Turbo Orca FXR..Ultimate FXR

All your life you've never seen

A woman taken by the wind

Would you stay if she promised you heaven?

Will you ever win?

Will you ever win?

Stevie Nicks

Fuck CVO Worship

A stock 1999 CVO2...not ours...just a

photo we found...same paint, same bike though.

We sort of changed it around...LSR

2-1, RSR Closed Loop Fuel Injection, different paint....same 21"

front 16" rear...

A number of years ago we picked up a

1999 CVO2 FXR and put on some old custom paint we had...You know

keeping things stock is illegal and we sure as hell don't

worship this "CVO" business. We put on a different seat and got

rid of the shorter, stiff as hell, shocks and some chrome side

covers we bought from Ebay. We kept the bike's motor stock and

put on one of our 00-1010 B Style Turn Out exhausts and our RSR

Closed Loop Fuel Injection.

Way before this we had a Shovelhead

FXR that Carl Pelletier of Competition Motorcycles had loaned us

for product development. We used it for carburetor and exhaust

testing for several years, like developing the 41mm FCR

carburetor for Keihin Corporation. Then one day Carl called us

up and asked if we still had the FXR as he had a buyer for

$10,000.00. We gave it back to Carl.

We also had a 1987 FXR that we used for turbocharger, exhaust and camshaft development but we eventually pushed it into the corner and then sold it.

Funny story. We let a Yamaha XS1100

owner ride our 1987 Turbo FXR and he came back saying he was

surprised at how well it handled, even when it was dragging

things, but that "It seemed to flatten out around 9000

RPM"...flying over the Vincent St. Thomas Bridge in San Pedro.

Ouch! ..It sounded a bit rough when he brought it back..Pieces

of piston rings were coming out the exhaust. The Branch heads

had bits of rings embedded in them.

We should have kept it but we needed the money. Enter the CVO2 pictured above.

Another FXR we got involved with. Read about it here.

Harley Davidson and the Marlboro Man bike.

The ultimate FXR for some...not for

us.

FXR CVO2 Round Two

We got bored with the former CVO2 and

its smallish 3.5 gallon gas tank so we adapted an FLHX 5 gallon

tank, painted the bike and changed the wheels. We also converted

it to chain drive and got rid of the 21" front wheel that we

never liked and adapted a 19" Dyna front wheel. We got rid of

the shorter rear CVO rear shocks and put on 13.5" shocks

for better ground clearance and a Dresser rear wheel.

Result: It handled better, we could drive further without looking for a gas station and we got 56 MPG. We ended up putting in a 24 cell Lithium Battery as it held at 13.3 VDc even after siting for months, and had less of a voltage drops in cranking, which gave it much better and quicker starting. EFi simply hates voltage drops...Anything below 11VDc and the fuel pump output declines drastically. We still left the engine stock...no cams.

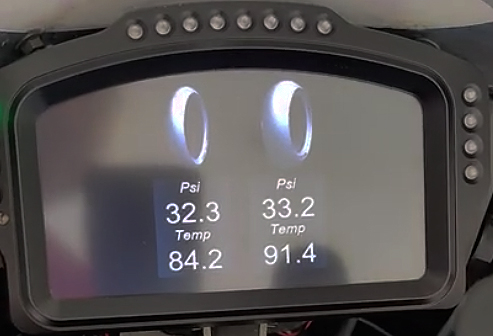

We added our instrumentation

consisting of our digital Orca Bonneville Tach, GPS Speedometer

, Digital Gear Indicator and our Dual RSR Air Fuel Ratio Gauge.

The 5 gallon tank gave us a 200 mile range under closed loop

efi. We left the tank and fenders with a painter and he came up

with the copper/bronze color.

Everyone drove the bike. It was sort

of quick, mainly because it was about 300 lbs lighter than a

Dresser and it had instantaneous throttle response with our 56mm

RSR EFi. Then we got locked into Bonneville, advanced Cosworth

electronics and the Bullett. There was no time to work on the

FXR. Racing eats all your time and money.

Bonneille...FXR Turbo Development

Well, we spent a lot of time and

money setting records at Bonneville and since the late 1980's

and we have constantly been developing Turbocharged Intercooled

ORCA Turbo Motors and fuel injection technology. We set records

on BMW's, Kawasakis, Suzukis and Harley's...at El Mirage, Muroc,

Maxton, and Pro Gas Drag Racing Champioships...pretty much on

our nickel. Ouch!

Over 400 HP on long course at

Bonneville. Once you ride the Bullett you don't want a stock 80"

FXR anymore. The Bullett occupied all of our time and

money and any development on the FXR ground to a halt. FXR, the

Stepsister. We left the Bullett in 2017 after spending many tens

of thousands of dollars and getting a soft 200 mph record (poor

conditions) that held for 5 years. Untold 3000 mile round trips.

Time to work on our own projects. As

we were told by a famous tuner..."There is no end to free".

Men in Black....

When you spend more

than

40 years... Holy Shit where did the time go!... working on

and designing high performance motorcycles and equipment,

spending untold thousands of hours, and more late nights and

lost weekends than you can imagine, a lot of people get dragged

into the Vortex.

A large cast of characters, both good

and bad, from many continents, have at one time or another

hitched a ride on the RB Racing Express...and then faded away.

Once the party starts they show up and once the party is over

they head for the door. Something about not living with the

consequences, or just being practical, whatever that is. As the

song says "Players only love you when they're playing".

Good or nice people can make our

lives more interesting..people are always interesting but, when

it come to race bikes, it sort of boils down to one person and

the rest sitting in chairs.

The Bullett has

been

a test bed for ORCA Engine technology and it's complexity is

way, way, beyond things we have done before. 139 cubic inch

"EVO", water cooled, 60mm fly by wire throttle body, water

injected and intercooled.

It forced us to confront engineering

issues and learn new disciplines. 1000 lbs, no higher than your

waist, 45 degrees of rake and over 400 hp with a 560 HP Turbo...

