LSR 2-1 Confederates

There's a Confederate Hellcat G1 in the UK with one of our 00-1194 Slash Cut systems on it. A very clean bike with Dymag wheels and ISR calipers. Certainly a rare duck in the Harley world. They actually sold a fair number of these a long time ago but have since digressed into sculptural, expensive, barely functional toys for the uber-rich.

Purchasing the LSR 2-1Exhaust

1. Go

to the Partnumbers Page to Locate your bike

2. Systems come complete

with

a. Included in price: Look Up Heat Shields to see what comes

with your exhaust: Heat

Shields

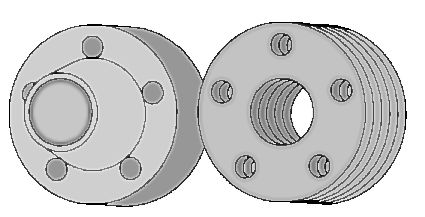

b. Included in price: 00-1000 / 00-1001 / 00-1002 Flanges

/ Clips / Nuts

Hellcat

Customer writes: "I bought

the exhaust from you guy a couple years ago and never told

you how well it fit and performs. Well, it fit perfect and

performs outstanding. Thanks. Keep the rubber side down.

Matthew." 00-1193 LSR 2-1.

There's new Confederates these days, but there are around 500 or so of the earlier ones with various S&S/TP/or Merch motors. RB Racing borrowed a Confederate to design a turbo system for Confederate but economics at Confederate caught up with that project.

We offer a "C Style" LSR 2-1 in either a Turn Out or a Slash Cut design. Three finishes are available: Chrome, Silver Ceramic or Black Ceramic.

We have LSR 2-1 pipes for these in the "C Style" in either turn out or slash cut designs. Pictured above is a 00-1194 Slash Cut in chrome. We only build these with 2" primaries as with the larger motors the 1 3/4" designs originally supplied don't do much to help the performance.

We also have LSR 2-1 Pro Stock designs for these bikes. As to which is "better"...well that depends. Generally you're safer with the LSR 2-1 because the internal baffle provides a bit of noise reduction while not holding back peak hp. The LSR 2-1 Pro Stock design is more race oriented and has a higher throughput with a smoother internal design... and works best with high compression larger motors.

As for the turbos: read our turbo

section. You just don't bolt a 250 or 350hp turbo

on a high compression motor. Then again, the Confederate

has a nice final chain drive with an outboard support

bearing. A lower compression forged piston and special

gaskets could give you the horsepower you are looking

for. We once prototyped one but Confederate (Chambers)

did not order one.

Three LSR 2-1 Finishes

1. Show Chrome:

The brightest chrome, the "Hexavalent" process, has

been outlawed in California since January 2024. Chemicals in

the Hexavalent process can be cancerous to chrome

shop operators, not the end consumer. The currently legal "Trivalent" chroming

process has a darker hue and does not visually "pop".

Our chrome shop of 26

years finally shut down their Hexavalent plating line

in 2024 in spite of having a two year extension to

operate.

We are working with a new chrome plater,

in business for many decades, who still uses the

Hexavalent Show Chrome process and understands

motorcycle exhausts.

2. Silver Ceramic:

Looks like polished aluminum, Can be re-buffed with

Mothers Magnesium & Aluminum Polish. Will not

"Blue" and will not come off or rust. Holds in heat.

Usually used with chrome or silver heat shields. Fired

twice @ 600F. Zero problems in more than a decade. Not

internally coated and no internal media contamination

as exhausts are sealed during the process.

3. Dual Coat Black Ceramic: Silver Ceramic base with secondary coat of Black Ceramic. Fired three times @ 600F. Only black Finish that will hold up. Zero problems in more than a decade. Not internally coated and no internal media contamination as exhausts are sealed during the process.

Welded Non

Removable Baffles

All

LSR 2-1 designs have a welded-in, non-removable,

baffle. LSR Pro Stock 2-1 designs have no baffle

(optional welded-in baffle at time of order).

00-1416

Quiet Baffle is standard on Black Hole designs and

optional on Spyder and +5" Slash Cut designs.

