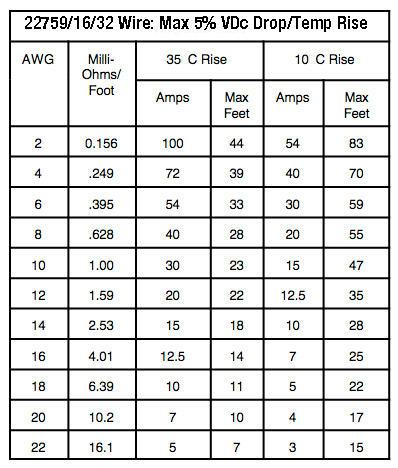

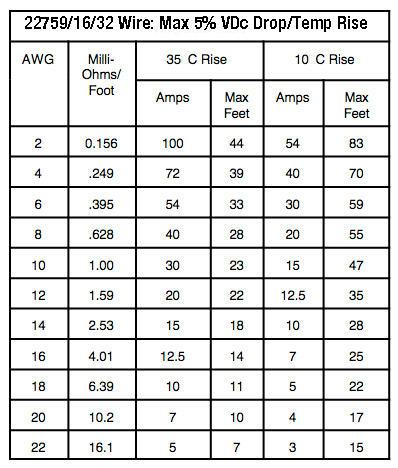

Amperage Ratings Mil-Spec 22759/16/32 Wire

The above chart gives a general

amperage rating for the mil-spec 22759/16 and 22759/32

wires. In reality, it gets a little more complicated than

this as wires have resistance and the longer they are the

less capacity they have, and the greater the voltage drop.

In a motorsports wiring harness the wires will be enclosed

in DR25, twisted together, and not in free air, so there

will be more heat, which further degrades their capacity.

The chart is based on maximum length to maintain a 5% VDc

drop. For a more complete explanation on temperature rise in

harnesses

view

this pdf.

In automotive use with longer runs here are safe

recommendations:

Battery Positive Direct 10AWG

Battery Negative Direct 10AWG

Other Battery Positive 14AWG

Fuel Pump Positive 14AWG

Radiator Fan 14AWG

Switched Ingition 20AWG

12V 5A Fused 20AWG

Tach Output 20AWG

Sensors 20 AWG

Injectors 20AWG

For motorcycle use where the runs are very short we use

14/18/16/20/22AWG. For example: Injectors 20AWG (better seal

plugs); Lambda Sensor (5)20AWG to Autosport; Lambda Harness:

12V+ 20AWG, Heater(-) 20AWG, Vs 22AWG, Ip 22AWG, Lambda

Analog GND 22AWG; 5V Sensors 22AWG; Fuel Pump +/-

16AWG; VBat+ 14AWG; Chassis Ground VBat- 14AWG.

To see what the effects of length have on your wire AWG

choice

visit

this calculator which gives you your end voltages and

maximum lengths. We suggest you use the 2% drop figure

mentioned in choosing your wire sizes.

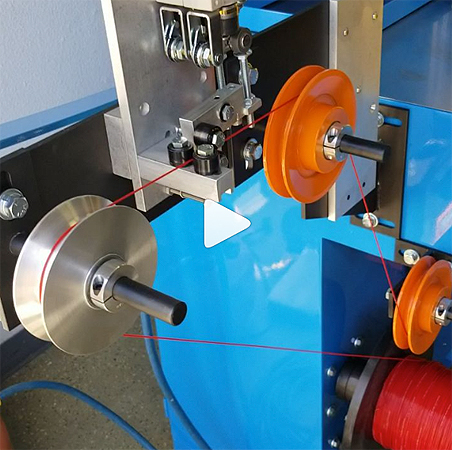

Prowire USA

Custom Mil-Spec 22759

Wire

Striping

In case you wondered how

mil-spec wires are color coded with up to 100

combinations of base colors and stripes here's a link to

Prowire USA's

mil-spec

wire

striping machine in action which can print up to

three stripes simultaneously as well as alpha/numeric,

hash marking, band marking, longitude striping and

dotting. Complex expensive puppy.

Identifying wires in your harness is easier with colors

and stripes.

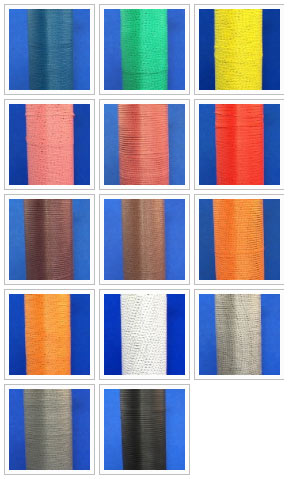

Spec55

Wire color codes. There are ten basic wire colors.

Add the stripes and there are 100 combinations.

If you wish to get your wires organized by numbers

(1-12) , and not by colors, Prowire offers a

White

Wire numbering service...say 1-6 for Fly By Wire

etc. Bi-directional.

Prowire USA

Mil-Spec Wire Modular Rack System

(Note: Not Currently Available due to COVID Price

Increases)

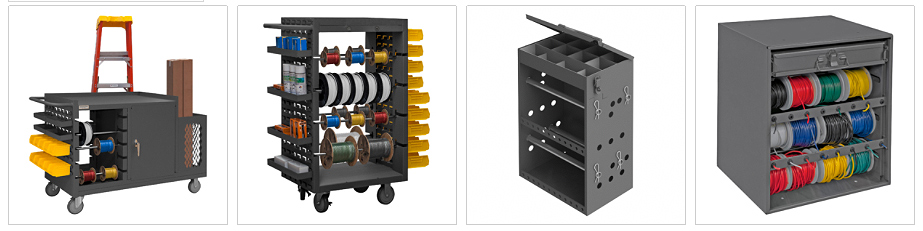

How do you organize

multiple spools of wire and Raychem DR-25? Well, not

like in the picture above. There are all sorts of wiring

spool racks available, but none were created exactly for

Motorsports Mil-Spec 22759/16 and 22759/32 wires and

also Raychem DR-25 Heat Shrink use.

ProWire USA

Mil-Spec Modular Rack System:

Stackable modular racking system for Mil-Spec wire,

cable and DR-25 heat shrink. Shown here in

powder coated blue. This rack, as shown, will hold

55 spools of Mil-Spec wire as well as 6 large spools

of DR-25 tubing. ProWire made several variations of

these racks....even some in stainless for NASA.

All 3 cabinets bolted together are about 70" tall by

28" wide and 24" deep on the tubing cabinet.

This rack will hold full rolls of 1/2" to 3/4" DR-25

tubing on the bottom section (19" diameter rolls).

The Middle and top sections are stackable. On those

Prowire made: 2 row (20 spool) and 3 row (30 Spools)

cabinets. The unit, as pictured, stands 70 1/4" tall

and is 28 1/4" wide and weighs in at 112 lbs bare.

This is the best way to keep your sanity and reduce

clutter. Go vertical and save time and space. Time

is money.

These are currently not

available due to COVID price increases which

raised the price way above the original start

price of $750.00.

If you want to male your own: 1 3/8" tube for the

DR-25 and 3/4" tubing for the wire spools to spin

on.

With ProWire no longer offering racks

Durham

is your best best bet for organizing your wiring

reels...wire as well as DR-25.

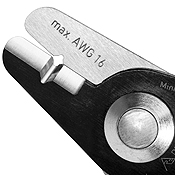

Cutting Mil-Spec

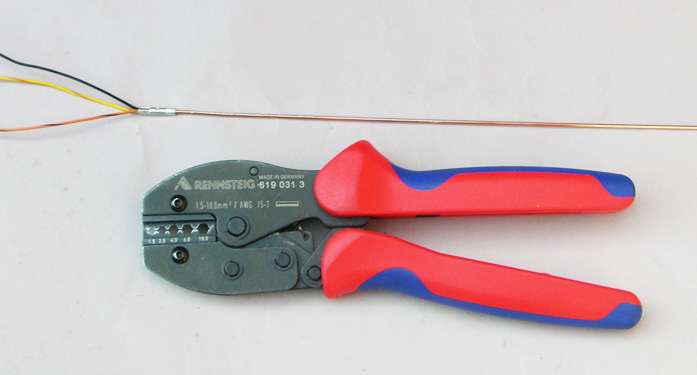

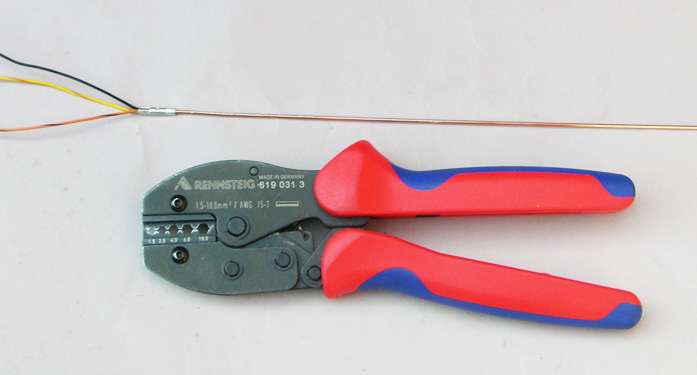

22759/16/32 Wire...Rennsteig and Ideal Cutters

If you've cut thousands of wires with regular blade type

cutters from Ideal, Snap-On, and others you know there

must be a better way so the twisted strands stay round

instead of being flattened or mushed out a bit.

The answer for a perfect round cut is the Rennsteig

8000 1001 3 RT Miniature wire cutter and strand

trimming tool (Flush Cut). It cuts wires from AWG 26 to 16

according to aerospace standard AS6173/1. It is not spring

loaded to open so you use your finger next to your pinkie

to open it. Be careful with these as the cutting edge is

easily damaged if you get a bit overzealous, don't get the

wire in the slot, or cut the wrong type wire...like

thicker GXL or TXL.

You have to align the wire each time so this takes time

as opposed to usual diagonal cutters. Its major advantage

is it leaves the 19 strands of the 22759/16 and 22759/32

wires round. Very clean

Another choice is the spring loaded Ideal

45-260 ESD safe knife blade cutter. You don't have

to line up the wire in the slot as it is a knife blade.

High quality diagonal cutters are available from

Knipex

https://www.knipex.com/products/electronics.

Polished and laser-hardened steel. Everthing from Knipex is

A-1.