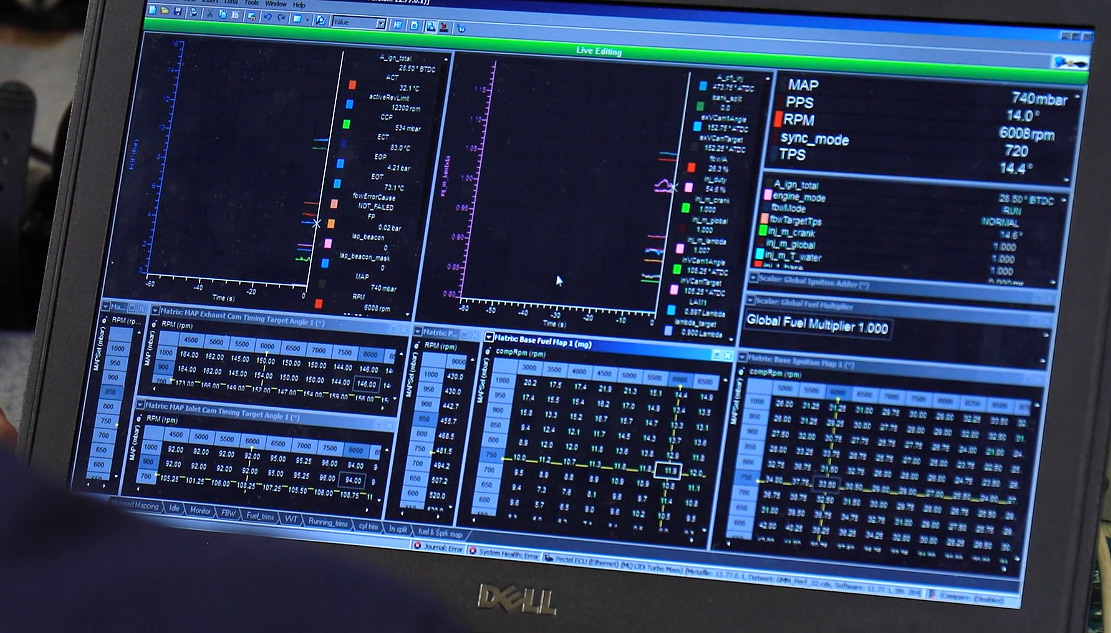

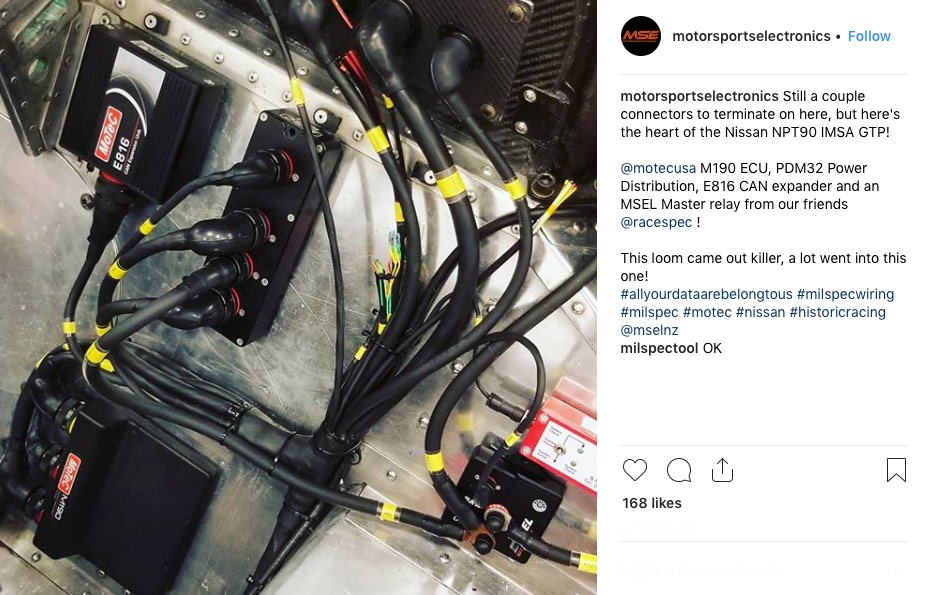

Advanced Cosworth electronics, phase anti-phase boost control

and traction control. One hell of a lot on RB Racing's plate as

no one else understood or wanted to understand the technical

issues.

Only designed for Bonneville, it is the ultimate pushrod motorcycle and is a handful to ride until it settles down around 100 mph. Geared for 300 mph @6500 rpm it is not something you putt around on...but once you've driven it, you want that kind of power and sophistication that you can hop on anytime...like a lightweight flick-able FXR.

We got a soft 200 mph record under

poor salt conditions then ended our Bullett development and

participation in 2017 on our terms.

Why not take the Bullett's ORCA Engine and control technology and put it into an FXR...Screw the stock 80" CVO2. We are upping the complexity and control we learned at Bonneville and applying this to our FXR. Something we can ride every day...and not have to deal with people that do not believe in either learning or testing complex systems.

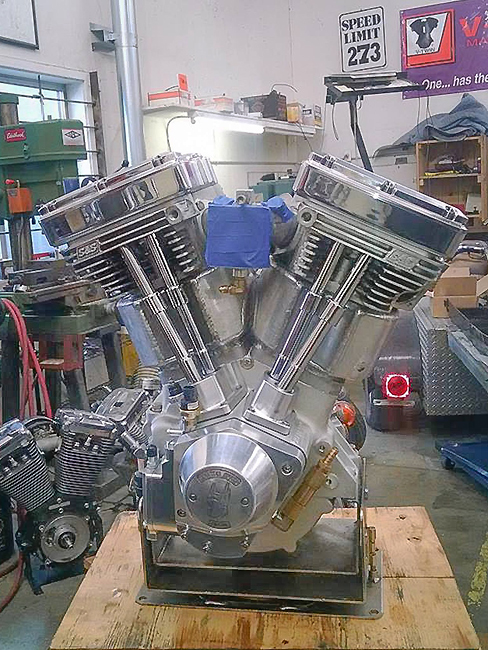

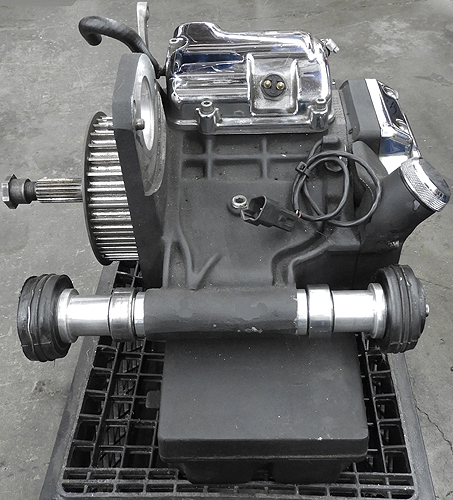

Take a 113" S&S SA B1 motor we

had previously developed and use it... Or a new variation on the

same and adapt it to our much modified CVO2 FXR.

Lots of decisions to make...Like go

radical , or be somewhat practical, or prep it to race, or

simply do all of the above. It's all ground zero. Write yourself

a check and get going. Development is a bitch.

Round Three...Come Up with a Plan

Since we've been around for awhile and have a long memory for things we are interested in, and since we had spent a lot of time at Camber Fairing in 1977 with Jerry Greer working on our 1977 Bol D'Or Monoshock racers body work and fuel tanks, we knew Jerry had been involved with Don Vesco and his Rabid Transit fairings that were marketed for a few years to the BMW and Jap crowd. We tracked two down and adapted one to our FXR before we stripped it down.

Why? Simply because around 180 mph,

and faster, the wind gets a bit fierce and you need a frame

mounted fairing that is wide enough to get your shoulders

behind...The Rabid Transit fairing is a hand-laid, sturdy piece

because Jerry knew his craft. A very sophisticated aero design

that gives good protection...Way better than an FXRT

fairing. Get down on the tank and look over the fairing's

edge.