There

is no possibility of a baffle or end cap coming loose

because there are none. Zero maintenance for life. No

tone change over time,

Our

00-1306R Pro

Stock Resonator designs have a welded-on non-removable

Db reducing resonator with zero restriction.

For those of you who want to "tune" your exhausts...Not ours as they are already optimized. Consult your baffle advisor for appropriate anxiety medication.

RSR Air Fuel

Ratio Gauges...Real World Tuning

The Mother of all gauges! Not a gauge, but a precision tool that will tell you exactly what your engine is doing in real-time. Gives you instantaneous read-outs of air/fuel ratios from 17:1 to 10.5:1 and indicates maximum power ratios. Four color display is easily read in direct sunlight and automatically dims at night. Waterproof, billet aluminum construction. Your significant other will cheat on you but this gauge will never lie! It won't keep you warm at night, but a perfectly running engine will look and sound the same when you wake up next to it the morning after.

Single RSR O2 Gauge: Reads the front cylinder in non-efi models. It is simply the best way to evaluate the tune of your motorcycle and saves expensive and often inaccurate dyno time. Real world tuning while you ride...Observe and then make adjustments. Mounted permanently. Waterproof

The gauges have a center back mount 5/16" x 18 x 1/2" Stainless Socket Head Cap Screw and stainless lock washer. You can fab your own bracket for this or use the 06-1025 hard anodized Billet Mount System for either 1.00" or 1.25" handlebars $49.95. Optional is the 06-1024 two piece laser cut 304 Stainless Steel mounting tabs for either near handlebar clamp or up the handlebar mounting: $9.95

Since we did closed

loop fuel injection systems for

Harleys for more than 25 years and have been putting

O-Sensor Ports in our exhausts for more than 35 years,

we have both single and dual O2 ports for our full

range of exhausts. Our RSR

Air Fuel Ratio Gauge is the

best investment you can make for monitoring and

optimizing your engine tune. Single O2 for carb bikes.

All LSR 2-1

exhausts come standard with one or two O2 ports

(Sequential EFI models)...18mm or 12.5mm. O2 or Lambda

sensors are a necessity for either carbureted or non

closed loop efi (Weber Marelli and Early Delphi)

Harleys. We should know, as we have a lot of

experience with them and have been doing Closed Loop

EFI systems since 1989.

The Single

gauges ship with eight feet of MIL-W-22759/32 wire.

The first 24" is covered with Raychem DR-25 to where

the front O2 sensor signal wire branches out. The

remaining 4 wires od the single gauge are covered in

DR-25 to 70" from the gauge. The Battery Negative ring

terminal is pre-terminated.

The gauge is housed in a hard anodized round enclosure in a standard 2" format with a 2.250" bezel, center back mount, with a 5/16" x 18 stainless socket head cap screw. The gauge will show fuel ratios from 17:1 to 12.0:1 (or richer). The gauge is visible in daylight and automatically dims for nighttime operation. Only a single L.E.D. illuminates.

Very easy to interpret at a

glance. Scale is, left to right, lean to rich: three

greens, three yellows, two orange and two red l.e.d.s.

You simply cannot "read" spooling digital numbers.

The white arrow indicates the maximum power mixture, the second orange light, which is 13.2:1. Transitory enrichments should not, if the engine is warm (>200F Oil temp), go past the first red light. Readings at the far right side of the scale, the second red light, are simply too rich. Proper closed loop operation will cycle back and forth from green to orange around the center of the display.

It is simply the best way to evaluate the tune of your motorcycle and saves valuable dyno time. Mounted permanently. Waterproof.

Whether your

bike is carb or efi this is the best way to tune...By

riding and observing, not on a static dyno. Dynos are

not exactly real world in terms of loads, airflow, or

transitionals, and even if you had a million dollar AC

Transient dyno room, you would still have to do real

world testing. The gauges are dead accurate and are

millisecond fast responding which makes it very simple

to interpret or remember, even at a glance, while you

are dodging cars watching for cops. We have a Superflow

CycleDyn which

gives a better real world correlation than other

dynamometers but we still evaluate air fuel ratios

when riding.

Anyone who

tells you optimizing tuning is easy is full of shit.