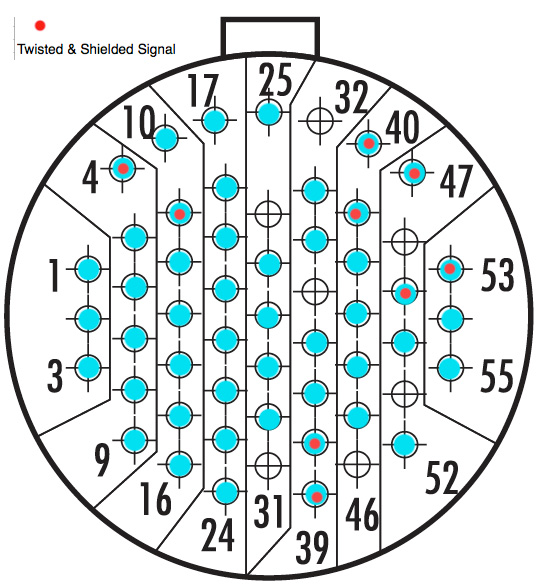

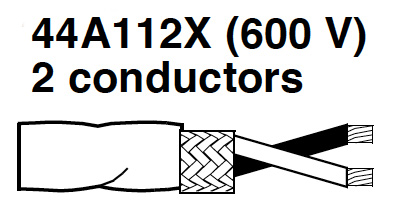

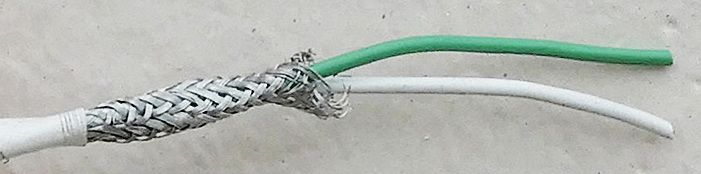

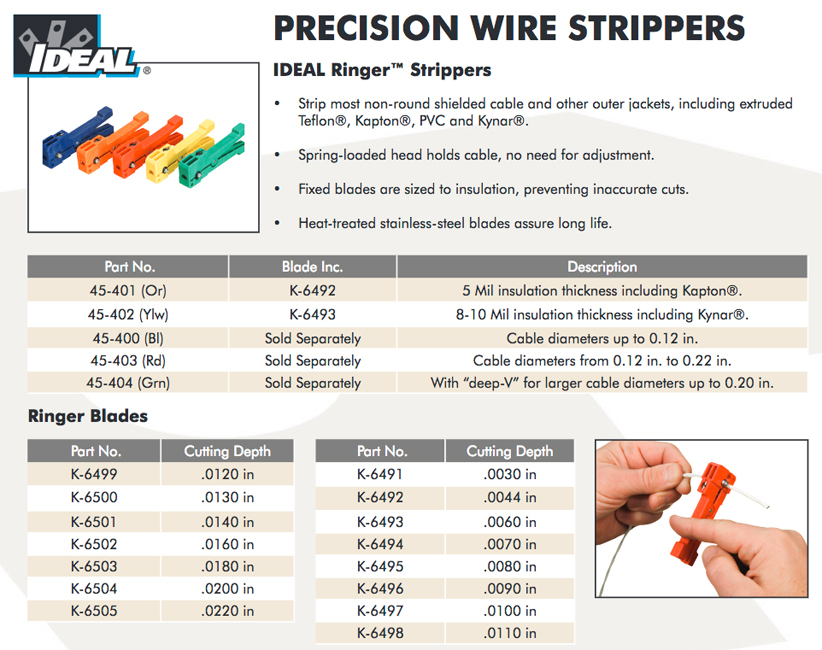

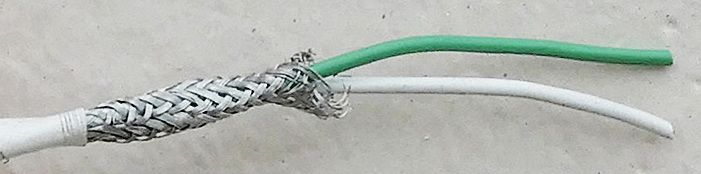

Twisted Pairs: Protection From EMI Interference

How do you strip shielded cable for a solder sleeve?...Well

there's always a tool. The

Ideal

45-402

Ringer Cable Stripper.

Crankshaft sensors, camshaft sensors, RS 232 and other

communications should use twisted pair, shielded, wiring. 20 or

22 AWG is typical for twisted pair sensor and communications. We

use 22 gauge

Shielded

Tefzel

Cable wires from Prowire USA for our two wire crank

position sensors and three wire hall-effect sensors.

Twisting the wires reduces magnetically induced interference.

Forcing the wires together reduces the loop area and therefore

the induced voltage. Since the currents are flowing in minimum

loop areas, magnetic field generation is reduced. Good idea to

avoid signal problems due to noisy ignitions, coils etc.

Note that the commonly used model 45-402 comes with a blade and

is used on 20-24AWG M27500 SB cable.

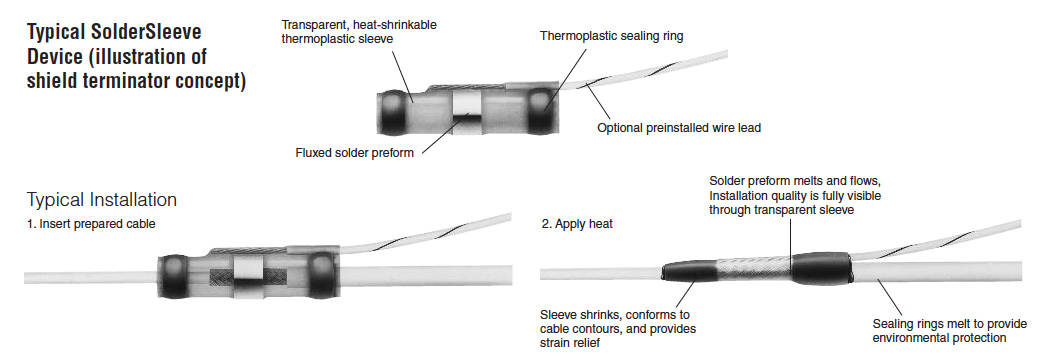

Grounding of the shielded cable is accomplished by using

dedicated solder splices. Section 8-3 of Tyco Electronics

(te.com) main

Wire and

Cable 27.9Mb Catalog lists these solder splices. They are

available with or without leads. We ground our shielded wire

jackets directly at the SQ6M ecu.

Procedures are defined for grounding the of the shielded wires.

Best practice is that you leave the shield open at the sensor

side for shielding to be effective. If this side is

grounded in some way, the shield doesn't work. Shielded gounds

are tied to a single ground point at the ECU side.

Solder

Sleeves are available from ProwireUSA

Video:

Installing Solder Sleeves

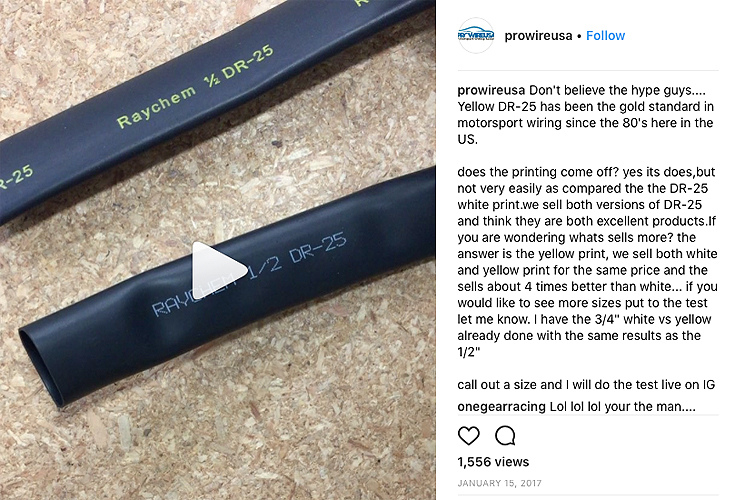

Where to Buy Motorsport Wiring

Supplies

An excellent source for your motorsport wiring supplies for you

go-it-alone types is

ProwireUSA

as they stock about everything you need and sell in small

quantities. It a good place to pick up your MIL-W-22759/32 and

MIL-W-22759/16 wire and supplies. They have 140 Mil-Spec wire

color combinations in stock and even custom stripes and numbers

wires to order.

ProwireUSA has extensive experience building wiring harnesses

and only stocks the best and competition proven parts. Quick

service and excellent prices.

Don't make the mistake of using less quality supplies from

autopart and general supply houses. Prowire also stocks oem TXL

and GXL wires as well as the mil-spec 22759 Tefzel wires.

Follow Prowire

on Instagram.

ProwireUSA

22230 S Scotland Court, Queen Creek, AZ 85142

Phone: 619-440-9473

Email: sales@prowireusa.com

Connectors

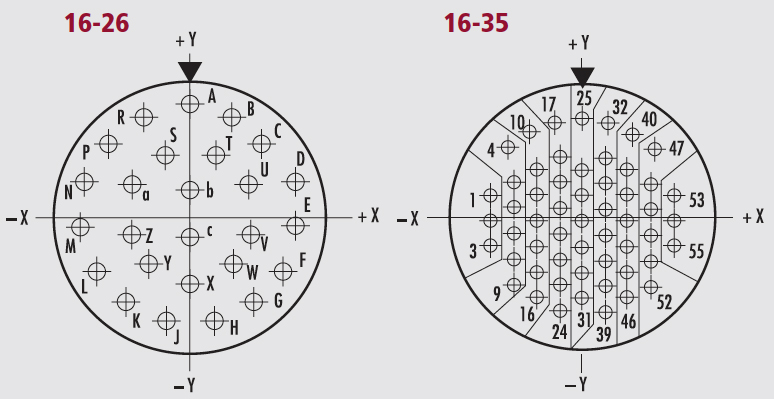

Deutsch

Autosport: Specifically designed for motorsport.

Lightweight. Expensive. Requires Mil-Spec crimping and stripping

tools. This is

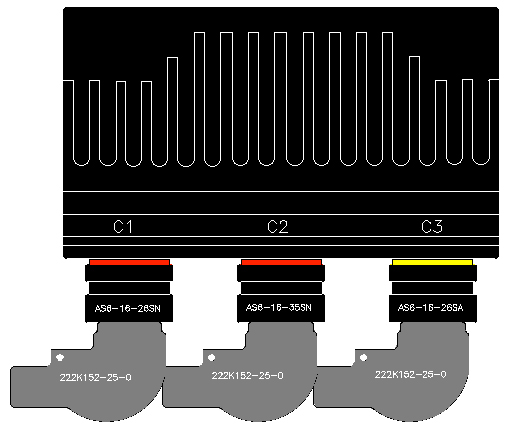

Cosworth Pectel SQ6M

that we use on our ORCA motor

turbocharged

Harleys. The color bands denote the connector shell

keyway. The left and right connectors are 26 Pin 20 gauge of

different keyway locations so you cannot mix them up. The center

connector is a 55 pin 22 gauge connector. Figure on spending

about $400.00 for the associated connectors, sockets, and

insertion tools for the SQ6M. 107 pins total.