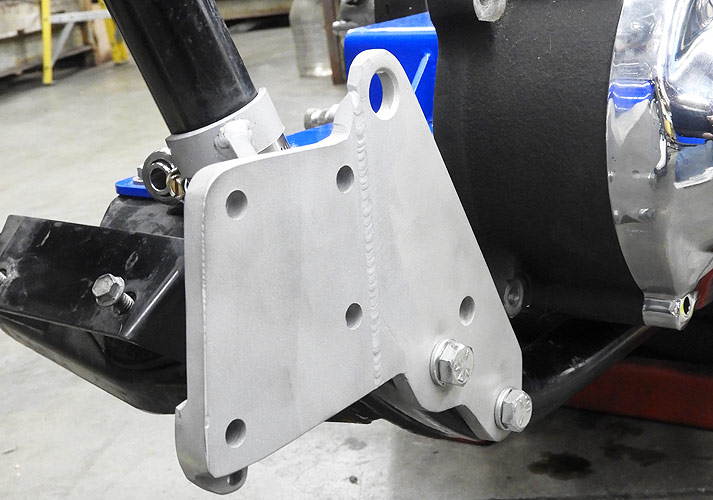

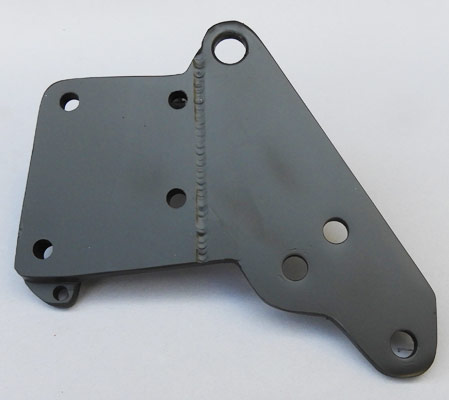

We fabbed up these mounts and had them powder coated. They bolt to the steering head and frame.

FXR Turbo Cockpit...

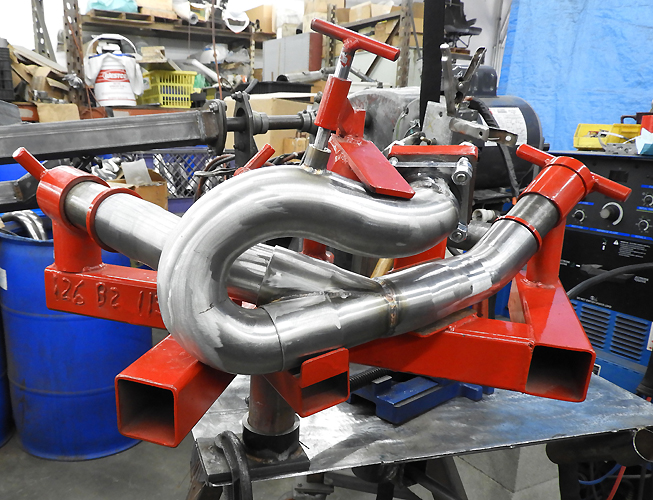

We welded up a set of stainless

handlebars prepared for our 60mm Bosch Turbo Fly By Wire

Throttle Body. No available bars will fit... they have to be

made. Your hands are out of the air stream and the bars go full

lock staying inside the fairing. No ape hangers. No forward

controls. Lock to lock inside the fairing.

Bye bye to our previous FLHX 5 gallon tank...She was too wide for the Rabid Transit fairing. We only have 1/2"clearance side to side with the smaller tank. We'll get the lost gas capacity back another way.

Clutch Cable Through

the Bars

Once you start this you have to make

all sorts of adaptations. In this case, the low bars are

designed to keep your hands out of an 180 mph airstream and

inside the fairing even at full lock.

This necessitated running the clutch

cable through the bars and welding on a stainless steel exit

tube with an internal Delrin liner.

FXR Narrow Glide Forks

Modification for the wider 17" rim, front tire, and custom fender we will be using.

Narrowglide forks are definitely not

made for the wider 110/70ZR-17 Michelin Pilot front tire. 120

series tires are too wide. We machined off the inner oem fender

mount to make room for the 110 series tire on the 3.5" Buell

rim.... Tire has a wider footprint than the 21" original tire.

We made a temporary fender / fender

mount

We then fabricated a temporary two piece clamp-on fender support. We will be installing a machined fork brace. Final finished position above. Very solid.

The chromed FXR2 single disc forks

have a 3/4 axle. A separate 60 tooth wheel sensor is added to

get front wheel speed for speedometer / odometer as well as

traction control functions.

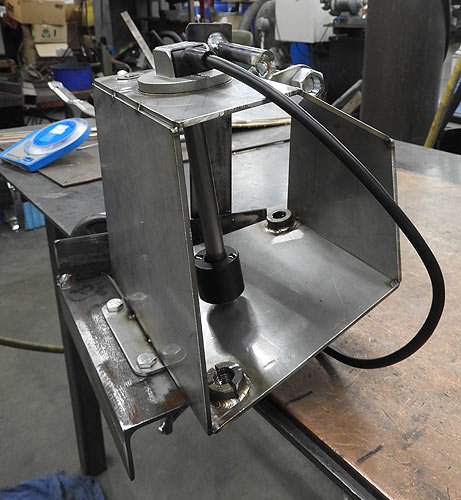

FXR Turbo Oil Bag Transmission

The smaller gas tank just was not

going to get us the range we needed even at 50 mpg

fuel-injected. Our solution was to ditch the FXR Transmission

and Oil Bag and put in a 1998 Bagger transmission with integral

oil bag/pan. In place of the FXR's oil bag we are building a

stainless steel secondary gas tank with an external fuel pump,

regulator, and filter..

No, we are not going to cut the 1998 Evo Bagger Oil Pan to clear the under motor braces. Having welded on castings a lot in the past you get into porosity issues and we do not want to lose any oil capacity.

No, we are not going to use a Twin

Cam engine. Twin cams suck.

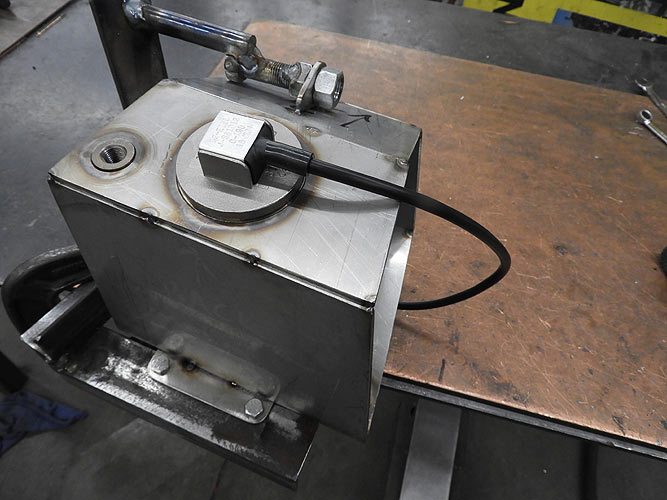

Secondary, under the seat, Gas Tank:

Fuel feed, bypass, vent to main tank, float level sending unit,

and a secondary fuel tank gauge in the fairing.