Engineers at Ford say they spend two years just

perfecting tip-in or initial throttle openings. Ride,

observe,..then change or edit. Real world.

Pretty soon Harleys will all be watercooled then you really won't be able to tell the difference between Milwaukee and Hammatsu. "The Man" will be sniffing your butt and planting microchips and gps modules up your ass so they can mail you a speeding ticket and keep track of your movements. They already have data recorders on your car so they know what you were doing when the biggie happened. Brave new world. Monitor your engine to get the most out of it before the NSA monitors your tail pipe.

Customer Comments...RSR Air Fuel

Ratio Gauge

Customer writes: "When the gauge arrived I knew it would be of a very high quality, it has far surpassed my expectations. I was very eager to get this installed and take a look at my tune. Amazing to see how little adjustments on the carb effect the AFR. As a result of this gauge, I have dropped one size on the low speed jet, raised the clip on notch and confirmed the main jet on my Mik48. Thank you, I really like this gauge. Ed"

Do Not Use OEM Gaskets with LSR

Exhausts

LSR 2-1 Exhaust Systems must use our CNC Machined Billet Gaskets (part number 00-1000) and our close tolerance aircraft exhaust nuts (part number 00-1001). The above OEM woven gasket will not work with our machined Turbo Venturis. Four special aircraft exhaust nuts come with the system but you must order four extra ones for $3.00 as they are easily dropped and the OEM 5/16" x 24 hex nuts will not "turn" on our machined Turbo Venturis.

We also offer machined from billet exhaust flanges. If you have a 2004 or later bike it will probably have the thicker exhaust flanges which are not compatible with our Turbo Venturis. Early style OEM Evo chrome die cast flanges and clips or our billet parts are called for. Our Chrome Billet Flanges and clips are $29.95 per set and are stronger than any oem part.

We have had several instances where people encounter "difficulties". Invariably, it is traced to someone not using our billet gaskets. The billet gaskets insure proper fit of the LSR 2-1 system and are designed to work with our Turbo Venturis to increase exhaust flow.

LSR 2-1's Bonneville,Dyno &Track Proven

If you want to make power on a multi-cylinder engine you have to use a collector system. Whether it's a V-Twin or a V-8 it's the same, and no less an authority than the famed engine builder Smokey Yunick will tell you that. Not using free exhaust energy to help your engine breathe is downright criminal. No matter what the conventional wisdom is, staggered duals on a Harley will not make more power. You simply cannot escape the fact that a properly designed 2-1 will give you more useable torque where you need it, in the 2000 to 4000 rpm range, which means less downshifts and less rpm to get the job done.

A set of short staggered duals at peak rpm can be made to produce good power but they will be dead on their ass until they get there, whereas an engine developed around an LSR 2-1 exhaust can be made to perform from the bottom up with no dips in the torque band! If you don't believe this then why is it always that the top Pro Stock bikes, cars etc. end up running collectors systems? Damn right they work! If you don't think torque between shifts or when you roll the throttle on, then buy those long sewer pipes or some short curly drag pipes you saw on the Discovery Channel.

Check out our new Exhaust Technlogy Section for information on how all this works.

New Cloisonne Tags

Like in the adage "The relentless search for perfection" we have upgraded the logos we put on our LSR Exhaust Systems. Previous tags were stamped and formed aluminum with silkscreened details. The new cloisonne tags are a precision die struck brass, nickel plated, with powdered glass fired in an oven then polished to a jewelry finish. These are direct replacements for our older tags and are available for US $25.00 postpaid via US Global Express (foreign) or Priority Mail (domestic US). They come with black headed rivets and are riveted in place with a light coat of high temperature silicone (Permatex 598B) behind the tag.