Metal shells don't melt like plastic ones do. Higher end

motorsport applications all use Autosport ECU

connectors...Pectel, McLaren, Magnetti-Marelli, and Bosch. We

model the SQ6M with the Autosport connectors to use in our

wiring diagrams.

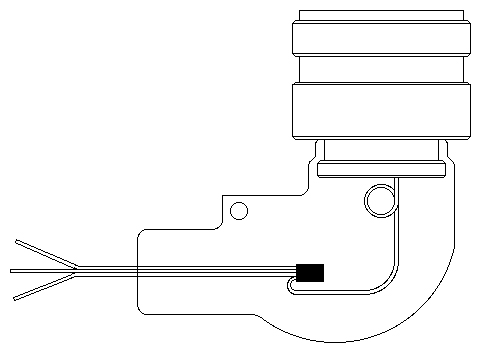

One simple way to do layout

planning for wire and heat shrink lengths, where the harness

makes some turns, is to use electrical wire that can be bent

into shape. Here we are figuring out the lengths where the

three SQ6M connectors will exit the three 222K-152-25-0

boots and go to the next boot, a Raychem 202A153-25-0.

8AWG works well. Here we used some 4AWG. It worked out to

16", 19" and 22". From there we subtract the overlap from

the boots to get the DR-25 lengths. We fudge wire lengths on

either end to allow for concentric twisting.

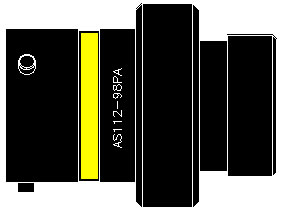

We model the various Deutsch Autosport connectors that we use in

our harnesses. Pricey devils, but they don't melt, and use

Raychem lipped boots sealed with Resintech RT125.

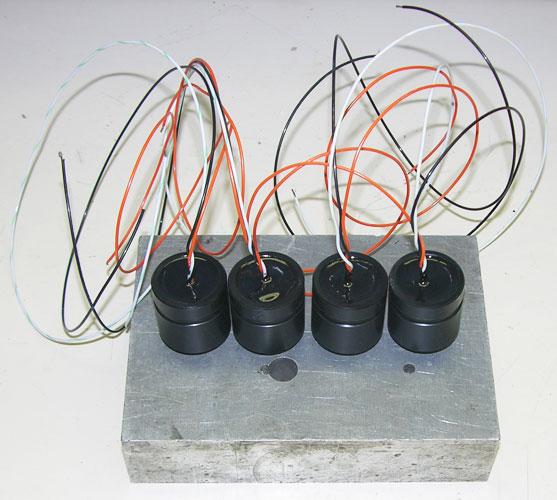

Pectel MQ12 controller. Same as used by Aston Martin, Lotus,

Nissan Nismo GTR and in World Superbike. Full Autosport

Connectors. In case you are wondering how fast this controller

can process things it has a MPC5200 processor that delivers 760

Million MIPS (Instructions per second) to keep track of all your

inputs. Four Autosport Connectors.

What's Between

Autosport and DTM Connectors?...Deutsch

369

Series Connectors

Deutsch 369

Series Connectors come in 3, 6 or 9 pin variations.

These are rated at 175 Celsius (347F) or about 50 degrees

Celsius higher than Deutsch DT or DTM Connectors. They are

also IP67 rated. Made of high temperature PEI/PEEK materials

with Flurosilicone seals, they are about 5 times more

expensive than DTM connectors. Designed for aerospace they

use #22 Contacts 26-22 AWG and #20 Contacts 24-20 AWG. Rated

at 500 mating cycles.

Just the ticket for motorsports wiring with its high heat,

weight, space, and harsh environment requirements. Less

expensive than Deutsch Autosport anodized metal variations.

Where exposure and corrosion is an issue PEI/PEEK can offer

an advantage over anodized aluminum. We had Autosport

aluminum connectors corrode at the Bonneville Salt Flats.

This

video

explains the 369 Connector features

The 369 Series are really small parts. Above left is an

oversize model of the Deutsch three pin 369 Receptacle.

Above right is an actual size model of the 3 pin Receptacle.

The actual part is .389" Width by .752" Length...Smaller

than a comparable Autosport Connector. Nice items

for motorsports wiring with FBW (6 wire) and other

sensors which use 22 Gauge wires where heat, space, and

packaging issues are at a premium. Pins / Sockets for these

are in two sizes: 22 (26-22 AWG) and 20 (24-20 AWG).

We use these in conjunction with Black DTM connectors, with

the DTM connectors being used with larger 20/18/16 gauge

wires.

Where to Buy Deutsch

Connectors & Mating DT/DTM

Raychem Boots

Deutsch DT, DTM and DTP Sealed

thermoplastic connectors are the cost effective motorsport

standard...A step above the ubiquitous Weatherpack

connectors.Used by all motorsport wiring professionals in

Mil-Spec and Race-Spec Motorsport wiring.

The best place to buy these is the

Deutsch Connector

Store. With 100 rated mating cycles and precise pins

and sockets these are the next step below the all metal

Autosport Connectors which are way, way, more expensive. Its

best to buy these from someone who can provide a complete

solution in both parts and tooling. Fast shipment and

excellent prices. One thing you might consider as these will

not corrode as can happen with the more expensive Autosport

Connectors. Connectors and the Rayhem Boots are available

for

purchase

from

Prowire

USA.

Using the Raychem boots is the cleanest most durable

method of sealing DT/DTM Connectors. Raychem ATUM works well

with its high shrink ratio but will degrade faster under

high heat conditions. Using the proper boot and sealing it

with RT125 is the preferred solution. Things stay sealed and

no seeping adhesive from overheating the ATUM in fabrication

or use. Rock solid.

If you get confused by all the Deutsch Suffixes in the part

numbering scheme

check

out this page done by LADD.

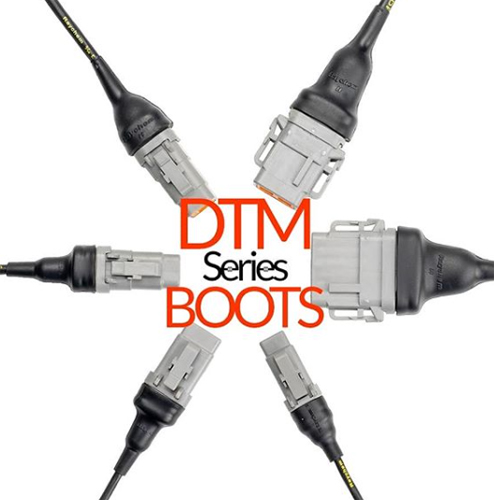

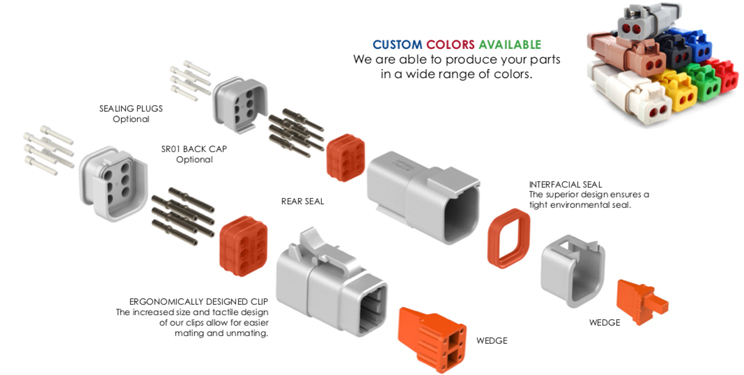

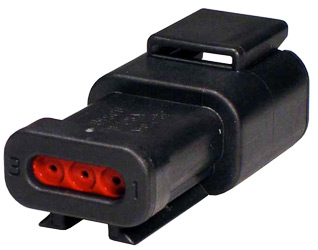

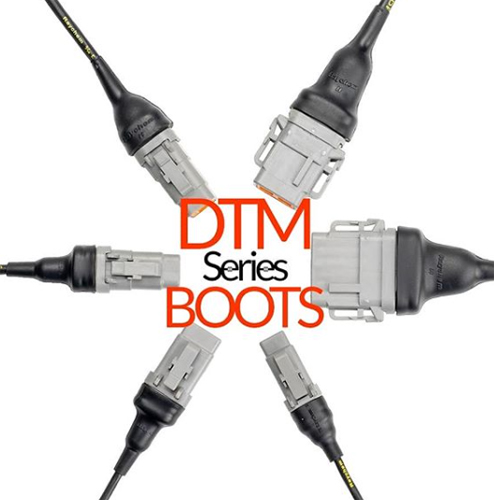

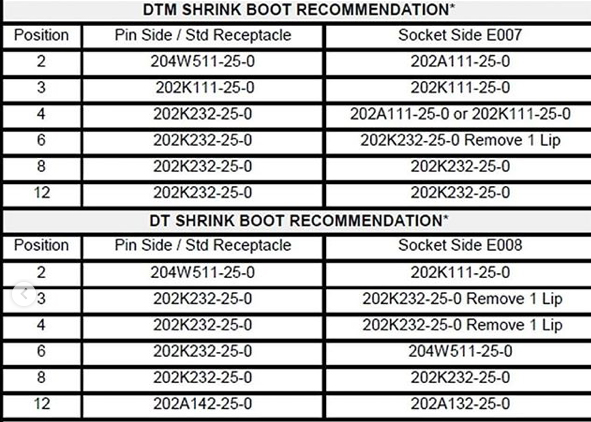

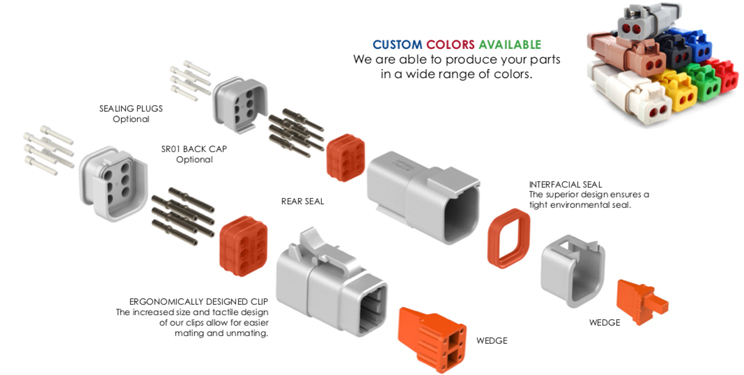

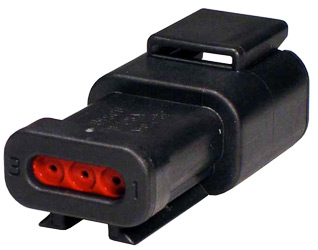

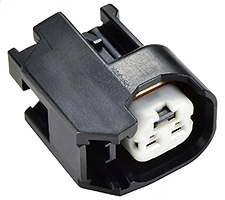

Deutsch DTM

Deutsch DTM Series : Sealed thermoplastic connectors

designed for harsh environments like engine compartments.