A Bosch temperature sensor monitors

the fuel return or bypass temperature. We are using a fuel

cooler to drop the fuel temperatures as the main gas tank sits

above the hot motor.

In addition, the secondary fuel tank

acts like a surge reservoir keeping fuel and not gulps of air

fed to the pump... Unlike an in-tank Harley pump in a gas tank

shape that was never meant for efi in-tank feed with fuel

sloshing around.

We put in a vent that goes back up,to

the main tank.

We welded in a stainless return vent

port that runs from the top of the secondary tank to the main

tank. A stainless tube extends to the top of the main tank to

vent air from the secondary tank.

.625 Transmission shaft with machined

spacers for Twin Cam Dresser 2008 Swingarm spherical bearings.

We are using a 2008 Touring Swingarm that we have modified for 2" chain adjustment. We use the CVO2's 5/8" pivot shaft with our $895.00 swingarm that uses the 2008 Spherical Bearings. There are no more Delkron FXR cases for 3/4" pivot shafts. Don't try to drill the bagger transmission for the 3/4" shaft.

Pictured above is our FXR Turbo Orca swingarm with 1" higher shock mounts. It has 2" of adjustment for the chain drive and uses a 25mm late model axle for a 17" Sportster rear wheel. The 2008 Swingarm has been modified to use our 5/8" 1999 FXR CVO2 transmission pivot shaft. A late model 4 piston CVO Dresser caliper provides the rear stopping power.

We are using a 1998 Dresser Oilbag 5

speed transmission with Jims Fat5 gears.

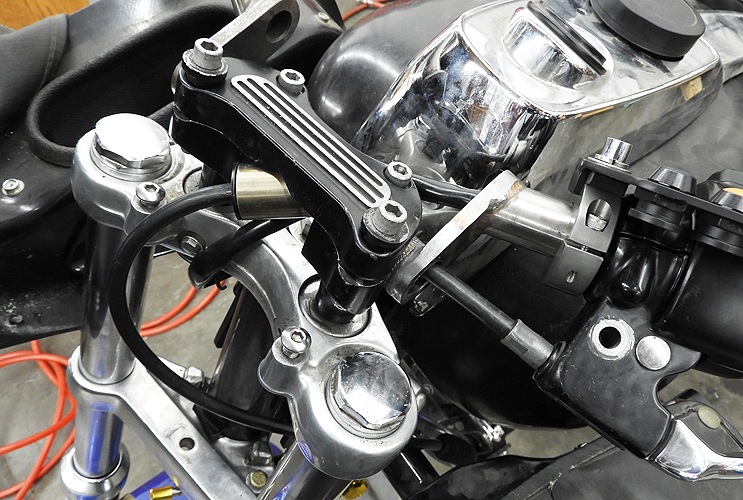

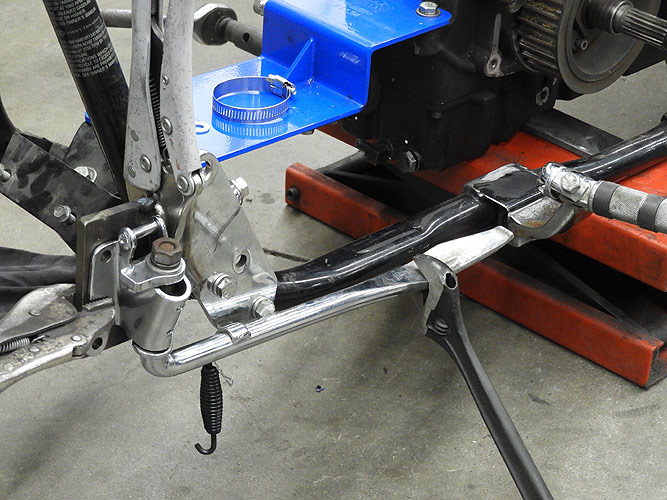

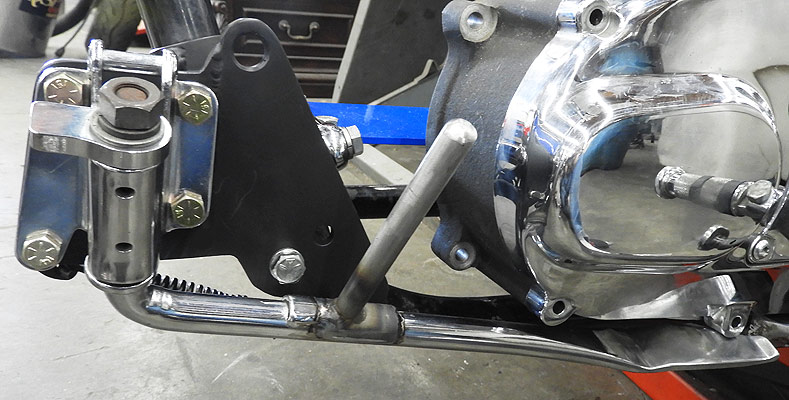

Steering Damper

The FXR does not come with a steering

damper so we fabbed one up. We welded a saddle with a 1/4"

steel tab to the left down tube and machined in an offset anchor

point into the triple clamp

You don't want to be on a 29 degree

rake, 300 Hp FXR, with 39mm Narrowglide forks, even with a fork

brace, without a steering damper.

At Bonneville steering dampers are

required and you have to limit the fork stops to about 10-15

degrees left to right from center to save your ass if you get

into a wobble. The damper cannot act as a stop. Having been in a

lock-to-lock horizon-altering wobble at 172 mph in 1985 at

Bonneville verified the need for limited lock on a race bike. We

made a bolt in limiter for the FXR.

Our handlebars are not stuck up in

the air like the "Ape Hanger" style bars everyone else has come

up with when they try to make fairings for FXRs. The bar

arrangement pictured above comes from Big Bear Choppers. You

might remember them from their previous Chopper ventures. They

were going to put Harley out of business. They folded shop...now

they are making FXR clones and trying to force Dyna technology

to the engine mount system (!!!).

We are go fast racers, not

cruisers, and we don't need to show the world our armpits.