Baffling

Alien Discs and Aluminum Butt Plugs

Our testing has shown that the Harley V-Twin is extremely sensitive to back pressure which is why 2-1's that use small or restrictive collectors don't breathe well, and why restrictive baffles shut the motor down. Disc type baffles are good for spark arrestors on dirt bikes but they have no place on a big inch V-Twin. You don't make power by adding restrictions to your exhaust system whether it's a bunch of stainless discs or some damn piece of aluminum billet machined into a Harley butt plug! Ever wonder why they had to put a hole up the center of the discs? Well, one reason was the discs are so damn restrictive you have to have several pounds of them to get enough flow through their waffle shaped passages. Good mufflers, but they have nothing to do with performance and they sure as hell do not create vacuum as has been claimed. When you get confused by all the bullshit simply ask the following question.." Do they run them in NASCAR or in Formula One?". Nope, they run straight pipe collector systems without any stupid discs or aluminum butt plugs.It's always funny how when the money is on the line, all the little things like discs, billet caps, anti-reversion flaps, reverse megaphones and other such nonsense somehow don't make the field.

All RB Racing LSR Exhaust Systems feature our "new" (we've been quietly doing it since 1985!) CNC machined Turbo Venturis that actually "scavenge" to help your motor breathe. Machined from billet, these allow full 2" flow and eliminate the phony restrictions that other 1 3/4" to 2 1/4" pipes have at your exhaust port. We supply special close tolerance aircraft nuts for your exhaust studs because our machined venturis are too wide for a standard hex nut.

Our CNC machined Turbo Venturis are not compatible with the "bowl-shaped" late model OEM exhaust port gaskets or early style "flat" gaskets for the LSR Exhaust Systems to both fit and seal properly. The narrow machined flat face of the Turbo Venturi must seat against a flat surface, not the bowl-shaped late model gaskets. Using the LSR Exhausts in combination with the wrong gasket will cause misalignment, inability to tighten the provided close tolerance aircraft nuts, and will force the bowl-shaped gasket into the exhaust port.

Mandatory for a nominal charge of $9.95 are a pair of our LSR CNC machined gaskets which mate perfectly with our Turbo Venturis. These are proven in over 16 years of use on our race and turbo applications...the only gaskets that will stay in a turbo bike for 25,000 miles! These gaskets prevent any gasket "creep" into the exhaust flow and are one more thing that will give you "an edge" on the competition. We always wondered why people would port their heads, put in bigger valves and then squish the gaskets into their exhaust ports. We bet you never paid attention to what was going inside your exhaust ports for one very simple reason...you can't see what's going on in there once the pipe is tightened! The LSR CNC machined gaskets also insure perfect alignment of the exhaust system. Most fitment and alignment problems are traced to using either the wrong type of gasket or using old gaskets that have taken a "set". We've always used these on our race applications and it's time everyone who's concerned about performance should do the same.

All LSR 2 into 1 exhausts require special close tolerance aircraft nuts to bolt the LSR Turbo Venturis to the exhaust port. Standard 5/16" x 24 hex nuts will not fit. Each exhaust comes with the required four nuts. It is recommended that you order an extra set (4) of these nuts, part number 00-1001, when you order your exhaust.

STD Cylinder Heads

We make special flanges for STD heads that match the rectangular bolt pattern that STD machines. If you order a RB Racing LSR 2-1 Exhaust you can order these flanges which have been designed to fit our standard turbo venturis. RB Racing Part Number 00-1003. Sold per pair $29.95. When you order a RB Racing LSR 2-1 Exhaust system we either polish and chrome these or bead blast and ceramic coat them.

Goo

RB Racing LSR 2-1 exhaust systems use either one or two slip joints depending on the model. We suggest you put a coating of Permatex 598B ULTRA BLACK in the slip joint. None of our slip joints use any clamps because then they wouldn't be slip joints anymore. The inner pipe gets hotter that the outer pipe and they grow into each other and form a tight seal. The 598B is a non hardening gasket material and will prevent any leakage from condensation that forms in the pipe and, with the usual carbon particles, will actually seal better over time. It also makes the pipes easy to take apart later on. Get a tube before you install your RB racing exhaust system.

All RB Racing LSR exhaust systems come standard with a machined and heliarced oxygen sensor boss just below your front exhaust port. This port is designed to accept and oxygen sensor (18mm x 1.5mm) which will allow you to use our RSR Air/Fuel Ratio Meter to tune and monitor in real-time your air/fuel ratio. Also, if you really wish to get 55mpg and kick ass, our RSR Fuel Injection's closed-loop heated O-Sensor will plug directly into this port.

Confederate: We provide a small angular bracket that attaches to the rear of a slotted bracket on our exhaust and then attaches to your frame.