Reasonably priced. Available from many sources, they offer

watertight silicone seals that also act as a strain relief.

Available in 2, 3, 4, 6, 8 and 12 pin contacts with size 20

contacts for AWG 16 to 24 gage wire. Either solid pins and

sockets or crimped pins and sockets can be used. Solid pins are

crimped and are easiest to work with. In no case should the pins

and sockets be soldered. Multiple wire size #20 contacts with

7.5A rating.

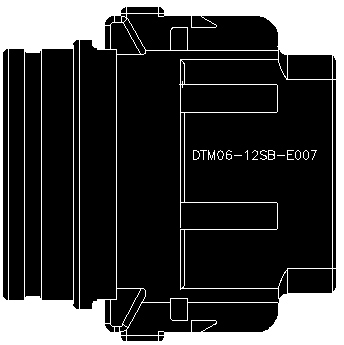

Pictured above are 2, 3,and 4 pin DTM connectors with the

optional shrink boot adapter (Option E007). There are all sorts

of suffixes for the DTM connectors and whereas you might spec

out a particular option i.e. like the shrink boot...It may not

be available in plug and receptacles. We suggest you check out

this

interactive

product

guide first.

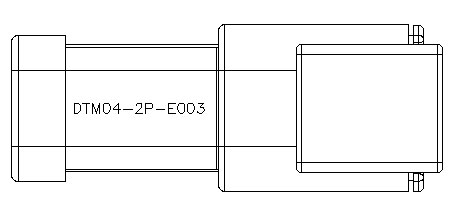

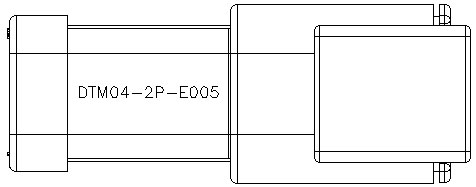

.DXF Files

Deutsch DTM Connectors

For our CAD wiring harness drawings we construct .dxf models of

these Gray Deutsch DTM Connectors on a 1:1 scale. There are

downloadable in Autocad R14 .dxf file formats. In Firefox

Browser Choose "File, Save Page As", and open in your CAD

program. They can be colored as is the gray two pin DTM above.

Alternatively you can import .dxf files into

Microsoft Visio Professional 2013

using

Autodesk

TrueView.

2

pin DTM04-2P-E003

2 socket DTM06-2S-E007

3 pin DTM04-3P-E003

3 socket DTM06-3S-E007

4 pin DTM04-4P-E003

4 socket DTM06-4S-E007

6 pin DTM04-6P-E003

6 socket DTM06-6S-E007

All of the pins and sockets are made from 98% pure copper and

then plated. Standard plating is Nickel. For critical circuits,

pins and sockets are plated with Nickel and then Gold. For

lighting, power and control circuits choose Nickel. For critical

and very low voltage and amperage circuits such as oxygen

sensors that operate at 0-1 volt or 0-5V (wideband) and for data

transmission circuits that operate at 5 volts, choose Gold. Type

K Thermocouple wire should use Chromel or Alumel terminals (see

below) in the DTM two or three wire connectors.

Note: rear silicone seal will seal on smooth insulation from

.053" to .120" O.D. Of importance is the fact they are rated at

100 cycles of engagement and disengagement. These are your

affordable step below the very expensive Deutsch Autosport line.

They will melt if they touch something like an exhaust so be

careful about securing things before you start an engine.

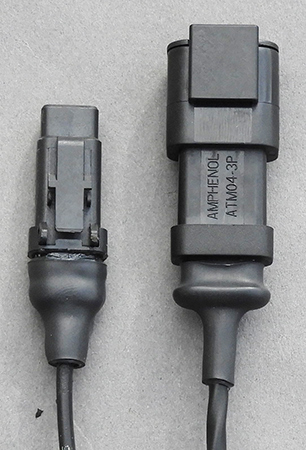

Amphenol-Sine

ATM Connectors: Same as DTM

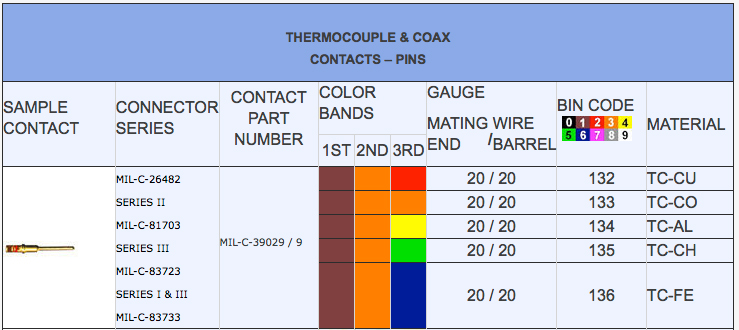

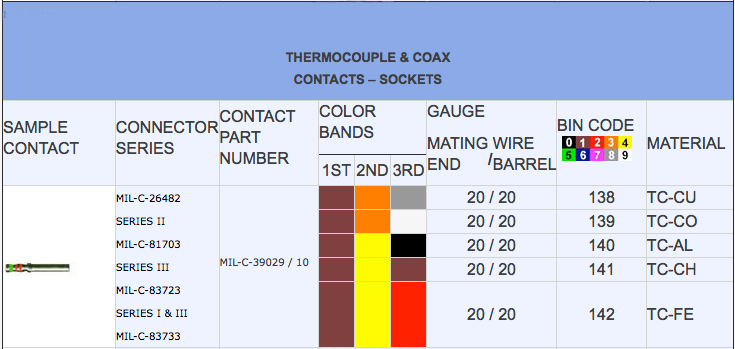

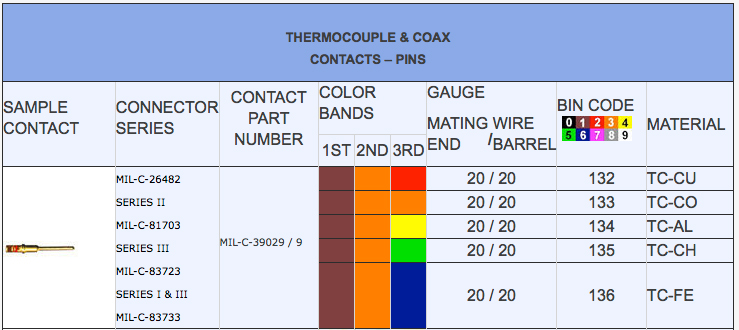

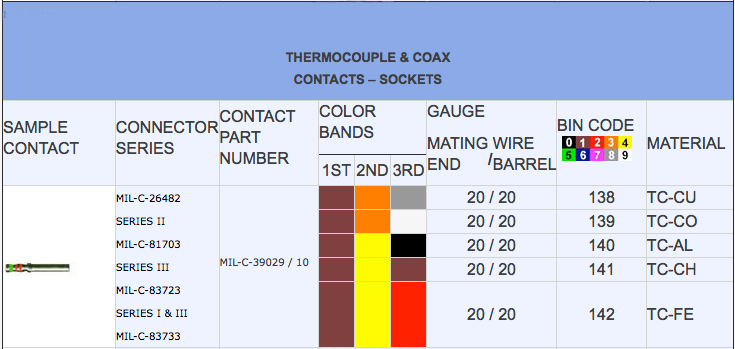

Motorsport Alumel and Chromel Thermocouple Terminals:

Deutsch DTM

Connectors (#20) an Autosport (#22)

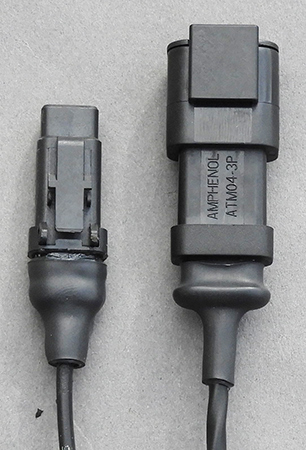

Amphenol-Sine has come out

with a complex array of

ATM

Connectors that are

DTM

compatible size 20 connectors. In some cases they

may provide boot and color options not available in

Deutsch DTM supply chains.

For instance DTM 3 way Black Plug and Receptacles do not

come with Raychem boot lips...ATM connectors do...Pictured

above. ATM06-3S-SR01BK; ATM04-3P-SR01BK. We have a

preference to black instead of the gray for our

motiorcycle harnesses.

Prowireusa

has the specialzed pins and sockets in Chromel (+) and

Alumel (-) in sizes 20 and 22. These are crimped with the

Crimp Tool M225201-01 (DTM) and MS22520/2-01 Crimp Tool

(Autosport) and the appropriate K41(M22520-06) and K42

(M22520-09) positioners,

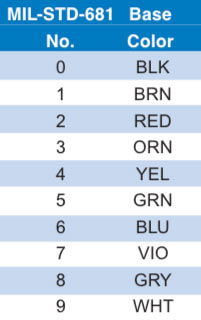

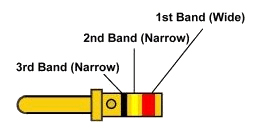

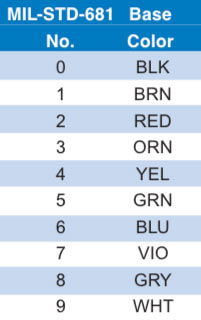

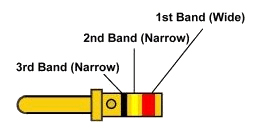

"MS"

Contacts

have a BIN (Basic Identification Number) code

consisting of three color bands around the crimp

barrel. There are 10 colors which designate a number.

The BIN codes are read from the wire barrel end of the

contact towards the mating end. The first band is

wider than the other two to further facilitate

identification. Bin-code can also be stamped on the

contact. Example: Red/Yellow/Black above would

be -240 suffix. Deutsch DTM #20 terminals in Alumel

and Chromel are available. The sequence of the color

bands defines the terminals material and type.

0 = Black

1 =

Brown

2 = Red

3 =

Orange

4 = Yellow

5 = Green

6 = Blue

7 =

Violet

8 = Gray

9 = White

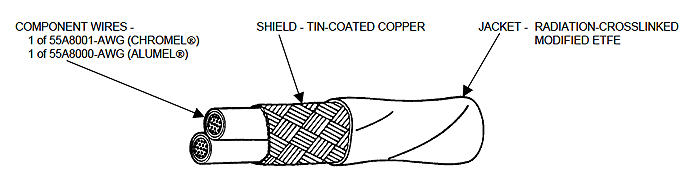

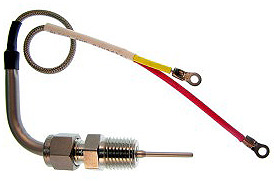

Thermocouples, either EGT probes or Cylinder head

temperature, have to be wired with special

thermocouple wire all the way to the ECU input pins. You

must use Alumel (-) or Chromel (+) wires and terminals

i.e. pins or sockets, or you will have cold-junction errors.