Strip Her... Show No

Mercy

Take her down to ground zero. With

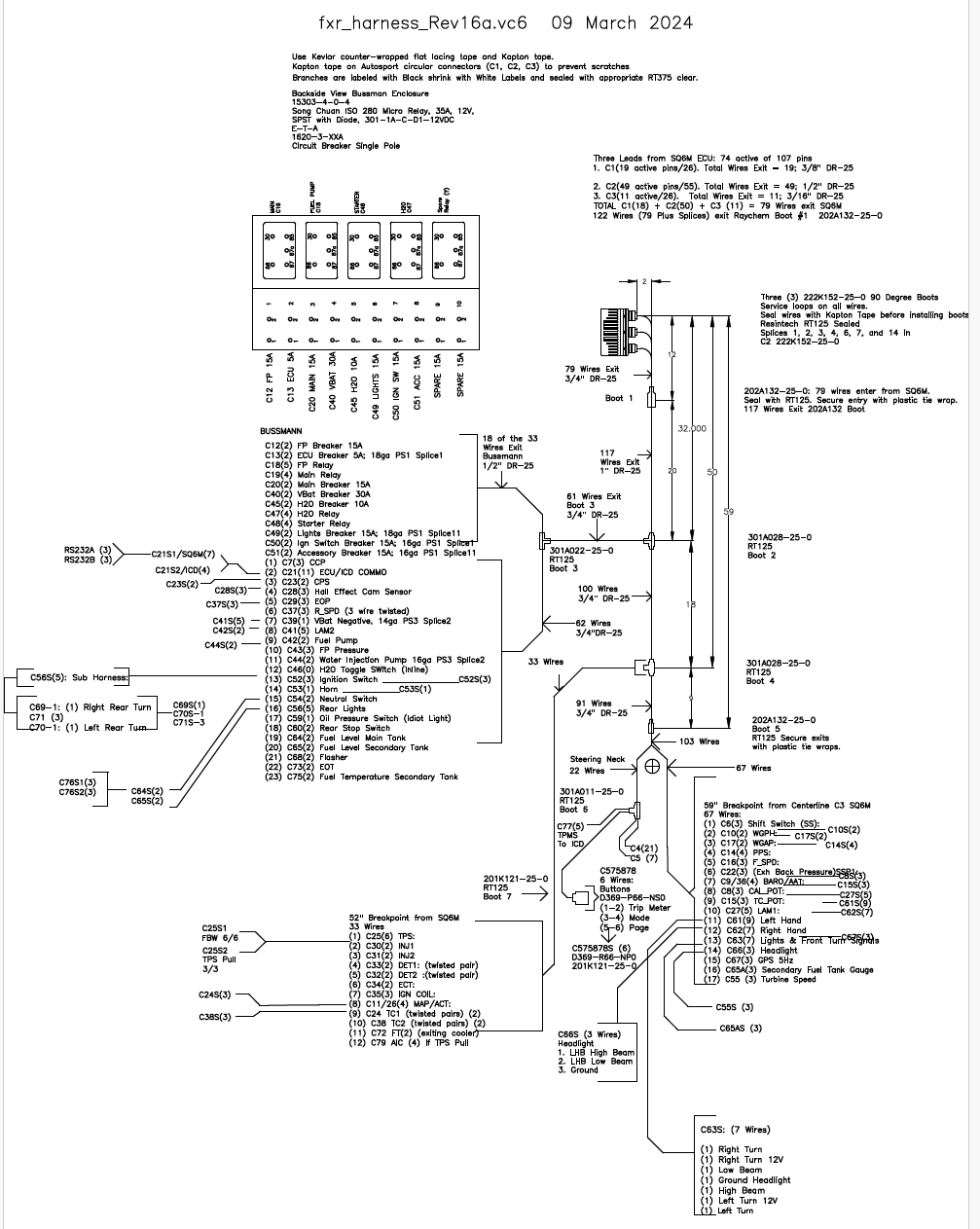

ORCA Turbo Power and Cosworth Pectel

SQ6M Electronics all the stock stuff has to go. Pull out

the CVO2 FXR 80" EVO and donate it to the Men In Black (Bryan

Stock) , replacing a worn out RevTech motor in Bryan's son's

bike Nick. Bryan thanked us. Nick did not.

We also donated a Twin Cam 88 with

Branch Heads, SE251 cams and an updated SE Oil

System out of our Turbo Road Glide (Road Toad) to Bryan, as his

own 95" Twin Cam in his chopped Dresser had passed the 100,000

mile mark and his Twin Cam was on it's last legs. Bryan upped

the 88 to 95" and corrected a mistake Ron Kravitsky had made in

the cam chain tensioner assembly...It runs "sweet" as Bryan

said. They call him "Flying Bryan" for a good reason.

Since the FXR was all apart we took a

set of STD heads we had planned to use on the 80" EVO down to

Branch O'Keefe so one of the Men in Black in Idaho could get a

good breathing EVO. The heads were later returned unused after

we split in 2017, so we sold them for what we had in

them...$1,400.00 to turbo customer.

Off to Dr John's Motorcycle Frame Straightening

Next : Take the bare frame down to Doctor John's to have it checked for straightness...If you put 300 hp to the road the chassis better be straight. It wasn't.

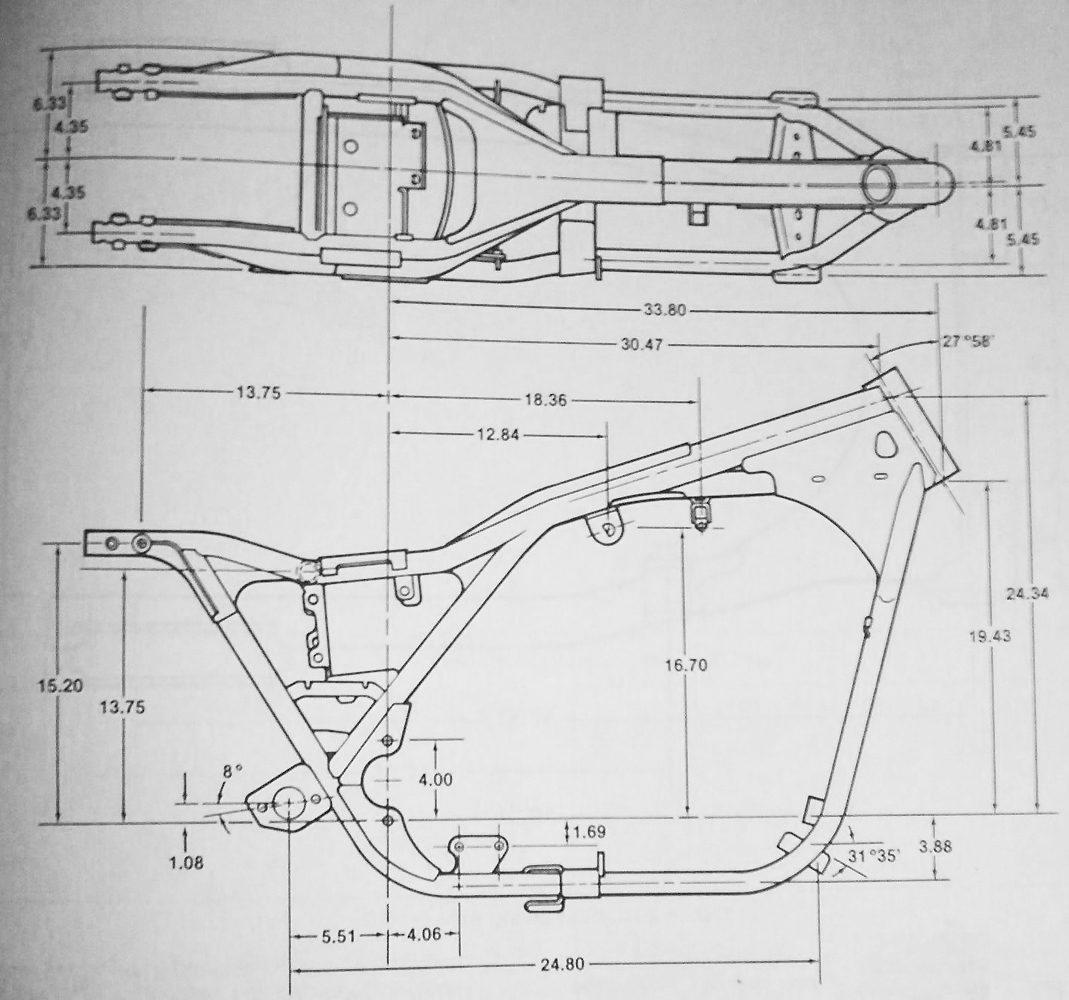

It all starts from known dimensions...FXR frame blueprint above. You have to have a frame table that has fixtures that will locate the centerline off of the neck and the swingarm pivot block locations. Rubber-mounted Harleys have special alignment procedures as the engine transmission and swingarm do their own things.