Custom Made for Your Application

Pictured above is a 00-1193 Turn Out, 2" Style C. Customer also ordered a RSR Air Fuel Gauge. Freedom of expression...do it while you can before someone decides to stick their nose in your business.

New Ceramic Black Finish...."Here Come Da Judge"

Even The Judge has to cover territory quickly, especially in a state as large as Texas. Pictured is a ceramic black 00-1194 LSR 2-1, C Style with 2" primaries. Growing part of the Confederate Air Force.

We have a lot more people looking for durable black finishes and we think we have the best finishes on the market. In the late 70's and early 80's we tried all sorts of coatings and paints and even used porcelain on some of our products in the late 1980's. The newer ceramic finishes are tougher and we use both polished silver and semi-gloss black to complement our usual chrome offerings. The newest black finish is a dual coat process that gives additional protection against scratches and nicks, providing two barriers against corrosion.

Newer "Turbo" Black Ceramic Finishes

We have a lot more people looking for durable ceramic finishes and we think we have the best finishes on the market. In the late 70's and early 80's we tried all sorts of coatings and paints and even used porcelain on some of our products in the late 1980's. The newer ceramic finishes are tougher and we use both Polished Silver and Dual Coat Black to complement our usual chrome offerings. The newest "Turbo" Black finishes are a dual coat process that gives additional protection against scratches and nicks, providing two barriers against corrosion.

In 27 years we have tried all sorts of black finishes: Kal Gard, VHT, Techline, and others. We also in the mid 1980's we even tried porcelain for awhile. It chipped and the heat distorted the parts. Most finishes will not survive over a long period unless they have a base coat to cushion rock strikes and scratches. The surface has to be perfectly prepared and most applications can fail if run too soon at elevated temperatures as they are typically baked at 450 to 500 deg F whereas the cure takes place at around 750 deg F. Lower temperatures will not cure the resins and they will fail once the bike is run. To get around this dilemma we have found the best solution is a 2500 Deg F Ceramic cushion base coat and a secondary Black Semi-Gloss finish on top of this.

"Turbo"

Black Ceramic finish

is a triple

process. First the parts

are polished to remove

any tooling marks.Then

the parts are zirconia

media blasted to prepare

the surface. Then parts

are cleaned. The parts

are base coated with a

silver ceramic base coat

and baked.

Then the parts are sprayed with a second ultra high temperature coating and baked a second time. The 2000 Deg F base or cushion coat adheres to the metal very well and provides insulation and corrosion protection. The black is a thinner coat and provides the smooth, dark black, finish we require.

Satin finishes scuff too easily so we do not use them. The old satin finish is shown above. We are refinishing the pipe for the customer with the new finish..

The Semi-Gloss black finish can be cleaned with soap and water and scuff marks can be removed with Mother's Aluminum and Magnesium Polish.

Funny Story: Seven years after we sold this system the second owner calls us up and wants the pipe recoated for "free". We explained the pipe was sold seven years earlier to the original purchaser and we do not recoat things for free. After much screaming and yelling the new owner wanted the above picture of "his bike" removed from our website...Not a chance. As we remember the original owner was very happy and sent us this picture....Guess we'll just leave it where it is. You meet the nicest people.

06' Dual O2 Sensor Systems / RSR Air Fuel Gauges

Since we have been doing closed loop fuel injection systems for Harleys for more than 15 years and have been putting O-Sensor Ports in our exhausts for the same amount of time, we have dual O2 ports for the 06 models for our full range of exhausts. Our RSR Air Fuel Ratio Gauge is the best investment you can make for these.

All LSR 2-1 exhausts can be ordered with two O2 ports. Actually O2 sensors are a really neat item. We should know, as we have a lot of experience with them. Tuning strategies are different and there are a lot of things that can go awry if you forget about temperatures, pressures etc.

Pretty soon Harleys will all be watercooled then you really won't be able to tell the difference between Milwaukee and Hammatsu. "The Man" will be sniffing your butt and planting microchips and gps modules up your ass so they can mail you a speeding ticket and keep track of your movements. They already have data recorders on your car so they know what you were doing when the biggie happened. Brave new world.