The all-metal Deutsch Autosport Connectors have specialized

size #22 Alumel and Chromel terminals as well as #23 for the

MicroLite Series.

There are also size #20

Chromel

and Alumel Terminals available for the less expensive

DTM series of connectors.

Pectel

SQ6M ECUs

have two dedicated EGT Chromel (+) pins: (TC1 POS [YEL

Wire], TC2 POS [YEL Wire]); and one common EGT Alumel (-)

pin (TC NEG [RED Wire]) in the AS216-35PN connector.

Chromel Pins Size #20: MIL-C-39029/9-135; Brown Orange

Green

Alumel Pins Size #20: MIL-C-39029/9-134; Brown Orange

Yellow

Chromel Sockets Size #20: MIL-C-39029/10-141; Brown

Yellow Brown

Alumel Sockets Size #20: MIL-C-39029/10-140; Brown Yellow

Black

Wiring thermocouples into a motorsport harness is a

bit different than industrial applications as we

typically use a a three position plug / receptacle

connection in a branch off the harness. If the

thermocouple is shielded then one terminal of the three

position connector should connect the shield/drain from

the main harness to the thermocouple. You never ground

the drain wires at the thermocouple but back at the ECU,

typically at the ECU's chassis ground splice.

Pectel SQ6M ECUs have two dedicated Chromel thermocopule

positive pins and a common (spliced) thermocouple Alumel

negative pin. You should always use Alumel and Chromel

thermocouple extension wires in your harness. Stranded

wires offer flexibility and foil sheathing and a drain

wire offer additional protection.

Motorsport Thermocouple Harness

Wiring

Example:

Connectors and wire for EGT Type K

Thermocouples.

Thermocouple ALCOR 86161

90 Deg 1/4" NPT

DTM04-3P-E007 with Raychem Boot

202K111-25-0 (abrade DR-25 and RT125 epoxy)

DTM06-3S-E007 with

Raychem Boot 202K111-25-0 (abrade DR-25 and RT125 epoxy)

Chromel Pins: Prowire

710106

Alumel Pins: Prowire

710104

Chromel Sockets: Prowire

710103

Alumel Sockets: Prowire

717102

Drain Pins: 0460-202-2031

Drain Sockets:

0462-201-2031

(3) Solder Sleeves (drain

wires): Prowire S01-03-R; use 22ga drain wire BLK

CTC-0018-24-9/5-9 (19

strand): Twisted Pair: Green Chromel(+); White

Alumel(-); Jacket White

Strip CTC-0018 with

Ideal

45-402

Ringer Cable Stripper.

DR-25 covering

thermocouple wires and harness wires.

Raychem

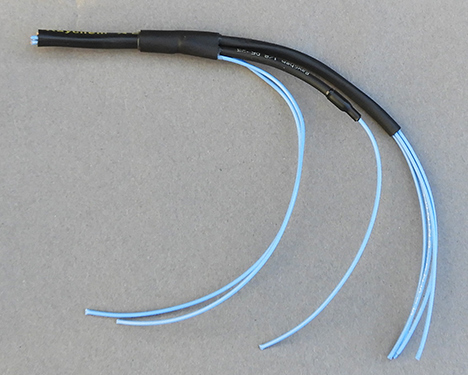

19 Strand CTC-018 Motorsport Thermocouple Wire

19

strand

CTC-018

19

strand

CTC-018 Raychem Motorsport Alumel Chromel

Type K wire. pictured above. This is the best motorsport

thermocouple wire, but not easily obtained and

expensive. TE Connectivity. About $300.00 for 25 feet of

44 gauge.

We use this wire in 24 gauge. Two Thermocouples: Green

wires (+) to pins 4 and 11, C2 Pectel SQ6M. Parallel

spice White wires (-) to pin 13 C2 SQ6M

CTC-0018-24-9/5-9

CTC-0018-22-9/5-9

CTC-0018-20-9/5-9

More common is 24ga stranded (7x32), typically shielded,

with a integral drain wire. Various sources. About

$300.00 for 25 feet.

If shielded with a drain wire, use 3 position connector

with gold terminals on the drain wire Cover leads with

Raychem DR-25 and heat shrink the 3 position DTM

connectors for strain relief. Typically is type K

Thermocouples.

The fastest acting thermocouples are the grounded type

with thinner probes. Grounded means there is a

continuity between the probe and either of the two

wires. The thinner diameter probes are made of

Hastaloy-X, or similar high temperature alloy. Depth

should be adjustable so the tip of the thermocouple is

centered in the exhaust stream. Place 1/8", 1/4" NPT or

1/4 x 20 welded-on mounting points on the upper

quadrants, not beneath the exhaust port. Expect 1%

accuracy.

In the case of single or multiple thermocouples they

should be equally spaced approximately 2"- 4" from the

exhaust port...The further away, the more of a

temperature drop. They should not be placed in a

collector.

Thermocouples with exposed tips and 1/4" thick,

insulated, probes are not as fast acting and are

susceptable to damage. See below for how thermocouples

actually act.

For testing and calibration purposes we use a

Thermoworks

Microcal 2K that can be set to a particular

temperature C/F to .1 degree F and .3 degree C accuracy.

A handy Deg C to F and Deg F to C

PDF

from Omega.

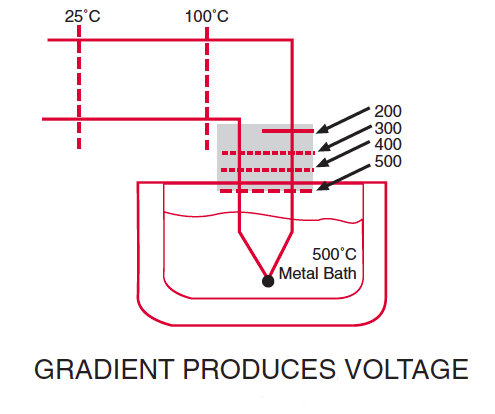

Thermocouple

Misconceptions

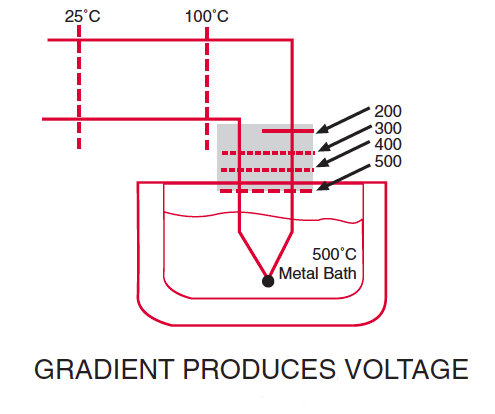

Robert Moffat in his

Gradient Approach to Thermocouple Thermometry

explains that the thermocouple voltage is actually

generated by the section of wire that contains the

temperature gradient, and not necessarily by the

junction.

For example, if we have a thermal probe located in

a molten metal bath, there will be two regions

that are virtually isothermal and one that has a

large gradient. In the figure above, the

thermocouple junction will not produce any part of

the output voltage. The shaded section will be the one

producing virtually the entire thermocouple

output voltage.

If, due to aging or annealing, the output of this

thermocouple was found to be drifting, then

replacing the thermocouple junction alone would

not solve the problem. We would have to replace

the entire shaded section, since it is the source

of the thermocouple voltage.

In short, keep the thermocouple, even fast acting

ones, well into the center of the exhaust stream,

not just the exposed tip. Designs with this probes

and grounded designs are the fastest and most

accurate.

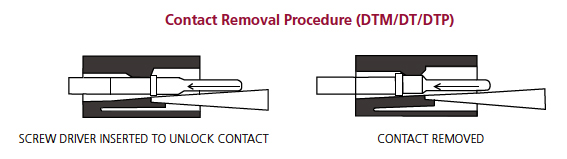

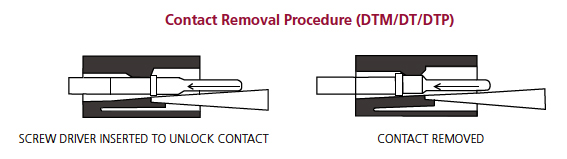

DTM Terminal

Removal

The simplest way to remove DTM

Terminals (Pins, Sockets) is to: (1) pull out the plastic

terminal lock with a small needle nose plier and then, (2)

use a small flat-bladed screwdriver...Typically the one you

have that has a magnet on the other end, and release the tab

lock by pressing down and pull out the wire. Simple.

Detusch DTM Black

Everyone seems to use only the Gray DTM connectors simply

because that's what they see everywhere. The DTM series

actually comes in 11 colors. We use the Black DTM connectors

on our production street harnesses as they blend in with the

DR-25, Raychem Boots, and heat shrink tubing. On motorcycles

Black sort of disappears whereas the Gray stands out. We use

the E005 End Cap option when it's available...like the

"Cat-Spec" DT Series pictured below.

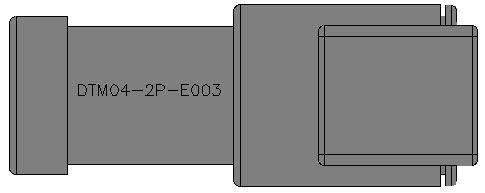

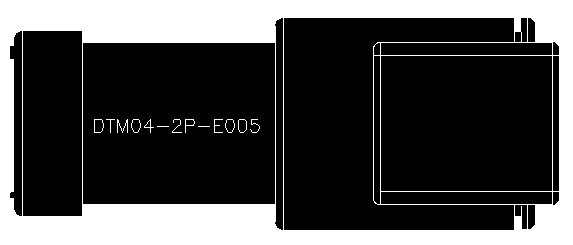

.DXF Files

Deutsch DTM Connectors

For our CAD wiring harness drawings we construct .dxf models

of these Black Deutsch DTM Connectors on a 1:1 scale. There

are downloadable in Autocad R14 .dxf file formats. In

Firefox Browser Choose "File, Save Page As", and open in

your CAD program. They can be colored as is the black two

pin DTM above or the 12 pin DTM connector below.

Alternatively you can import .dxf files into

Microsoft Visio Professional 2013

using

Autodesk

TrueView.