Back from Doctor John's...$500.00

worth of tweaking to get it perfect. He's the go to guy for

chassis alignment and repairs. We used to make racing frames and we build 200 mph

bikes. There was no way we were going to wind out the FXR with

25 lbs of boost without having the chassis checked. The frames

are not necessarily straight when they come from the factory.

Bye Bye Stock

Arm...FXR Turbo Swingarm

The stock FXR swingarm is way too weak for 300 HP. We do chain drive conversions for Dressers and FXRs so it wasn't a stretch cut up a 2008 FLT swingarm and put in higher shock eye mounts so we can use taller shocks with the tires we are running.. With all the changes we have 6.25" of ground clearance and a better rear swingarm angle.

Ground Clearance: OEM FXR's had

anywhere from 5.25" to 6.12" of ground clearance as Harley

marketing kept pushing the seat height lower trying to sell more

bikes as "Cruisers" and not "Go fast through the corner

types", chasing Japanese sport bikes. We'll stay with 6.5"

for the initial testing. 2" longer forks inpack sidestand

issues.

Our Road

Racing Monoshocks had seat heights of 30", raised folding

spring-loaded footpegs, and lean angles of 50+ degrees. Our FXR

ORCA has a seat height of 29.5".

Stock FXR's have around 30 degrees of

lean angle before you tuck your toes up and start scraping

things.

Pictured above is our FXR Turbo Orca swingarm (modified 2008 Dresser) with 1" higher shock mounts. It has 2" of adjustment for the chain drive and uses a 25mm late model axle for a 17" Sporster rear wheel. Stronger than oem FXR swingarm, it has been modified to use our 5/8" 1999 FXR CVO2 transmission pivot shaft. A late model 4 piston CVO Dresser caliper provides the rear stopping power.

We are using a 1998 Dresser Oil Bag 5

speed transmission with Jims Fat5 gears.

We raised the shock mounts to use with 13.5" shocks to get 6.5" of ground clearance with the smaller diameter 150 x 60-17 rear tire and the 17" front tire. We get an improved swingarm angle of 6 degrees downward as an additional benefit.

FXR Swingarm with Stock Shock Locations

FXRs have different pivot to axle

lengths as well as shock locations compared to Dressers. This is

our FXR Swingarm with the stock shock location for an FXR.

FXR's had crappy rear brakes and the

original caliper mount would not work anyway with the new,

larger, 25mm rear axle. Simply use a late model 4 piston FLT

rear caliper.

We sell these to FXR owners who put in 111/124" motors which still allows them to retain their 5/8" pivot shaft and use the late model spherical bearings.

Switch to late model caliper and

disc, typically 2008 and later with 11.8" disc.

FXR Twin Cam (pre

2009) 5/8" Shaft Spherical Bearing...No Plastic B.S.

In the picture above,

at the top, are some really questionable aftermarket Delrin

spacers that are sold with tubular inserts that, with the help

of some grease/paste, are supposed to act as bearings and

pivot in the Delrin. This is by no means a bearing in any

sense of the word. It is patently stupid...crude with

stiction. Those go in the trash.

At RB Racing we

machine up some spacers, black items pictured above, that

allow you to use the OEM 9208 Spherical Bearing...that is

actually a real bearing...and allows you to retain your one or

two-piece 5/8" axle. We install these in the pre 2009 Twin Cam

swingarms we modify for 2" adjustment, high horsepower, FXRs.

Use only Harley 9208 bearing. Don not buy others off of

EBay..Period (!!!).

If you choose to do

this be aware you must change your rear wheel, axle, and brake

assembly for the 25mm rear axle and later model brake

calipers. Do not attempt to drill or ream your

transmission case for the late 3/4" axle. There may be more

stronger Delkron FXR cases for sale with 5/8" and

3/4"pivots...even though Delkron went away long ago.

We can supply the complete swingarm ready to fit your FXR or earlier EVO Dressers. FXR and Dresser swingarms have different shock locations.