800 Horsepower LSR 2-1 Slash Cut

We're not really sure what a 2-1 has to do with Top Fuel Nitro motors but when Carl Pelletier asked us to make a collector for his top fuel 175c.i. PRP motor we whipped up a 4" diameter collector and sent him the tooling. Take a Tour of what it takes to run a top fuel bike. Doug Vancil's hard running Top Fuel Harley sponsored by Vance and Hines has a 2-1 that looks like one of their Pro Pipes so when Carl asked us to build one we made sure the collector area wouldn't restrict each of the 400hp explosions that were coming from each cylinder. Carl qualified 8th out of 32 bikes at the final Las Vegas meet and ran in the sixes at over 200 mph so the 2-1 probably didn't hurt anything. His best speed is 214mph with the 2-1 so it didn't seen to hurt anything. Top Fuel is pure insanity and is addictive as Heroin for those involved. Like they say " Gasoline is for washing parts...Nitro is for Racing!".

Risk

These days people have all sorts of expectations. They want to be loved. They want to be admired. They don't want their chrome to turn colors. They want "numbers". They want assurances. They want guarantees, warranties, trial periods, and return policies. They don't want the part, they just want everything that goes with their household baggage. It's all part of keeping everything nice and tidy and "best". Fear of rejection. Fear of making any decision.

We just come in and make the best parts we can and that's all there is to it. The rest of the equation is too complicated. There are plenty of people who will assure you till hell freezes over. We don't have time for this.

For those of you who do not understand that 1450 Deg F of exhaust flame front will discolor chrome, don't order the parts, or just leave the bike on the trailer..or order the heat shields to cover up the underlying discoloration. Ceramic or chrome the pipes get really hot and heat shields provide an air gap to protect and hide things.... Melted tennis shoes, burned pants. Air is the perfect insulator.

It isn't the old days anymore. People with $35,000.00 toys roll up in the screaming fetal position. Joy used to be a basket case that you could get running. Brave new world.

These days people have all sorts of expectations. They want to be loved. They want to be admired. They don't want their chrome to turn colors. They want "numbers". They want assurances. They want guarantees, warranties, trial periods, and return policies. They don't want the part, they just want everything that goes with their household baggage. It's all part of keeping everything nice and tidy and "best". Fear of rejection. Fear of making any decision.

We just come in and make the best parts we can and that's all there is to it. The rest of the equation is too complicated. There are plenty of people who will assure you till hell freezes over. We don't have time for this.

For those of you who do not understand that 1450 Deg F of exhaust flame front will discolor chrome don't order the parts, or just leave the bike on the trailer..or order the heat shields to cover up the underlying discoloration. Ceramic or chome the pipes get really hot and heat shields provide an air gap to protect and hide things.... Melted tennis shoes, burned pants. Air is the perfect insulator.

It isn't the old days anymore. People with $35,000.00 toys roll up in the screaming fetal position. Joy used to be a basket case that you could get running. Brave new world.

Angst

The agony of decision making can drive a poor consumer insane..."What is the best?"...".."How does it compare?"..."What will I get, what will I gain?"..."When can I get it?"..."Should I get a 2" or a 1 3/4" pipe".."Will the chrome blue?"..."Can I talk to someone who has one?"..."How long have you been in business"...""I've never heard of you"... "How black is the black?"..."Why haven't I seen these before?"..."My bike is at the builder and he has to have the pipe by Friday or I lose my slot!"..."Is the silver as shiny as chrome?"..."I have a wazoo998 cam and billet rocker boxes and a 280 rear tire...will your pipe work?"

Right brain, left brain. Fear of rejection. Fear of being different. Social standing. It's all too much for most people to deal with.

Look at the pictures, take the Red Pill, and start your journey. It's that simple.

If you wish avoid any decision and stay right where you are, just take the Blue Pill. If the journey for truth and power excites your spirit, take the Red Pill.

No Limp Dick Designs

Ever since Jesse James did his original Hell Bent pipes people have either copied them or tried to make whatever they were doing swoopy. If you are a slave to fashion then these might just suit your fancy. At RB Racing we build logical designs that work and leave the limp dick fashion trend to those who love to park and talk.