2

pin

DTM04-2P-E005

2

socket DTM06-2S-E005

3

pin

DTM04-3P-E005

3

socket DTM06-3S-E004

4

pin

DTM04-4P-E005

4

socket DTM06-4S-E004

6

pin

DTM04-6P-E005

6

socket DTM06-6S-E005

8

pin

DTM04-8PB

8

socket DTM06-08S-E007

12

pin DTM04-12PB

12

socket DTM06-12SB-E007

"Cat-Spec"

Deutsch DT

Deutsch DT Series have #16 contacts with a 13A rating. Often

called "Cat-spec as they are used by Caterpillar and have

improved seal retention on the plug and a cap on the rear of the

housing to retain the silicone wire seal.

The

Deutsch

DT-RT1 is a removal pick for the Deutsch DT Series only.

The tool has a double ended removal tool. One end has a sturdy

90 degree hook for non-slip wedge lock removal. The other end

has a standard flat head screw driver which can be used as a

straight pick or driver. Tool has a tapered one, four sided

handle.

DT-RT1

application instructions PDF.

Controller Area

Networks (CAN)

Specialized

DTM

Connectors for SAE J1939/15 2-wire CAN systems.

DTM04-2P-P007 Receptacle "Y" Connector above left. Right:

DTM06-2S-EP10 Plug with molded-in 120 Ohm Resistor. The

Valuecan3

is

helpful Diagnosing CAN issues.

CAN-BUS

Joysticks

Grayhill’s Series 3J Vehicle Display Controller (VDC) is

an operator interface device for on-board software. The

VDC features an optical rotary encoder for scrolling

through menu options and a center pushbutton for

selecting options. Five “hot key” pushbuttons are placed

around the center shaft to quickly pull up the most

common functions.

Legends on the hot keys can be chosen from a library of

ISO standard legends or customized with new symbols. An

optional 8-way joystick provides cursor control for

navigating on-screen. CANopen and J1939 protocols are

available as standard options.

Download

VDC Brochure on these.

Sureseal

Sureseal:

Interesting rubber push to connect seals. Like any specific

connector they require specific and expensive tooling. These

connectors are rated at 50 cycles of engagement and

disengagement. We have used them in the past but prefer

DT/DTM/D369 and Autosport connectors.

Weatherpack

Weatherpack: Ubiquitous automotive silicone sealed thermoplastic

connectors designed for harsh automotive environments. These

connectors are validated to perform to specification for 10

cycles of engagement and disengagement, but up to 50 cycles

probably will not see any signal degradation.

In short they are excellent for oem use but a bit wanting in a

motorsports environment where >10 engagement/disengagement

cycles are normal. For over 25 years we used all the one to six

pin variants with GXL and TXL wire and they were reliable but

not motorsport grade.

Weatherpack GM MAP Sensors can be further sealed with a [

HellermannTyton

(page 63)]

shrink

boot available from ProwireUSA.

GM 2 and 3 Bar Connector 12015384 Black; GM 1 Bar Connector

12020403 Green.

Although the Weatherpack

connector is "sealed" by the cavity seals it is a good idea to

provide additional strain relief. Alternatively seal the ends

of the DR-25 with 1.2" of ES2000-1.

If you use GM 1, 2, or 3 Bar Map Sensors and other Weatherpack

connectors with the thinner 22759/16 or /32 wire use the correct

cavity seals.

24-20

AWG Seals - OE # 12089679 / 15324985 Purple

22-20 AWG Seals - OE #

12015899 / 15324983 Red

20-18 AWG Seals - OE #

12015323 / 15324982 Green

16-14 AWG Seals - OE #

12010293 / 15324980 Gray

12-10 AWG Seals - OE #

12015193 / 15324981 Blue

Cavity Plug - OE #

12010300 Green

Terminals:

22-20 Pin 12080302-L; Socket 12020801-L

20-18 Pin 12089040-L; Socket 12089188-L

Before you automatically use the three pin GM MAP Sensors you

should consider engineering your project for BOSCH T-MAP sensors

that have four contacts and combine temperature and manifold

pressure in one sensor.

You can kiss some pneumatic tubing and tees good-bye. A

better way to fly. Cut your sensor count in half and get rid of

some problematic vacuum / boost tubing and clamps.

1 Bar: 0261 230 030; 0 261 230 333

2.5 Bar: 0261 230 266; 0281 002 514; 0 261 230 042

3 Bar: 0281 002 437; 0281 002 845; 0 261

230 280

3.5 Bar: 0 261 002 456

4 Bar: 0 281 002 576

For 22ga 22759/32-22 wire:

Connector BOSCH 1928403736; BDK Terminal 1 928 498 056 (20 AWG);

Seal BLUE 1928300599 (.35-1.0mm2)

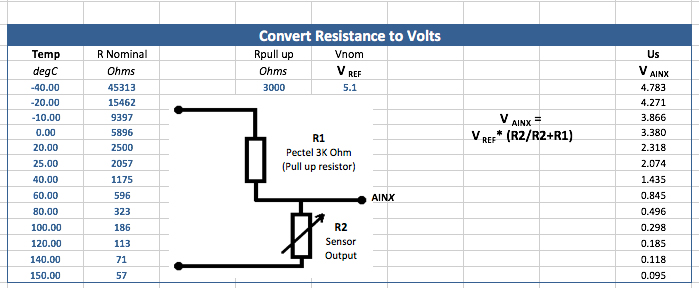

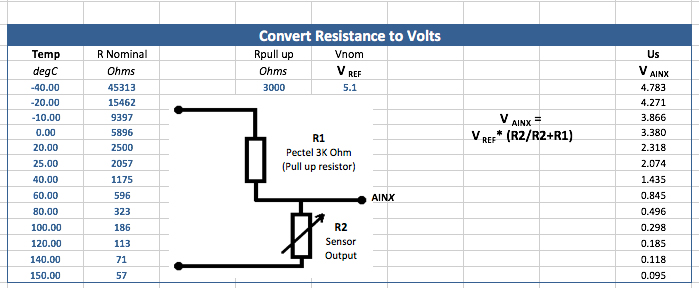

Sensor

Resistance Data: Polynomial Fit to 0-5V Data Entry

Sensor Data is often given in

resistance v. temperature. This does not correspond exactly

to equal divisions of 0-5VDc.

Use

this calculator (Cosworth Excel Spreadsheet) when

using 3K pullup resistor for temperature calibration.

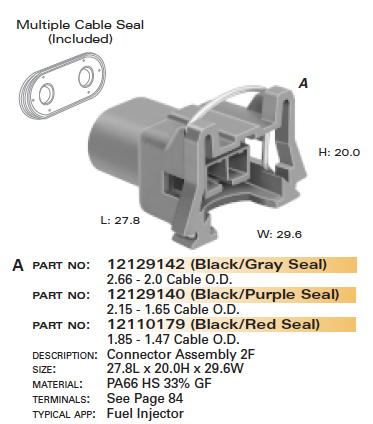

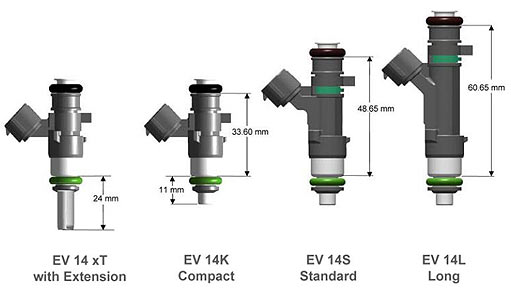

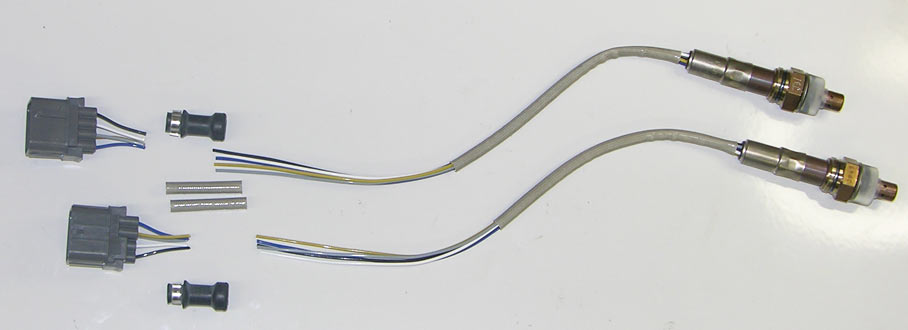

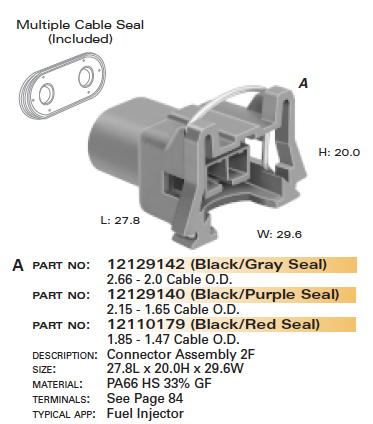

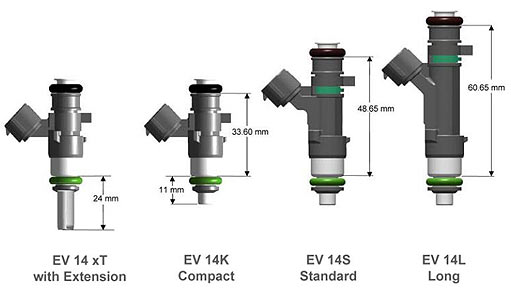

Injectors and EV6/14 Connectors

The trend in injectors is to use the

Bosch EV14

injectors which are high impedance, typically 12 Ohms,

instead of the older style Low Impedance (2-3 Ohms) as the

EV14's are very fast opening and very accurate. Most typically

use USCAR EV6 Type B Red style injector connectors (Green Cavity

Seal 22ga). The exception to this are the ID2000 Injectors which

use a

Sumitomo

6189-039

Injector Connector (Black Cavity Seal 22ga).

People tend to yank on the injector wires which are typically 22

ga. We use 20AWG. Make sure you have the proper crimping tool.

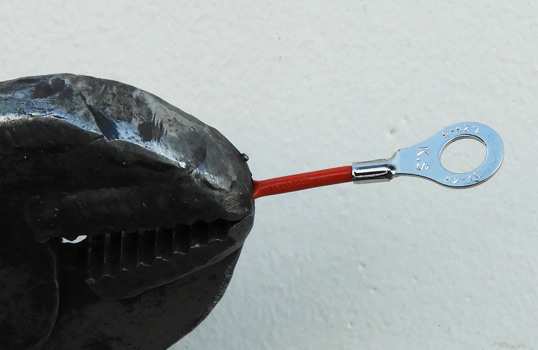

Do not solder the wires...ever. Crimp 20-22 gauge with the

Delphi GT150 Connector crimping tool

(15359996),

after removing the spring loaded plastic GT150 terminal stop,

using the 22-20 position. If you are using 20 gauge wires you

can use the general purpose

Delphi

12014254

Crimping Tool.