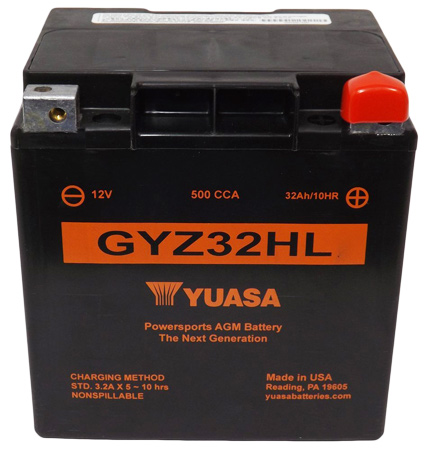

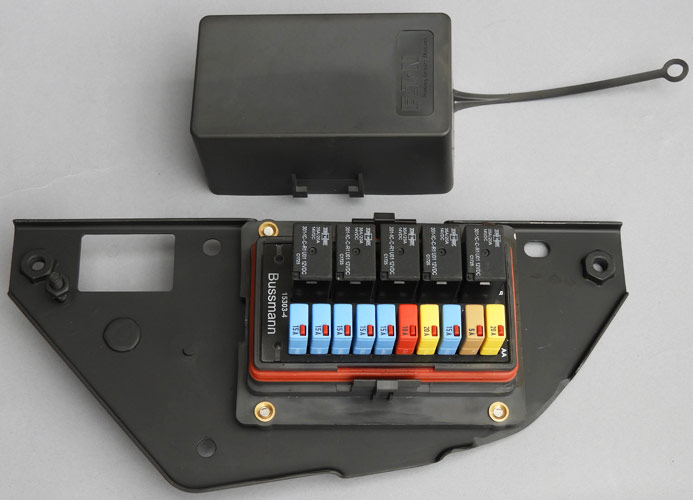

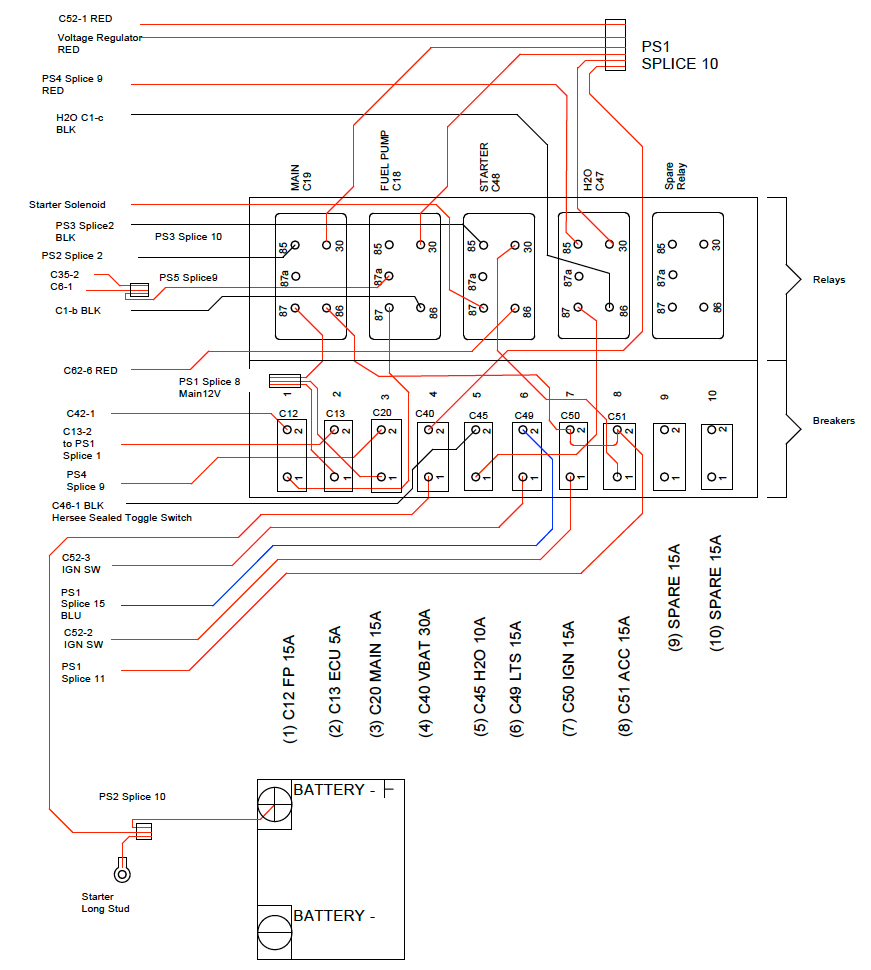

FXR Turbo Battery....Time to Cut her up.

We checked around for the best

battery..i.e. the highest cranking capacity for our 126 Road Toad and 139

Cubic Inch Bullett motors and found that Absorbent

Glass Mat (AGM) was our best option, and that the only

battery more powerful than the OEM Harley Batteries

(DEKA) that we had been using was this Yuasa Battery

with 500 CCA. GYZ32HL.

We tested a Lithium Iron Phosphate battery in a

smaller 80 Inch Evo motor and it worked very well for

a year, always starting the efi instantly and

maintaining a 13.2VDC charge...When we tried the same

24 cell battery on the Bullett it cranked very quickly

but gave up quickly.

In talking to the battery engineers at what we

consider to be the best Lithium Battery manufacturer,

earthX ,

they told us the following:

"Based on your engine size (139CID), which as a V-twin

engine requires much more cranking amps than a V-8

truck, we do have a battery that has 1,000 cranking

amps which should keep the voltage from dropping and

affecting your EFI. The model number is ETX48E and

weighs only 7.7 pounds. . The bad news is this battery

costs $699.00 .

Lithium batteries are very

different than a lead acid battery in that if you pull

too much cranking amps from the battery in order to

start the bike, you will damage the cells. They are

not as robust as an AGM battery and for your type of

application, it is very hard on any battery but I

would think an AGM would fare better. This

probably isnít what you wanted to hear but lithium

batteries are fantastic in the right application but

your bike's demands are at the upper edge of use."

Rare to find honesty these days. AGM Yuasa it is.

Make a fake wood battery with the new Yuasa GYZ32HL dimensions

and cut up some stainless 16 gauge 304 stainless steel

sheet. The seat frame brace has to be cut out and

moved back and that means the fender has to be

modified also. Fabricate a new battery hold-down and

isolate the "battery" on all sides with rubber. A

circular stop is added for the bump stop under the oem

seat pan.

Sheet metal the cut out in the rear

fender to allow clearance for the bigger AGM battery.

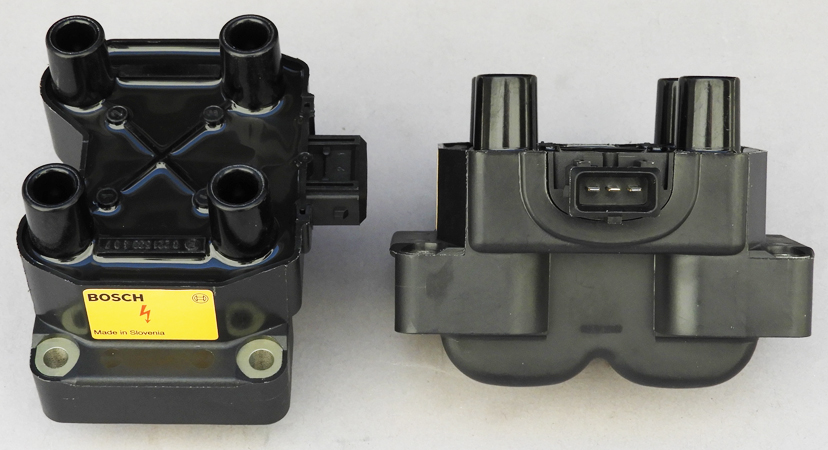

Bosch

Motorsport

Ignition Coils

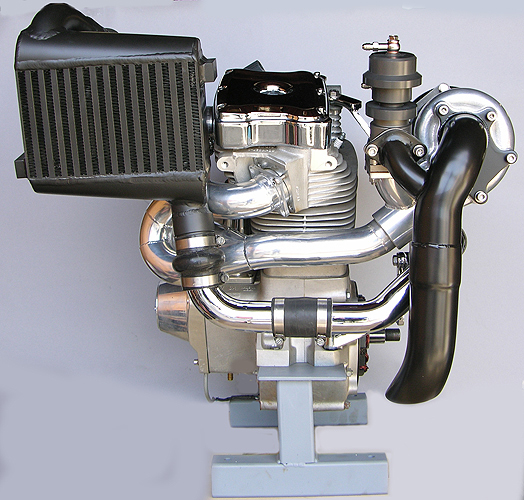

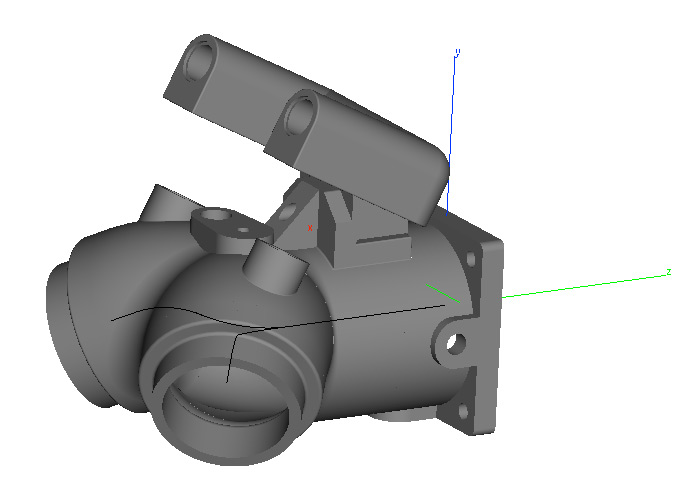

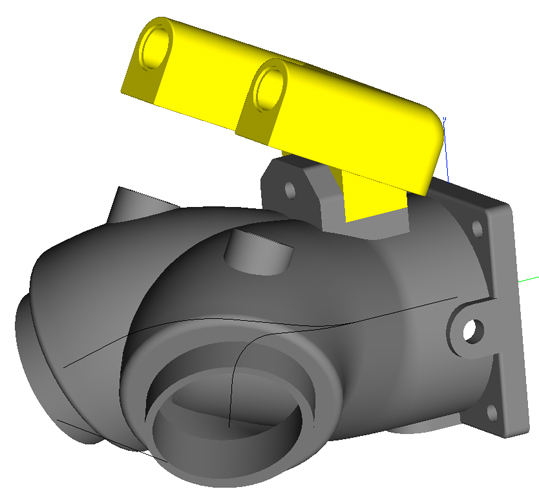

FXR Turbo Compressor Discharge Valve

On shifts, or closing the throttle under boost, this valve vents the pressure to prevent compressor surge wherein the boost goes backward through the compressor. Here we are testing it for function with boost and vacuum signals.

Compressor Discharge Valve

sockets into rear of the plenum. 60mm Bosch Fly By

Wire Throttle entry and two ports for the

Phase-Antiphase Wastegate Pectel SQ6M boost

control...Boost by gear, programmed throttle openings,

and eight levels of traction control.

Stay Tuned..It's going to get complicated.

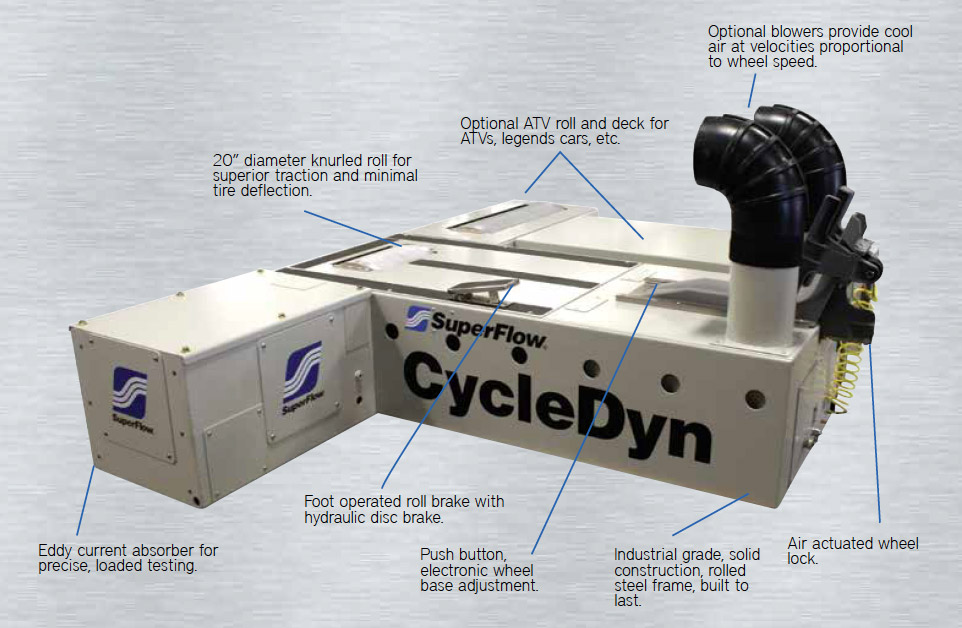

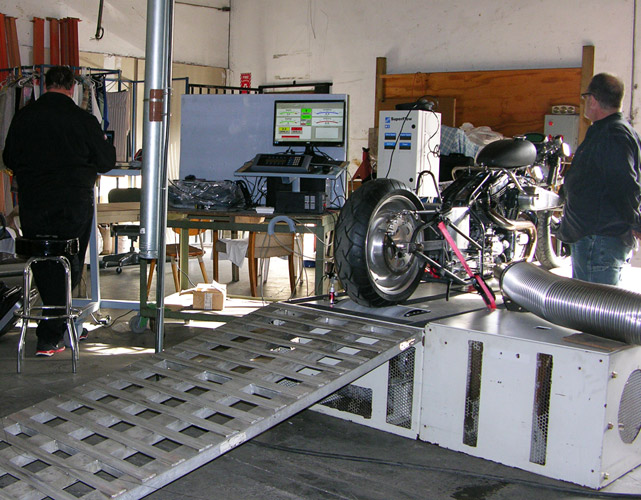

With over 8800 programming categories in the Cosworth Pectel SQ6M and a 360HP turbocharger, like we use on our 126 SAB2 Road Toad, we choose to use the Superflow CycleDyn for our development. Safer than running from the cops...not that we used to. Freeway cameras, helicopters, people on cell phones...you get the idea. With the Bonneville Bullett you can't do road testing...It's the Dyno and the Salt Flats.

Carbon Monoxide is a killer. It has to be positively scavenged and discharged away from the building. All exhaust fumes must be vented so the operator and the engine cannot re-breathe spent gases. Carbon Monoxide is odorless and flat-ass dangerous. We have a CO meter on the dyno operators console.

The FXR can be ridden to perfect

things in the real world and the Superflow CycleDyn is

about as close to the real world loads and speeds

(200mph) as you are going to get without leaving the

shop...Like Tom Bookhamer's 120CID Harley Bonneville

bike being tuned by Shane Tecklenburg on our CycleDyn.

Shane is the top Zen Master Motec Guru. Tom drove out

to RB Racing, all the way from Florida, to get his

M130 Motec tweaked. 8" stainess exhaust extraction

with an 1100CFM fan. No carbon monoxide in the shop.

We'll do initial testing on the FXR on the Superflow CycleDyn...A long way to yet go before we get to that point.

These days there are cameras everywhere on the freeways. There are automatic license plate readers. People call the cops and take pix on their cell phones...and the Highway Patrol and local cops seem to have lost their sense of humor. It's dynos and eyes in the back of your helmet these days..or go way out in the middle of nowhere.

"Hold on, hold on, my brother

My sister, hold on tight

I finally got my orders

I'll be marching through the morning

Marching through the night

Moving cross the borders

Of my secret life..."

Leonard Cohen