Prowireusa Bosch

EV6/14 USCAR Injector Connectors and Seals (Aptiv was

Delphi)

These days there is a lot of BS floating around about injector

matching etc...Take our advice and use

Injector Dynamics Injectors

as they work directly with Bosch Motorsport. Check out the

lengths they go to in

this video.

We use their 750cc, 850cc, 1000cc, 1050cc, 1300cc, 1700cc and

2000cc injectors. Pictured above are the new ID1700X injectors

developed in conjunction with Bosch Motorsport. Tony Palo drives

a 2400hp GTR so he's crazy like the rest us...only he has more

horsepower.

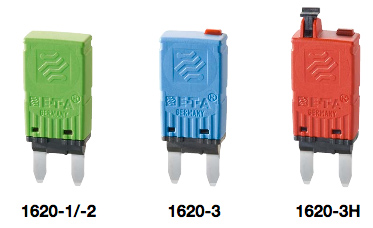

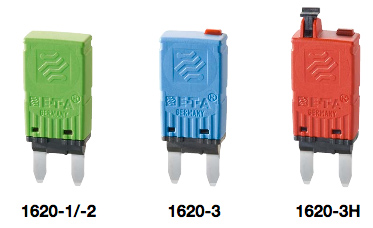

Circuit Breakers not Fuses

Passenger cars use fuses everywhere whereas, in motorsports,

re-settable aviation-style circuit breakers are preferred.

Circuit breakers have the advantage of being re-settable which

allows you to perhaps just "push it in" and get going until you

diagnose the problem. You also don't need to replace a fuse.

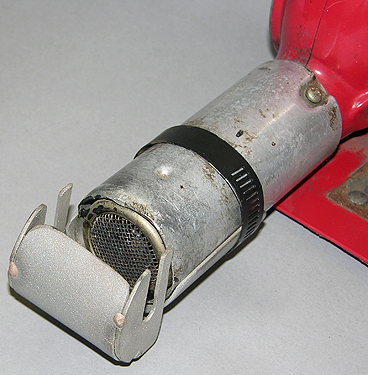

Harley uses truck style thermal breakers...your bike would sign

off due to some short and a few minutes later it would run

again...but you didn't melt your wires.

Tyco W23, ETA 483, and Klixon 2TC14 series push to set circuit

breakers are a standard aviation item and are available in many

amperages. They "pop up" when they trip and you push them down

to reset them. If you are using the popular sealed WeatherPack

silicone sealed fuse holders you can use Bussmann 227 series

circuit breakers that are a drop in replacement, albeit pricey,

for the cheaper one time fuses.

Klixon 2TC14-X (green breaker) are available from ProwireUSA

in varying amperages from 1A to 25A for about $20.00. Higher end

ETA 483 series are about four times more expensive.

Breakers like the Tyco W23 are usually installed in

panels that a race car driver can reach and reset. "Reach and

reset" doesn't work on motorcycles.

Space is also a premium on motorcycles and there is the issue of

being exposed to the elements like pressure washers. If you go

to the Bonneville Salt Flats like we do then corrosion is a

major issue. A second issue for our applications is high

vibration and the three threaded points...possible issues with

that.

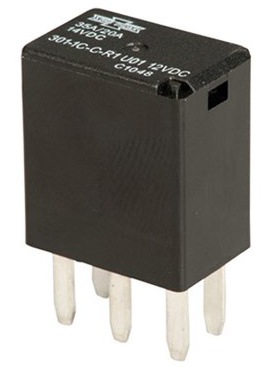

Cooper Bussman

227 Low Profile ATC Blade Type Manual Reset Circuit

Breakers pictured above. There are nornally installed in a fuse

box in place of the standard ATC duses. These are too tall to

fit in Delphi Metri-Pack Sealed Fuse Holders (12033731 Cap

Cover and 12033769 Female Connector).

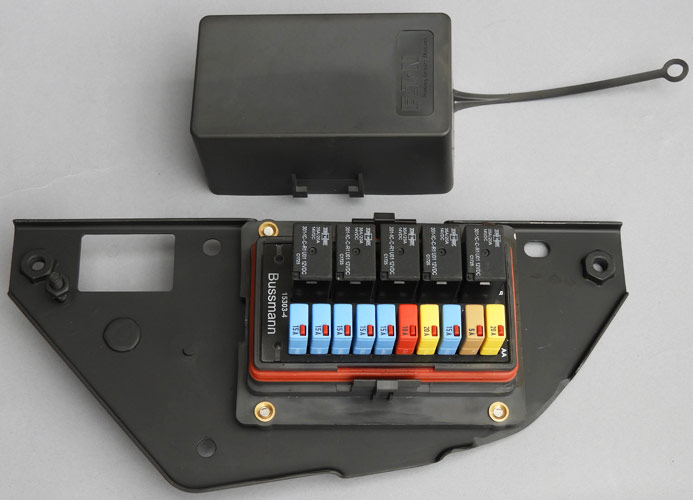

Waterproof

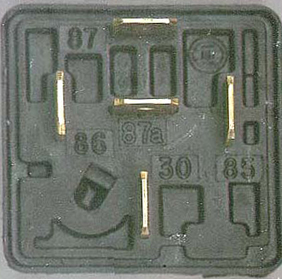

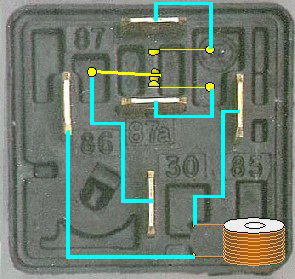

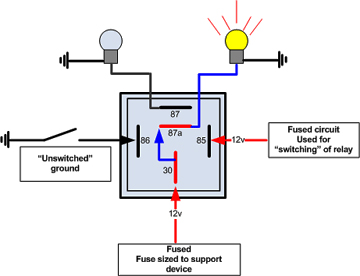

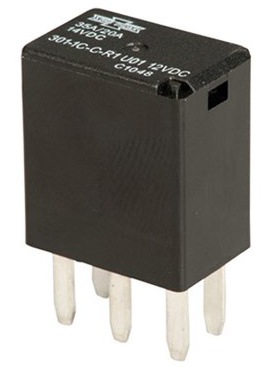

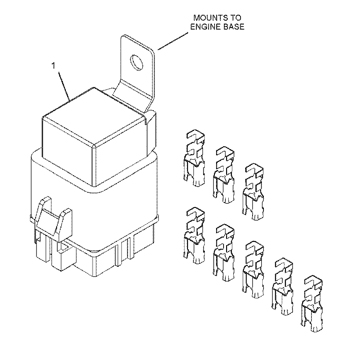

Fuse/Circuit Breaker and Micro Relay Enclosures

For motorsport wiring the

Bussmann enclosures present a simple, compact, solution in a

waterproof, sealed enclosure.

Sealed

Busmann Enclosures can house a various combination

of 280 series (.320" c-c) Mini Fuses,

280

series mini circuit breakers and

ISO 280

Micro Relays. There are a variety of these

bussed and non-bussed, so be careful when you order them. IP

66 weather tight sealed. Cheap and compact for $20.00...or

use $2000.00 and up programmable PDMs. Mini 280 series (SAE

J553) Circuit Breakers can be either auto-reset or manual

reset (2 versions).

These use Delphi Metri-Pack 280 Series (sealed-tangless)

connections on the back side:

Metri-Pack 280 silicone cable seals : 15324985 (purple

20-22ga); 15324982 (green 18-16ga GPT; 20-18 SXL); 15324980

(gray 14ga GPT; 16ga SXL);

Cavity Seal Green 12010300;

Terminals: 12084201-L (22-20ga); 12110847 (18-16ga);

12129409 (16-14ga).

All parts are available from

Waytek

Please note that the mounting screws go in from the fuse

side as the inserts are split, self-clinching, and the

I.D. is smaller on the "back" side. Part designations

are (3) 10-32 or (4) 5mm. Normally these enclosures are

inserted through a panel hole with the screws going

through the panel and into the fuse side. Typically,

with 10-32 threads, we use 18-8 Stainless Steel Pan Head

Phillips Screws 10-32 x 1/2" with 16ga thick

panels.

Should you have a space premium on the "back side" where

you wish to mount the Bussmann enclosure on top of a

panel cut-out (wires), and put the screws in from the

back side, then you can run the appropriate tap (10-32

or 5mm x .8) through the top of the insert so the screw

will easily thread into the back side. We use 18-8

Stainless Steel Phillips Screws 10-32 x 1/2" with #10

18-8 Stainless Steel Split Lock Washers on a 16ga panel.

In the picture above the Bussmann enclosure is installed

on a Harley-Davidson FXR (the side cover needed to be

spaced out). Lots going on in small space as space is at

a premium with about 80 outboard connections.

Pectel SQ6M controller for

a turbocharged application. 18-8 Stainless Steel

Phillips Screws 10-32 x 1/2" with #10 18-8 Stainless

Steel Split Lock Washers coming in from the back side.

Panel Mount Circuit Breakers

High Amp Series 17 Waterproof Panel Manual Reset Circuit

Breakers from Mechanical Products are available from

Waytek

Inc.

Amperage Ratings from 25 to 300 Amps

Trip-free operation

Industry standard terminations available in panel and

surface mount

New "Easy Access" Panel Mount and "Side by Side" Surface

Mount configurations available

Surface Mount available with 1/4" and New 3/8" stainless

steel terminal studs and sems nuts

Panel Mount available with 1/4" brass, nickel plated

terminal studs and stainless steel sems nuts

Auto, manual, or manual push-to-trip options

Dustproof and waterproof

Visible trip indication

Ignition Protected

Sealing Backs of Circuit Breakers

Raychem SCL heat shrink can be used to seal circuit breakers and

other types of switches from the environment. Much niftier than

trying to heat shrink a couple of screw terminals. It is a

dual-wall adhesive lined shrink tube with a 2.5:1 shrink ratio.

A greater shrink ratio (4:1) can be accomplished by using

Raychem ES2000, or

DSG-Canusa CDR adhesive-lined semi-rigid shrink tubing. Raychem

ES2000 is available in small quantities (4' sticks) from various

electronic suppliers like Mouser.

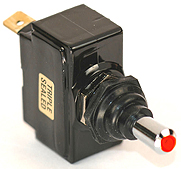

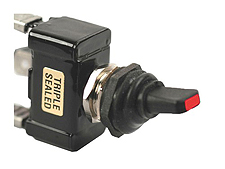

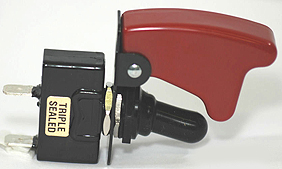

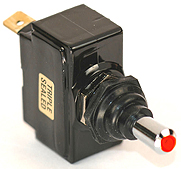

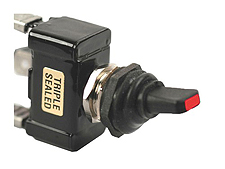

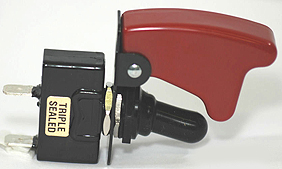

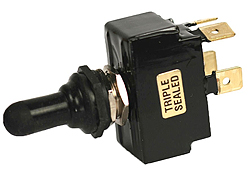

Sealed K4 Toggle

Switches

K4 Triple Sealed Switches are used in off road racing and other

motorsports where moisture and dust are your enemy.

Complete

K4 Catalog. Available from

ProwireUSA.

Sealed Toggle

Switches with Leads

Instead of having to deal with exposed blade contacts

or tiny brass screws with eylets, get a sealed toggle switch

with lead wires and install a Deutsch DTM Connector.

Grote

82-2111

SPST Toggle pictured above left. Switch is completely

sealed in epoxy. Silver contacts for long life. Waterproof

and Dustproof to IP68 standard.

Similar switches, above right, are also available from

Littelfuse.

Several less things to worry about...no loosening of screws

or issues of sealing blade contacts from corrosion. Here the

Grote 82-2111 with a DTM connector, Raychem DR-25, RT125

sealing and ATUM 16/4. Alternatively you can hardwire the

switch with two step-down butt connectors (offset them) and

seal the connections with 1.2" ES2000-1 and cover with 1/4"

DR-25 sealing both ends of the DR-25.

Otto P7

Waterproof Pushbuttons From Prowire

As we all know being waterproof

is better than not. SPDT Momentary.

Otto P9 Pushbuttons..Momentary or Latched...Plastic From Prowire

OTTO P9 pushbutton switches. They come in different

color buttons with buttons raised or flush and a myriad of

options, but you really need to label them where they are

installed. These have a 6 to 7 digit ordering number after

the "P9" so be careful when you order them. These are

plastic construction. 15/32 thread. IP 64 rated.

Prowire Otto

P7/P9 Switch Boot Adapter

Prowire-designed

Billet

Switch Boot Adapter allows for the fitting of a

Raychem

222D91-25-0 Boot to the back of an OTTO P7 or P9

switch. This adapter will also work with other switches

that use a 15/32" mounting thread. Furthermore, the

Prowire switch boot adapter includes an integrated

washer, so you will not mar the finish on your steering

wheel or instrument panel.

You solder the wires and form a service loop for strain

relief ...Then using Resintech RT125 to seal the boot.

Lead wires with 1/8" DR-25 should be abraded for maximum

RT125 adhesion. Do it right for reliability.

Grayhill 30

Series Pushbuttons...Momentary..Machined Aluminum

Grayhill

30 Series Momentary Pushbuttons. These are

machined aluminum with a Black Chrome finish. 1/2-32

thread. We use these for Cosworth ICD page, mode, and

trip reset buttons. IP67 rated. Threads on these are

shorter that the Otto P9 pushbuttons.

We also machined three stainless backshells to use a

Raychem Boot (222D921-25-0) and seal the assembly with

RT125 epoxy. We welded them to a bracket and epoxy

coated them. Handlebar mounted. Vibration proof.

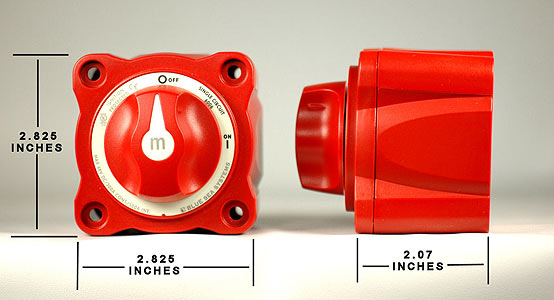

K4 Battery

Disconnect Switch

K4

Battery

Disconnect Switch. If you run expensive Lithium Racing

batteries you need to remove any parasitic draw to prevent the

battery voltage from dropping when the vehicle sits for awhile.

If the voltage drops too low due to long term milliamp draws it

can permanently kill the battery unless the battery has

circuitry to protect itself. The switch also serves as a safety

kill switch where regulations require and manual disconnect.

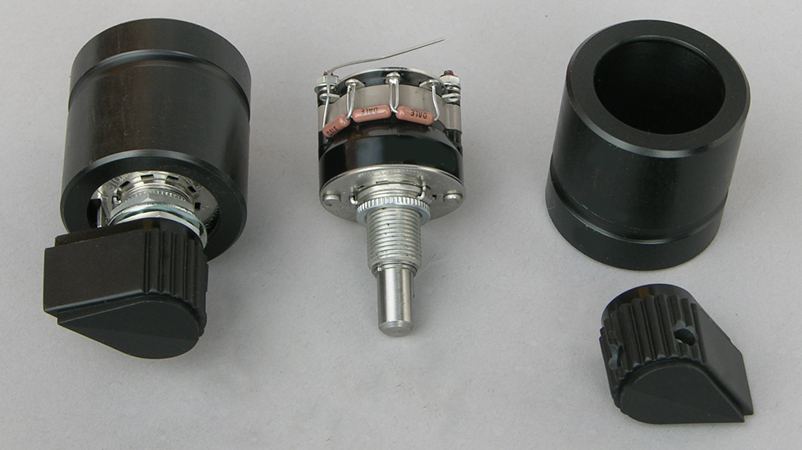

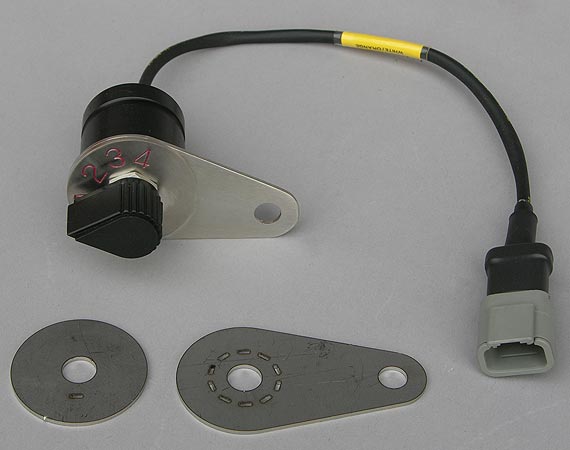

Rotary Map

Selection Switches

Rotary position switches are a fact of life in Formula 1...Fuel,

suspension, traction control, braking bias and whatever the

rules allow these days with the spec ecus from McLaren

Electronics are all switchable on the carbon fiber steering

wheel.

We make up our own Rotary Map Switches that have to survive on a

Harley-Davidson. We set these up for four map positions.

Traction control maps, fuel and spark maps...all changeable on

the fly. Four position switch pictured uses three resistors to

set voltages from 5 VDC to 0 VDC in equal steps.

Here is the final assembled switch with the laser cut stainless

steel mounting bracket and faceplate. Laser cut slots allow the

faceplate and the mounting bracket to index to each other. We

stamp the switch positions into the faceplate. The entire

assembly is sealed for reliability. We label the color of the

signal wire so it can marry up with the appropriate DTM

connector on the wiring harness.

We machine the switch enclosure from Delrin plastic and

encapsulate the rotary switch in epoxy to waterproof it and use

DR-25 heat shrink and formed boots to protect the wiring and

install a three position Deutsch DTM connector. 5 VDc, Analog

Ground and Signal wires (color coded). We pot the Delrin

enclosure / switch with Resintech RT125 on both ends. It takes a

few days to cure.

Eight Position Traction Control Rotary Switch. Seven resistors

set voltages from 0 VDC to 5 VDC in equal steps. Pectel SQ6M

controllers have 7 traction control settings. Position #1 will

be traction control “Off".

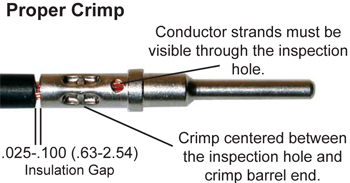

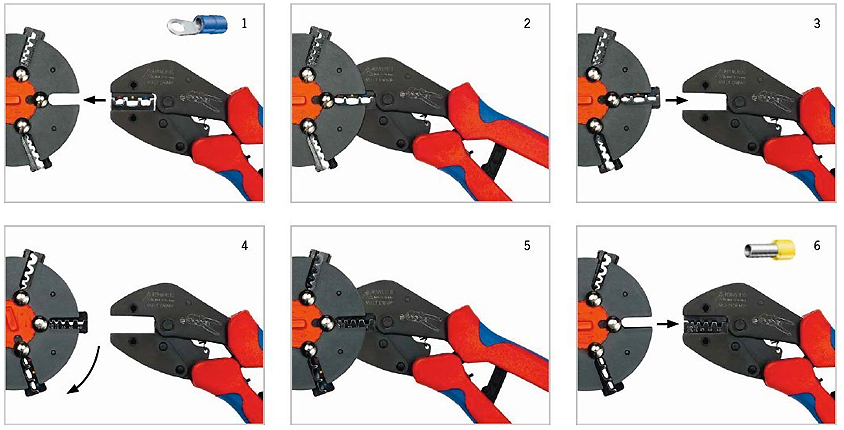

Stripping & Crimping

Ideal Ergo Elite, pictured on the left, is an excellent wire

stripper...Be sure you order the model 55-1987 for MIL-W-22759

wire plus the LB-1904 Clear Plastic Wire Stop. About $250.00.

The clear plastic Wire stop cuts accurately but can trap the

insulation between the stop and the blades. Often we leave the

stop off.

The Ideal 45-177 Stripmaster Lite (16-26 AWG, Type E Teflon), on

the right, is also an excellent choice. Keep the screws in the

jaw tightened as they tend to loosen with use. You should also

order the L5720 Wire Stop Assembly. About $150.00

We suggest you get the Ideal Ergo Elite for the most precise

work.

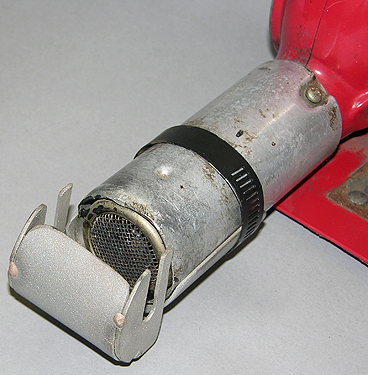

Wire Stripping

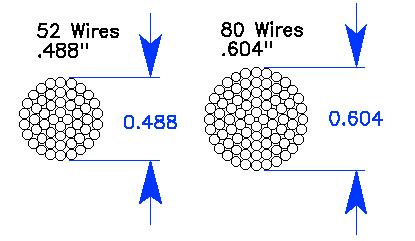

Thermal...Not